Patents

Literature

33results about How to "Low Power Transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

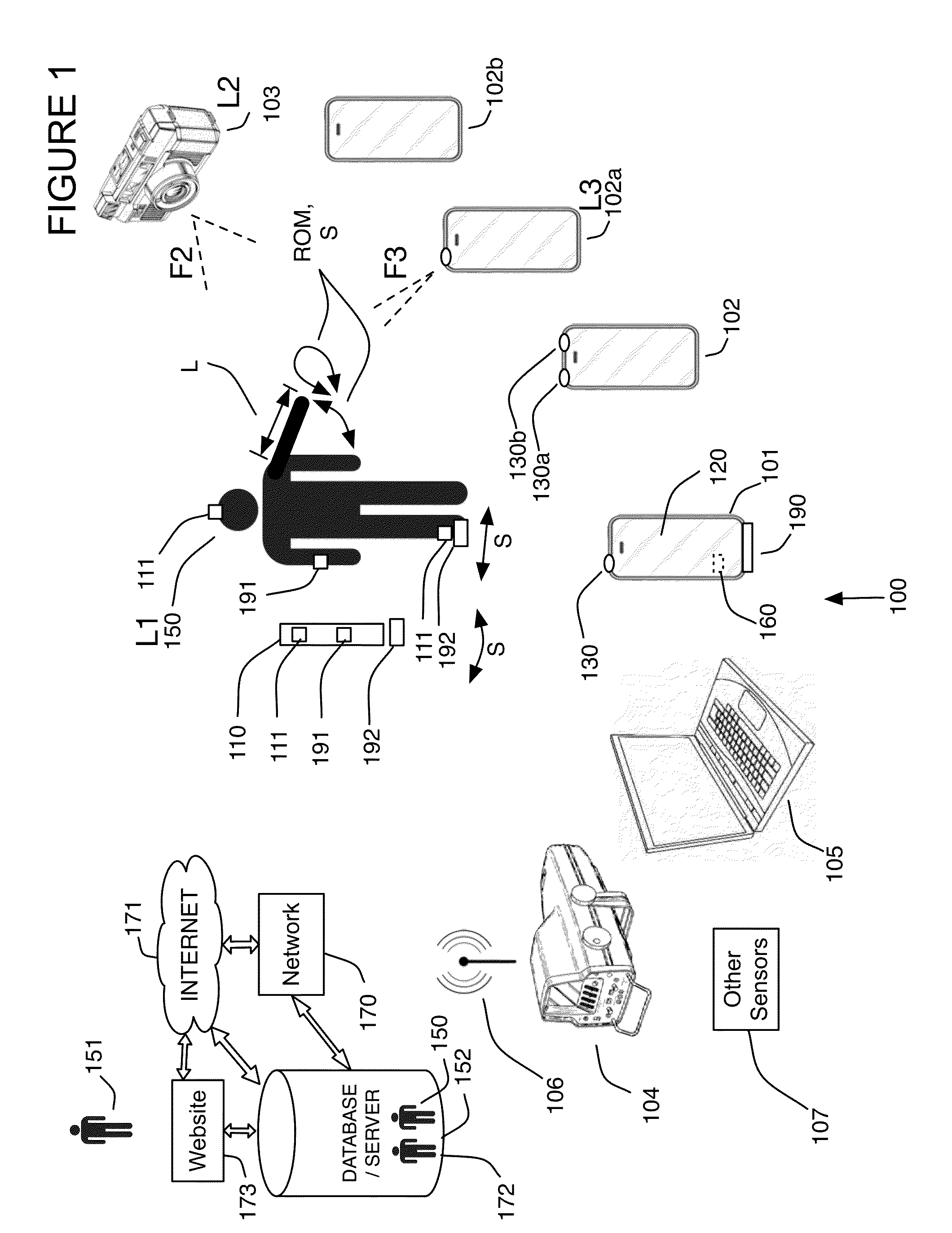

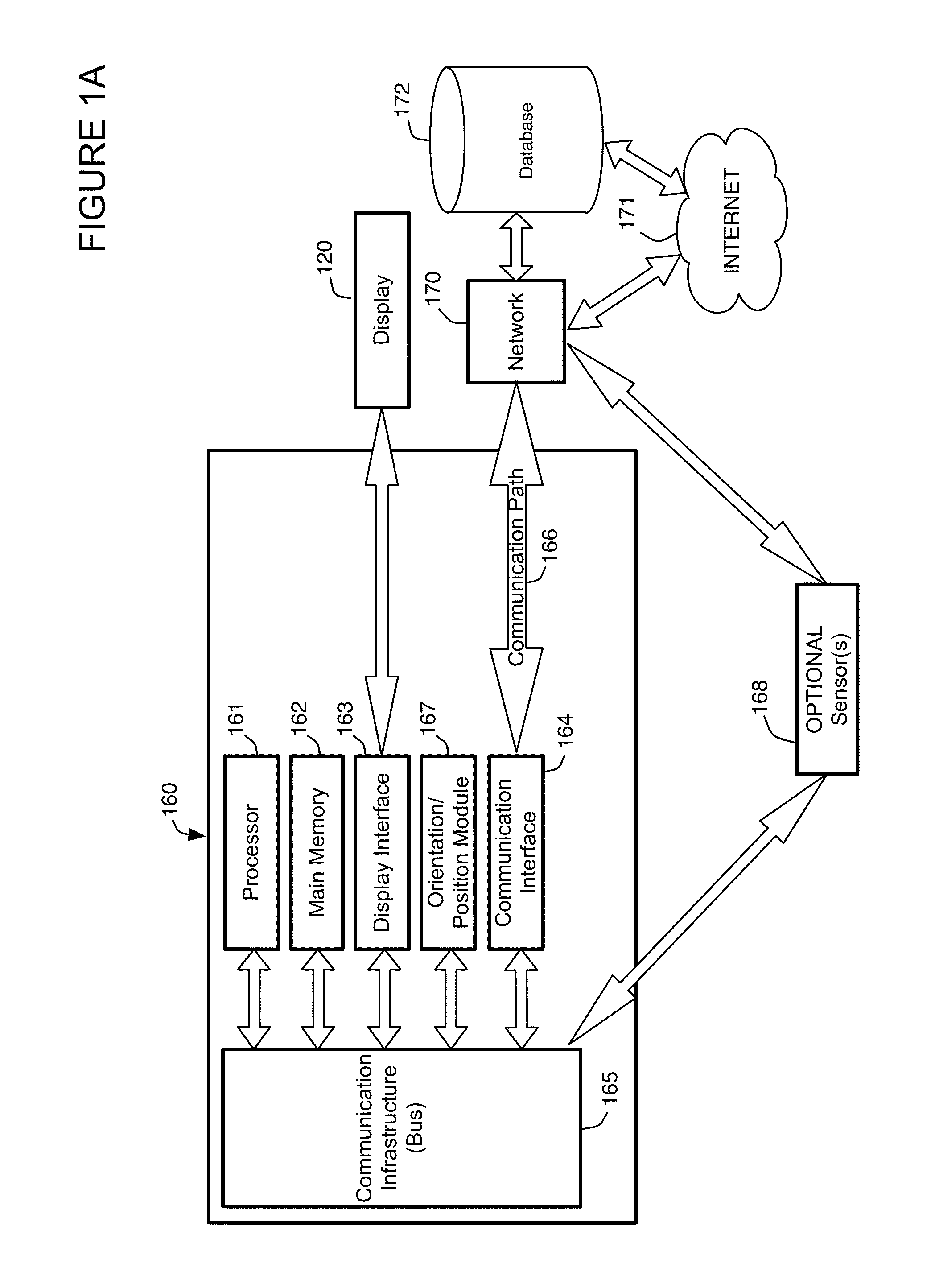

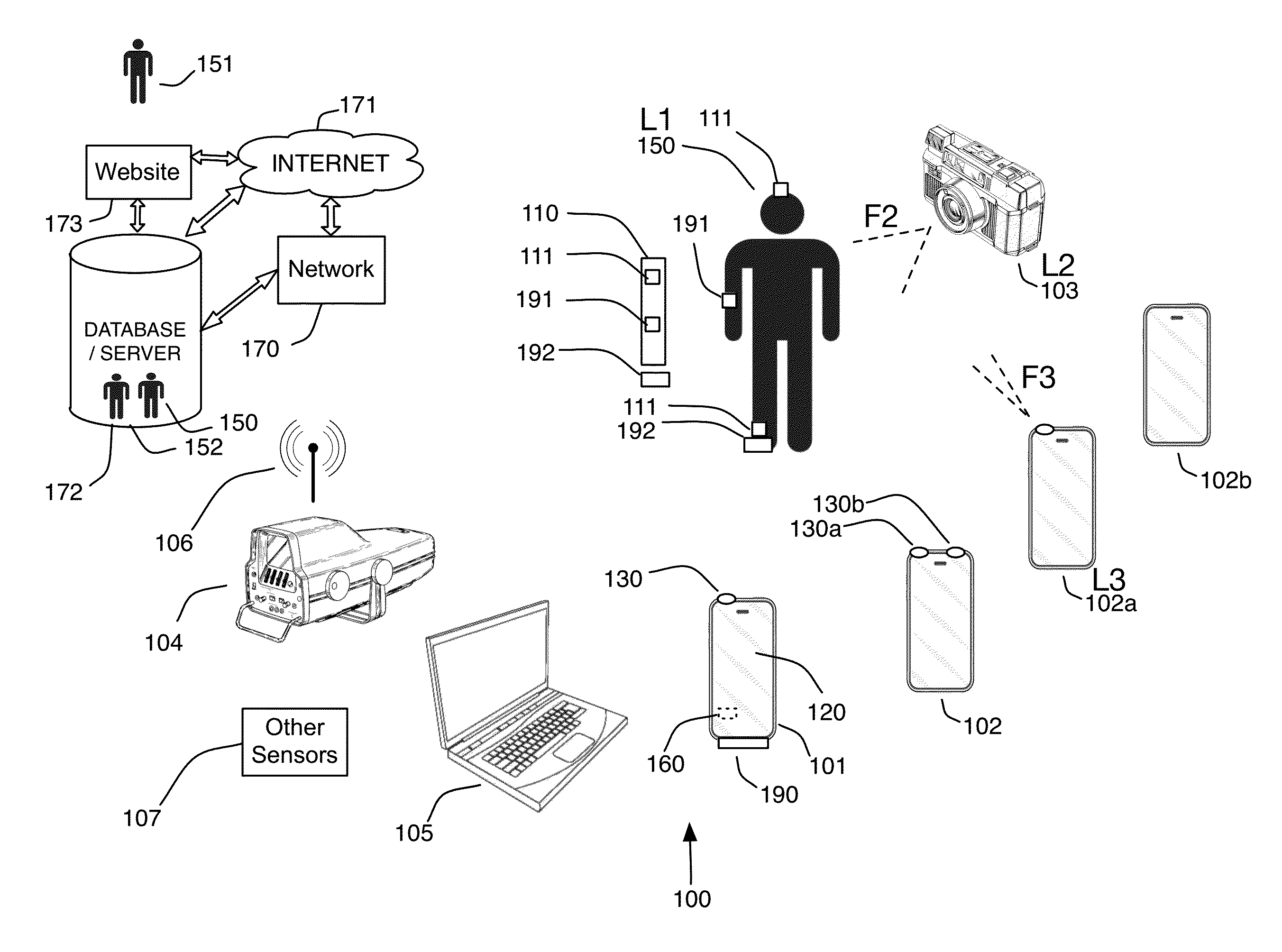

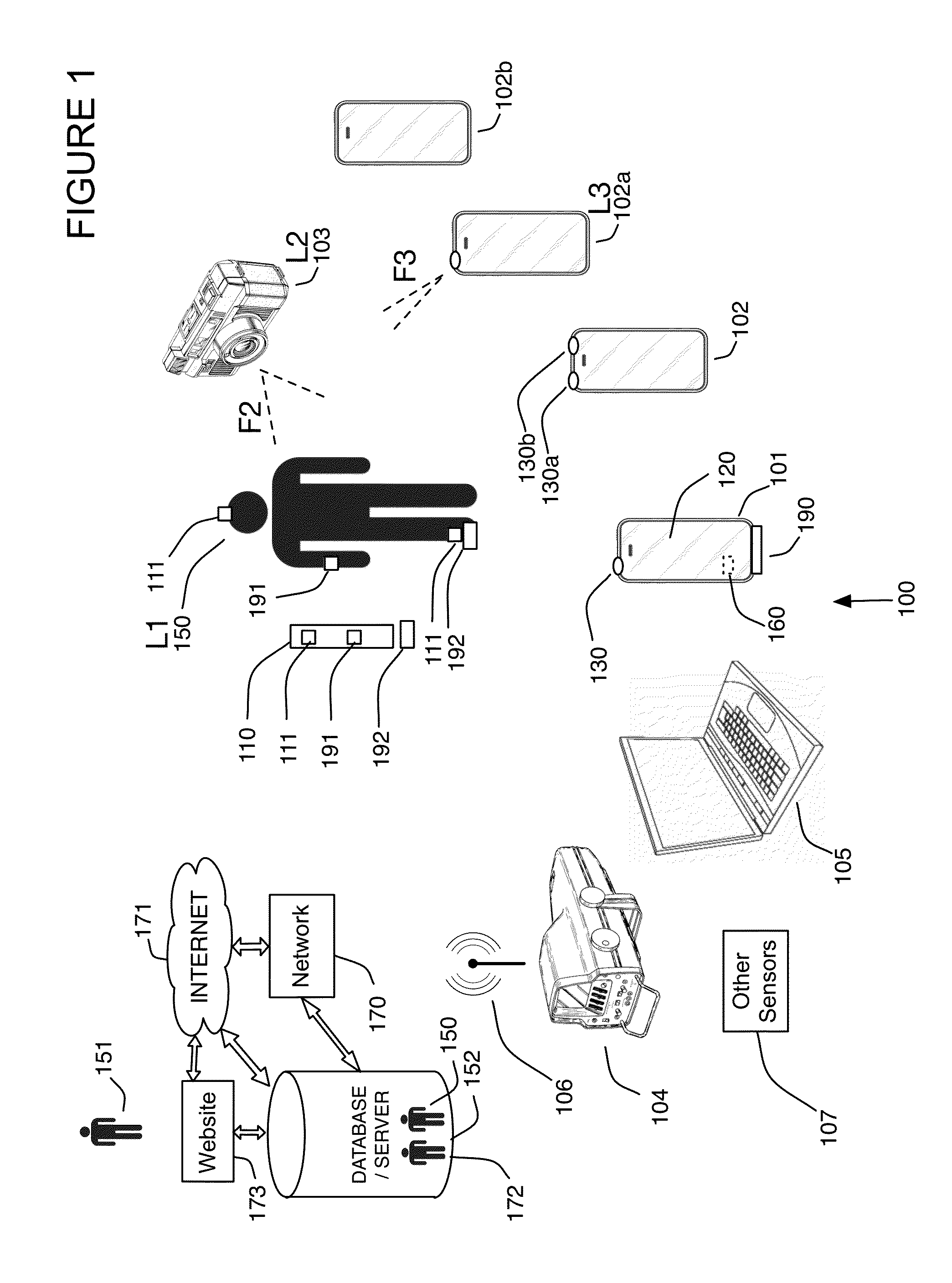

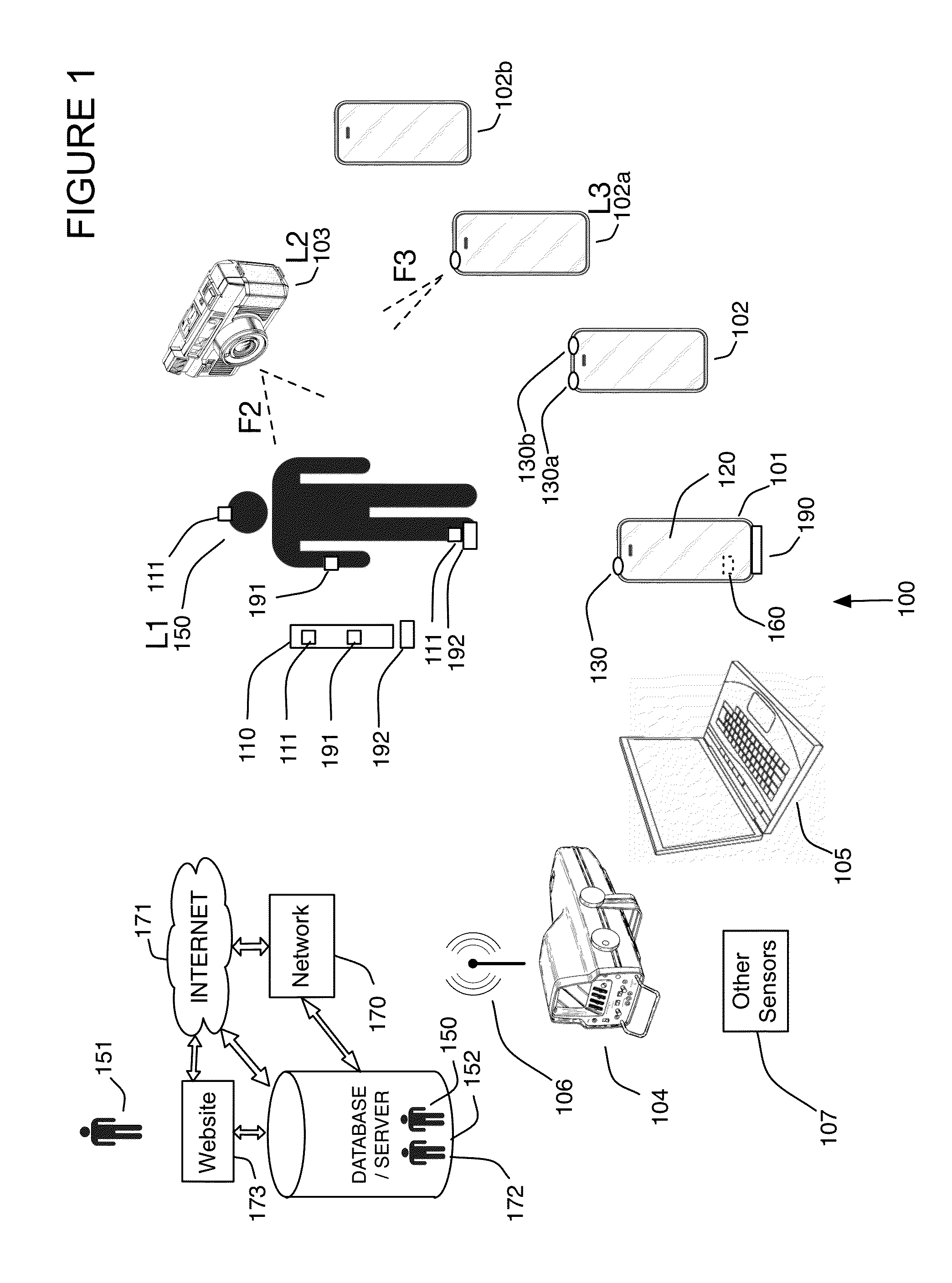

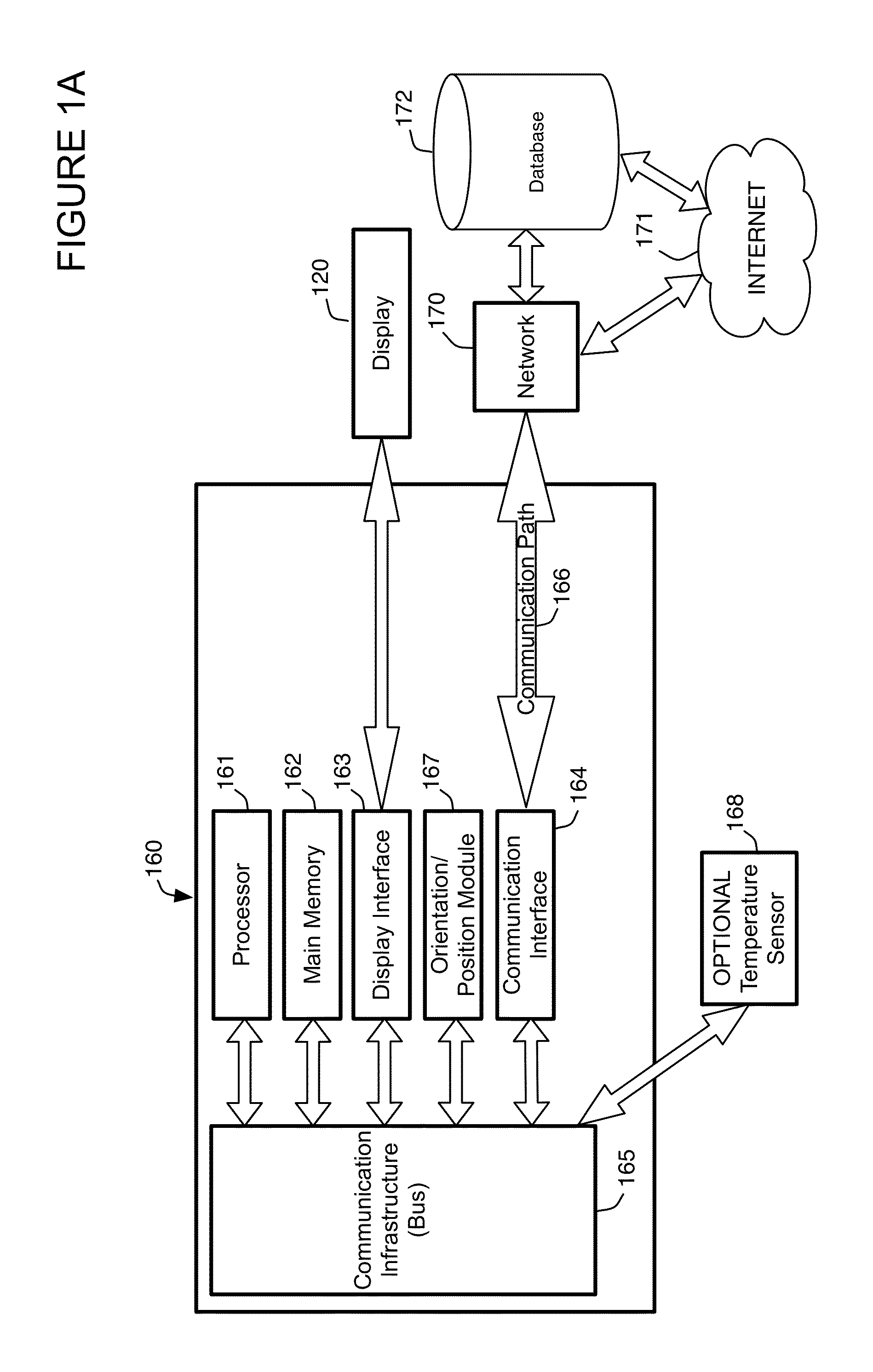

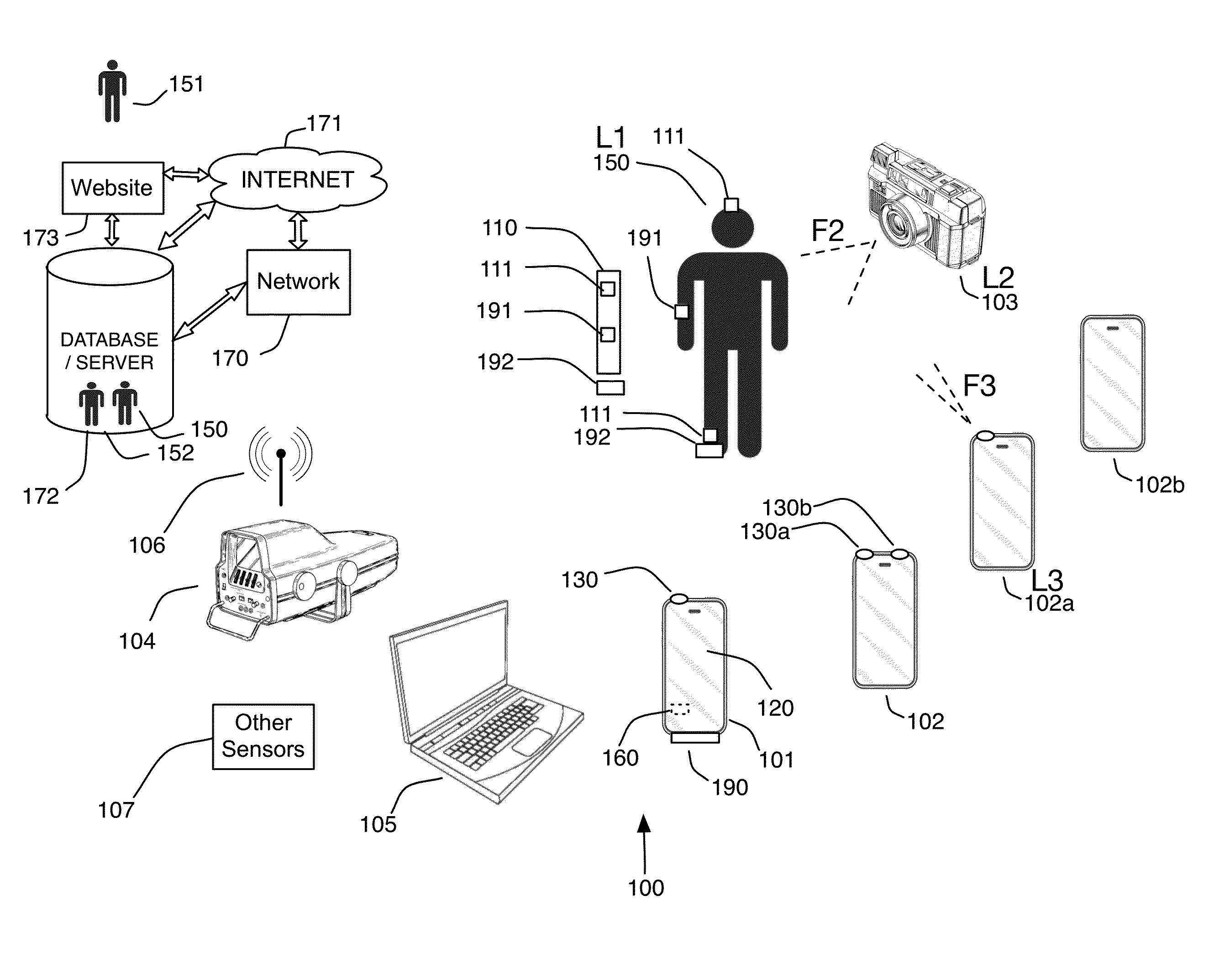

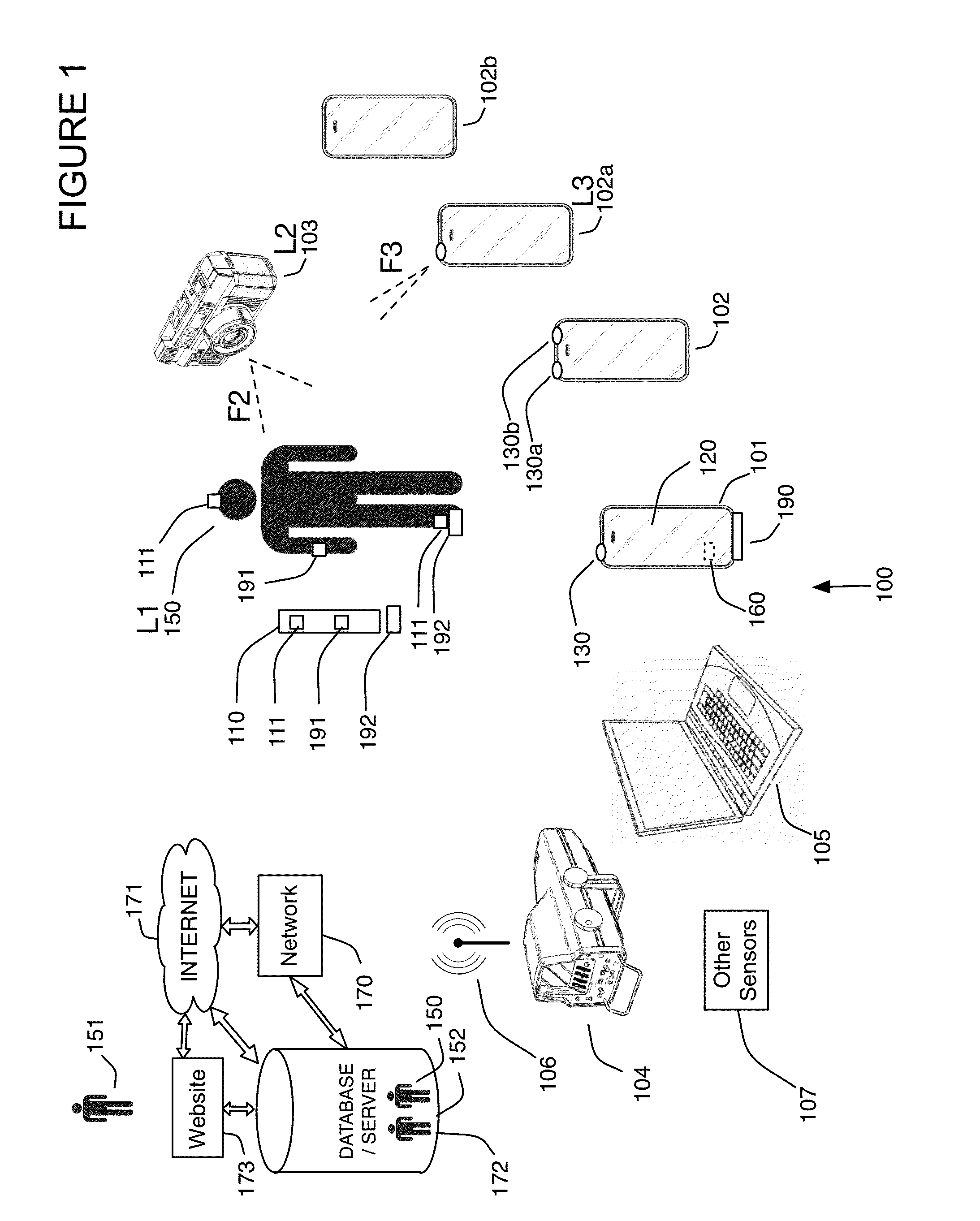

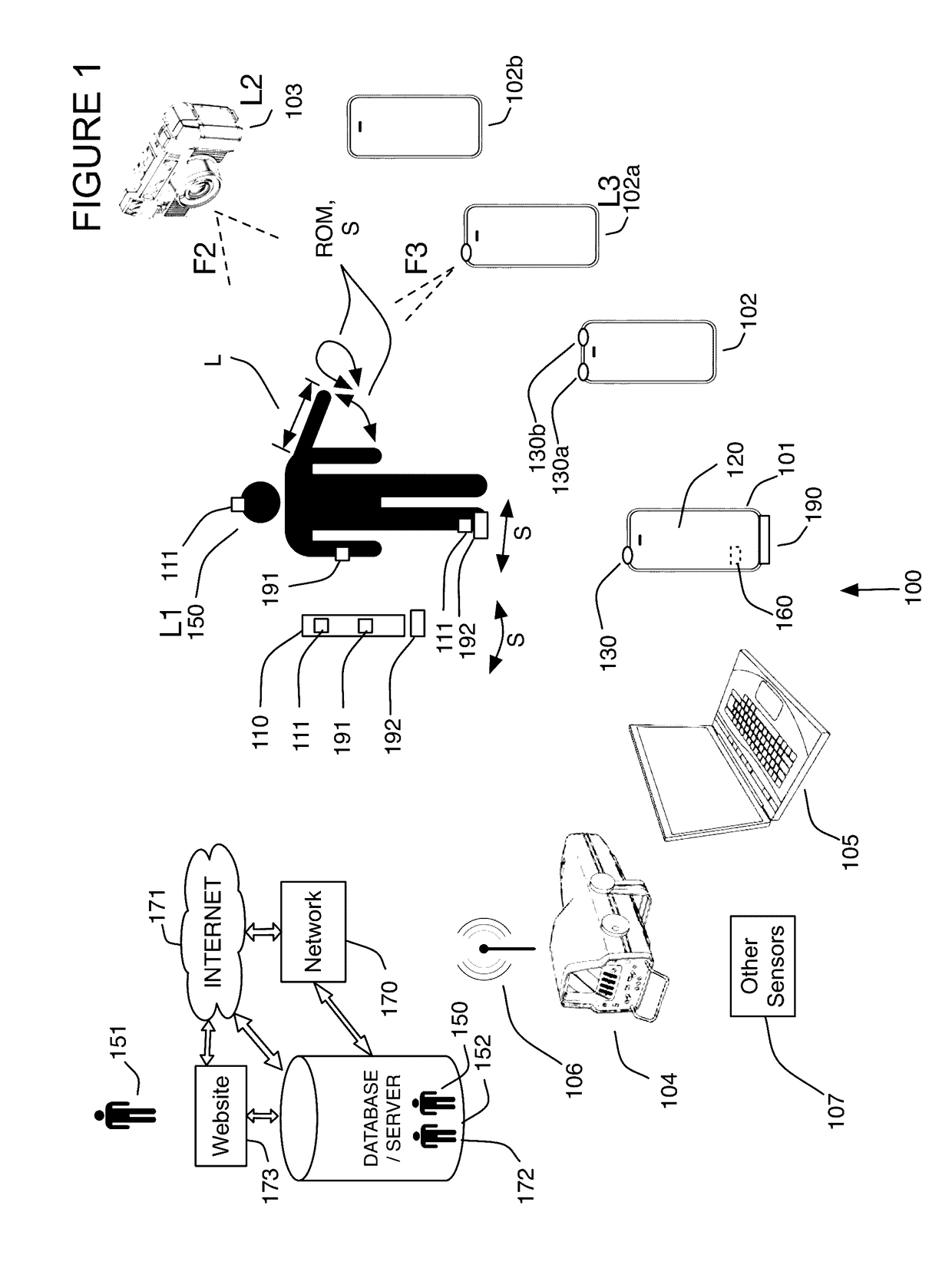

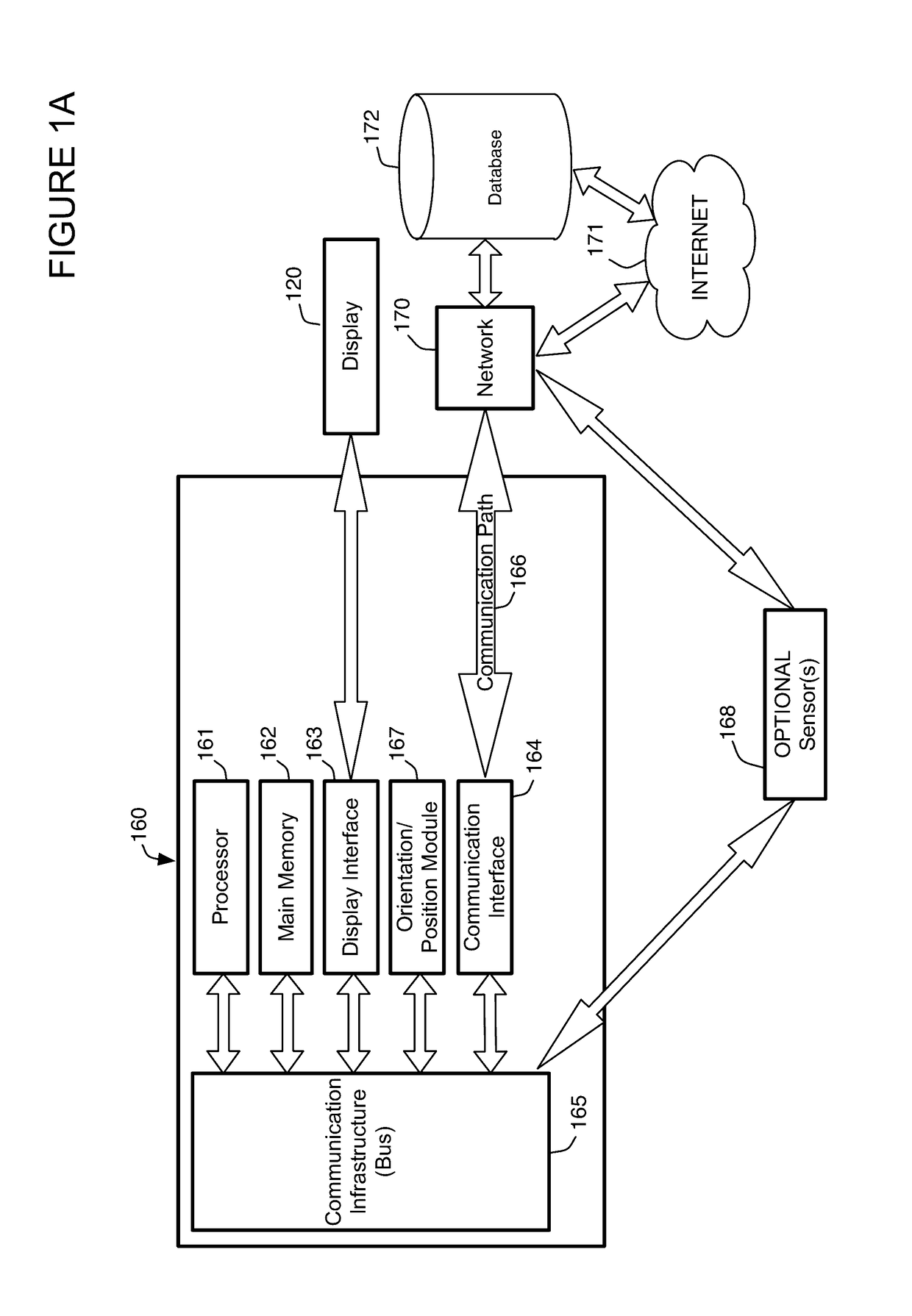

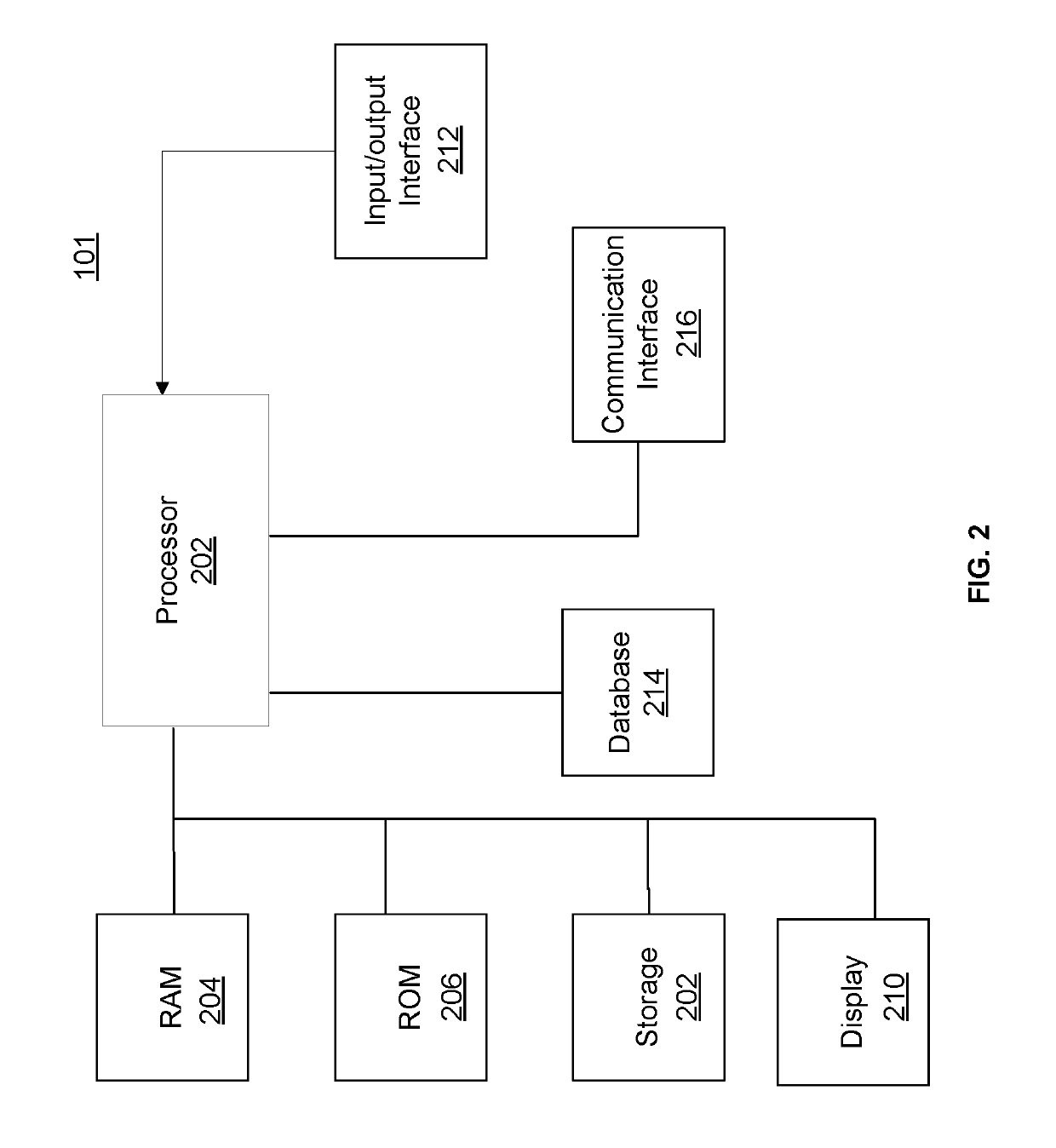

Video and motion event integration system

ActiveUS20150154452A1Low utilizationSave on storageImage enhancementTelevision system detailsEvent dataMultiple sensor

