Method for preparing vanadium-aluminum alloy

A vanadium-aluminum alloy and preparation process technology, which is applied in the field of preparation of vanadium-aluminum master alloys, can solve problems such as poor uniformity, difficult control of V element content, difficulty in melting vanadium-aluminum alloys, etc., and achieve obvious energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The vanadium-aluminum alloy with the grade of AlV40 was prepared.

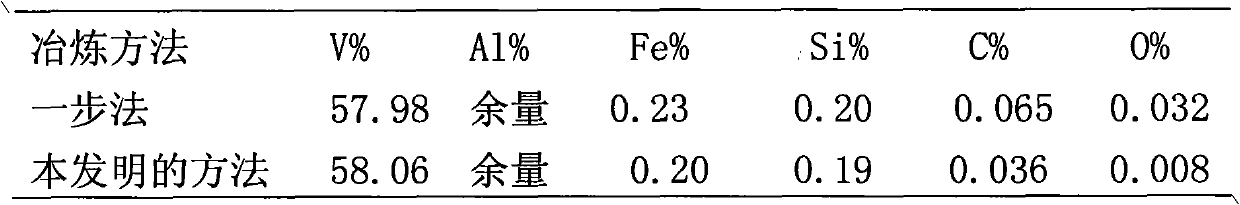

[0015] First set V 2 o 5 100kg, Al 126kg, using metal thermal reduction method, using aluminum as a reducing agent to reduce vanadium pentoxide to prepare a one-step vanadium-aluminum alloy; then crush the prepared one-step vanadium-aluminum alloy into a particle size of 30-50mm, and dry it at 120°C Dry in the kiln for 10-12 hours, then add 7.45kg of aluminum beans, and carry out two-step refining in a vacuum intermediate frequency induction furnace to obtain the final product of vanadium aluminum alloy. , Si is less than 0.25, C is less than 0.08, 0 is less than 0.05, and aluminum is the balance. The content of alloy impurities is low, and the uniformity of the alloy is good.

Embodiment 2

[0017] A vanadium-aluminum alloy with a grade of AlV50 was prepared.

[0018] First set V 2 o 5 100kg, Al 100kg, using metal thermal reduction method, using aluminum as a reducing agent to reduce vanadium pentoxide to prepare a one-step vanadium-aluminum alloy; then crush the prepared one-step vanadium-aluminum alloy to a particle size of 30-50mm, and dry it in a kiln at 120°C Dry it inside for 12 hours, then add 5.45kg of aluminum beans, and carry out two-step refining in a vacuum intermediate frequency induction furnace to obtain the final product of vanadium aluminum alloy. 0.25, C is less than 0.08, 0 is less than 0.05, aluminum is the balance. The content of alloy impurities is low, and the uniformity of the alloy is good.

Embodiment 3

[0020] The vanadium-aluminum alloy with the grade of AlV55 was prepared.

[0021] First set V 2 o 5 100kg, Al 86kg, using metal thermal reduction method, using aluminum as a reducing agent to reduce vanadium pentoxide to prepare a one-step vanadium-aluminum alloy; then crush the prepared one-step vanadium-aluminum alloy to a particle size of 30-50mm, and dry it in a kiln at 120°C Dry it inside for 11 hours, then add 9.27kg of aluminum beans, and carry out two-step refining in a vacuum intermediate frequency induction furnace to obtain the final product of vanadium-aluminum alloy. 0.28, C is less than 0.10, 0 is less than 0.08, aluminum is the balance. The content of alloy impurities is low, and the uniformity of the alloy is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com