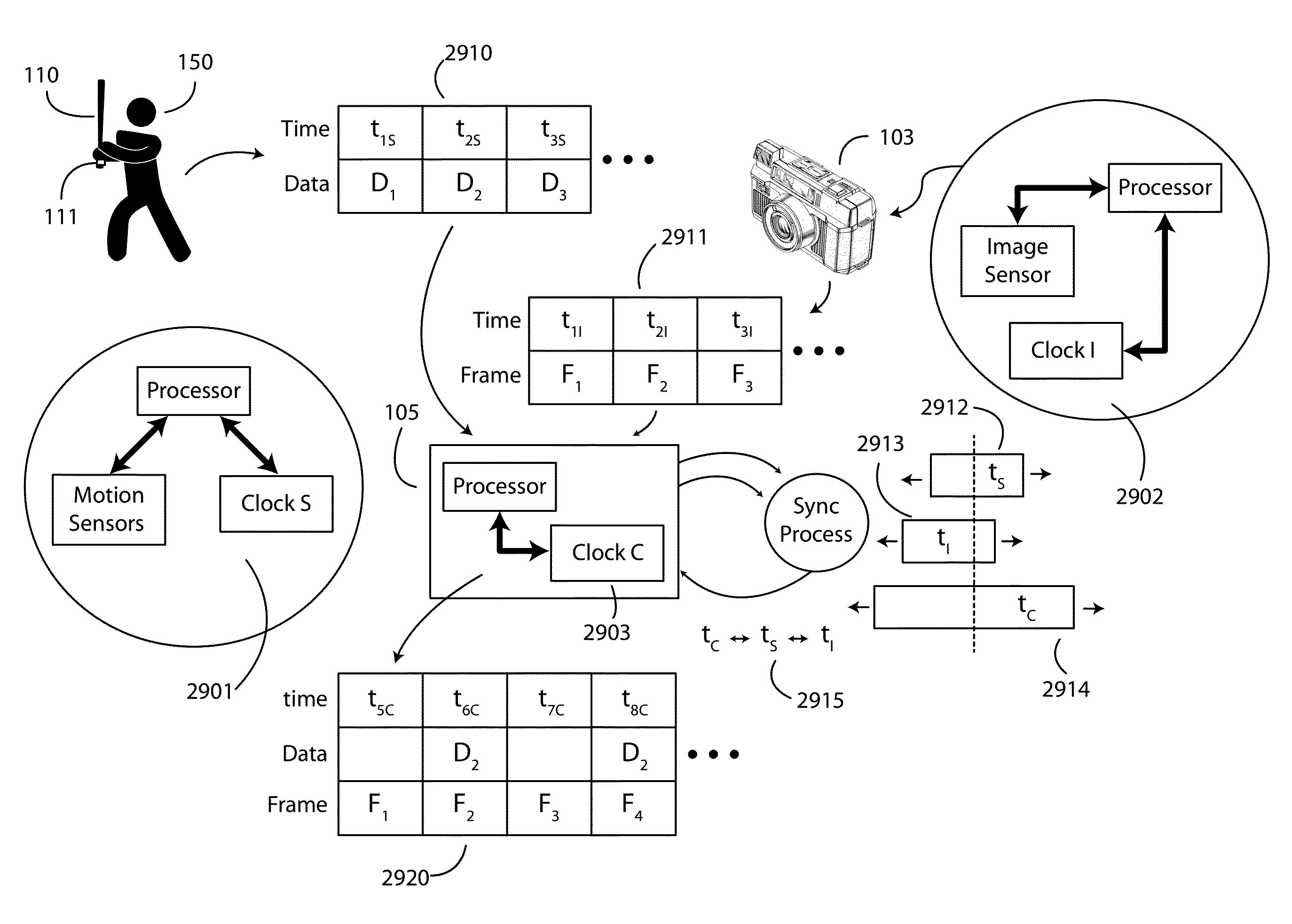

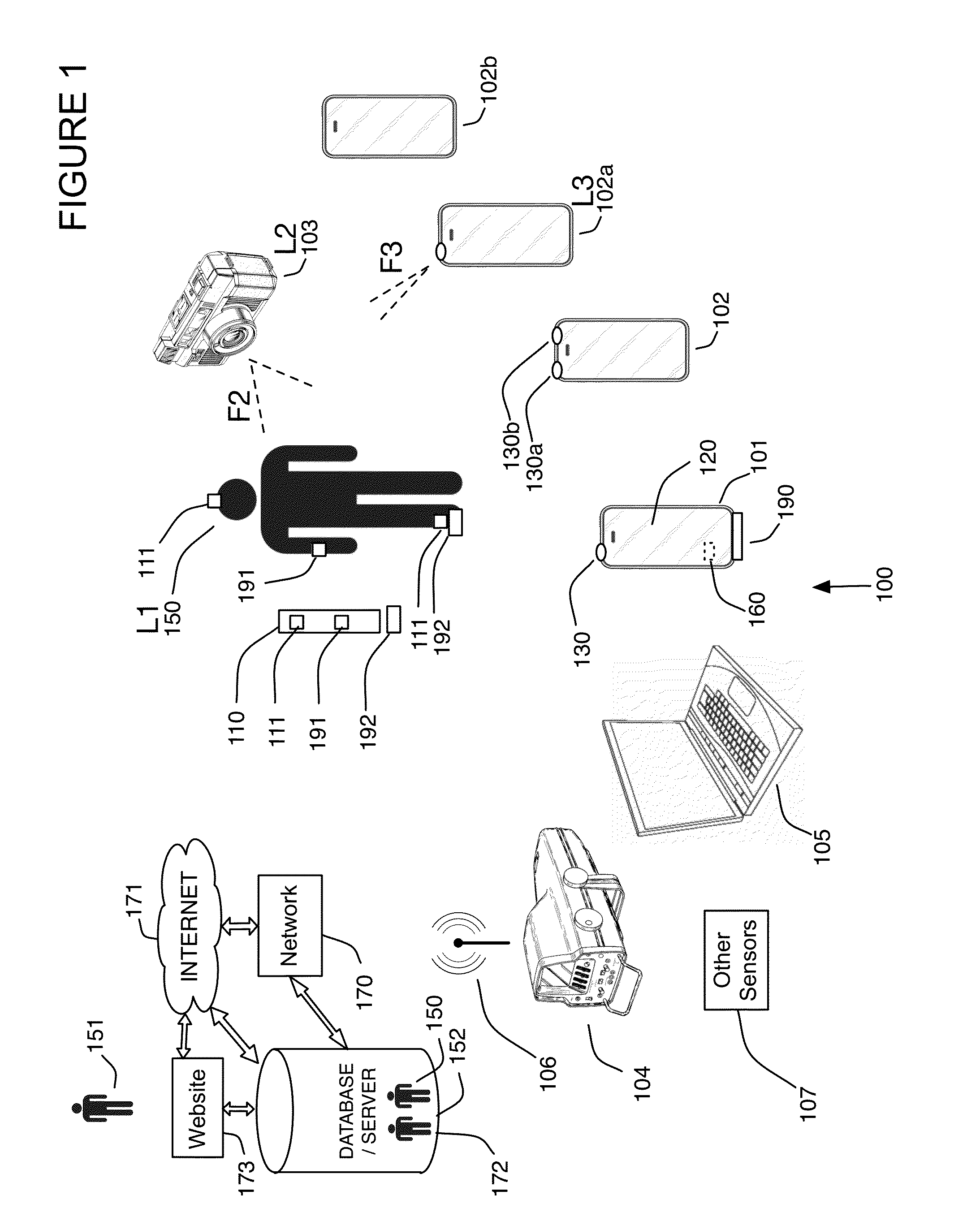

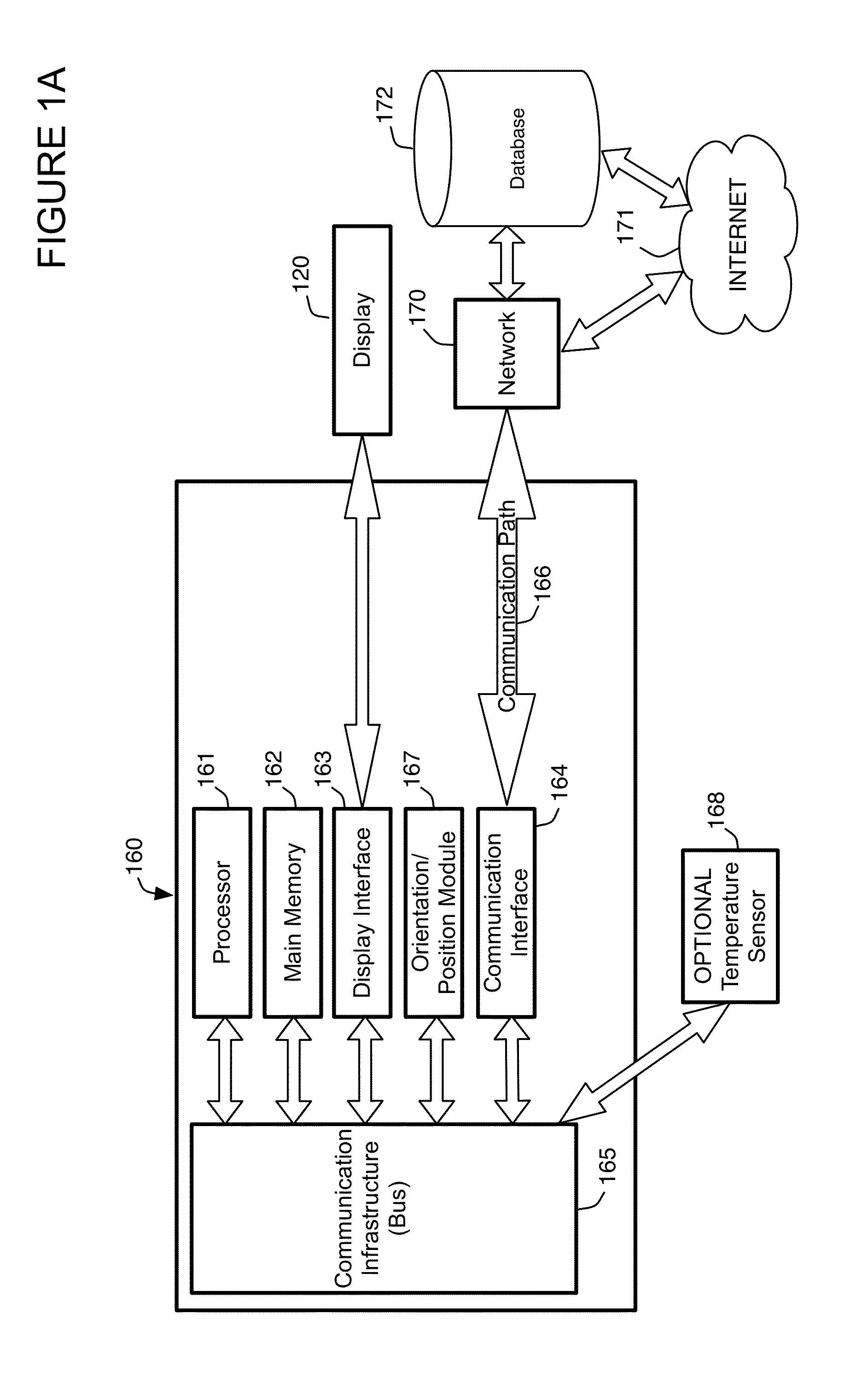

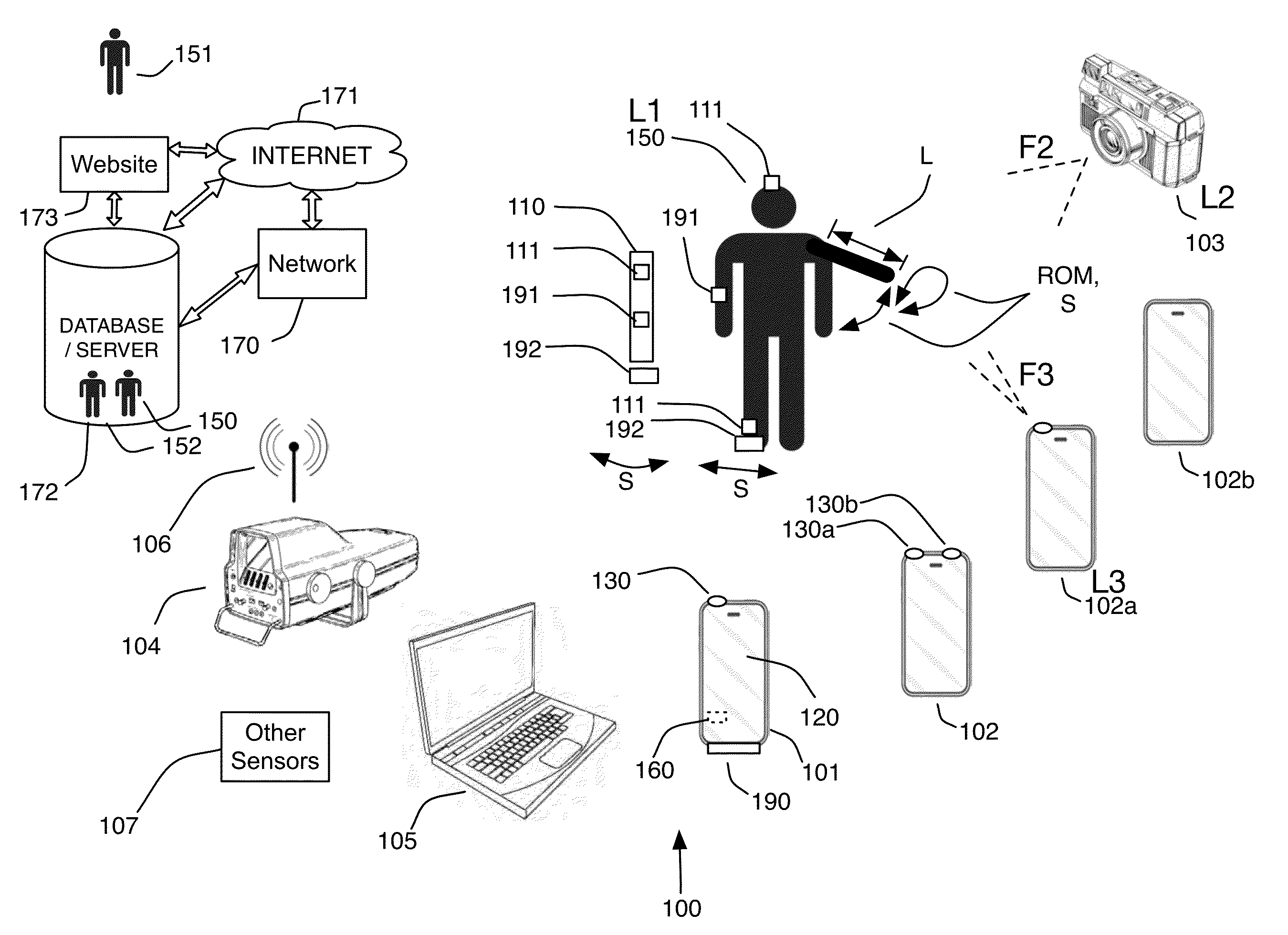

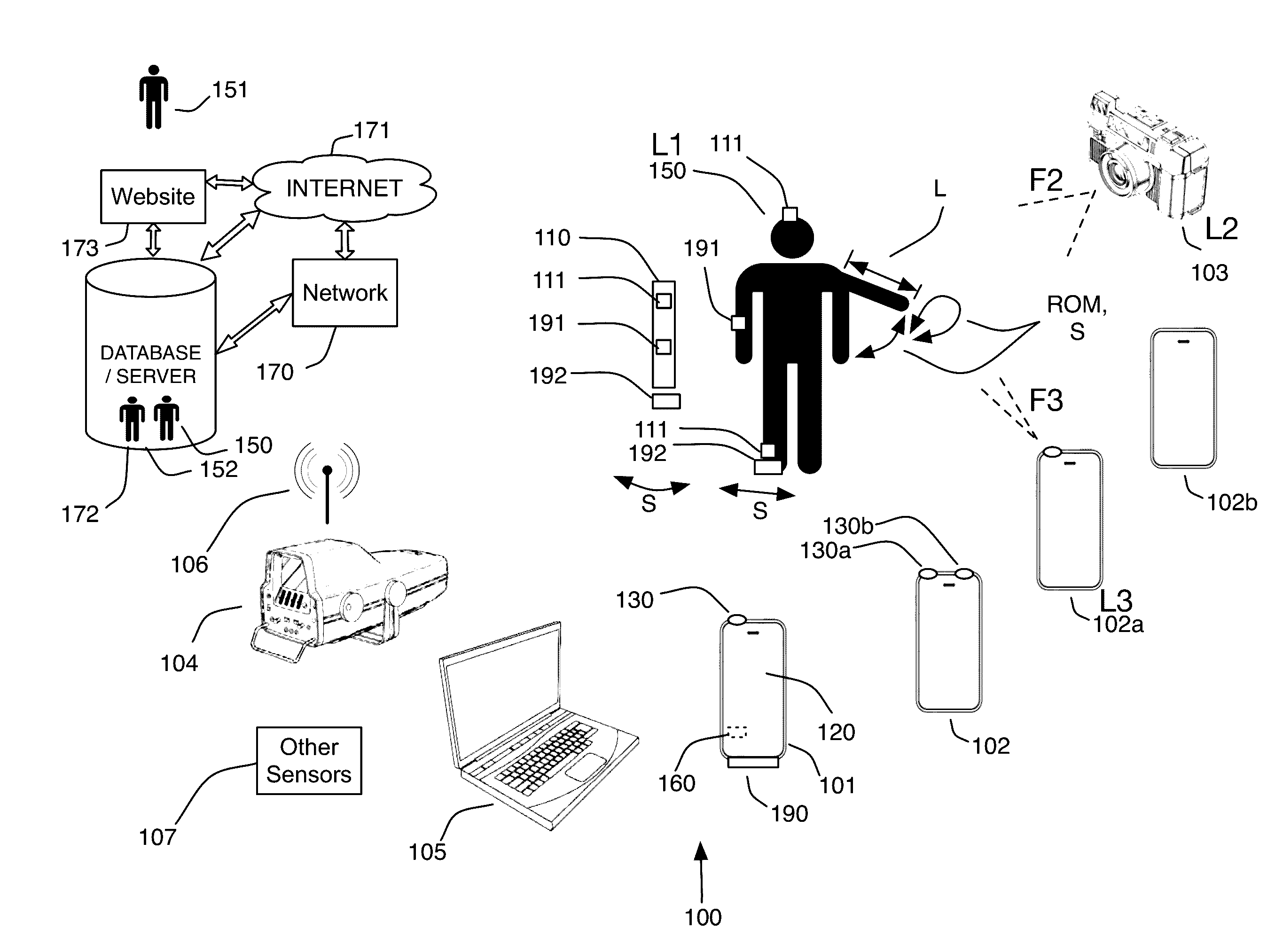

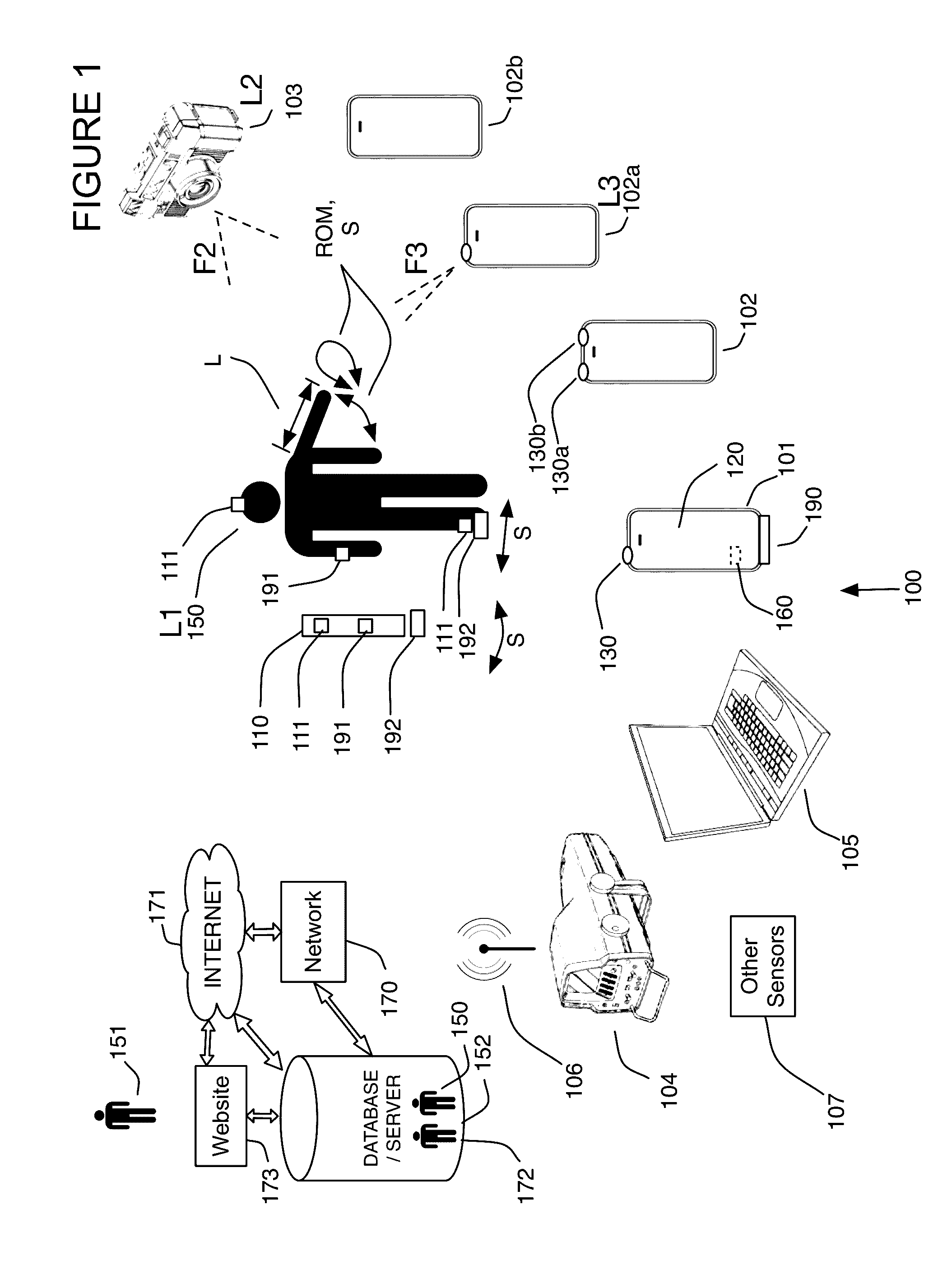

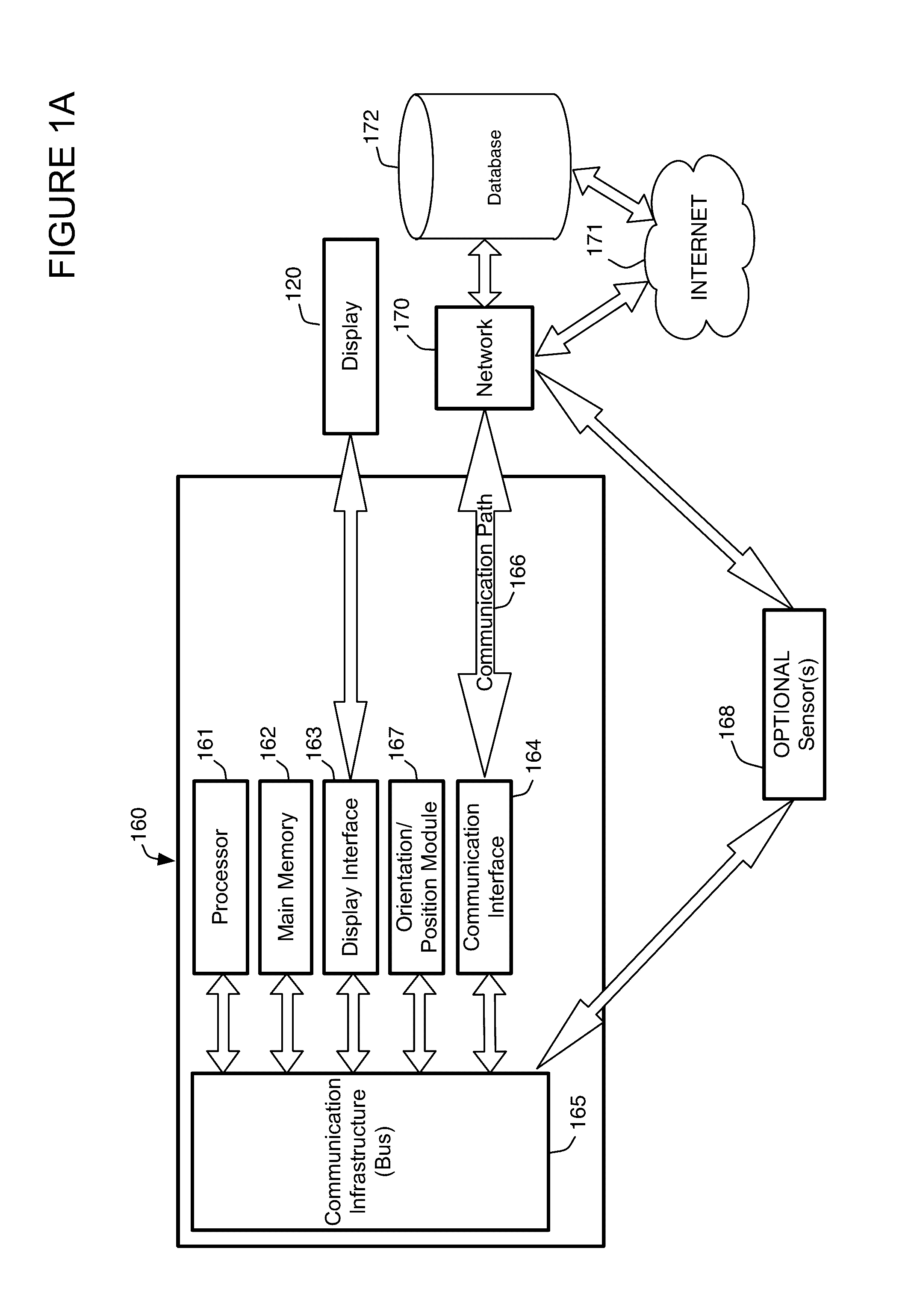

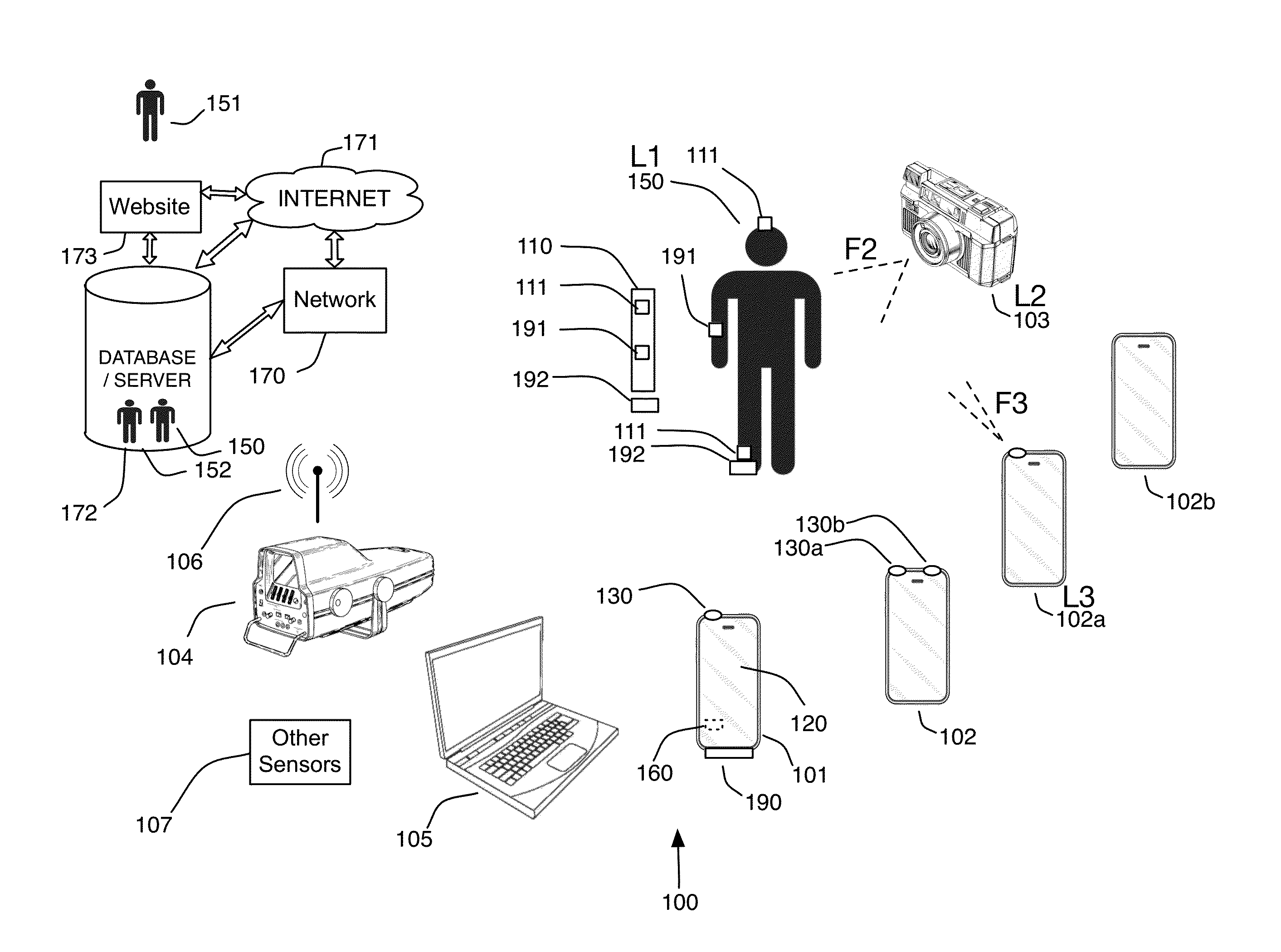

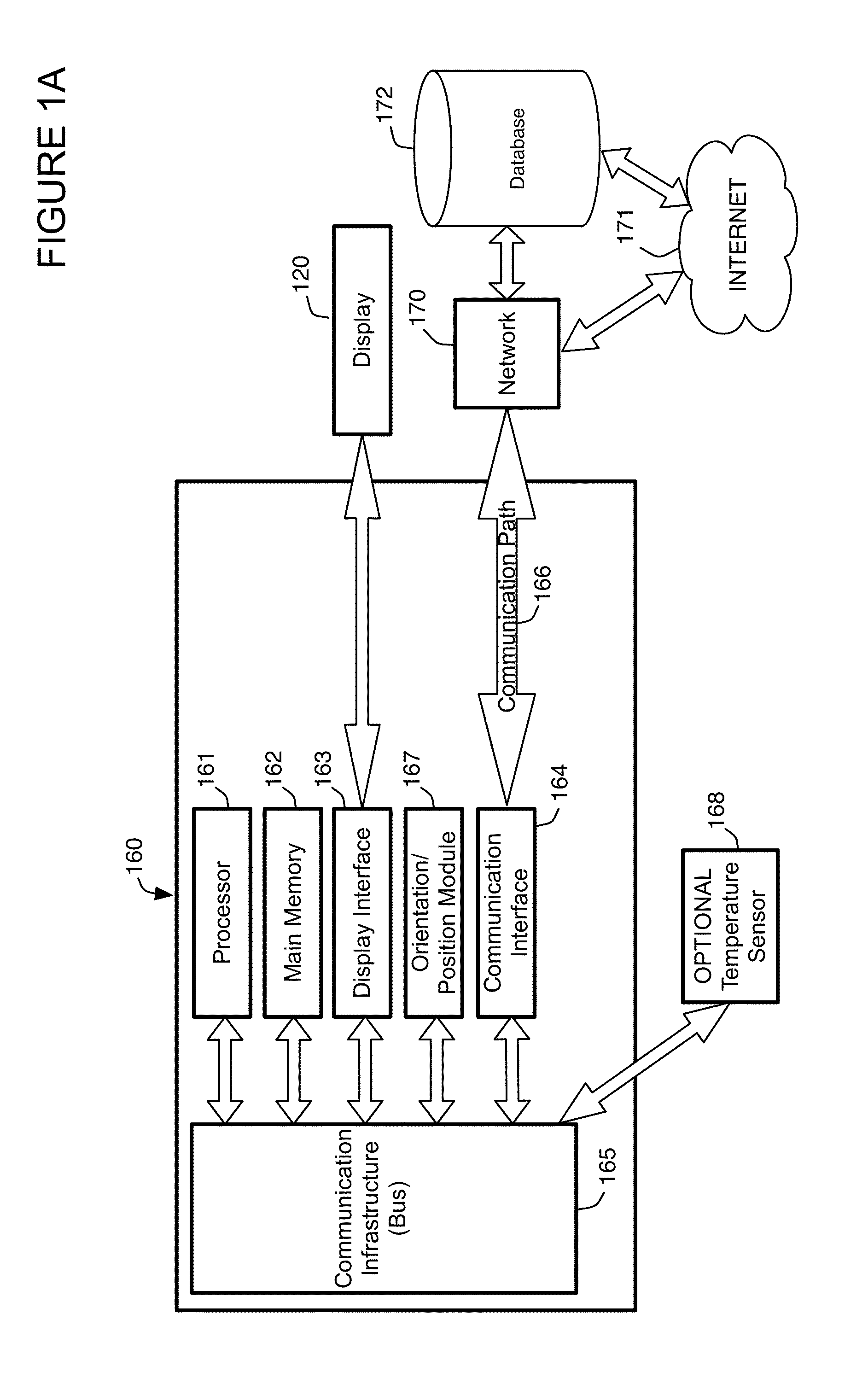

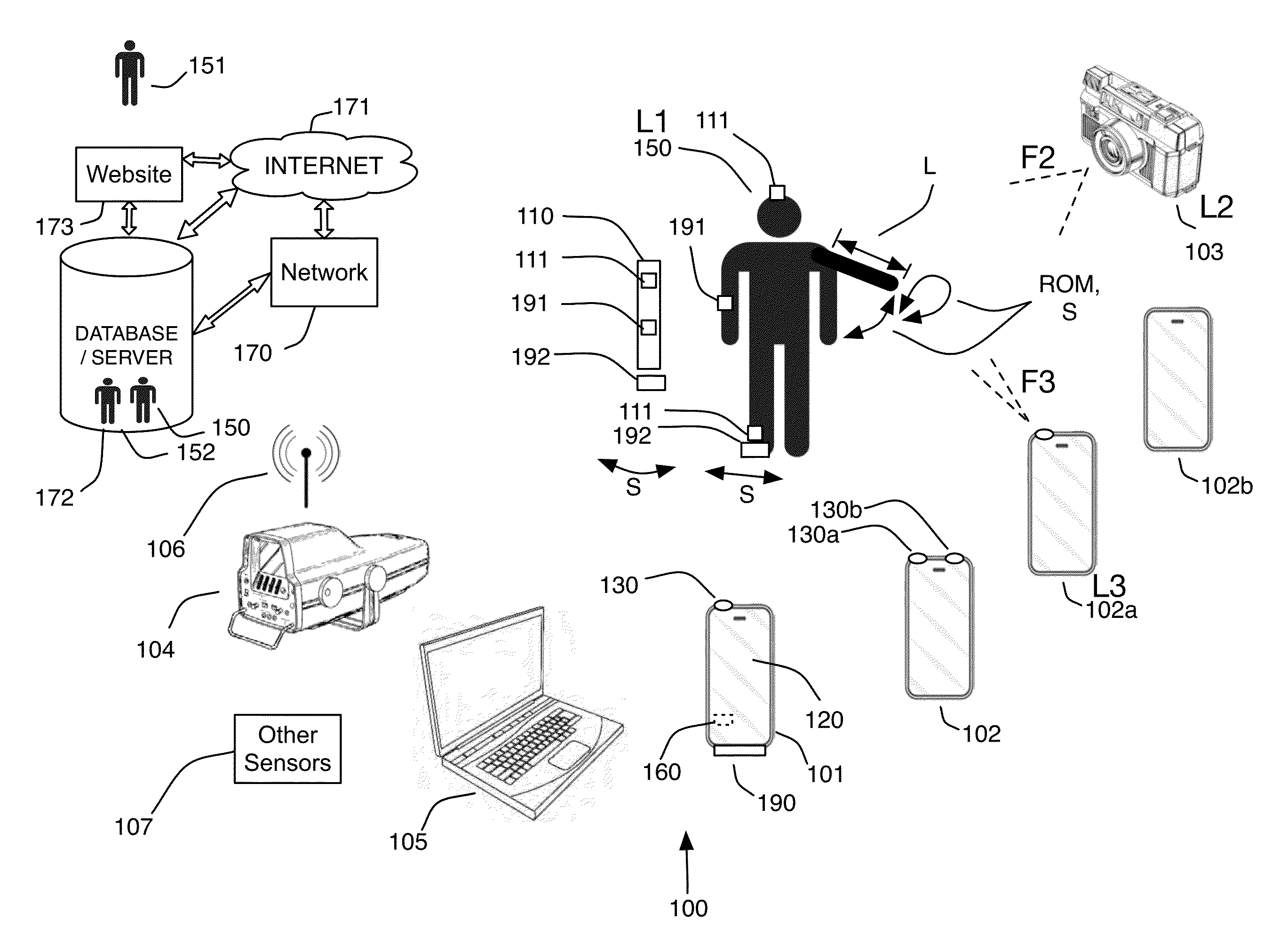

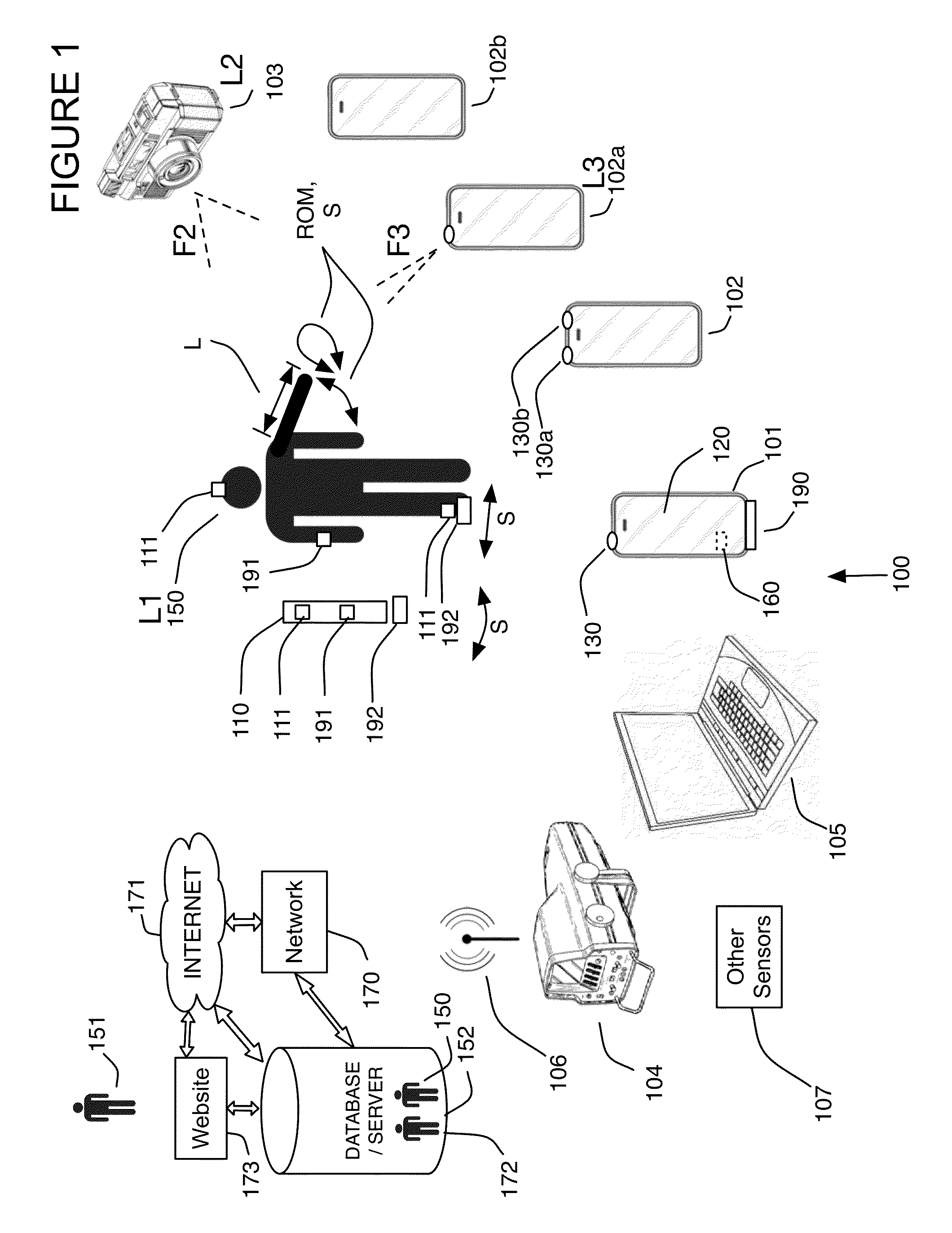

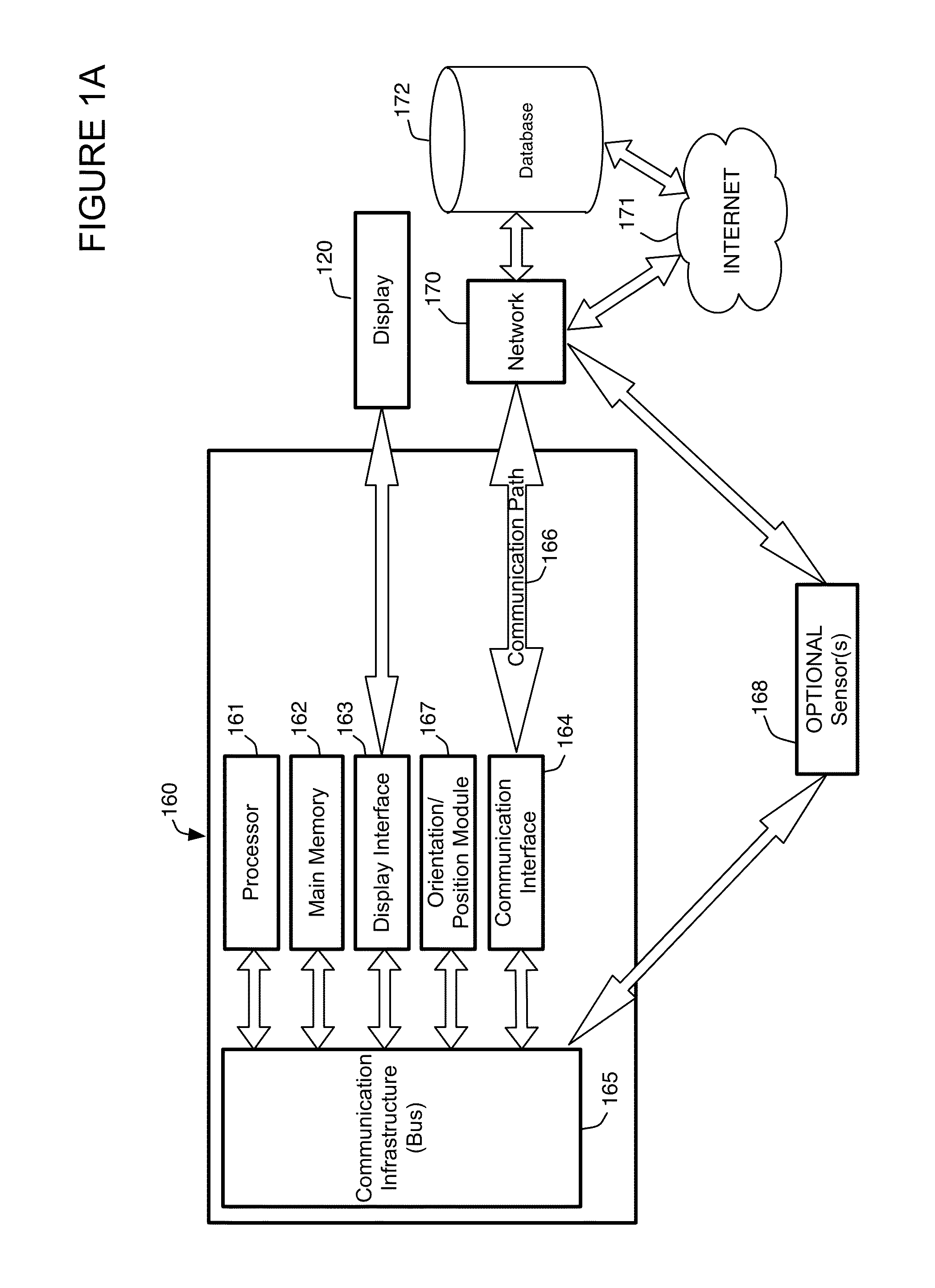

Enables intelligent synchronization and transfer of generally concise event videos synchronized with motion data from motion capture sensor(s) coupled with a user or piece of equipment. Greatly saves storage and increases upload speed by uploading event videos and avoiding upload of non-pertinent portions of large videos. Provides intelligent selection of multiple videos from multiple cameras covering an event at a given time, for example selecting one with least shake. Enables near real-time alteration of camera parameters during an event determined by the motion capture sensor, and alteration of playback parameters and special effects for synchronized event videos. Creates highlight reels filtered by metrics and can sort by metric. Integrates with multiple sensors to save event data even if other sensors do not detect the event. Also enables analysis or comparison of movement associated with the same user, other user, historical user or group of users.

Owner:NEWLIGHT CAPITAL LLC

Sensor and media event detection system

ActiveUS20150348591A1Low utilizationSave on storageImage enhancementTelevision system detailsSocial mediaSocial network

Enables detection of events using motion capture sensors and potentially other sensors electromagnetic field, temperature, humidity, wind, pressure, elevation, light, sound, or heart rate sensors to confirm and post events, differentiate similar types of motion events to determine the type of equipment or activity or quality of the event, such proficiency. Enables motion capture data and other sensor data to be utilized to curate text, images, video, sound and post the results to social networks, for example in a dedicated feed. Embodiments of the system also may post or filter to social media sites using any other filter besides location and time and the text in the social media posts for example. May use motion or other sensor data to define and event, eliminate false positive events, post true events, and / or correlate the events with social media to confirm the events, or post the events in a particular channel.

Owner:NEWLIGHT CAPITAL LLC

Integrated sensor and video motion analysis method

ActiveUS20150324636A1Conserve camera powerConserve video memoryTelevision system detailsImage enhancementObject motionSensor fusion

A method that integrates sensor data and video analysis to analyze object motion. Motion capture elements generate motion sensor data for objects of interest, and cameras generate video of these objects. Sensor data and video data are synchronized in time and aligned in space on a common coordinate system. Sensor fusion is used to generate motion metrics from the combined and integrated sensor data and video data. Integration of sensor data and video data supports robust detection of events, generation of video highlight reels or epic fail reels augmented with metrics that show interesting activity, and calculation of metrics that exceed the individual capabilities of either sensors or video analysis alone.

Owner:NEWLIGHT CAPITAL LLC

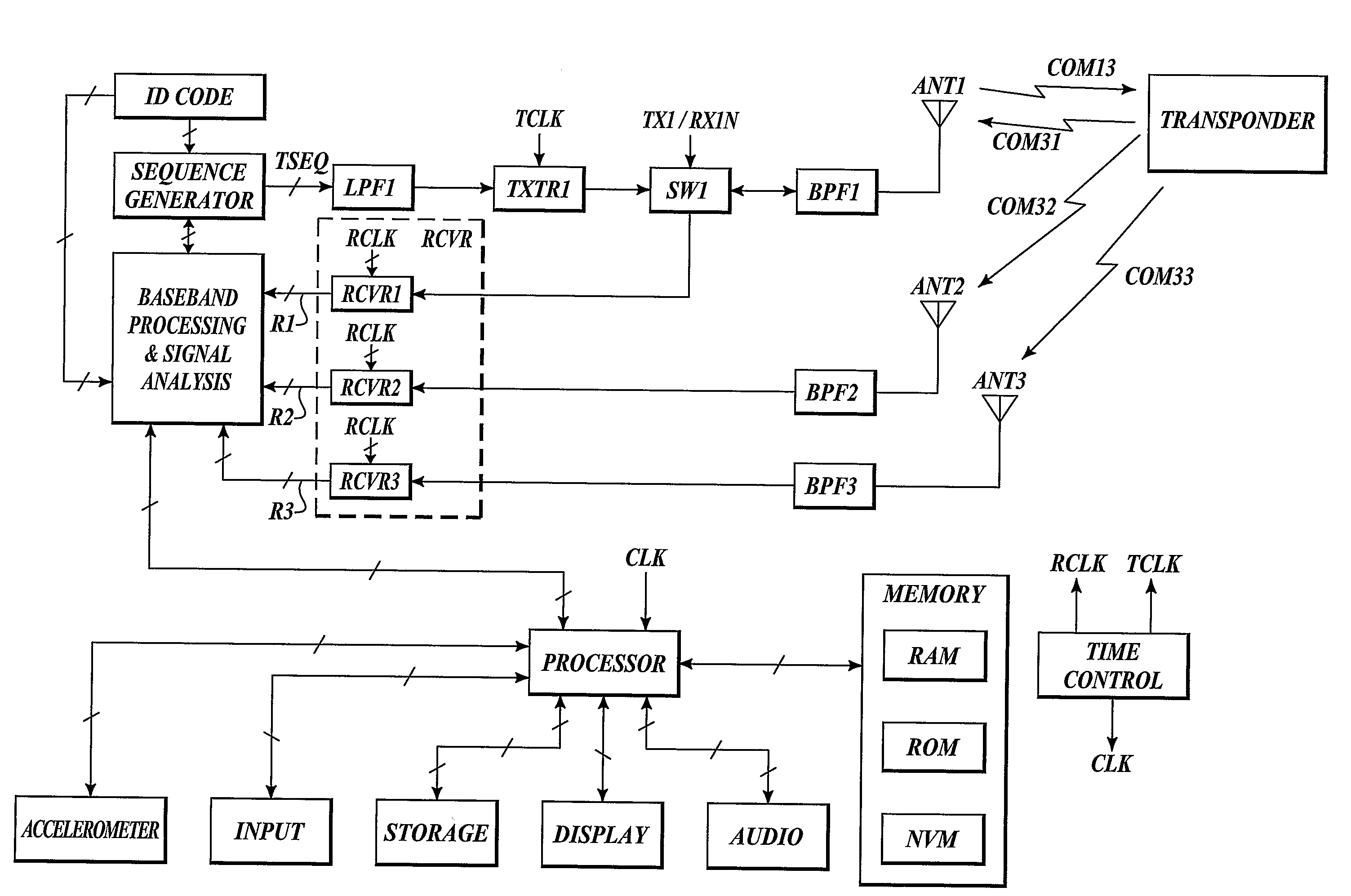

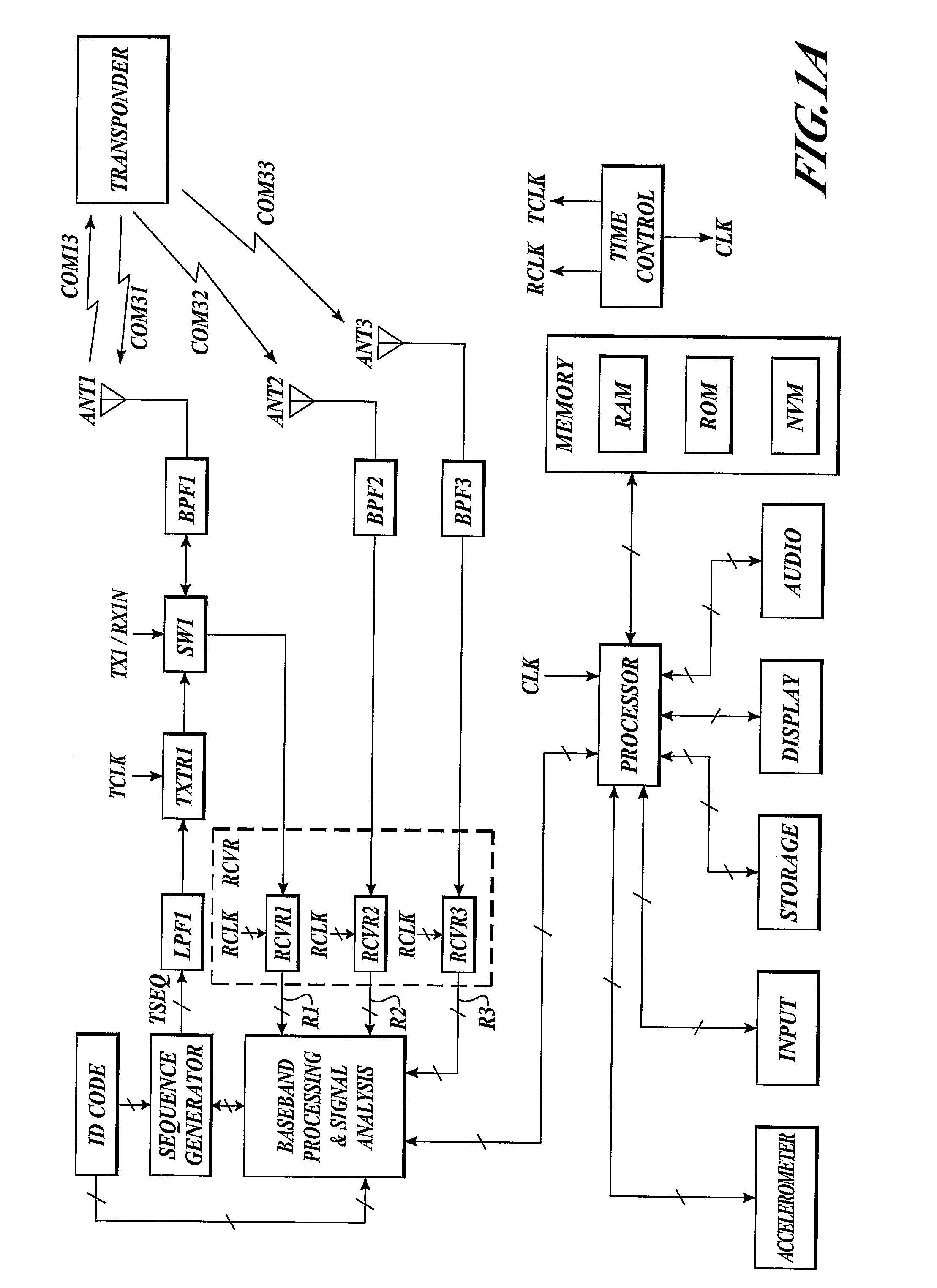

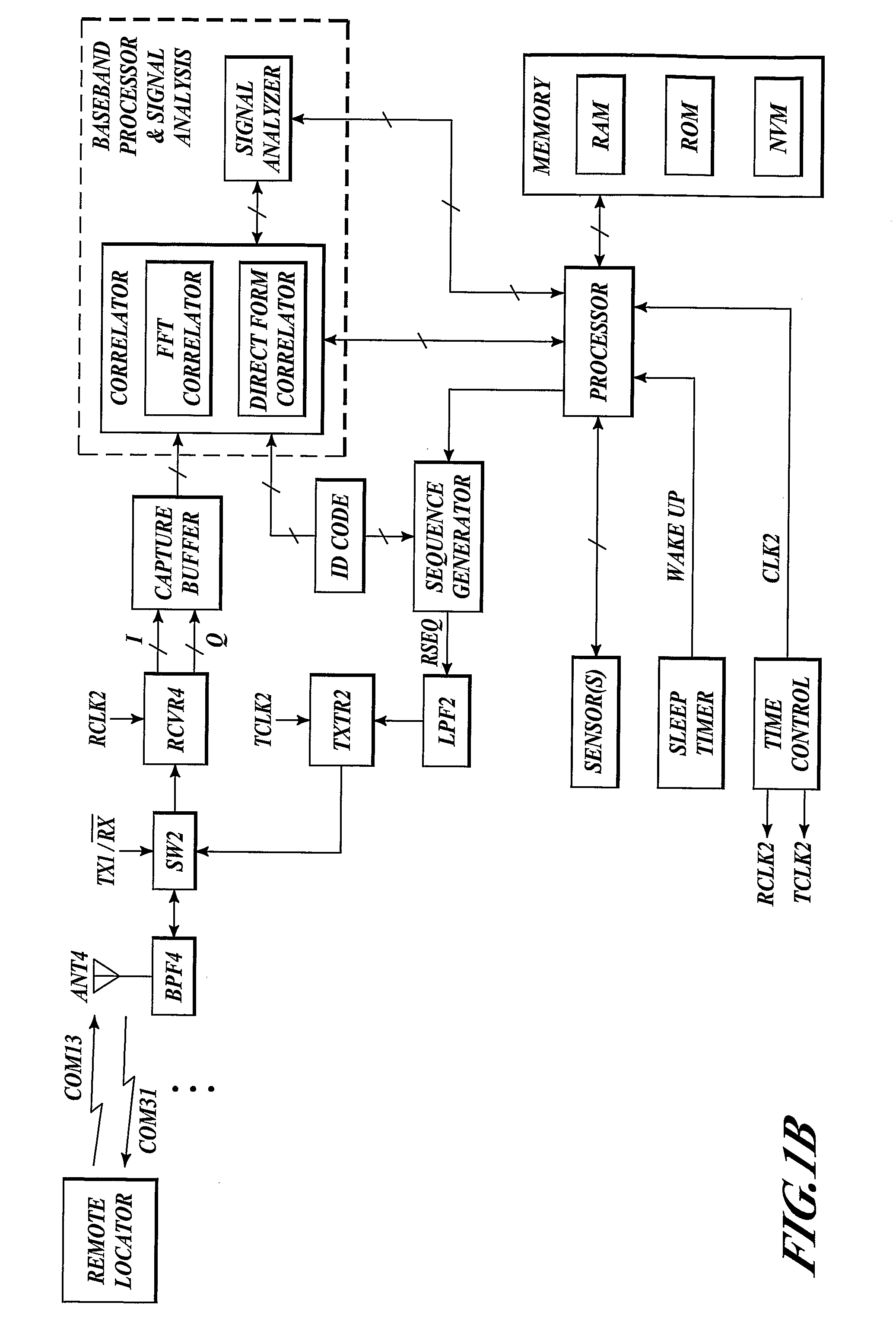

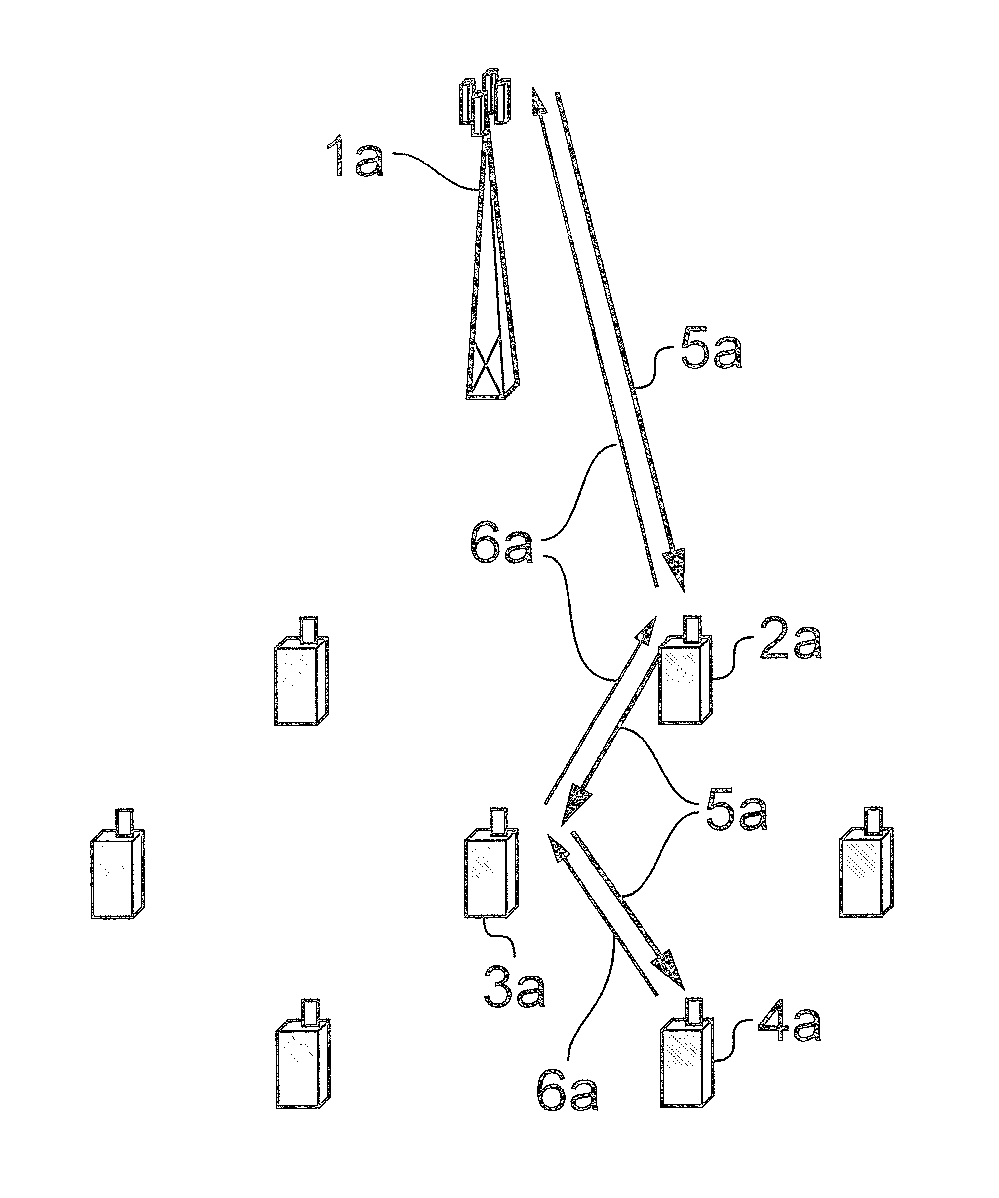

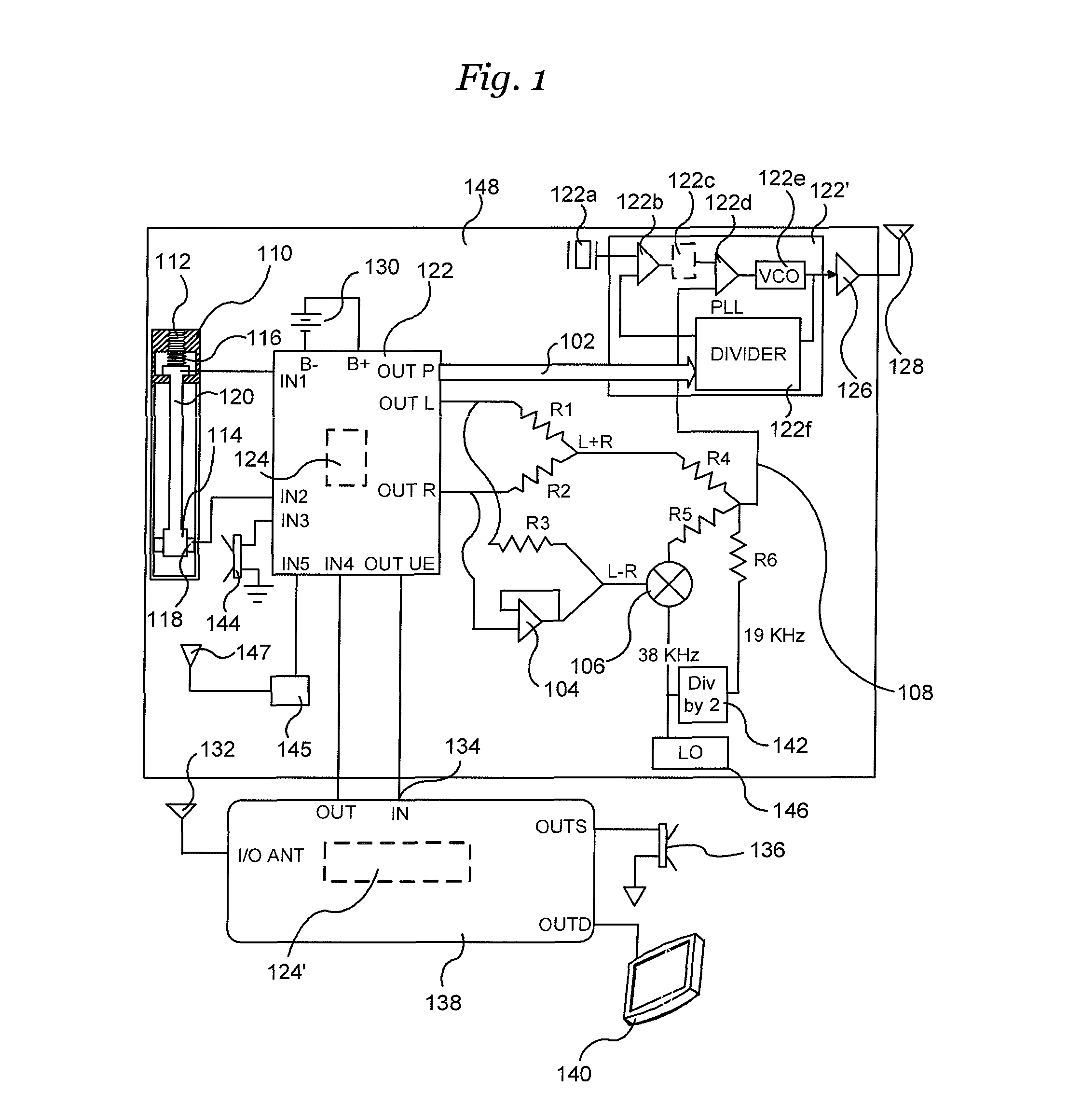

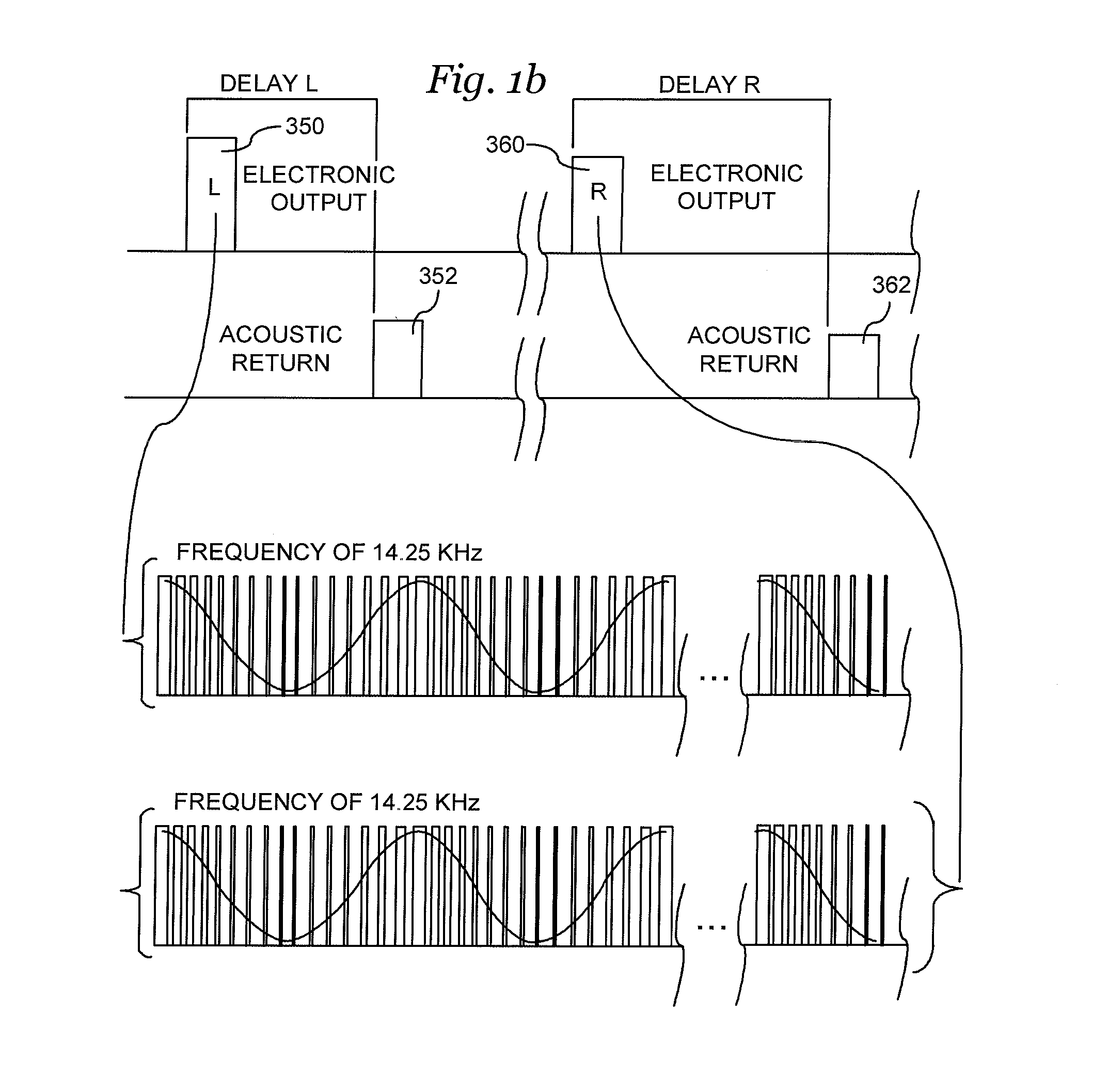

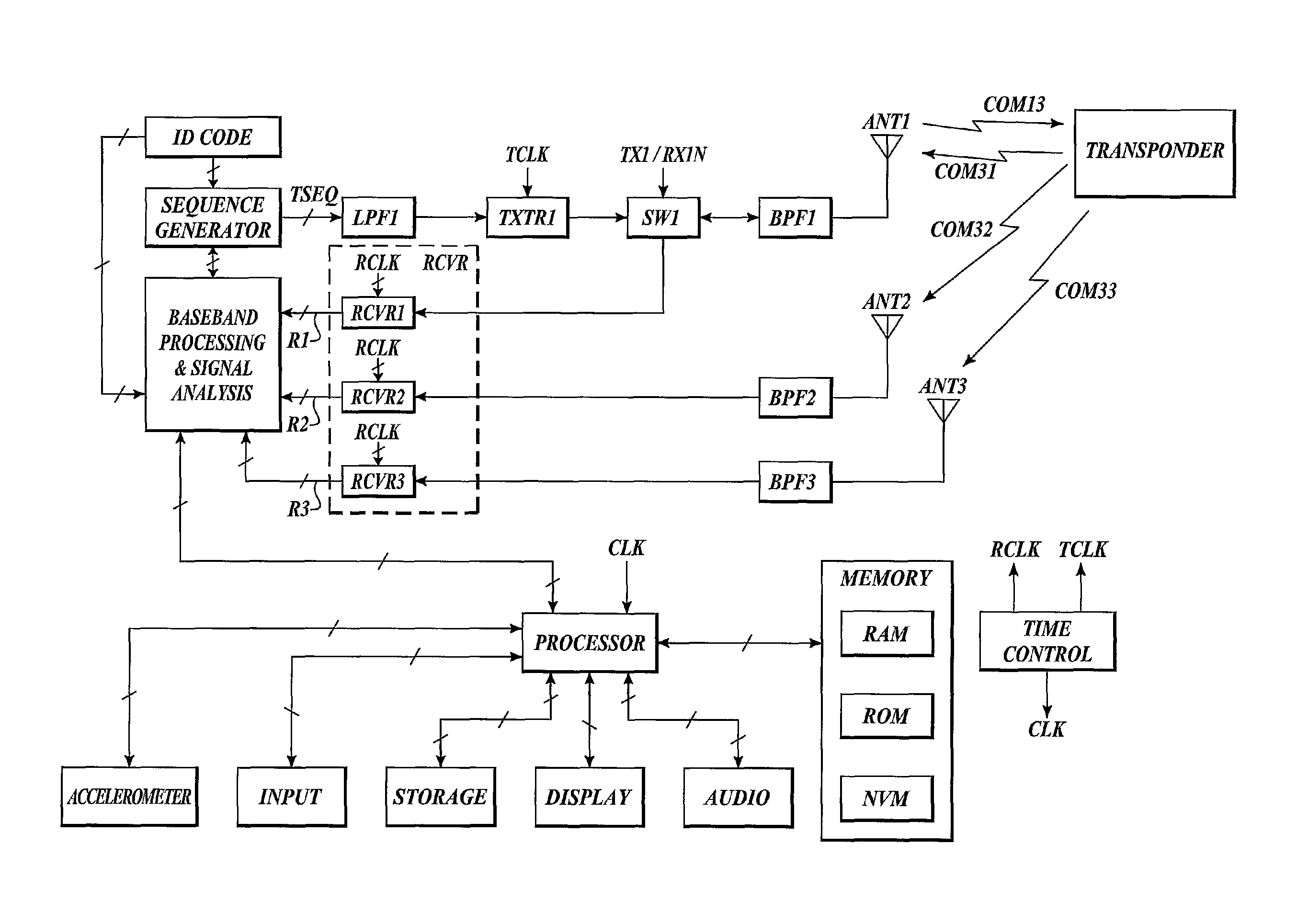

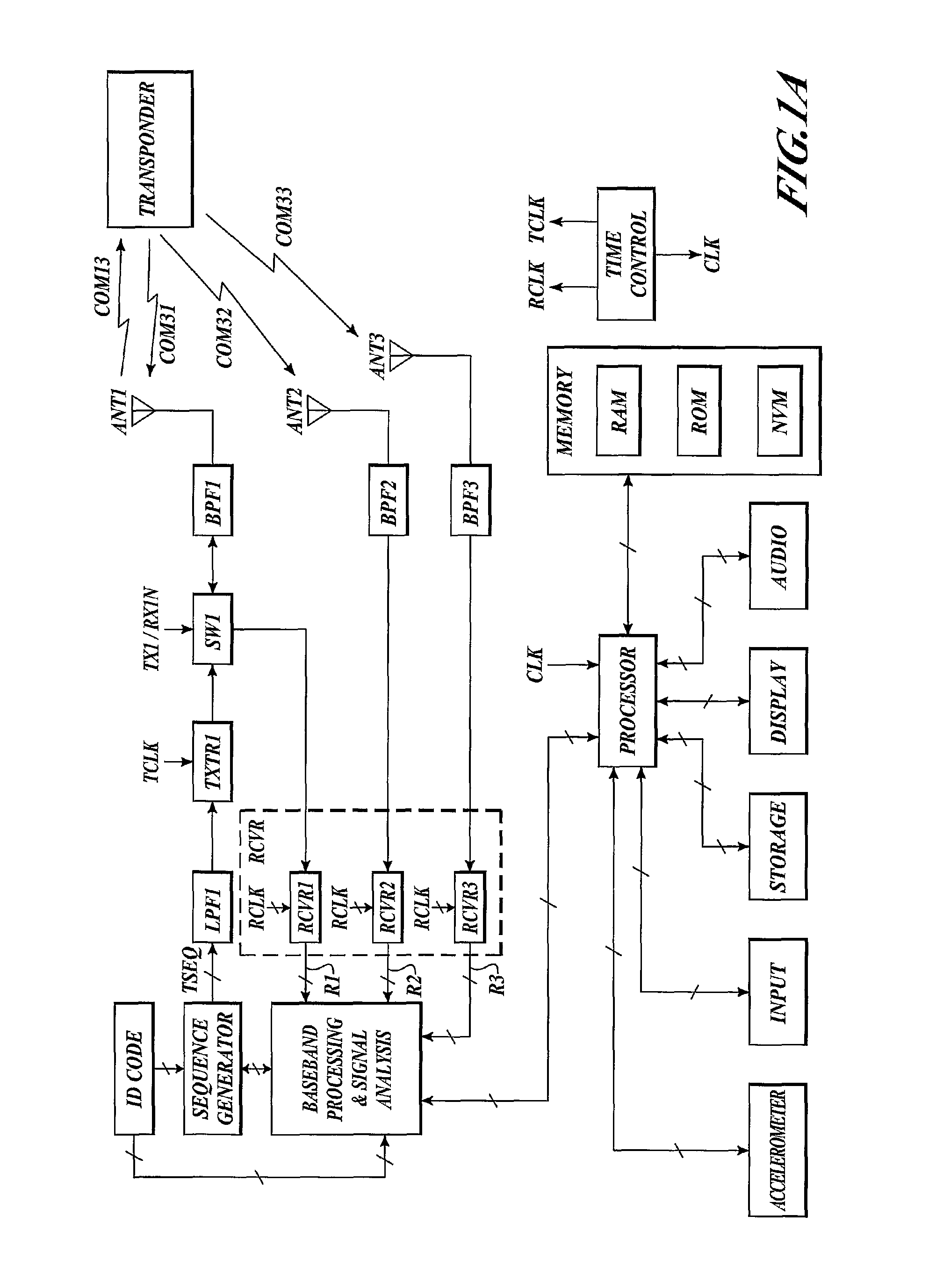

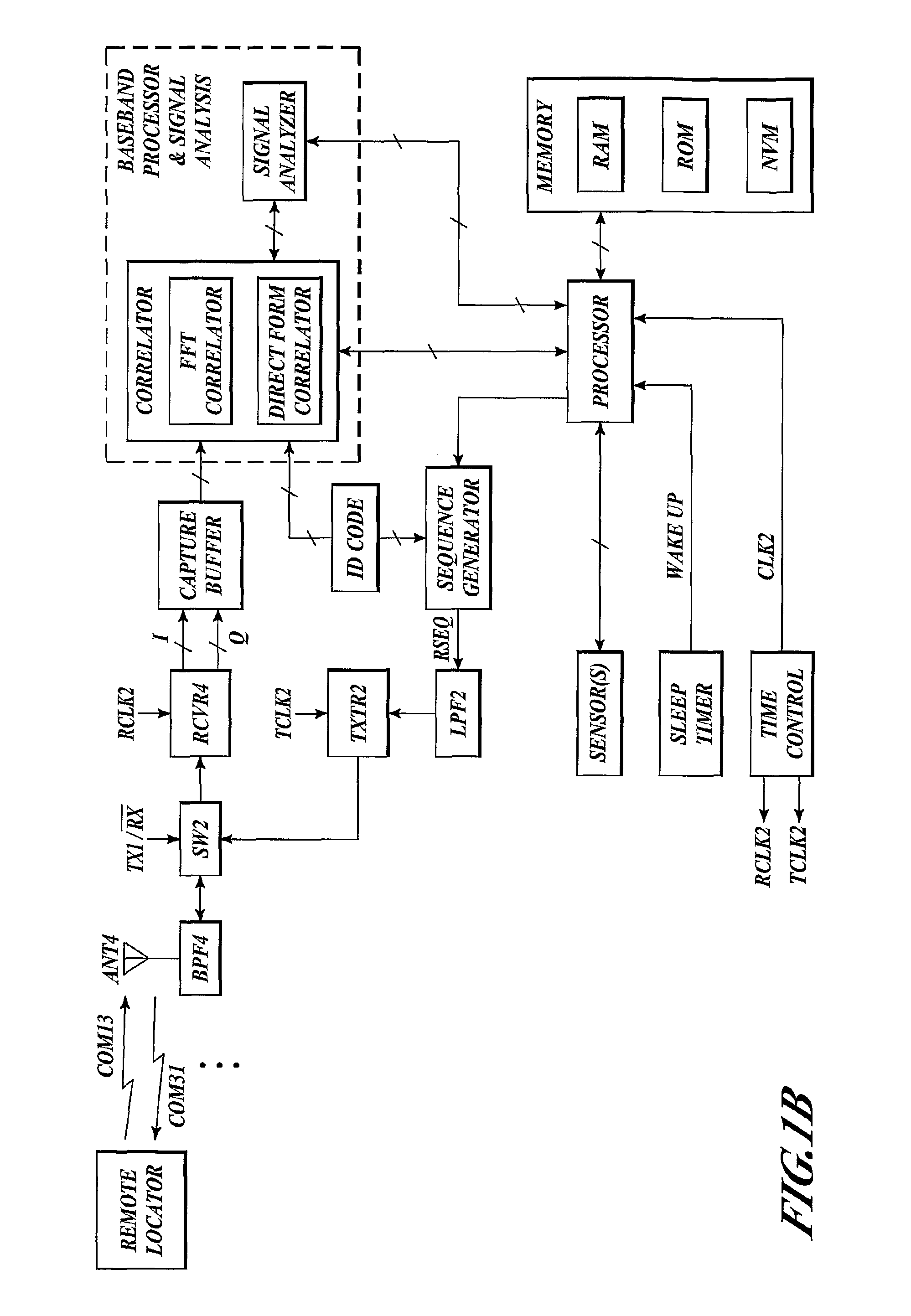

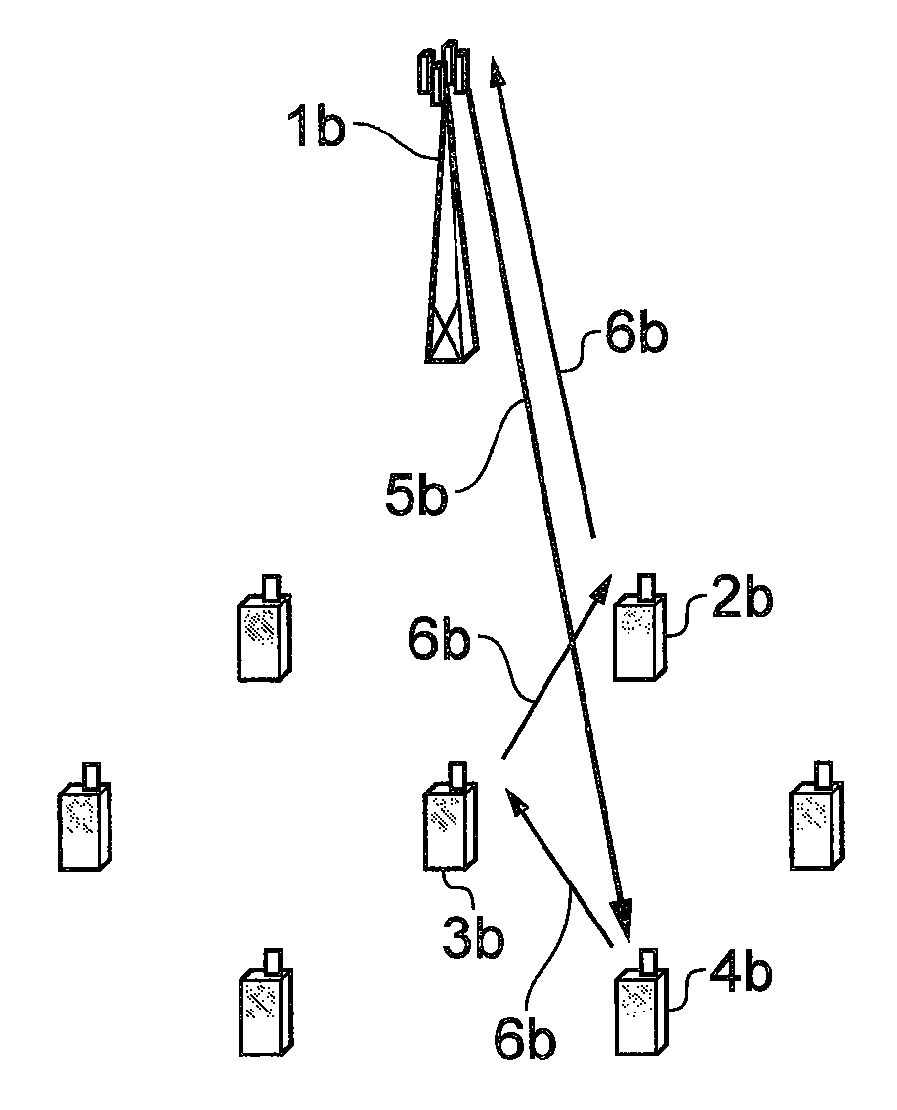

System and method for locating objects and communicating with the same

ActiveUS7646330B2Level signalImprove signal-to-noise ratioRadio wave direction/deviation determination systemsFrequency-division multiplex detailsEngineeringTime of flight

Communication between a remote locator and a transponder is used to determine the relative position of the transponder. The transponder and locator each include a transmitter and a receiver. The locator transmits an inquiry in the form of a relatively powerful cyclically encoded signal with repetitive elements, uniquely associated with a target transponder. Periodically, each transponder correlates its coded ID against a possible inquiry signal, determining frequency, phase and framing in the process. Upon a match, the transponder transmits a synthesized response coherent with the received signal. The locator integrates multiple cyclical response elements, allowing low-power transmissions from the transponder. The locator correlates the integrated response, determines round-trip Doppler shift, time-of-flight, and then computes the distance and angle to the transponder. The transponder can be wearable, bionically implanted, or attached to, or embedded in, some object.

Owner:SANTA MONICA SEMICON

Sensor and media event detection and tagging system

ActiveUS20160292509A1Labor savingEasy to analyze and useImage enhancementTelevision system detailsSocial webData science

Enables detection and tagging of events using sensor data combined with data from servers such as social media sites. Sensors may measure values such as motion, temperature, humidity, wind, pressure, elevation, light, sound, or heart rate. Sensor data and event tags may be utilized to curate text, images, video, sound and post the results to social networks, for example in a dedicated feed. Event tags generated by the system may represent for example activity types, players, performance levels, or scoring results. The system may analyze social media postings to confirm or augment event tags. Users may filter and analyze saved events based on the assigned tags. The system may create highlight and fail reels filtered by metrics and by tags.

Owner:NEWLIGHT CAPITAL LLC

Integrated sensor and video motion analysis method

ActiveUS9396385B2Low utilizationSave on storageImage enhancementImage analysisObject motionSensor fusion

A method that integrates sensor data and video analysis to analyze object motion. Motion capture elements generate motion sensor data for objects of interest, and cameras generate video of these objects. Sensor data and video data are synchronized in time and aligned in space on a common coordinate system. Sensor fusion is used to generate motion metrics from the combined and integrated sensor data and video data. Integration of sensor data and video data supports robust detection of events, generation of video highlight reels or epic fail reels augmented with metrics that show interesting activity, and calculation of metrics that exceed the individual capabilities of either sensors or video analysis alone.

Owner:NEWLIGHT CAPITAL LLC

Video and motion event integration system

ActiveUS9235765B2Low utilizationSave on storageImage enhancementImage analysisEvent dataMultiple sensor

Enables intelligent synchronization and transfer of generally concise event videos synchronized with motion data from motion capture sensor(s) coupled with a user or piece of equipment. Greatly saves storage and increases upload speed by uploading event videos and avoiding upload of non-pertinent portions of large videos. Provides intelligent selection of multiple videos from multiple cameras covering an event at a given time, for example selecting one with least shake. Enables near real-time alteration of camera parameters during an event determined by the motion capture sensor, and alteration of playback parameters and special effects for synchronized event videos. Creates highlight reels filtered by metrics and can sort by metric. Integrates with multiple sensors to save event data even if other sensors do not detect the event. Also enables analysis or comparison of movement associated with the same user, other user, historical user or group of users.

Owner:NEWLIGHT CAPITAL LLC

Sensor and media event detection system

ActiveUS9418705B2Low utilizationSave on storageImage enhancementImage analysisElectromagnetic fieldMotion capture

Enables detection of events using motion capture sensors and potentially other sensors electromagnetic field, temperature, humidity, wind, pressure, elevation, light, sound, or heart rate sensors to confirm and post events, differentiate similar types of motion events to determine the type of equipment or activity or quality of the event, such proficiency. Enables motion capture data and other sensor data to be utilized to curate text, images, video, sound and post the results to social networks, for example in a dedicated feed. Embodiments of the system also may post or filter to social media sites using any other filter besides location and time and the text in the social media posts for example. May use motion or other sensor data to define and event, eliminate false positive events, post true events, and / or correlate the events with social media to confirm the events, or post the events in a particular channel.

Owner:NEWLIGHT CAPITAL LLC

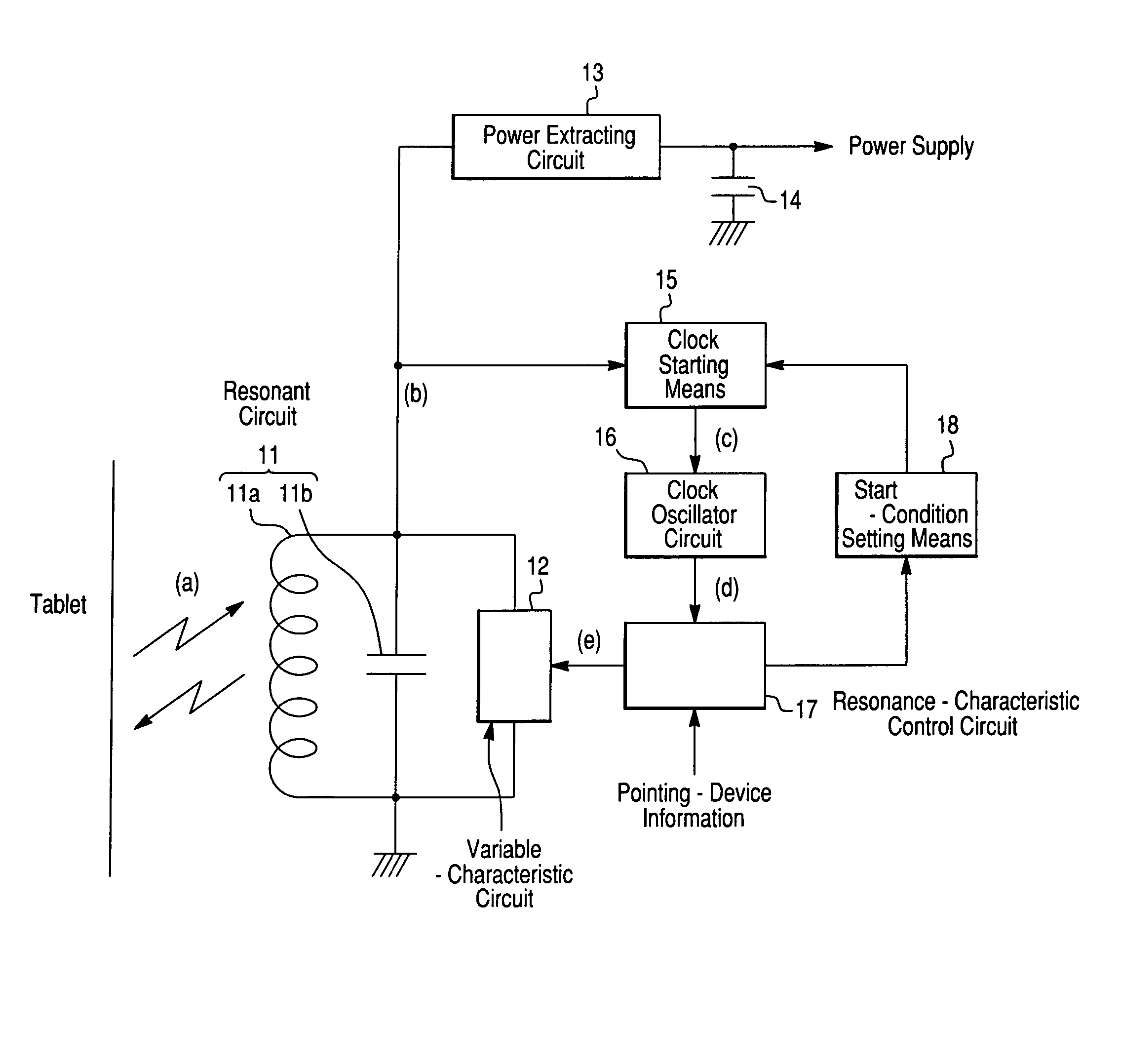

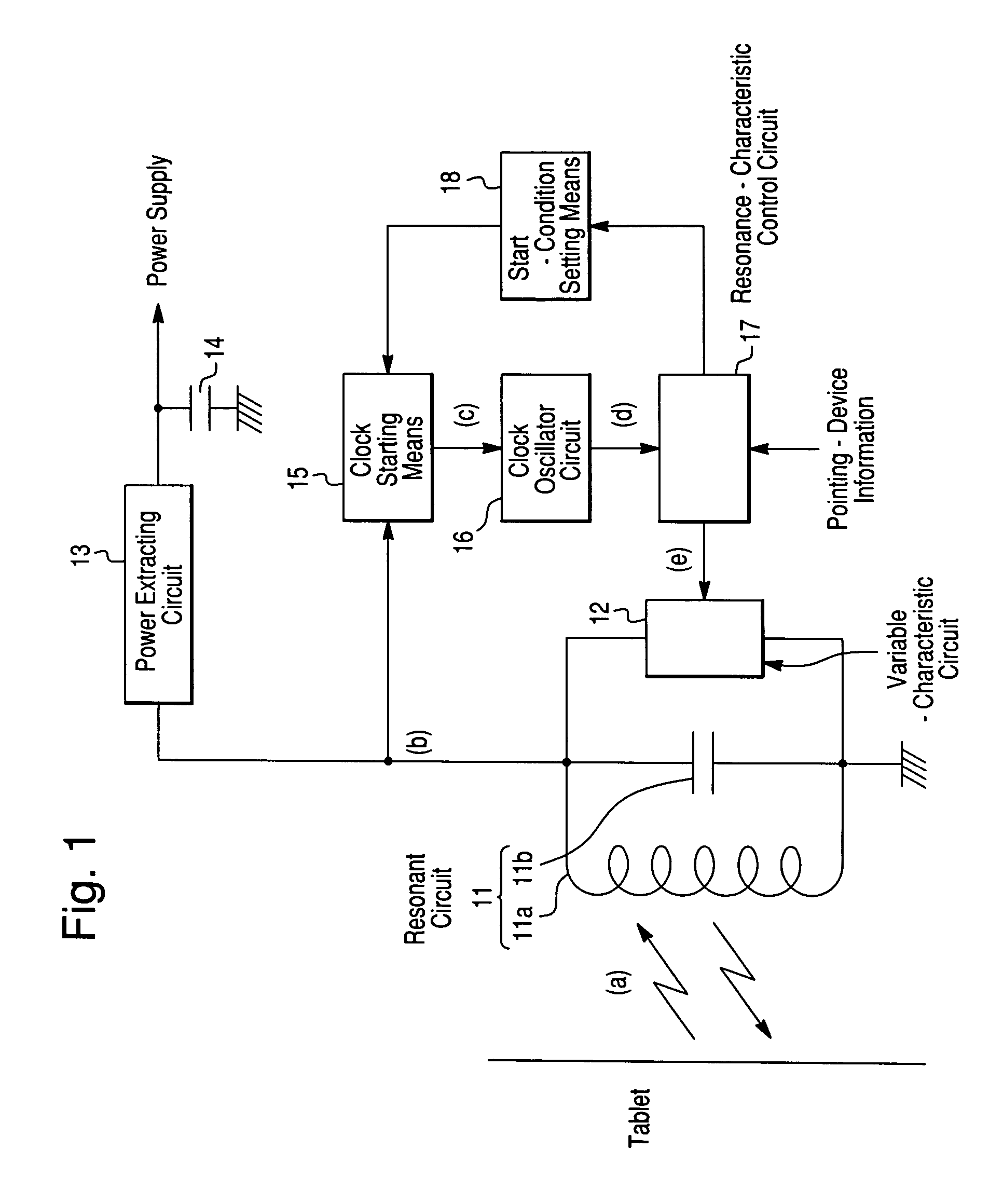

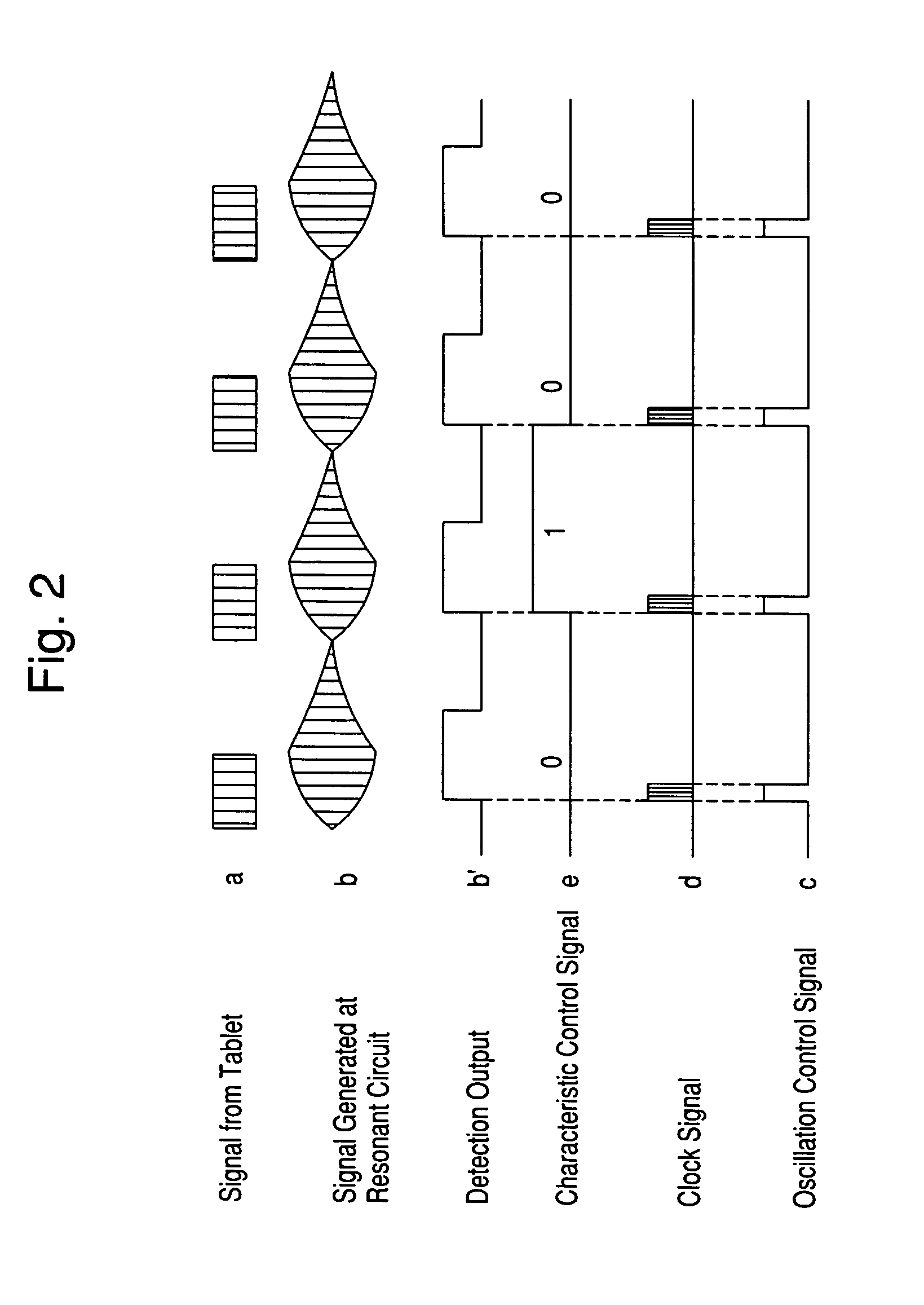

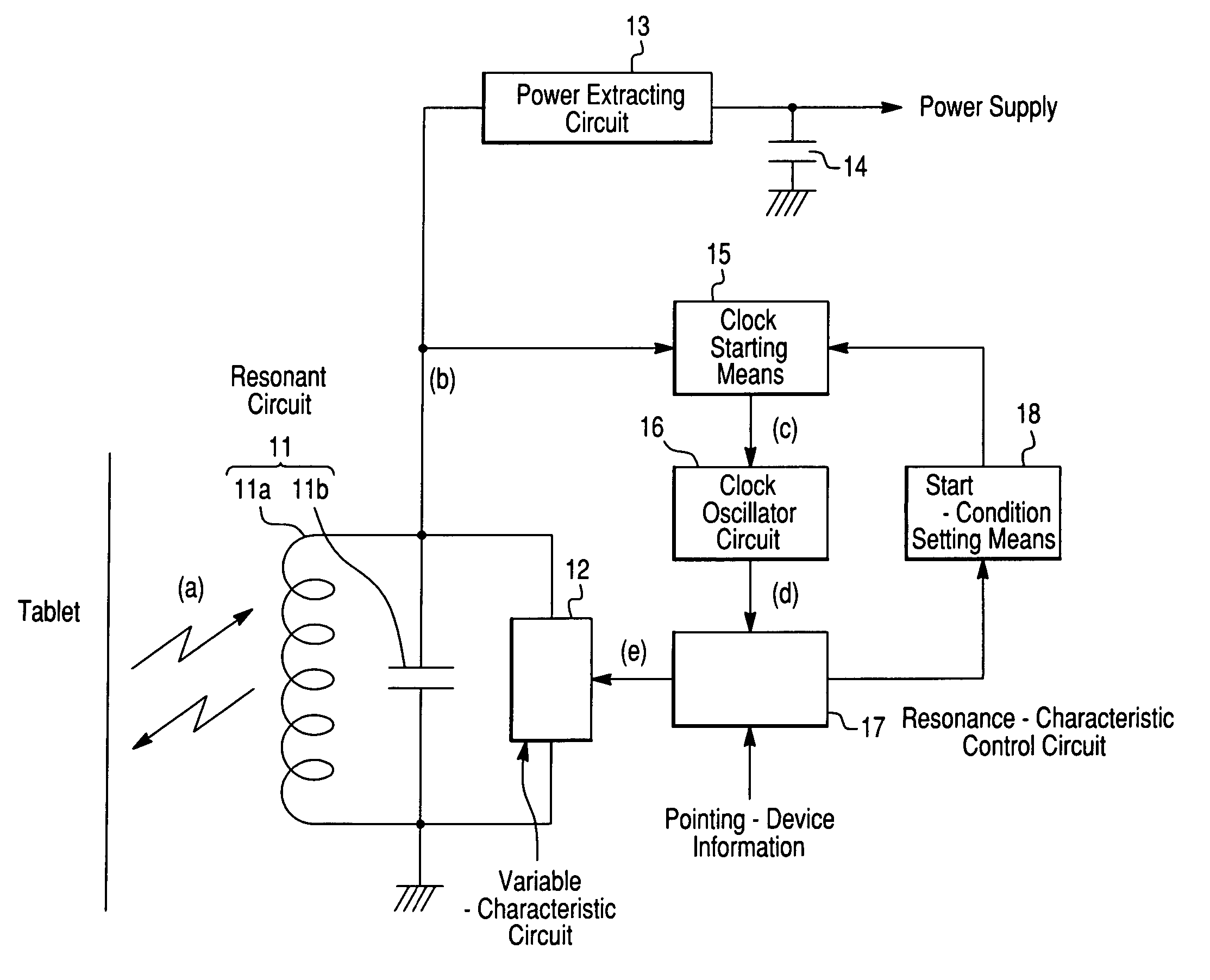

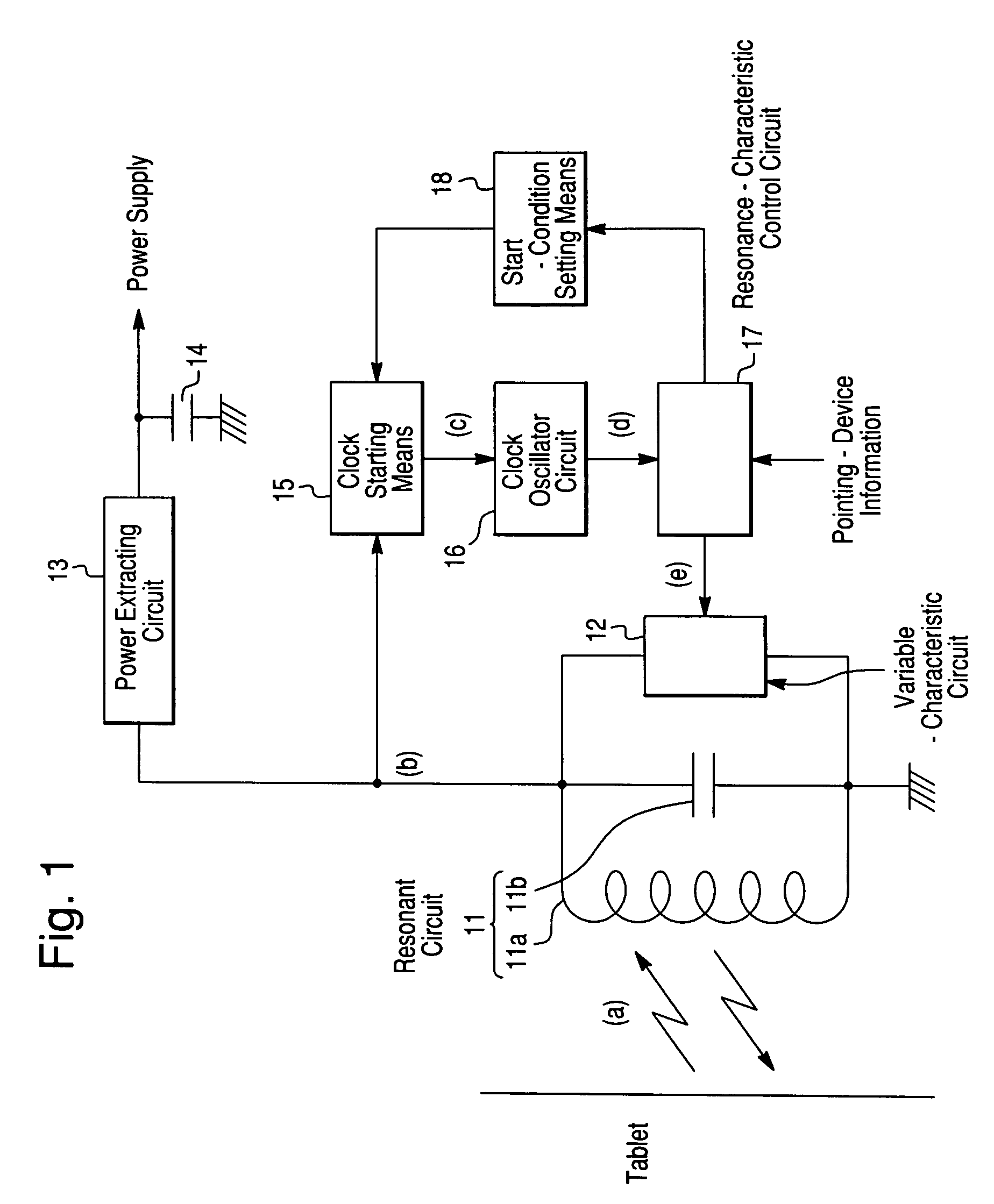

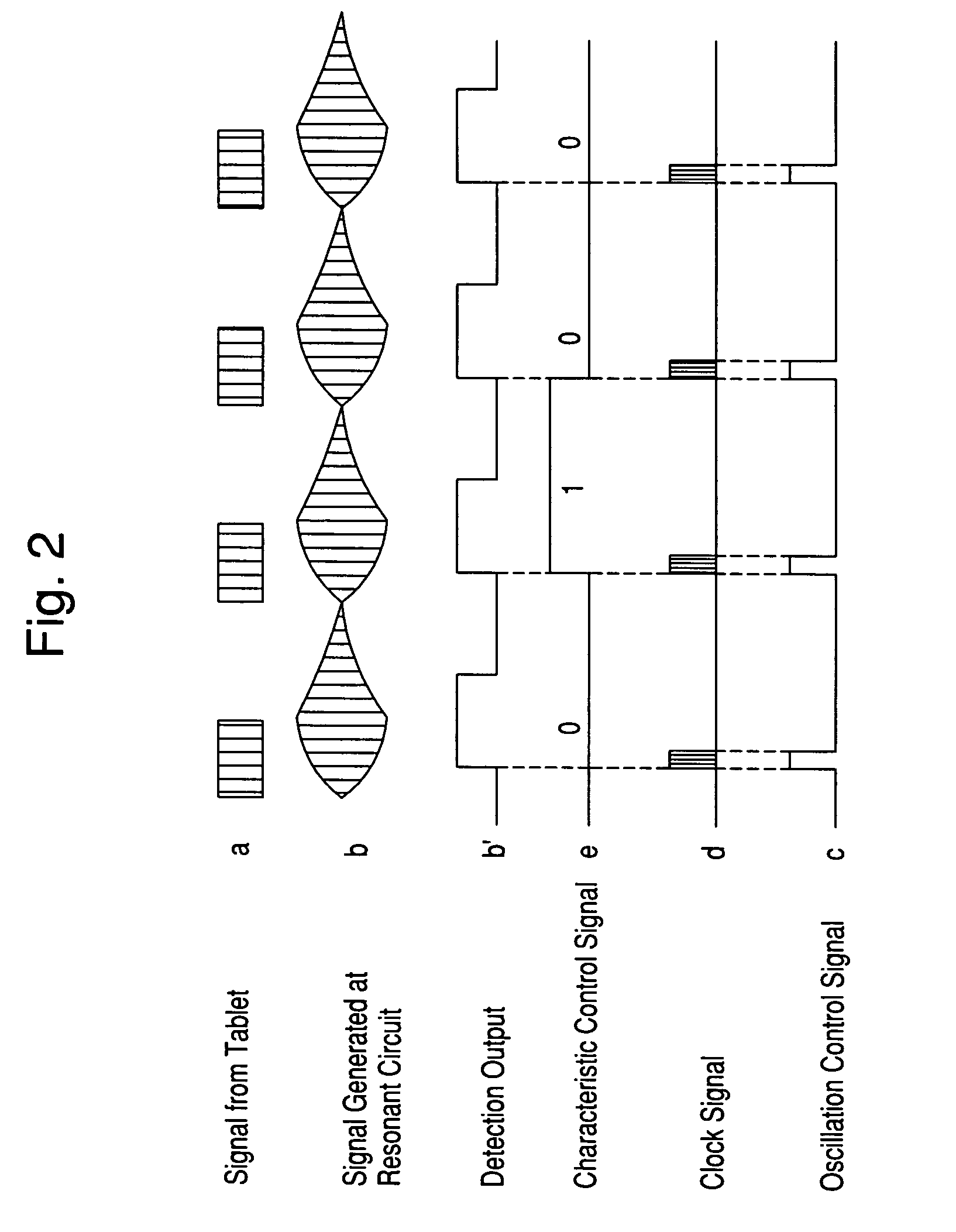

Position pointing device

InactiveUS20050043918A1Low Power TransmissionBattery-less operationTime indicationDigital data processing detailsResonanceEngineering

A position pointing device includes a resonant circuit, a resonance-characteristic control circuit for controlling characteristics of the resonant circuit in accordance with pointing-device information at timing synchronized with at least part of an electromagnetic wave that is intermittently transmitted from a tablet and for returning the pointing-device information to the tablet, a clock oscillator circuit for generating a clock signal for driving the resonance-characteristic control circuit, and clock starting means for stopping an operation of the clock oscillator circuit when a start condition is set and for starting the operation of the clock oscillator circuit when the resonant circuit generates a signal specified by the start condition. The position pointing device further includes start-condition setting means for setting the start condition in the clock starting means at timing in accordance with an operation of the resonance-characteristic control circuit.

Owner:WACOM CO LTD

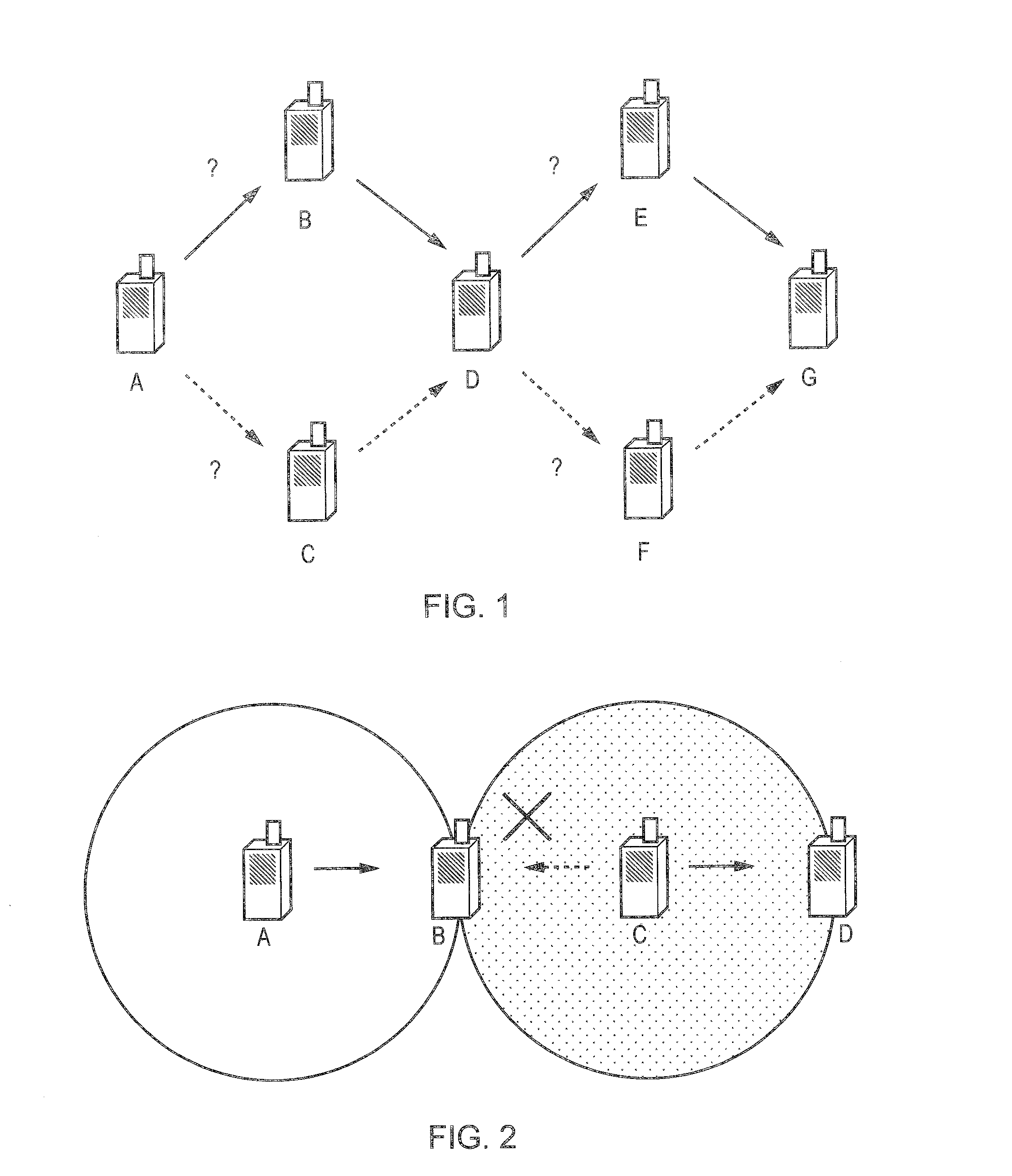

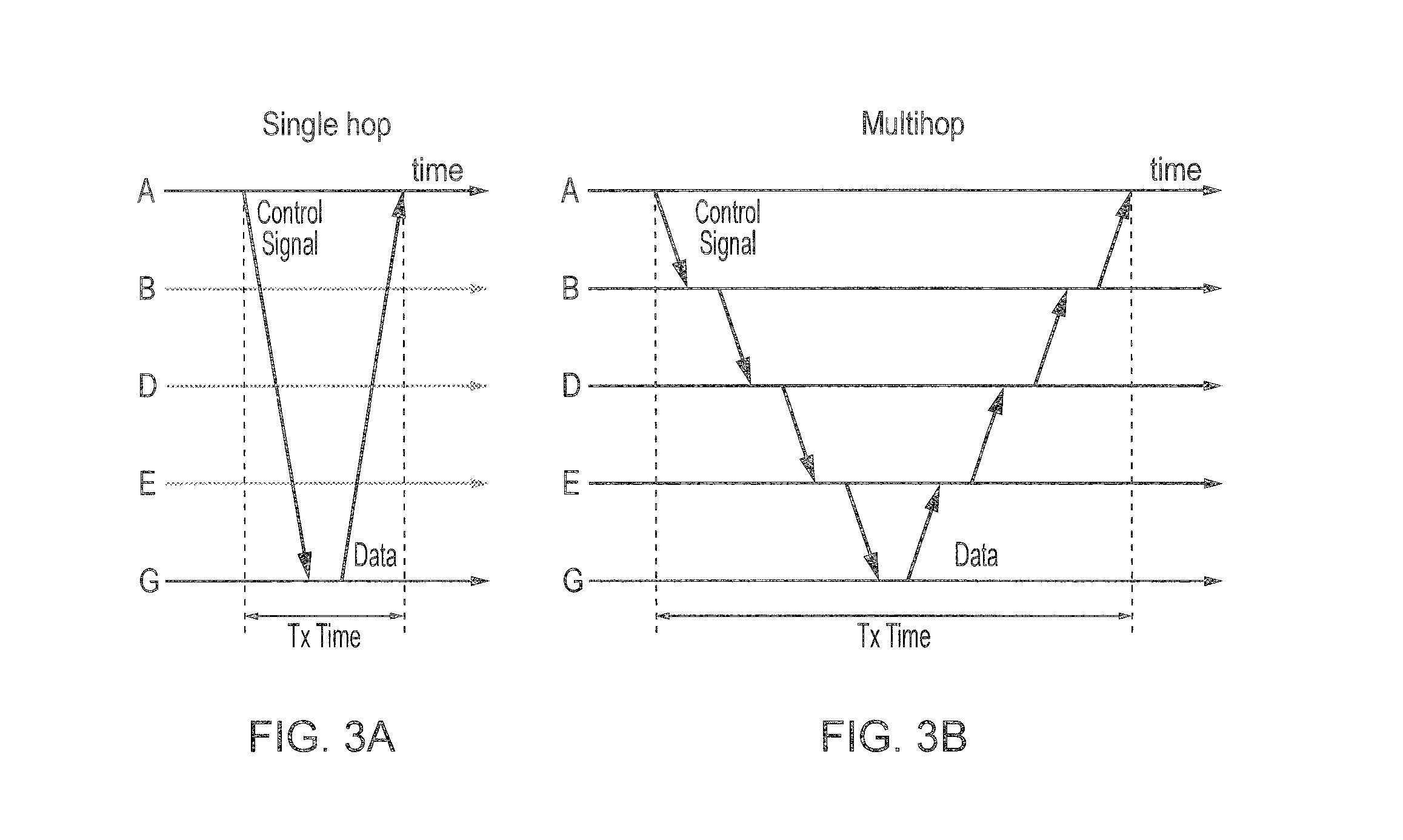

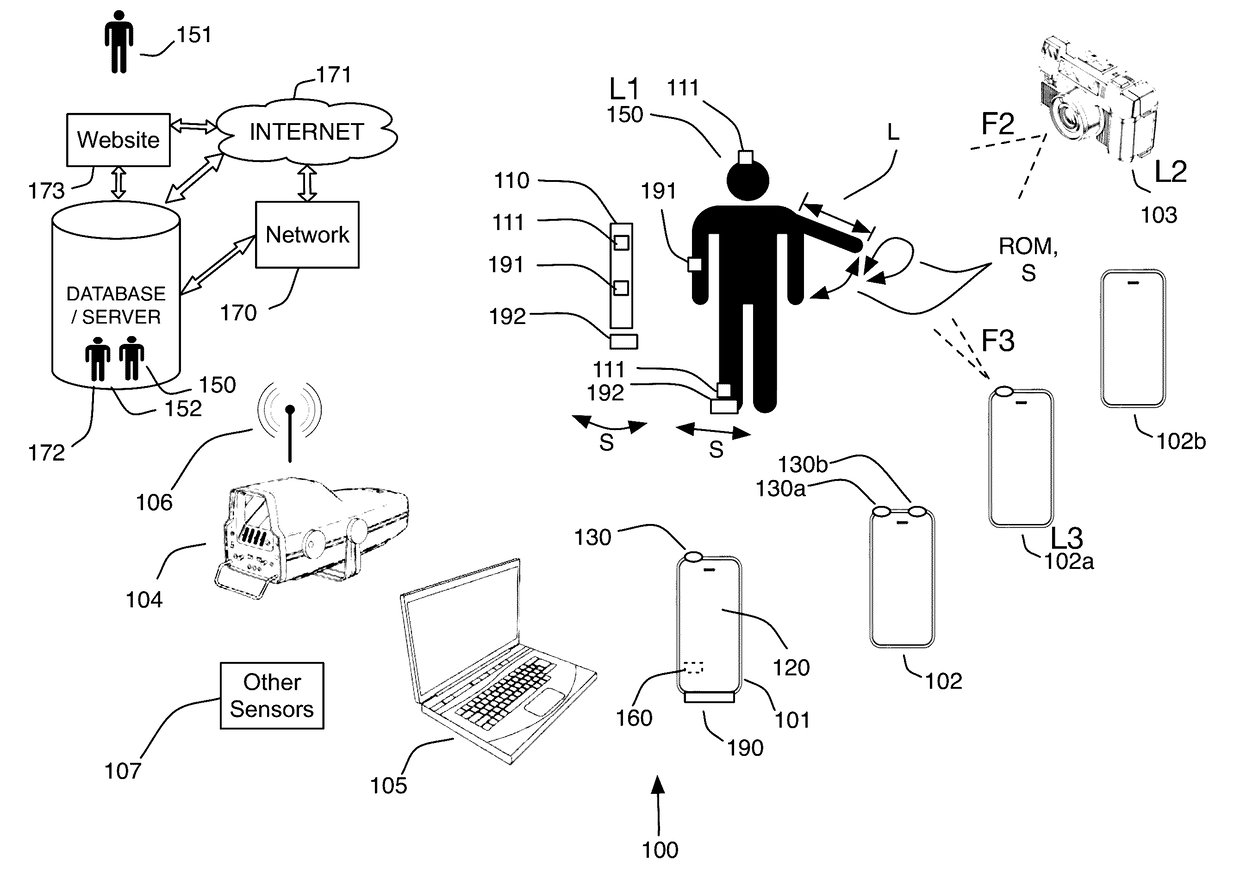

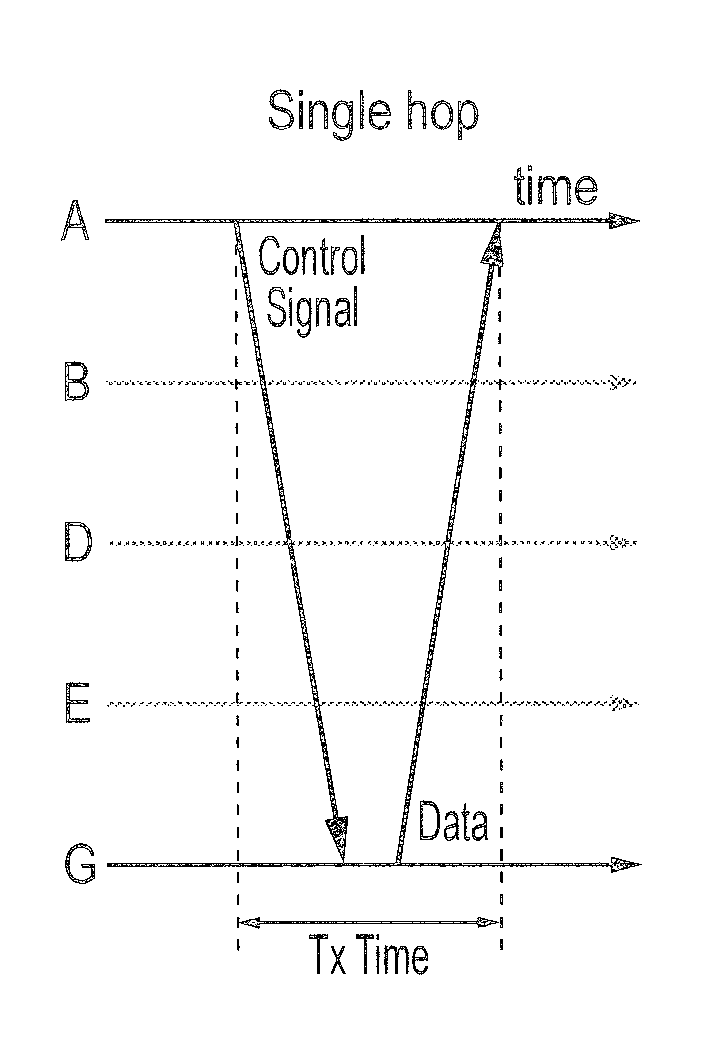

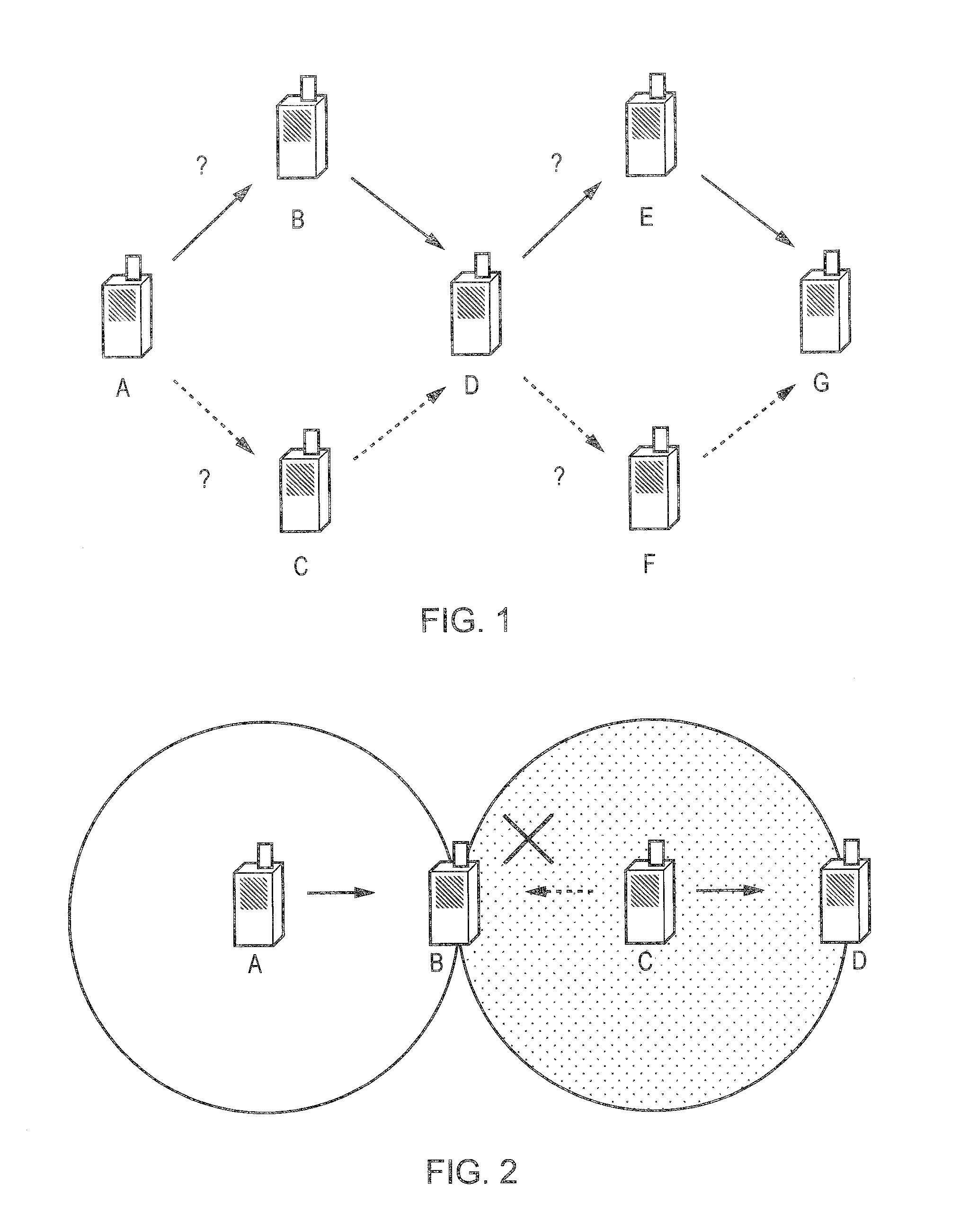

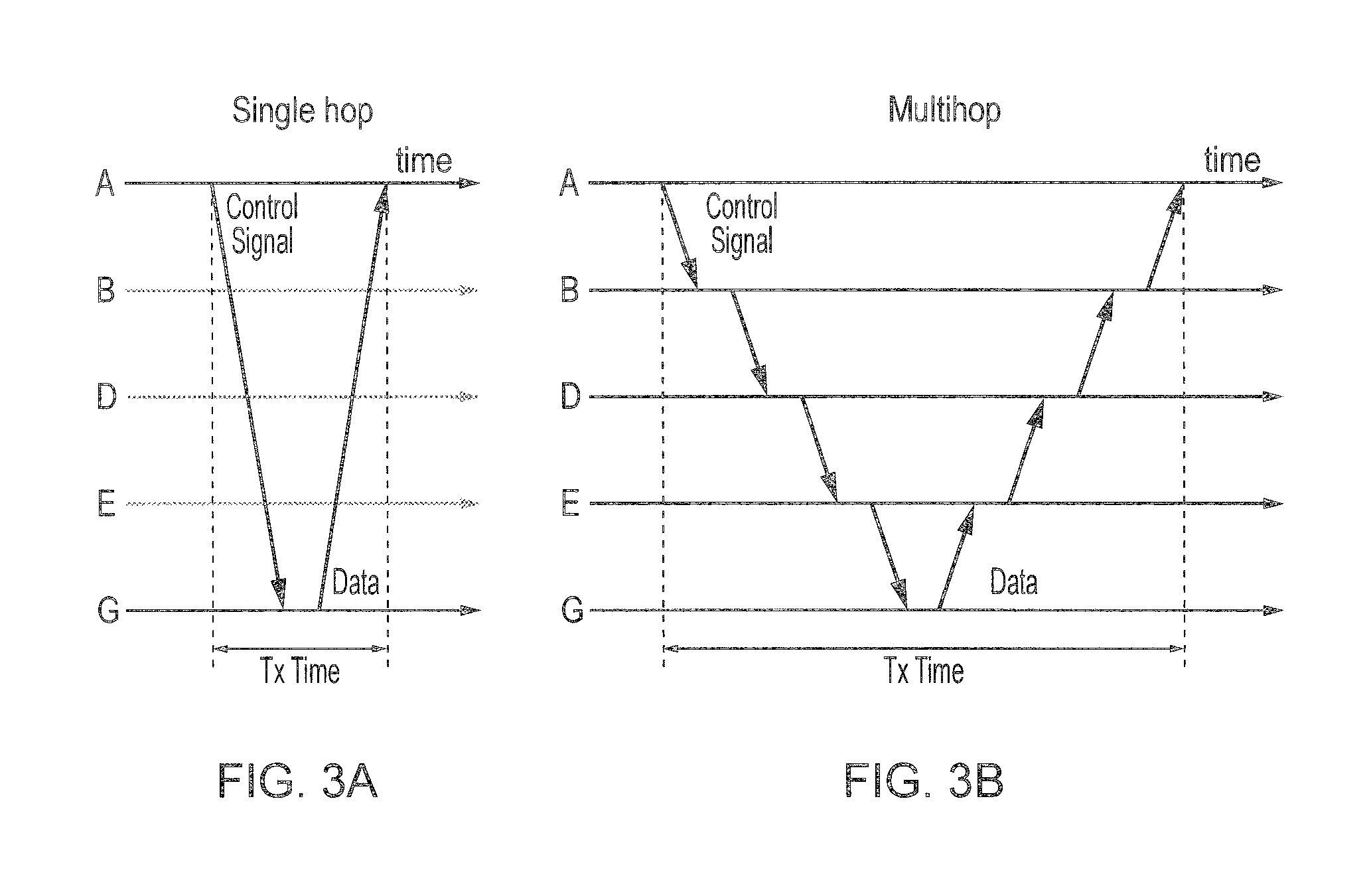

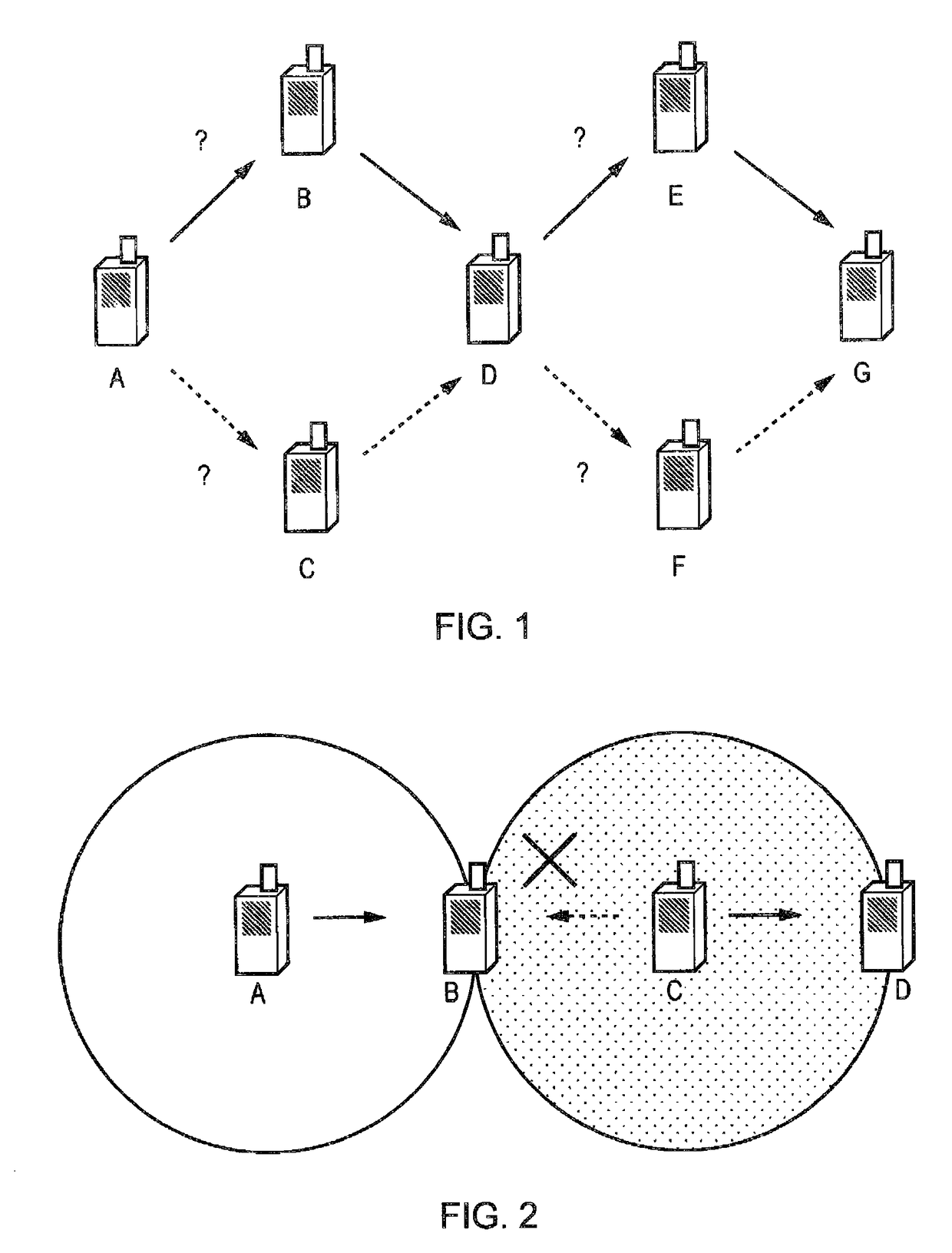

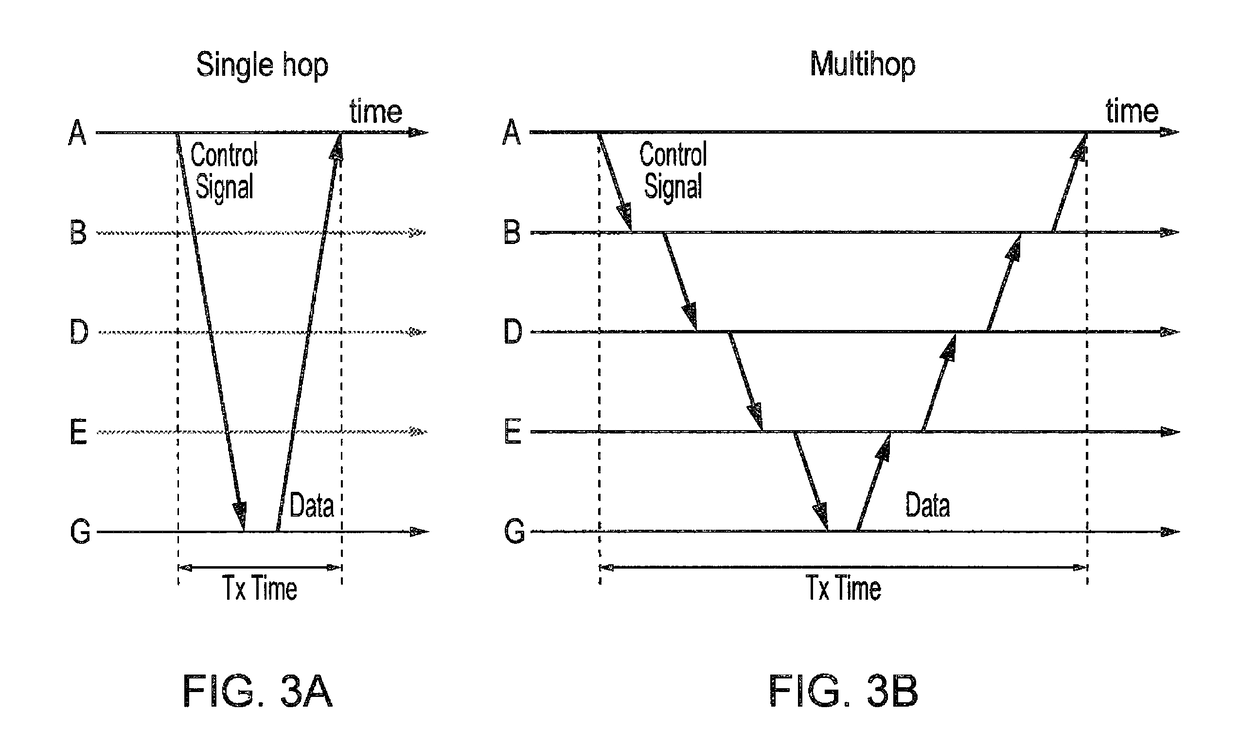

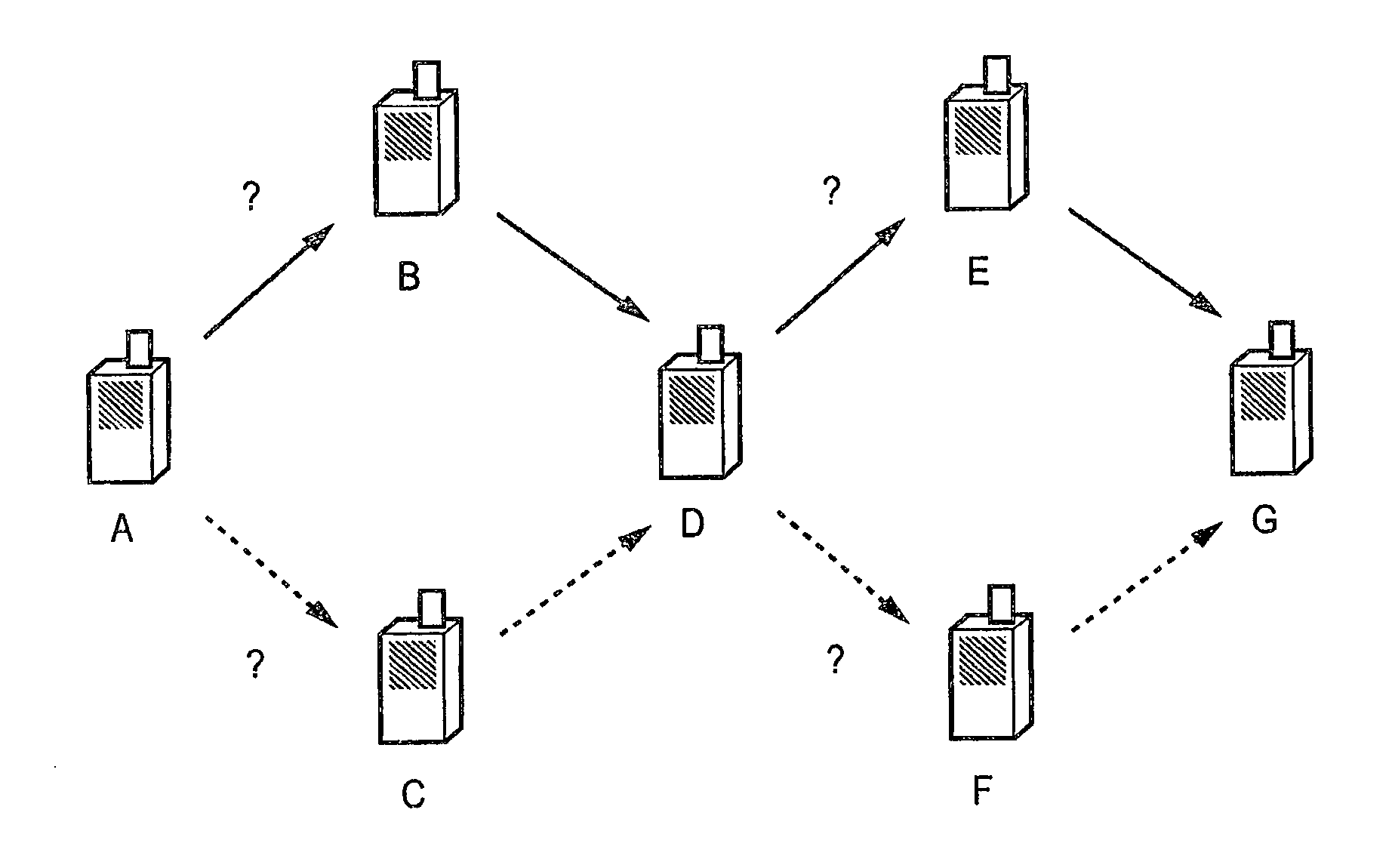

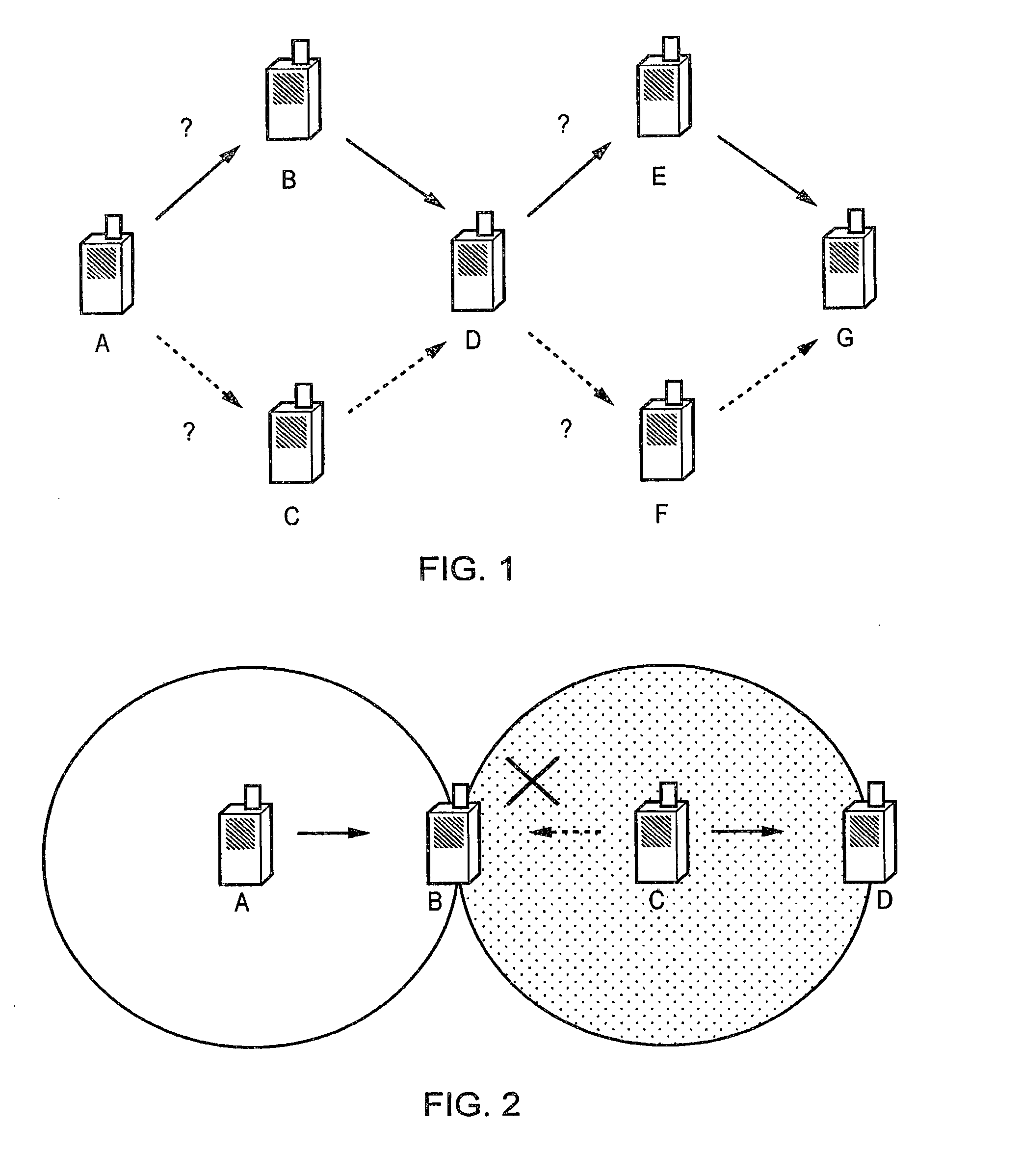

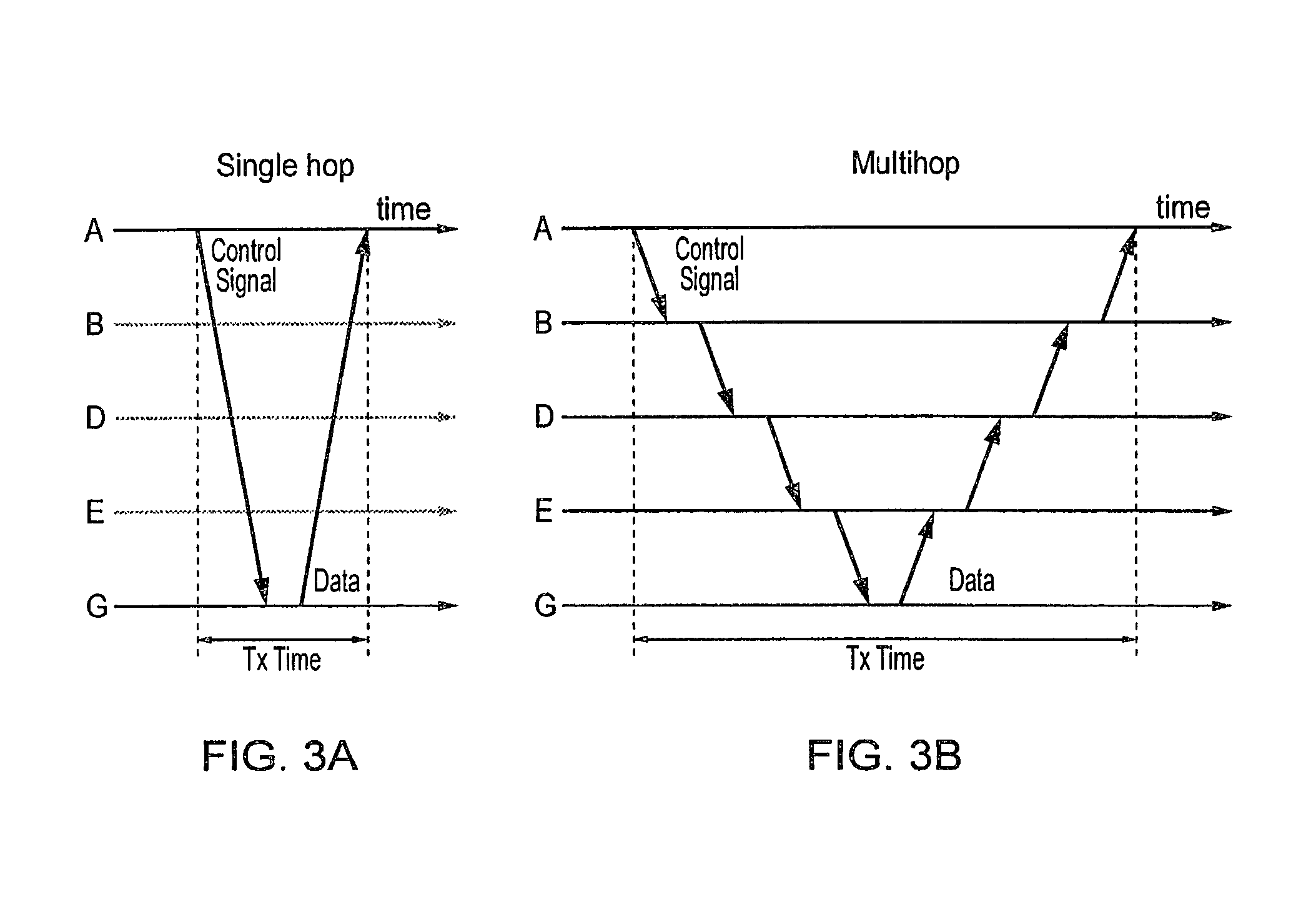

Wireless communications system and method

ActiveUS20140086141A1Low Power TransmissionPower managementFrequency-division multiplex detailsBase stationTerminal equipment

A wireless communications system includes a base station, a plurality of intermediate devices and a terminal device. The base station is operable to wirelessly transmit downlink signals to the terminal device, the downlink signals including terminal control signals identifying one of the intermediate devices as a target device to which the terminal device is to direct uplink signals intended for the base station. The terminal device wirelessly transmits the uplink signals to the base station via the intermediate device identified by the terminal control signals. In this way, downlink communications may be provided directly from the base station to the terminal device, including control signals which instruct the terminal device where to send uplink data. This enables the base station to directly control scheduling of uplink communications, and in particular to define the uplink route from the terminal device to the base station via one or more intermediate devices.

Owner:CONVIDA WIRELESS LLC

Sensor and media event detection and tagging system

ActiveUS9646209B2Low utilizationSave on storageImage enhancementTelevision system detailsSocial webData science

Enables detection and tagging of events using sensor data combined with data from servers such as social media sites. Sensors may measure values such as motion, temperature, humidity, wind, pressure, elevation, light, sound, or heart rate. Sensor data and event tags may be utilized to curate text, images, video, sound and post the results to social networks, for example in a dedicated feed. Event tags generated by the system may represent for example activity types, players, performance levels, or scoring results. The system may analyze social media postings to confirm or augment event tags. Users may filter and analyze saved events based on the assigned tags. The system may create highlight and fail reels filtered by metrics and by tags.

Owner:NEWLIGHT CAPITAL LLC

Position pointing device

InactiveUS7149647B2Low Power TransmissionBattery-less operationEnergy efficient ICTTime indicationInformation controlResonance

A position pointing device includes a resonant circuit, a resonance-characteristic control circuit for controlling characteristics of the resonant circuit in accordance with pointing-device information at timing synchronized with at least part of an electromagnetic wave that is intermittently transmitted from a tablet and for returning the pointing-device information to the tablet, a clock oscillator circuit for generating a clock signal for driving the resonance-characteristic control circuit, and clock starting means for stopping an operation of the clock oscillator circuit when a start condition is set and for starting the operation of the clock oscillator circuit when the resonant circuit generates a signal specified by the start condition. The position pointing device further includes start-condition setting means for setting the start condition in the clock starting means at timing in accordance with an operation of the resonance-characteristic control circuit.

Owner:WACOM CO LTD

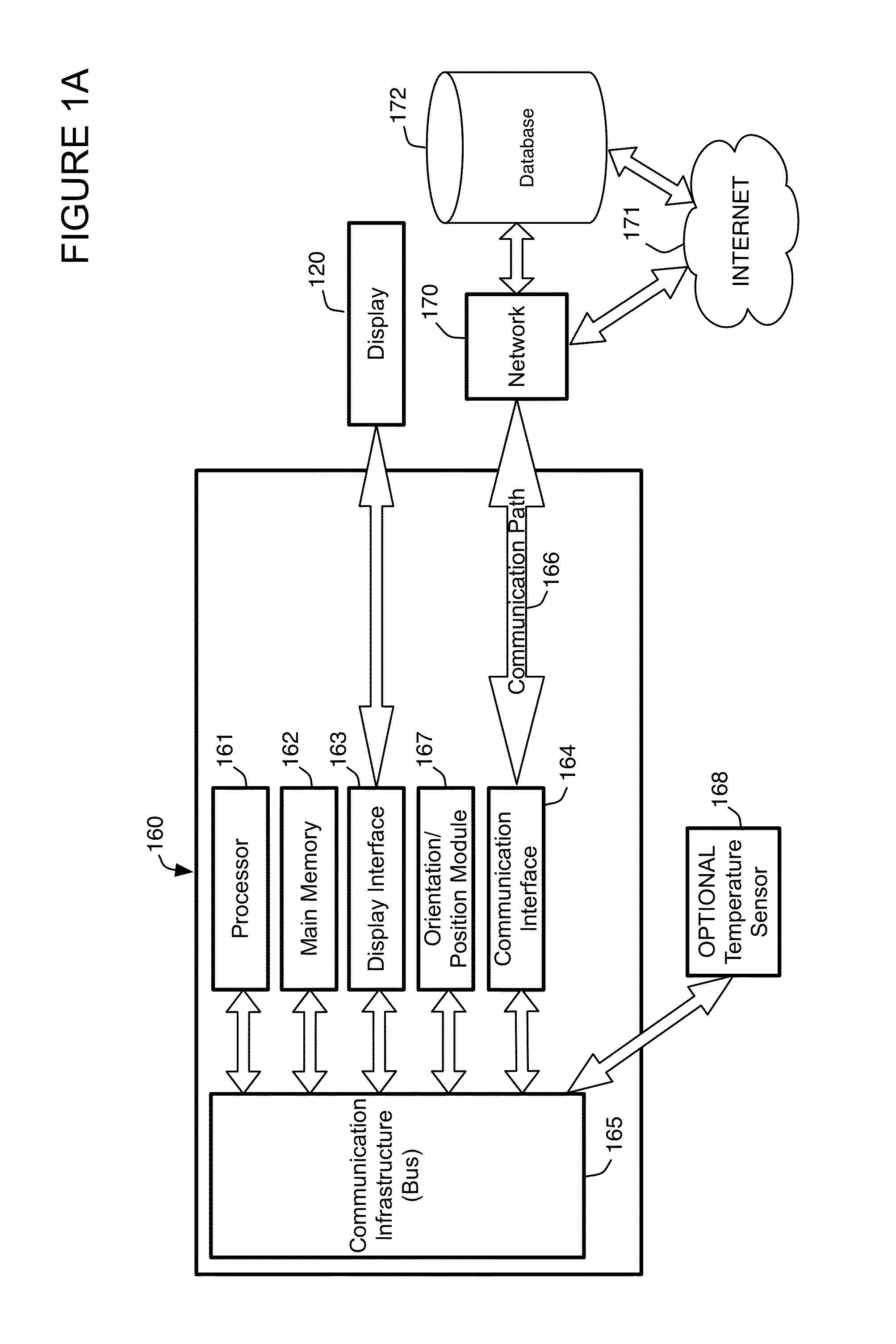

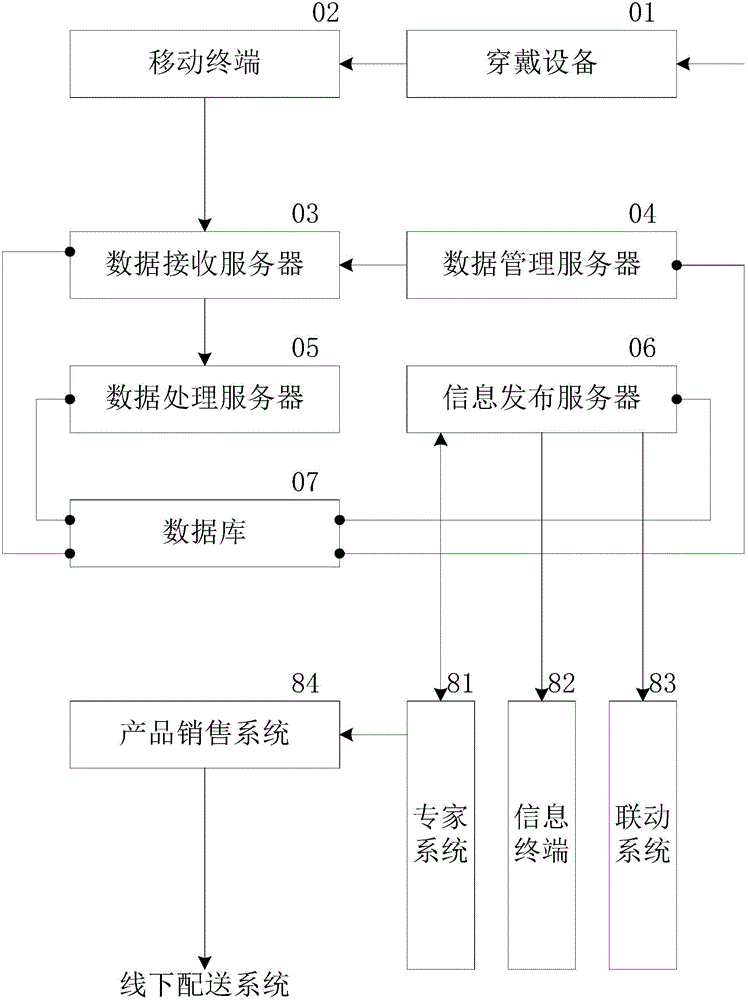

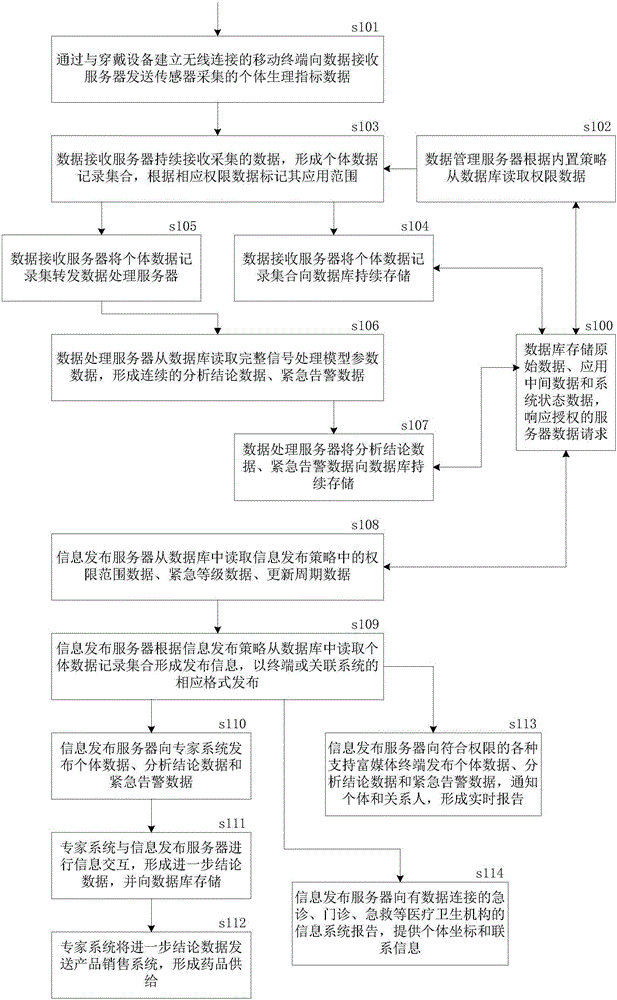

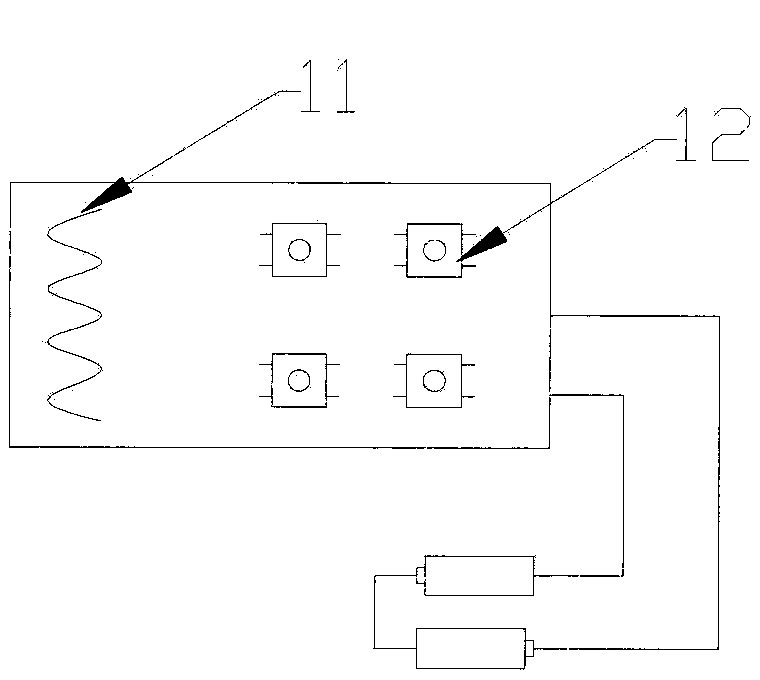

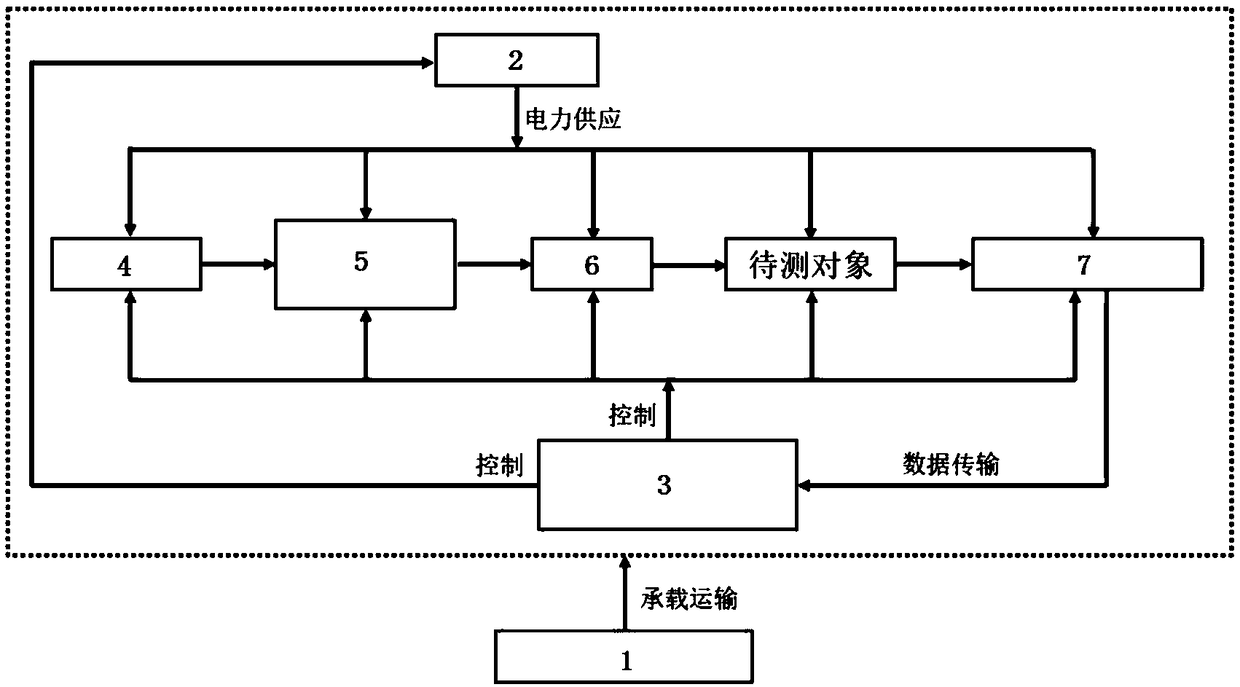

Health life behaviour management system and method based on mobile terminal

InactiveCN106126895APerfect signal accessNo significant increase in power consumptionHealth-index calculationEvaluation of blood vesselsOriginal dataOnline doctor

The invention relates to a health life behaviour management system and method based on a mobile terminal. The health life behaviour management system comprises wearable equipment and further comprises the mobile terminal, a data receiving server, a data management server, a data processing server, an information publishing server and a database, wherein the data receiving server, the data management server, the data processing server and the information publishing server are at a cloud side; a narrow-band wireless data link is established between the wearable equipment and the mobile terminal through short-distance wireless transmission; a broadband wireless data link is established between the mobile terminal and the data receiving server through long-distance wireless transmission; a bidirectional data link is established between the database and each server respectively; an original data transmission link is established between the data receiving server and the data processing server; a processing data transmission link is established between the data processing server and the information publishing server; and a control data transmission link is established between the data management server and the data receiving server. Numerous individual users can be served when the efficiency is high; and abundant functions, such as an online doctor consulting function, a relative and friend binding function, an emergency call function, a real-time locating and tracking function and a health product purchasing function, can be provided.

Owner:上海朗朗信息科技有限公司

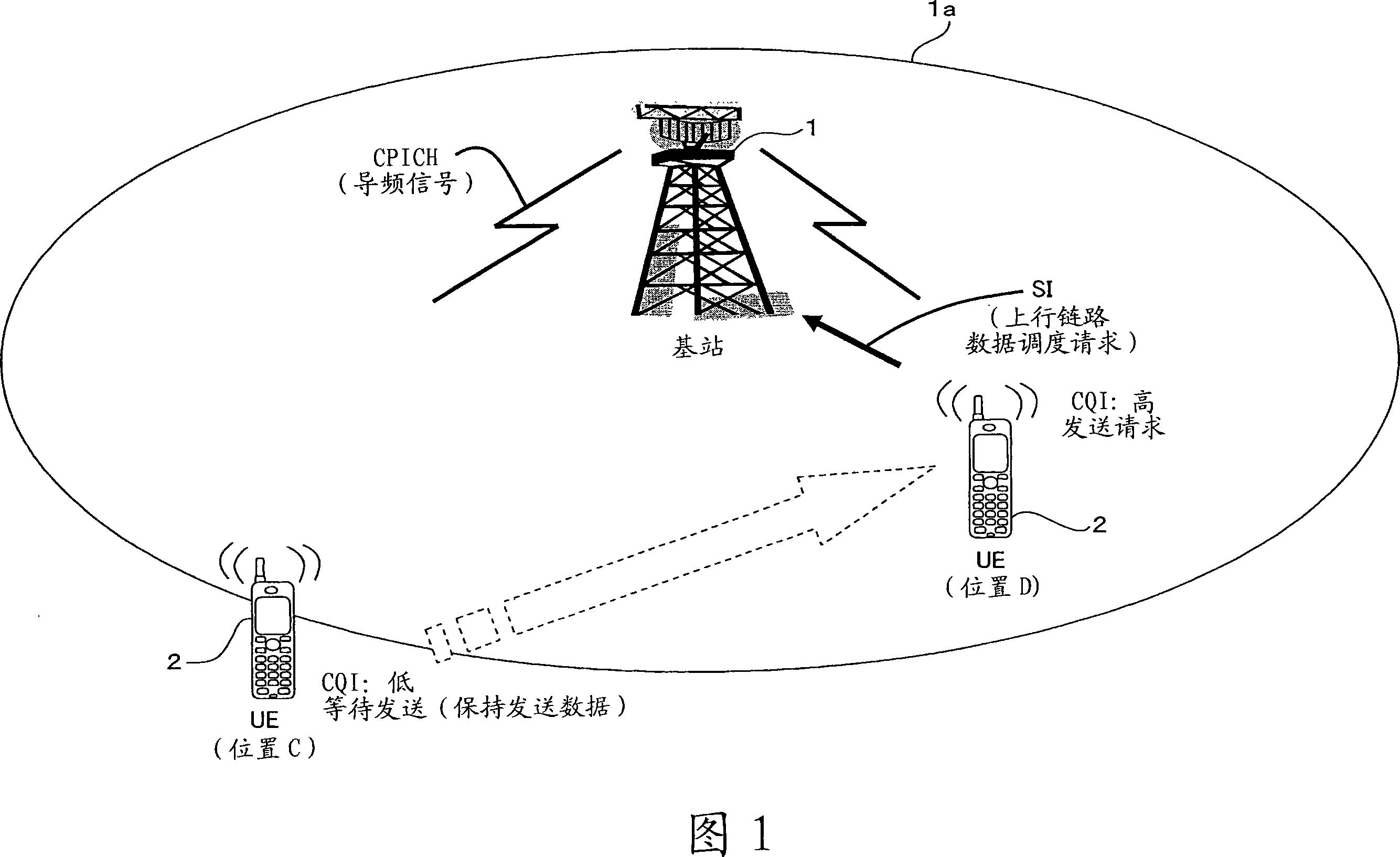

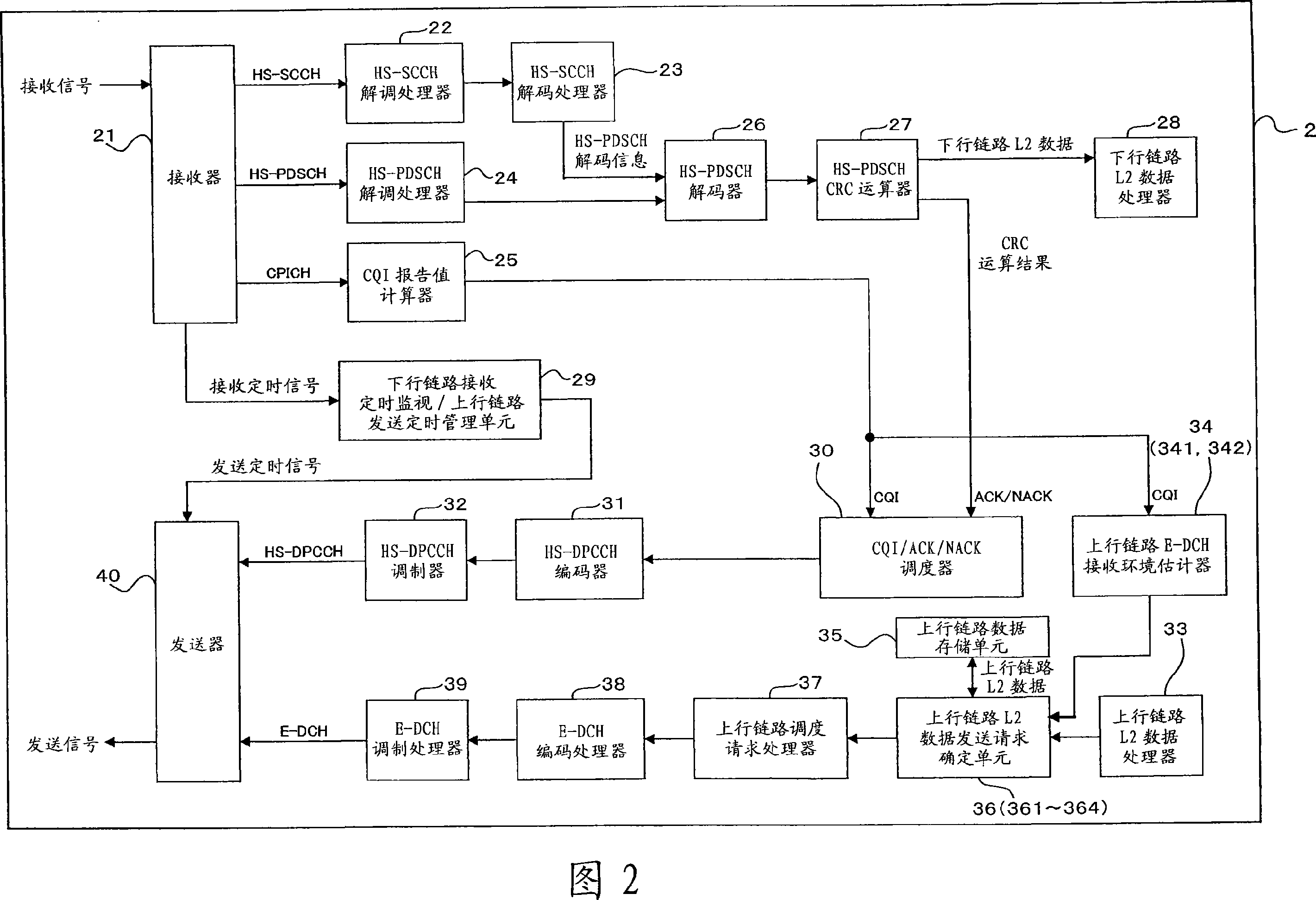

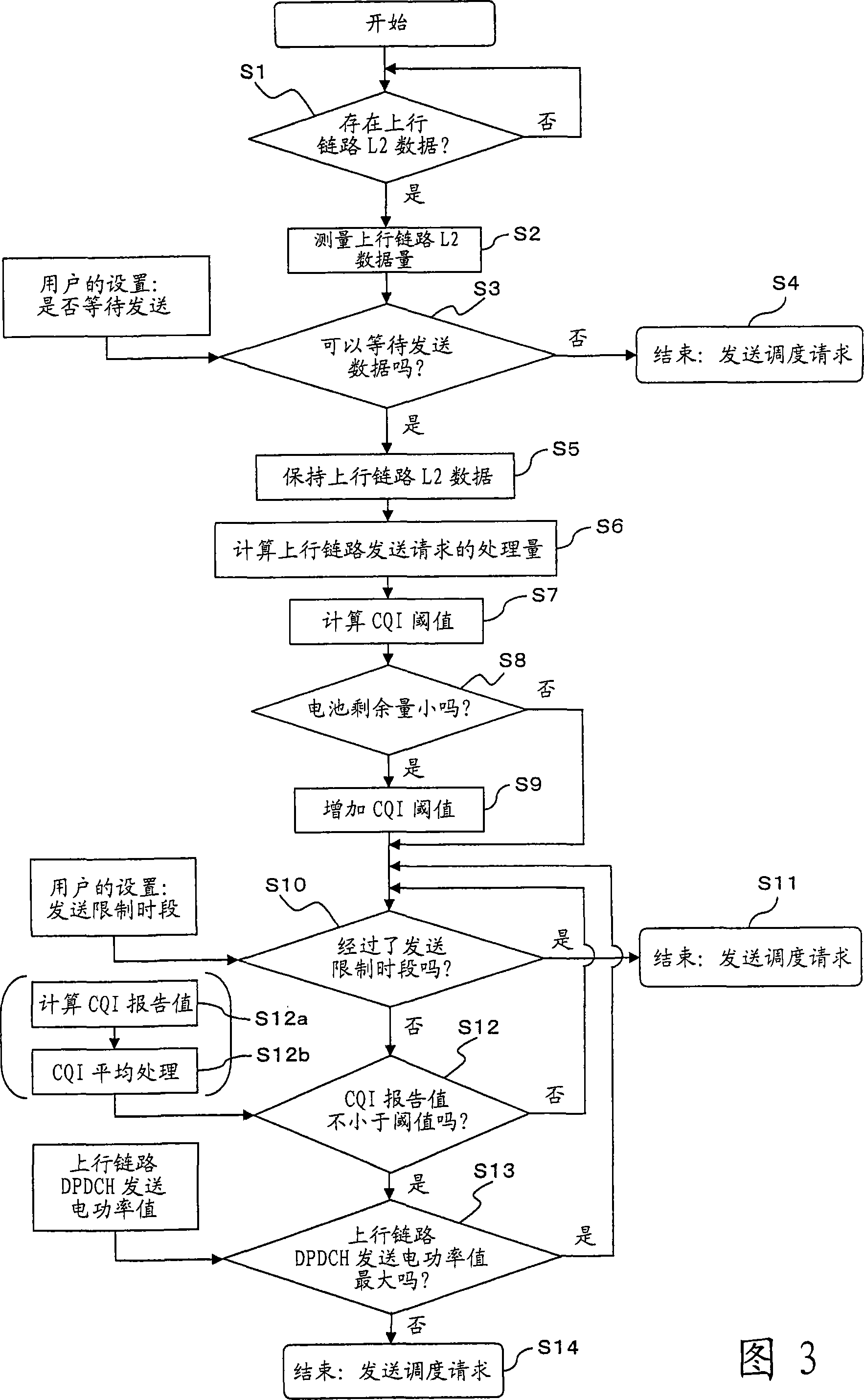

Uplink communication method and radio terminal in radio communication system

InactiveCN101146354ALow Power TransmissionReduce distractionsEnergy efficient ICTPower managementCommunications systemRadio Base Station

A radio terminal (2) estimates a reception quality of an uplink signal at a radio base station (1) based on a downlink signal received from the radio base station (1), and controls transmission timing to the radio base station (1) of a transmission request (SI) for obtaining permission to transmit the uplink signal. Whereby, it is possible to control the transmission timing of the request for obtain permission to transmit the uplink signal from the radio base station (1), decrease a transmission electric power of the radio terminal (2), and obtain an expected throughput.

Owner:FUJITSU LTD

Wireless communications system and method

ActiveUS20140133335A1Low Power TransmissionError preventionFrequency-division multiplex detailsCommunications systemControl signal

A wireless communications system includes a base station, a plurality of intermediate devices, and a terminal device. Downlink communications may be provided directly from the base station to the terminal device, including control signals which instruct the terminal device where to send uplink data. This enables the base station to directly control scheduling of uplink communications, and in particular to define an uplink route from the terminal device to the base station via one or more intermediate devices. Power is conserved at the terminal device on the uplink because a lower power transmission can be used which although insufficient to reach the base station can reach the intermediate device. The terminal device is not required to determine the uplink path itself and therefore does not require complex, expensive, and power consuming control logic.

Owner:CONVIDA WIRELESS LLC

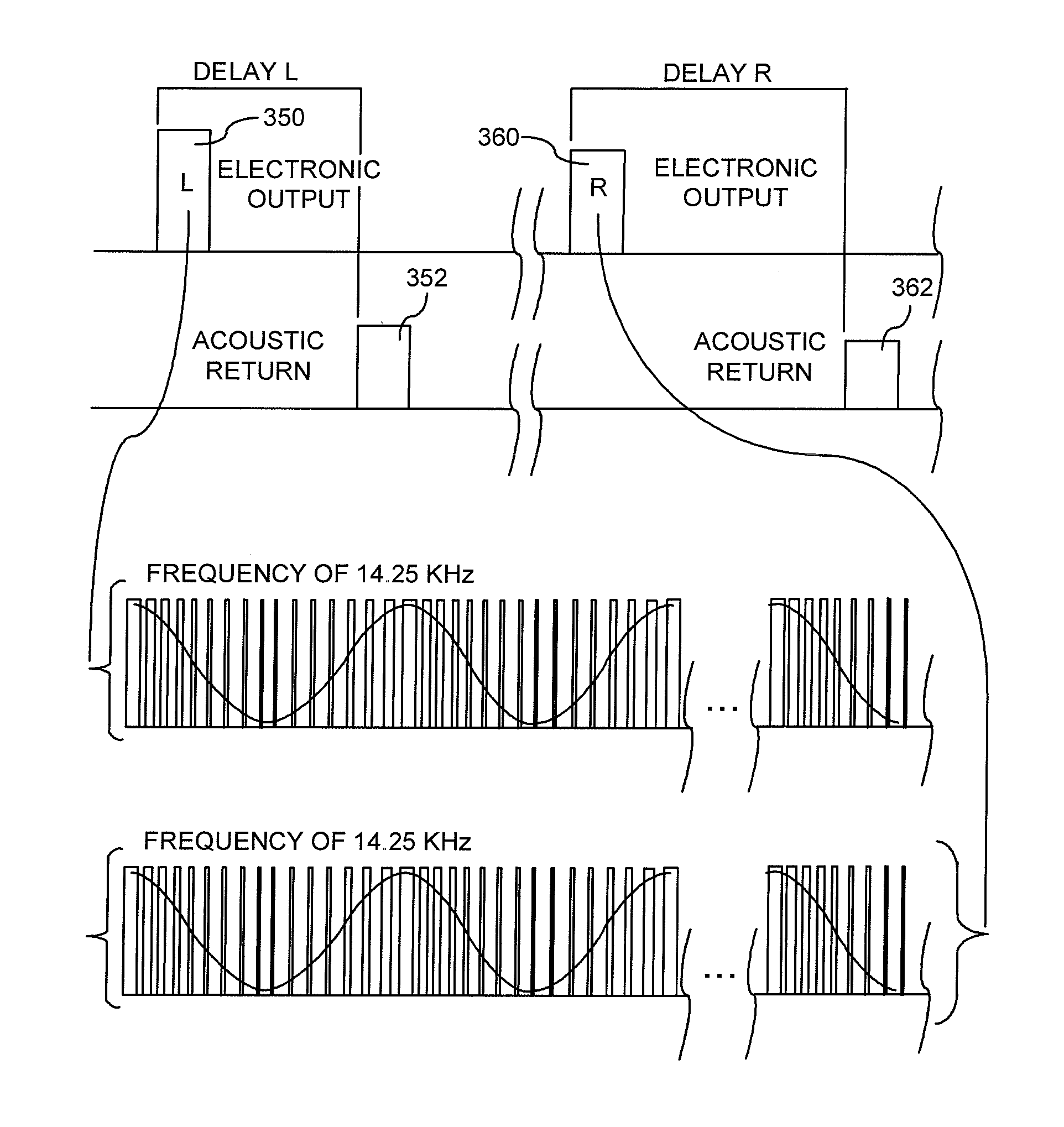

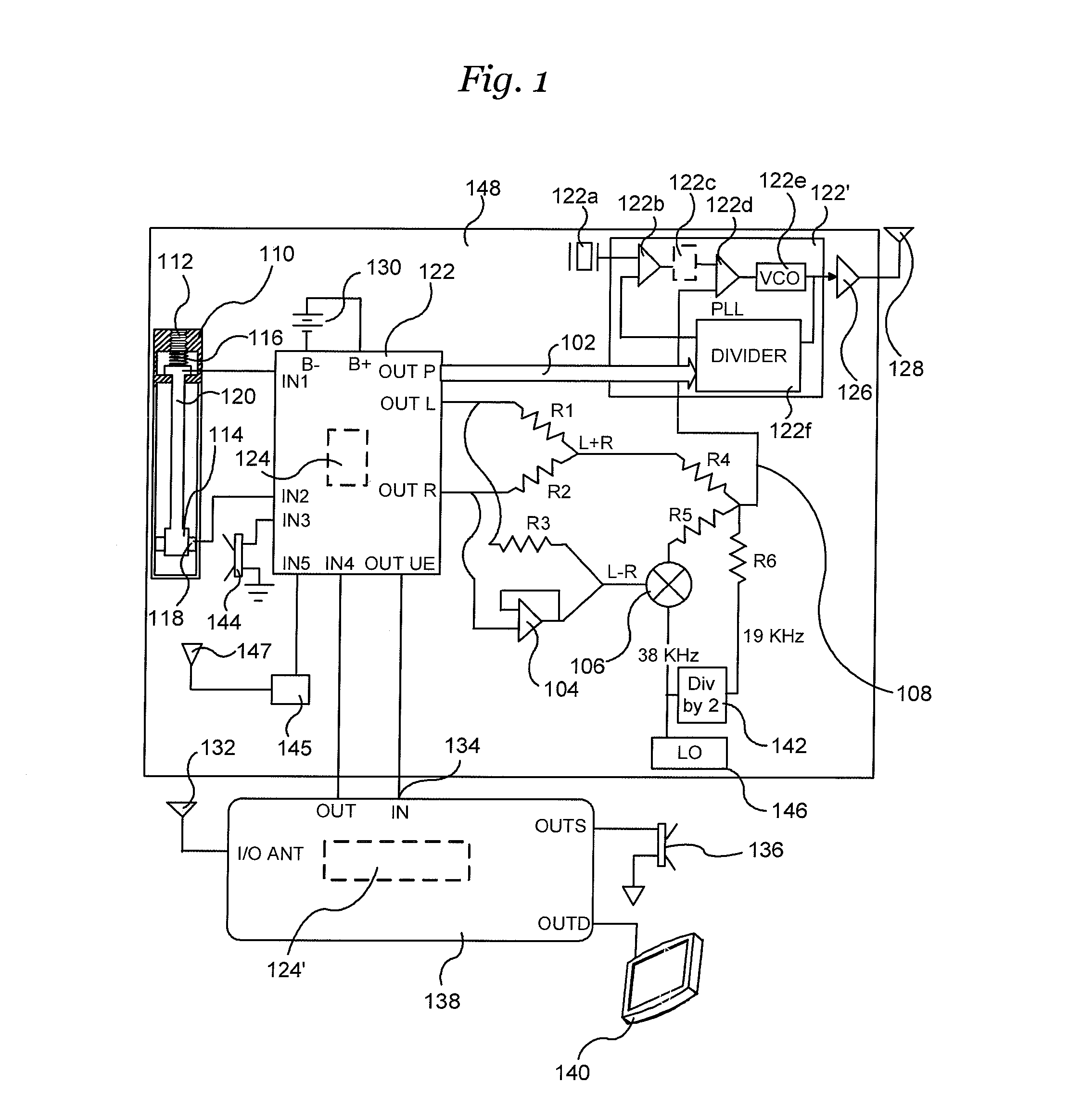

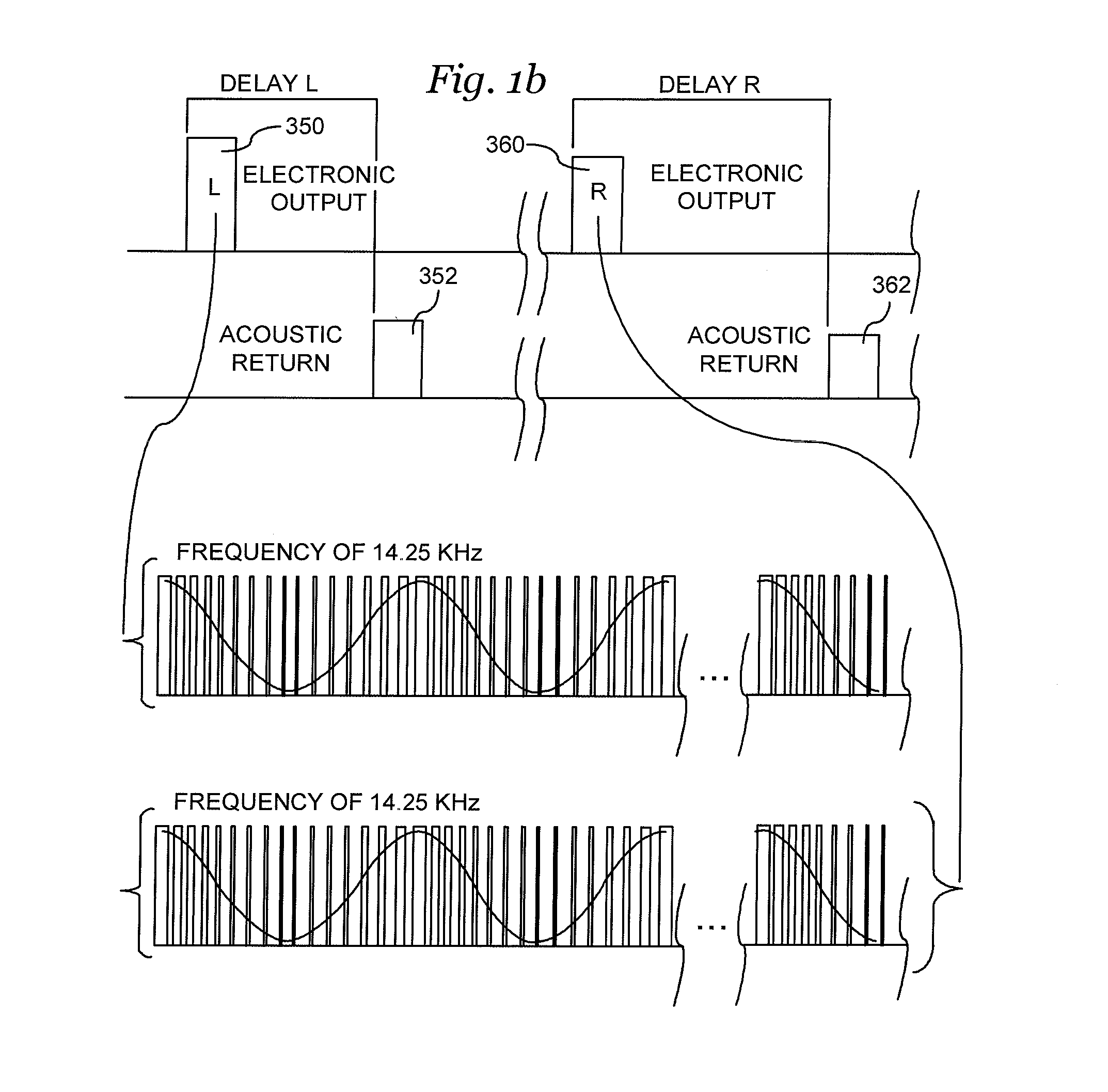

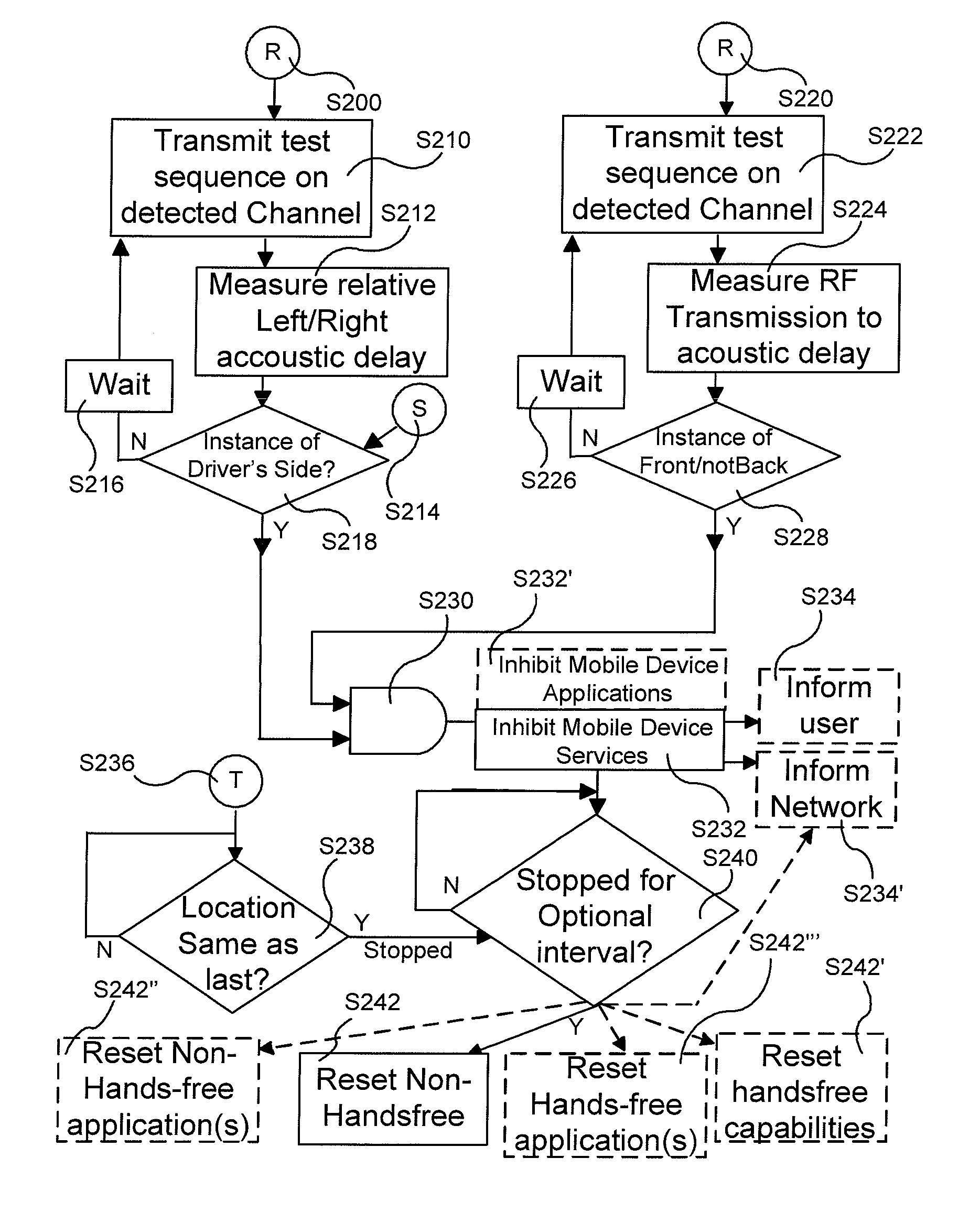

Apparatus and method for inhibiting portable electronic devices

ActiveUS20140162616A1Reduction in hardwareLower latencyAssess restrictionParticular environment based servicesDiscriminatorRadio equipment

This accessory is apparatus capable of implementing a method that can affect one or more features of a portable electronic device when brought into a vehicle having a radio with a right and a left speaker. The accessory has a sender for initiating transmission of an RF test signal at the portable electronic device. The RF test signal is arranged to cause the radio to produce a distinct pair of audio responses from the right and the left speaker. The accessory has a discriminator for determining for the right and the left speaker the corresponding return delay between transmission of the RF test signal and arrival of the distinct pair of audio responses at the portable electronic device.

Owner:BRADLEY JAMES ROY

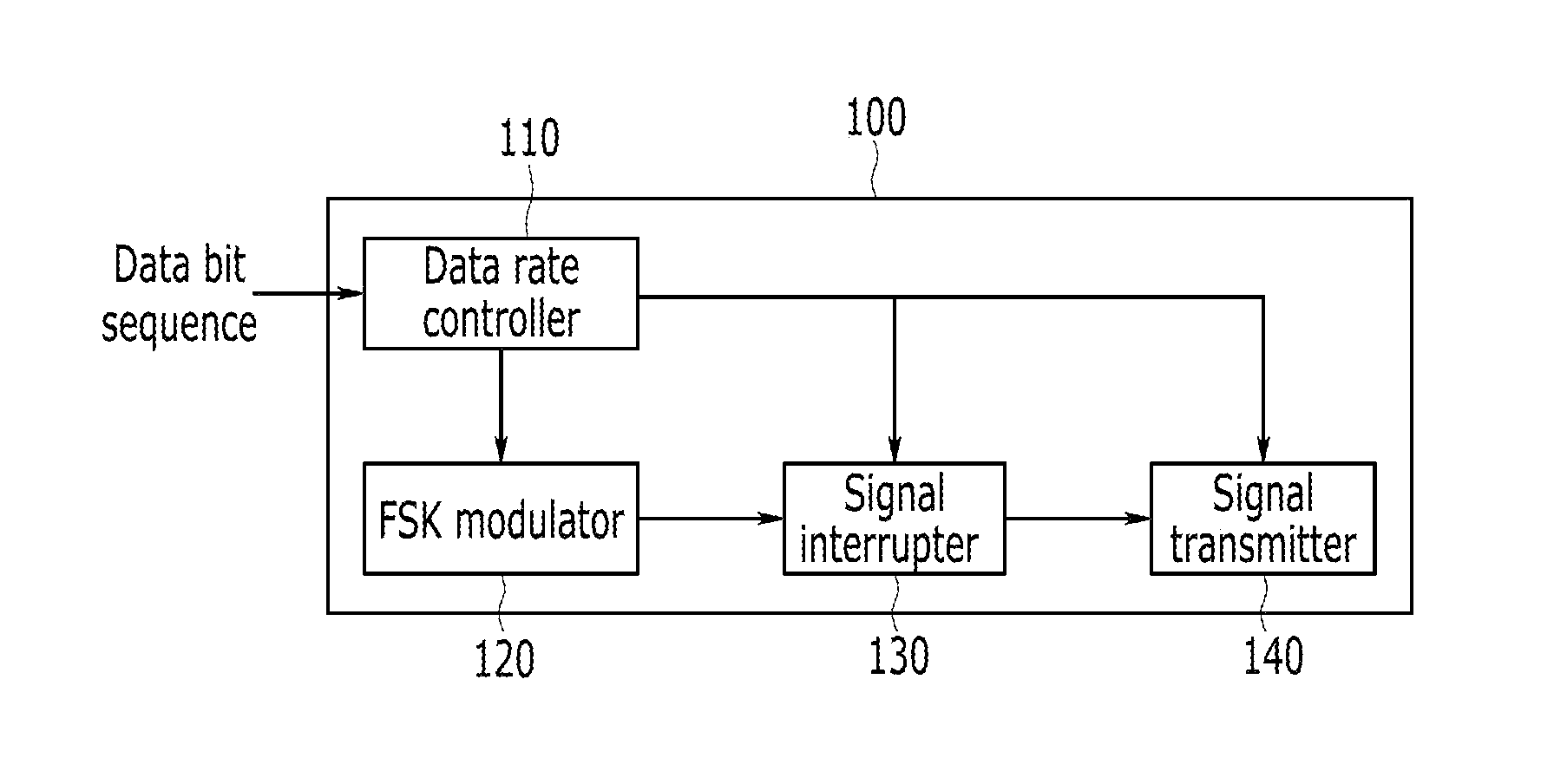

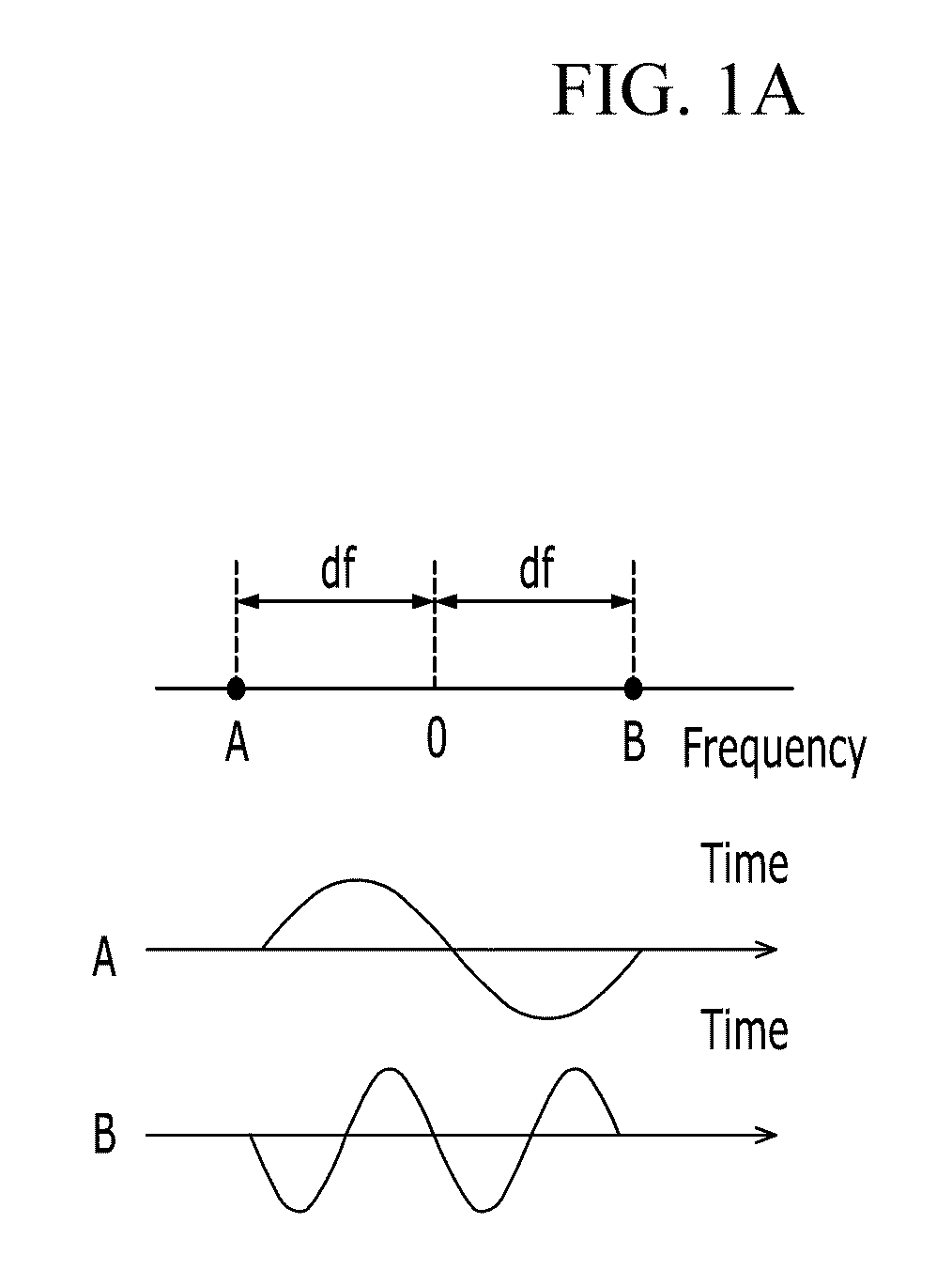

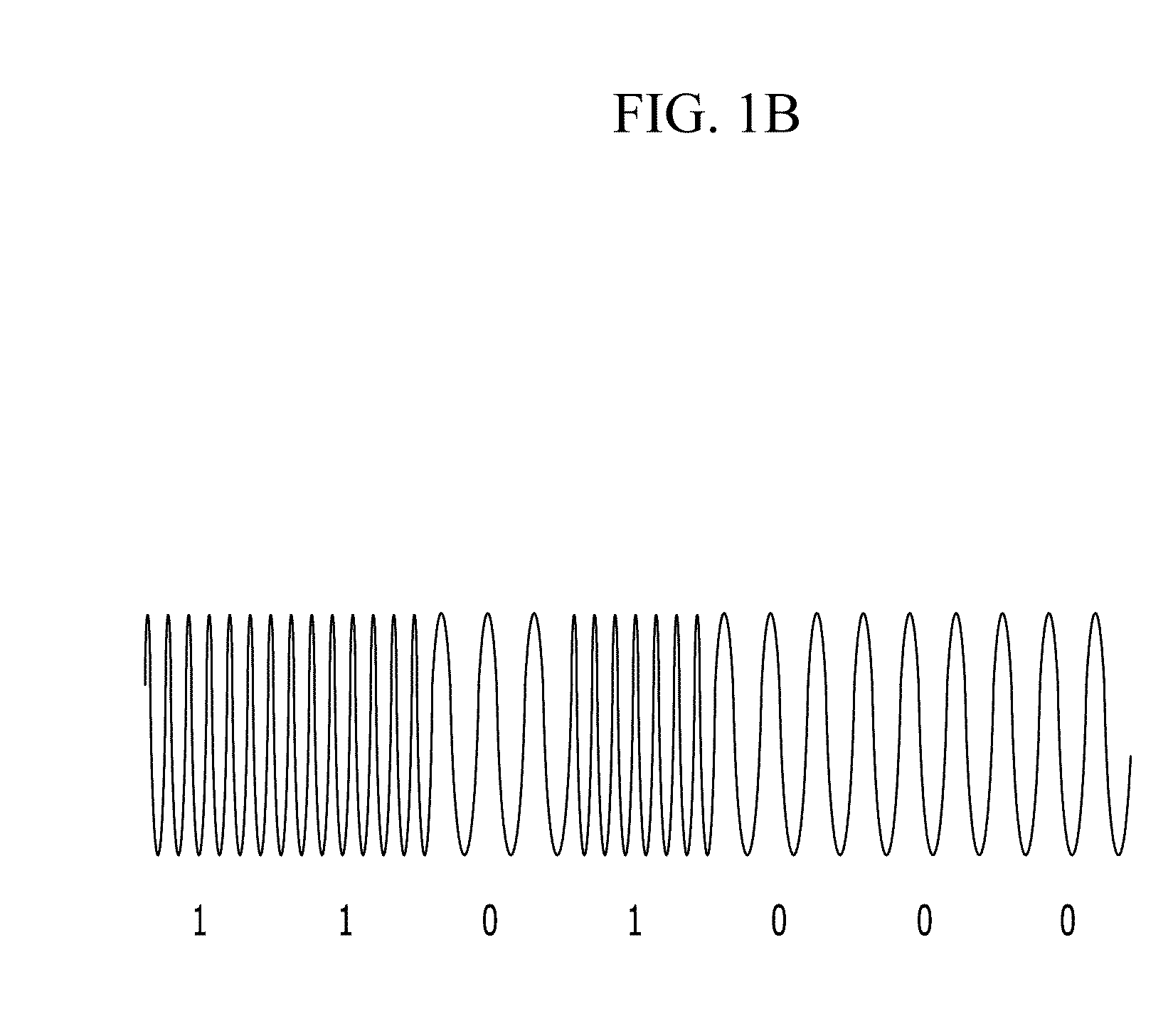

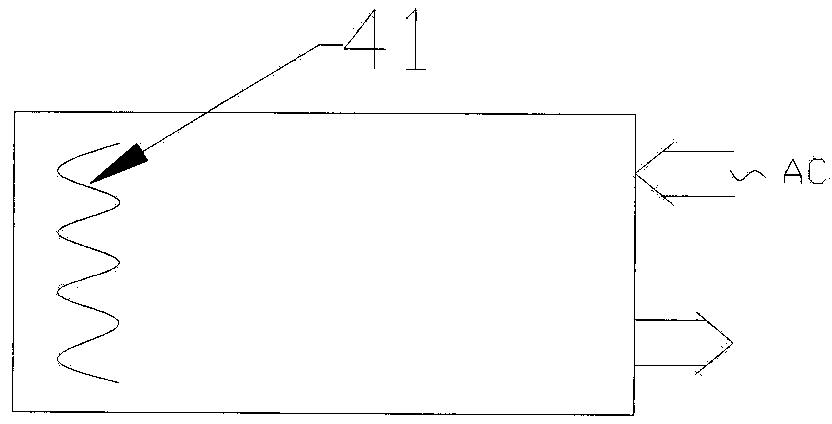

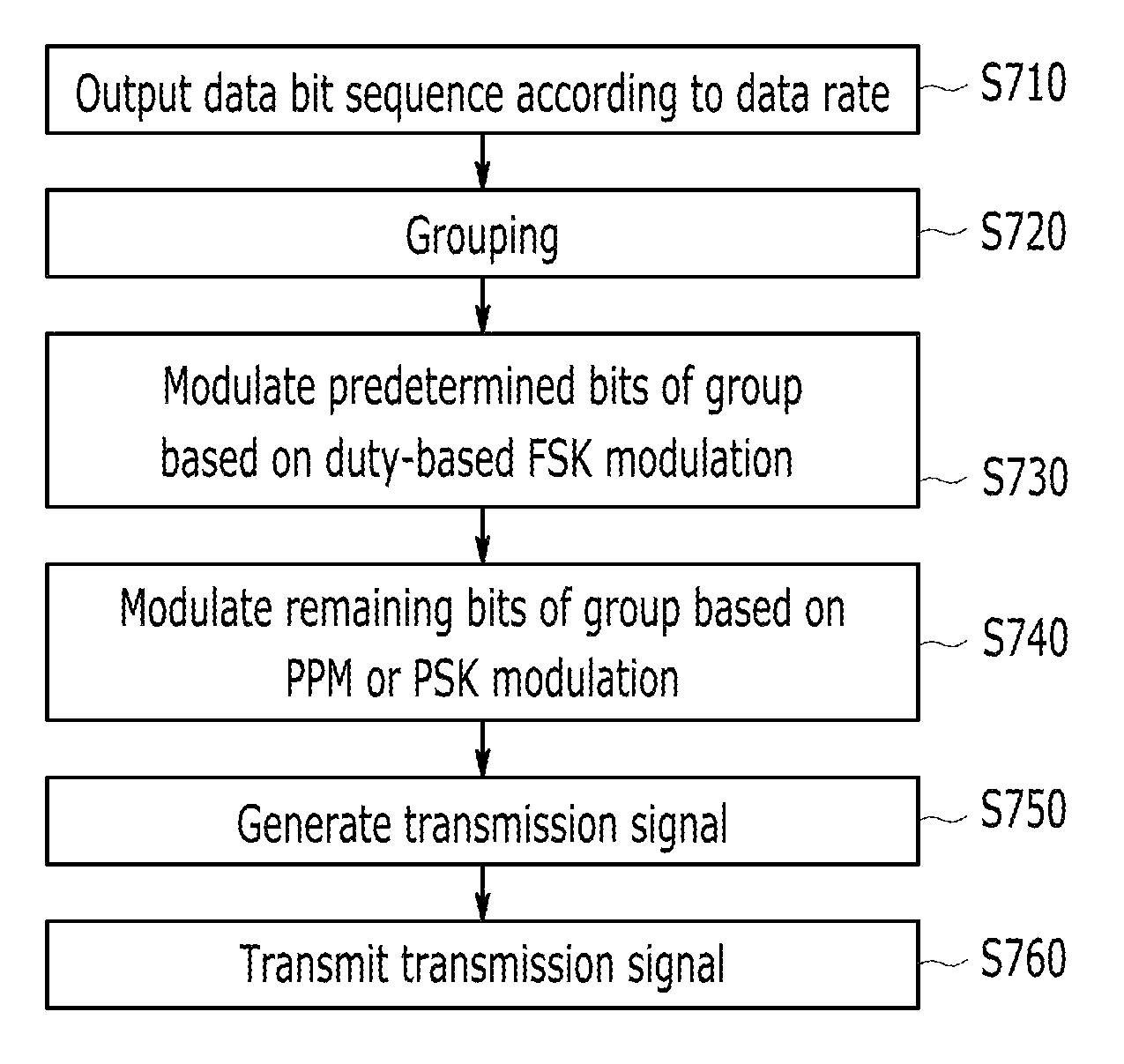

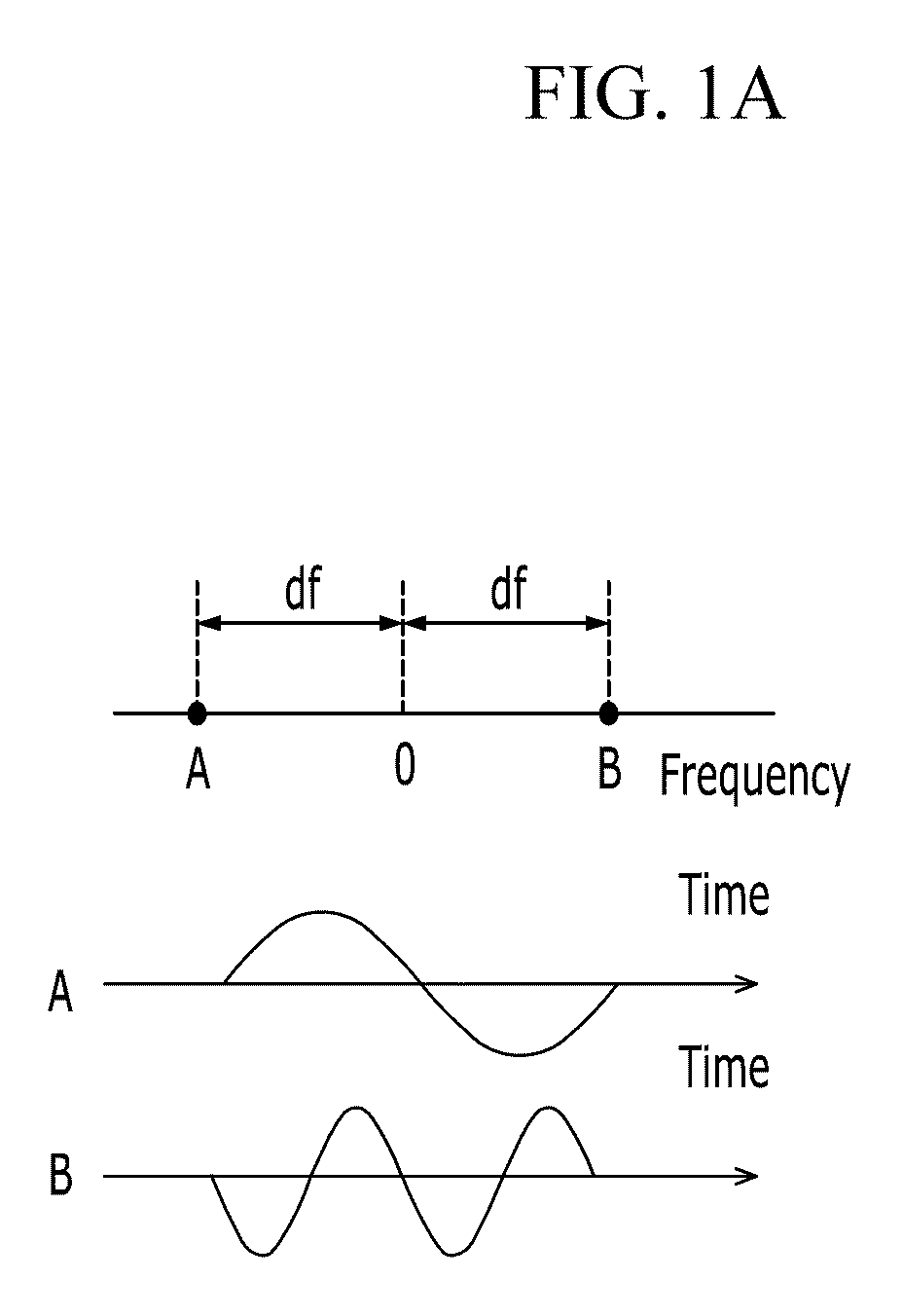

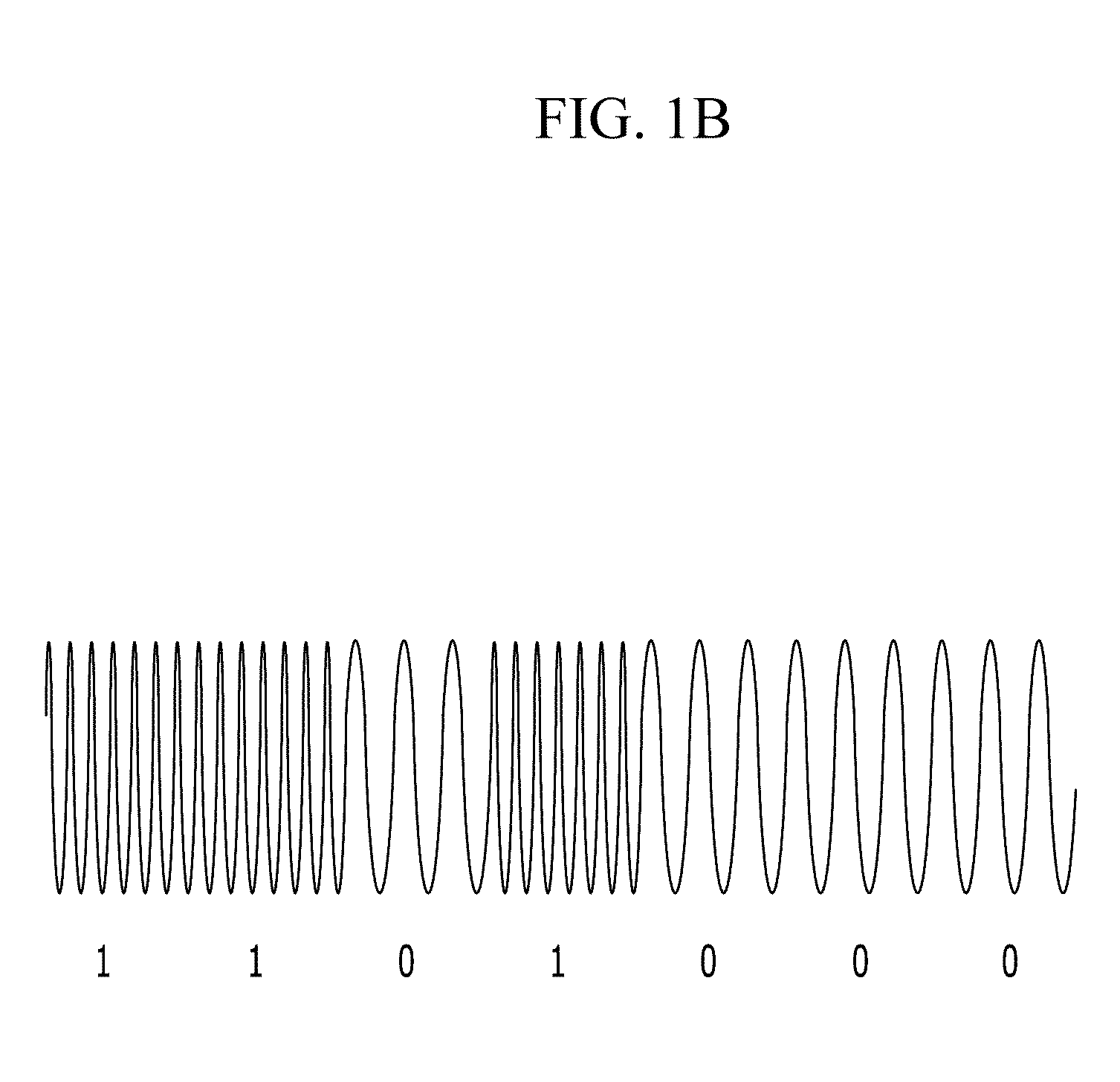

Apparatus and method for transmitting and receiving

InactiveUS20120163444A1Signal processing be simplifyLow power transmissionFrequency/rate-modulated pulse demodulationAmplitude-modulated carrier systemsVIT signalsFrequency shift

A transmitting apparatus groups a data bit sequence to groups each formed of a predetermined number of bits, modulates predetermined bits of one of groups through a frequency shift keying (FSK) modulation method, non-continuously aligns the FSK modulation signals, and transmits the non-continuous FSK modulation signals.

Owner:ELECTRONICS & TELECOMM RES INST

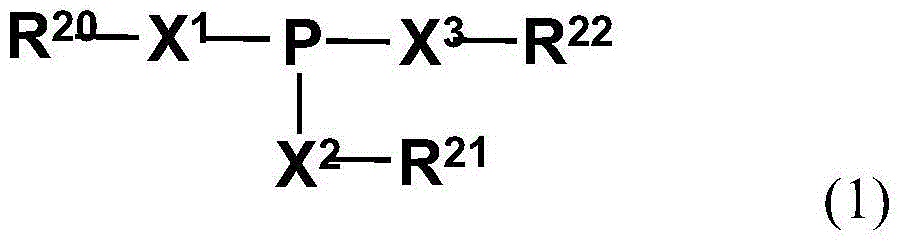

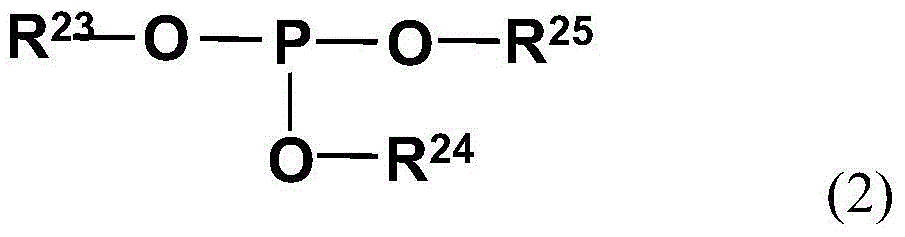

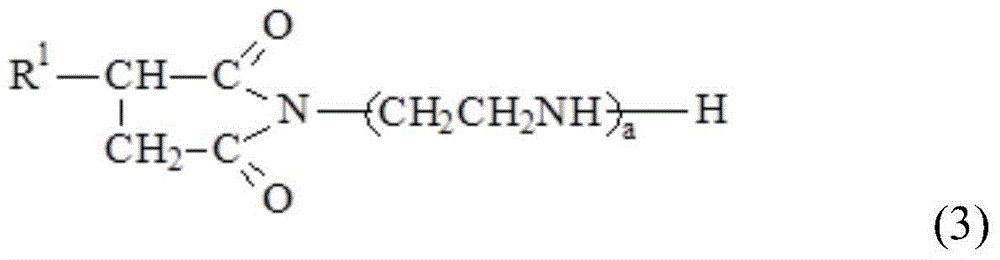

Lubricating oil composition for continuously variable transmission

ActiveCN104487557AReduce coefficient of frictionLow friction propertiesAdditivesChemical compositionEngineering

Provided is a lubricating oil composition for a continuously variable transmission, said composition exhibiting a low viscosity whilst maintaining the viscosity required of the lubricating oil composition throughout a period of use in a mechanism, and maintaining a high friction coefficient between metals so as to ensure a high power-transmitting force provide the wet clutch friction characteristics and the shudder prevention properties required in a transmission. The composition also achieves improved fuel economy due to a low traction coefficient. In the composition, (B) a phosphorus compound, (C) a calcium salicylate and / or a calcium sulfonate, (D) a boron-modified ashless dispersant, and (E) a friction regulating agent are included, each at a specified amount, in a base-oil that has been adjusted so that the product (ECxV40) of the mass percent (EC(mass%)) of a saturated cyclic component, as based on the total base-oil mass, and the kinematic viscosity (V40(mm2 / s)) at 40 DEG is equal to or less than 500, and the kinetic viscosity at 100 DEG is 3.6-4.1mm2 / s. The lubricating oil composition has a kinematic viscosity at 100 DEG of 5.2-5.6mm2 / s and a viscosity index of equal to or greater than 165.

Owner:JX NIPPON OIL & ENERGY CORP

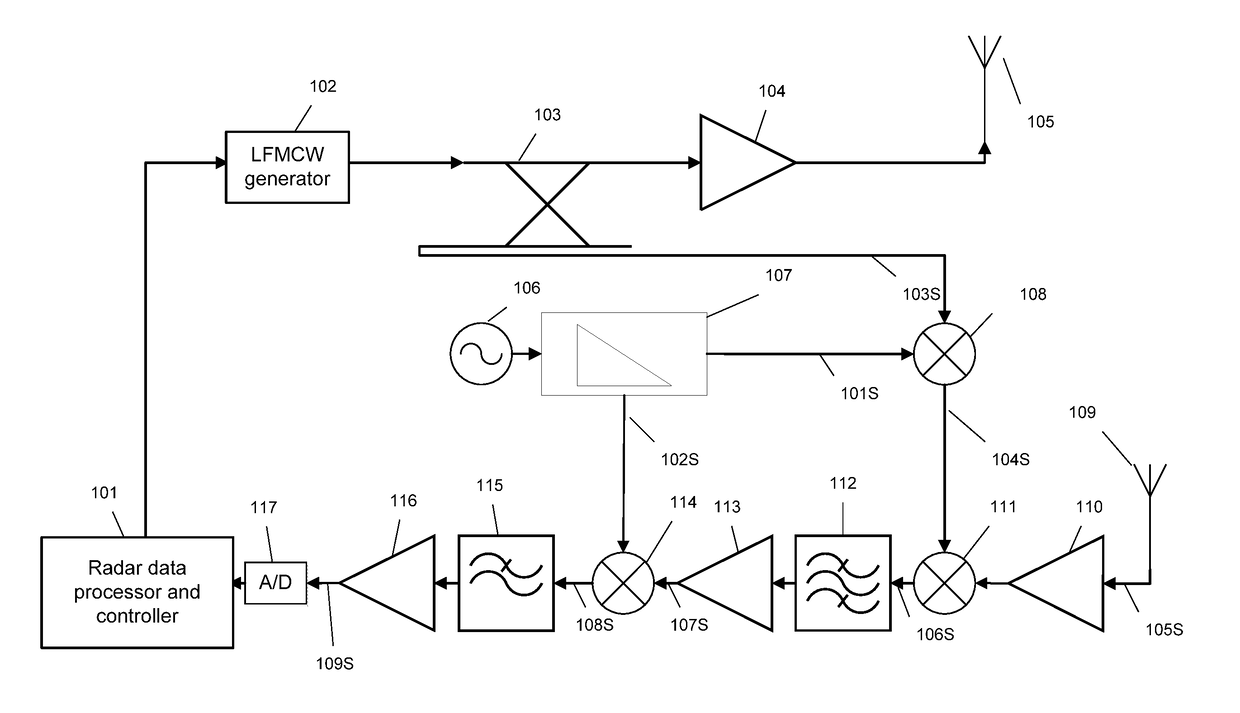

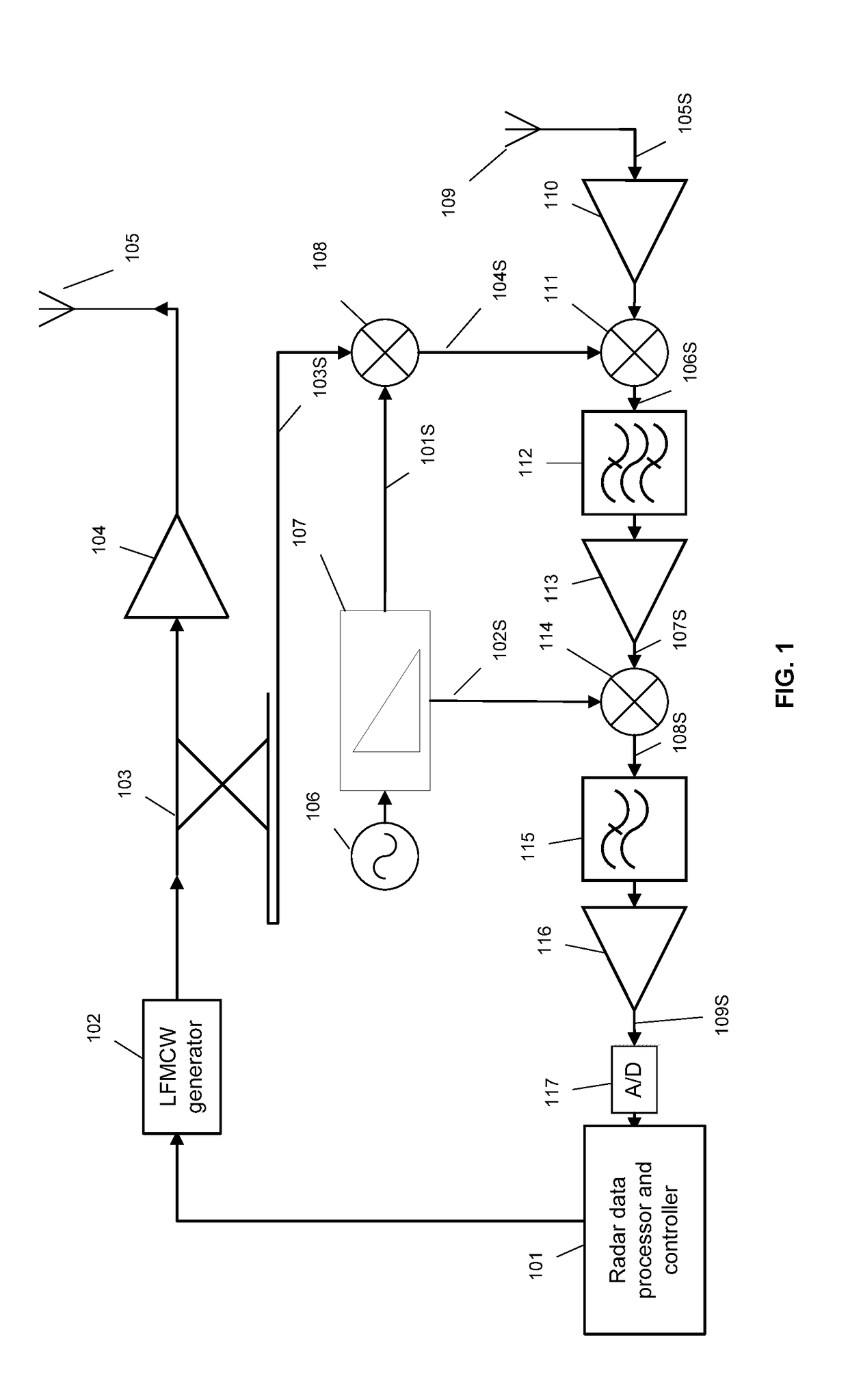

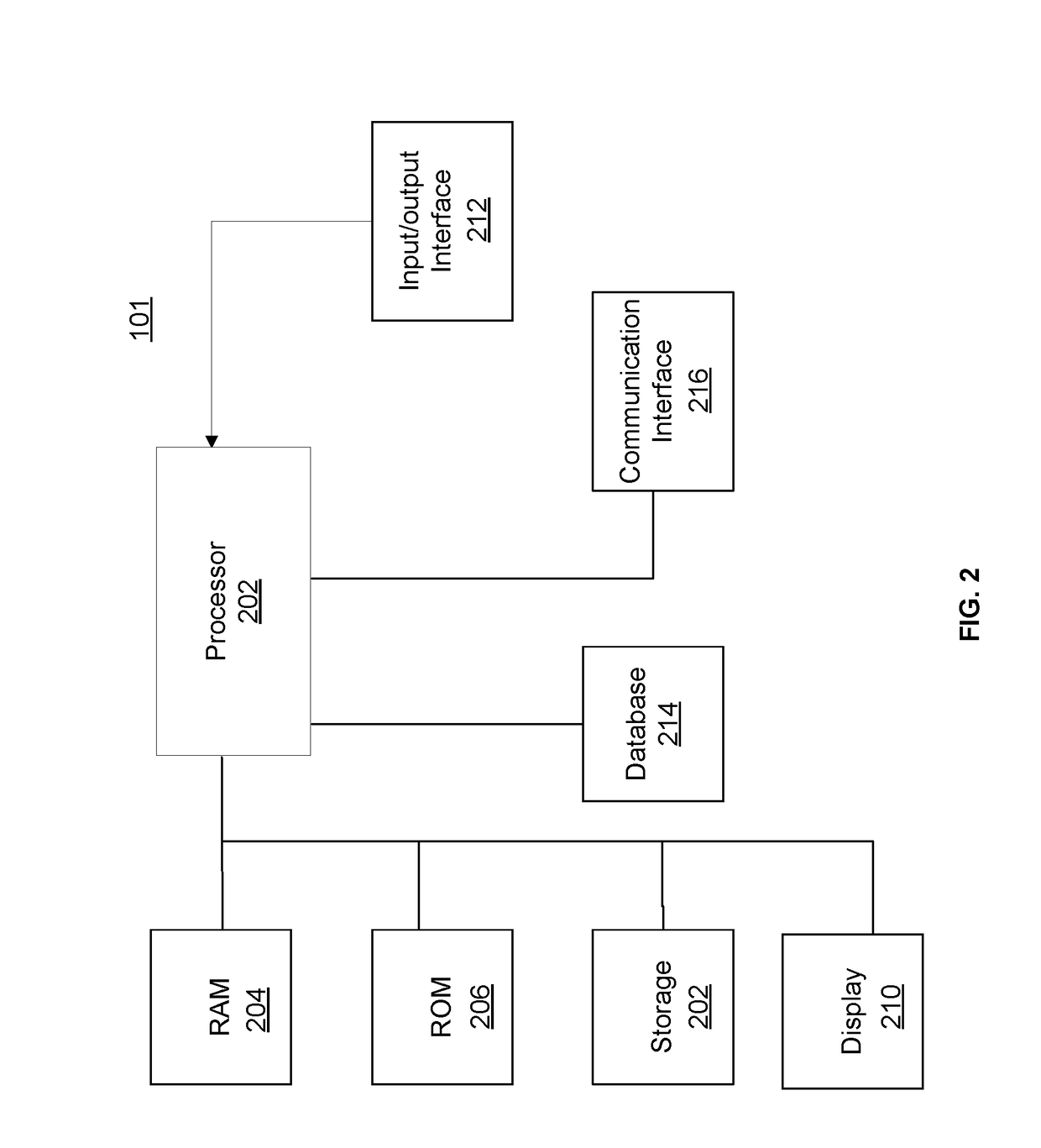

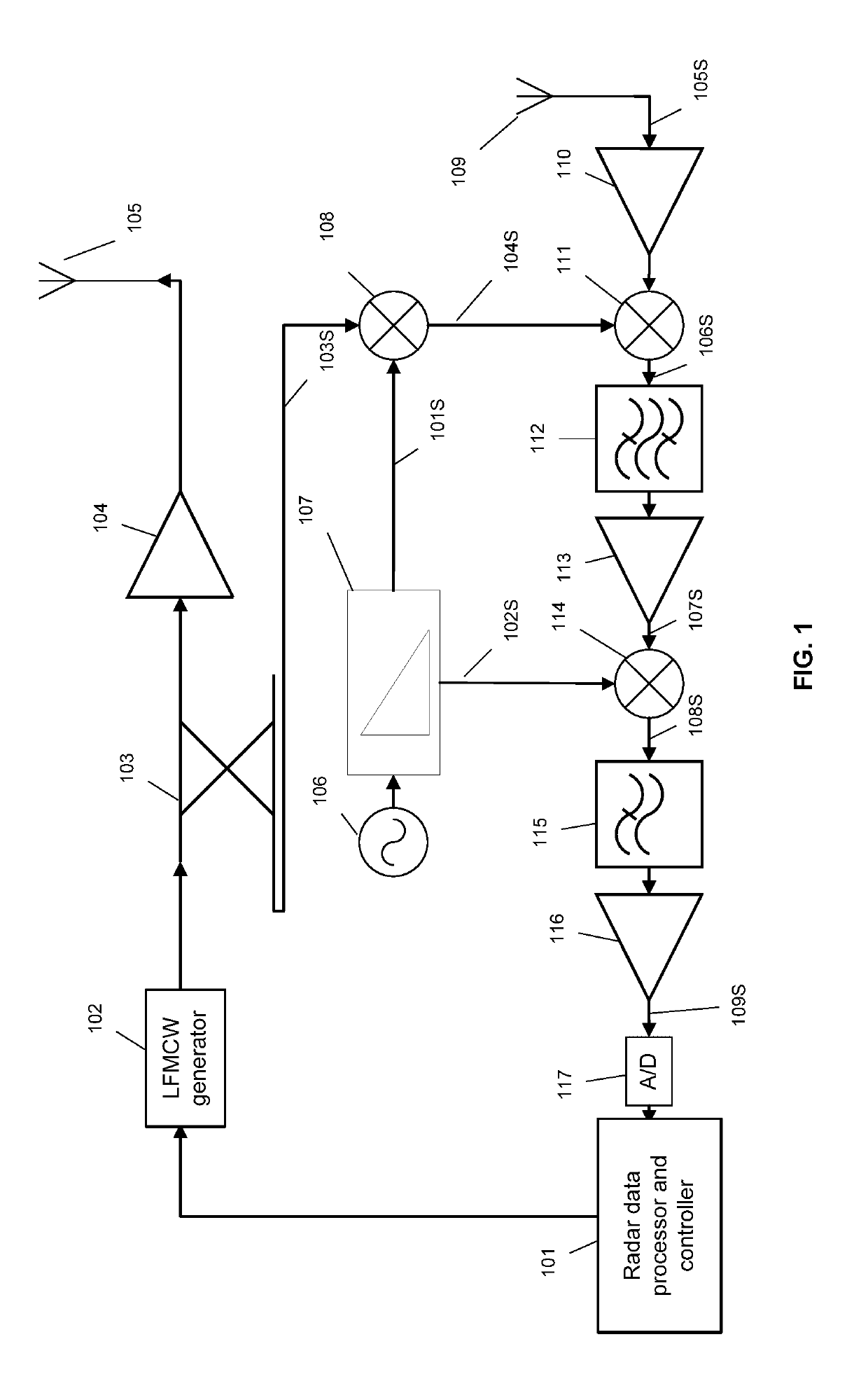

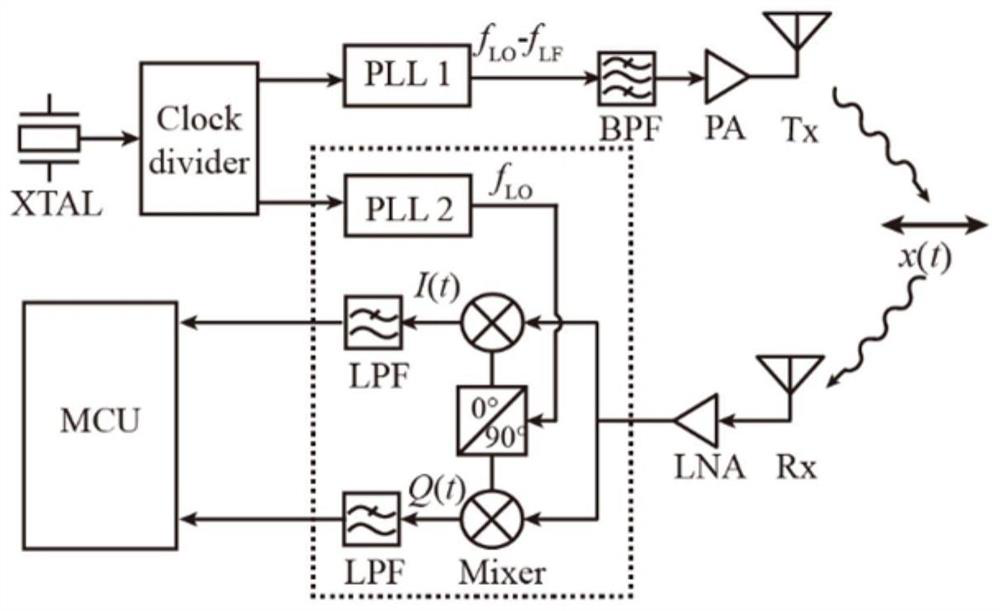

Gated range scanning lfmcw radar structure

ActiveUS20180329047A1High sensitivityImprove sensitivityRadio wave reradiation/reflectionIntermediate frequencyPhysics

The present disclosure provides a gated range scanning linear frequency modulated continuous wave (LFMCW) radar structure, including: a frequency synthesizer, a first mixer, a second mixer, a first filter, and a third mixer. The frequency synthesizer is configured for generating a first local oscillating signal and a second local oscillating signal, a frequency of the first local oscillating signal varying in a frequency range, each frequency corresponding to a sub-range of a coverage range scanned by the LFMCW radar structure. The first mixer is configured for mixing a copy of a transmitted signal and the first local oscillating signal to generate a first output signal (the receiver's first local oscillator). The second mixer is configured for mixing the first output signal and a received signal from a receiving antenna to generate a second output signal that includes an intermediate frequency (IF) signal being received by the first filter.

Owner:INTELLIGENT FUSION TECH

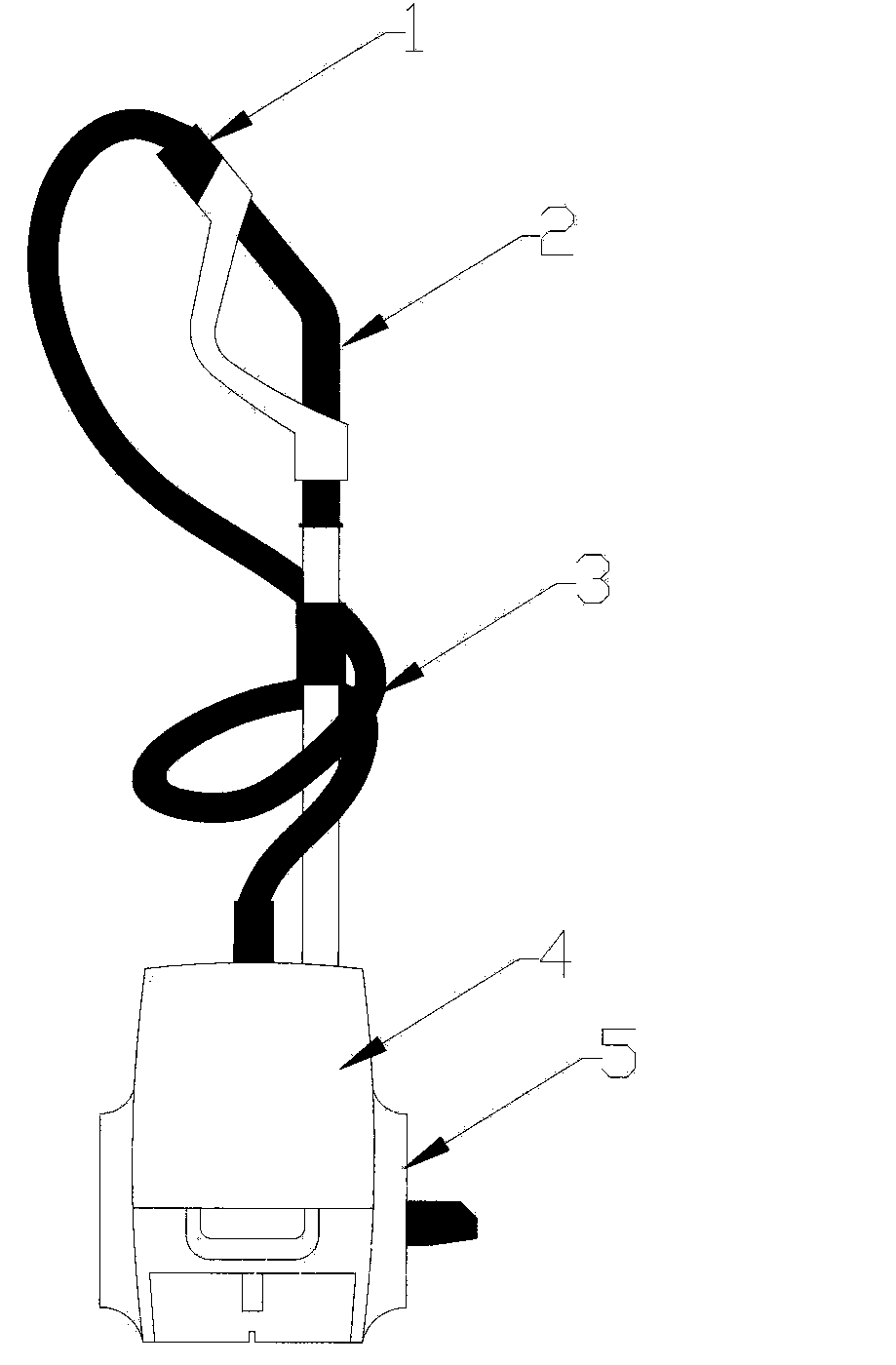

Radio frequency wireless control dust collector

InactiveCN103860101AWill not cause interferenceFlexible operationSuction cleanersWireless controlElectric machine

The invention relates to the field of the cleaning tool dust collector device, in particular to a radio frequency wireless control dust collector. The radio frequency wireless control dust collector comprises a dust collector engine base, an operation handle and a pipeline, wherein the operation handle and the pipeline are connected to the engine base; a control unit radio frequency emitter is arranged in the operation handle; the control unit is used for controlling the radio frequency emitter; a power supply module is used for supplying power to the radio frequency emitter; the radio frequency emitter is provided with a plurality of control keys and a wireless signal emitting antenna; a radio frequency receiving controller is arranged in the dust collector engine base; a wireless signal receiving antenna on the radio frequency receiving controller is used for receiving a wireless signal emitted from the radio frequency emitter and is used for controlling a motor. The radio frequency wireless control dust collector disclosed by the invention has the beneficial effects of flexibility, convenience and freedom in operation, wide applicable range due to global universal free frequency band and safety to the human body due to low-power emission, and other pieces of electronic equipment are free from being interfered with.

Owner:宁波国鑫电子科技有限公司

Apparatus and method for inhibiting portable electronic devices

ActiveUS8909209B2Lower latencyIncrease power consumptionEnergy efficient ICTAssess restrictionDiscriminatorRadio equipment

Owner:BRADLEY JAMES ROY

System and method for locating objects and communicating with the same

ActiveUSRE45061E1Improve signal-to-noise ratioHigh power transmissionDirection finders using radio wavesFrequency-division multiplex detailsResponse elementEngineering

Communication between a remote locator and a transponder is used to determine the relative position of the transponder. The transponder and locator each include a transmitter and a receiver. The locator transmits an inquiry in the form of a relatively powerful cyclically encoded signal with repetitive elements, uniquely associated with a target transponder. Periodically, each transponder correlates its coded ID against a possible inquiry signal, determining frequency, phase and framing in the process. Upon a match, the transponder transmits a synthesized response coherent with the received signal. The locator integrates multiple cyclical response elements, allowing low-power transmissions from the transponder. The locator correlates the integrated response, determines round-trip Doppler shift, time-of-flight, and then computes the distance and angle to the transponder. The transponder can be wearable, bionically implanted, or attached to, or embedded in, some object.

Owner:SANTA MONICA SEMICON

Wireless communications system and method

ActiveUS9622166B2Low Power TransmissionEnergy efficient ICTPower managementCommunications systemControl signal

A wireless communications system includes a base station, a plurality of intermediate devices and a terminal device. The base station is operable to wirelessly transmit downlink signals to the terminal device, the downlink signals including terminal control signals identifying one of the intermediate devices as a target device to which the terminal device is to direct uplink signals intended for the base station. The terminal device wirelessly transmits the uplink signals to the base station via the intermediate device identified by the terminal control signals. In this way, downlink communications may be provided directly from the base station to the terminal device, including control signals which instruct the terminal device where to send uplink data. This enables the base station to directly control scheduling of uplink communications, and in particular to define the uplink route from the terminal device to the base station via one or more intermediate devices.

Owner:CONVIDA WIRELESS LLC

Wireless communications system and method

ActiveUS20150327235A1Low Power TransmissionWireless commuication servicesHigh level techniquesCommunications systemControl signal

A wireless communications system includes a base station, a plurality of intermediate devices, and a terminal device. Downlink communications may be provided directly from the base station to the terminal device, including control signals which instruct the terminal device where to send uplink data. This enables the base station to directly control scheduling of uplink communications, and in particular to define an uplink route from the terminal device to the base station via one or more intermediate devices. Power is conserved at the terminal device on the uplink because a lower power transmission can be used which although insufficient to reach the base station can reach the intermediate device. The terminal device is not required to determine the uplink path itself and therefore does not require complex, expensive, and power consuming control logic.

Owner:INTERDIGITAL PATENT HLDG INC

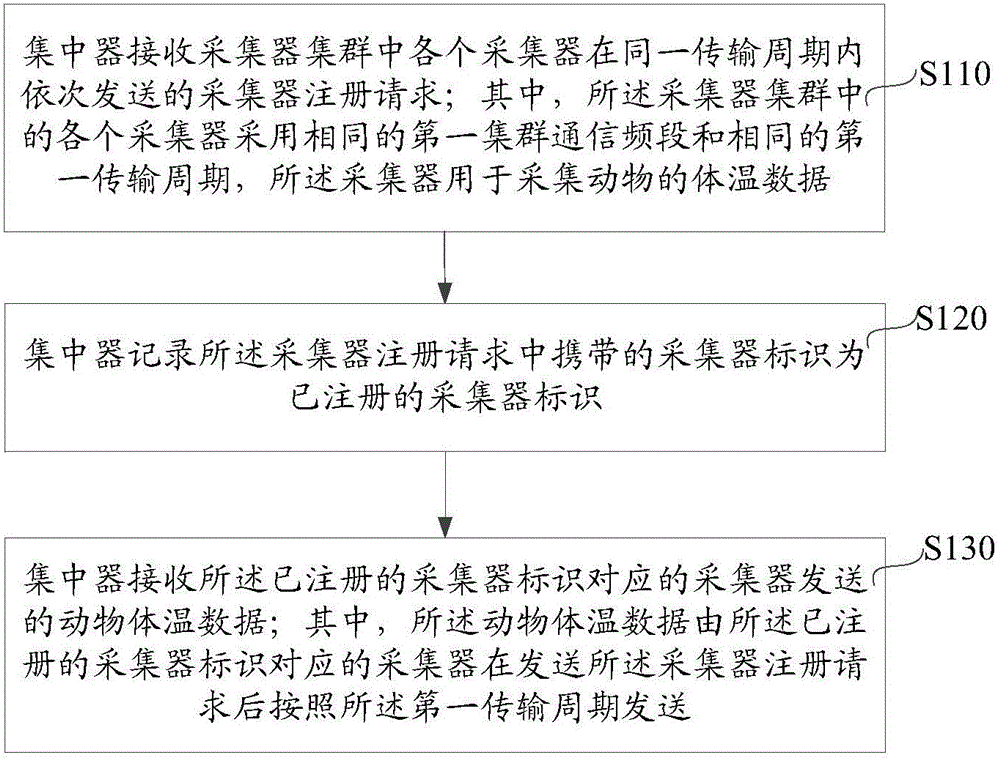

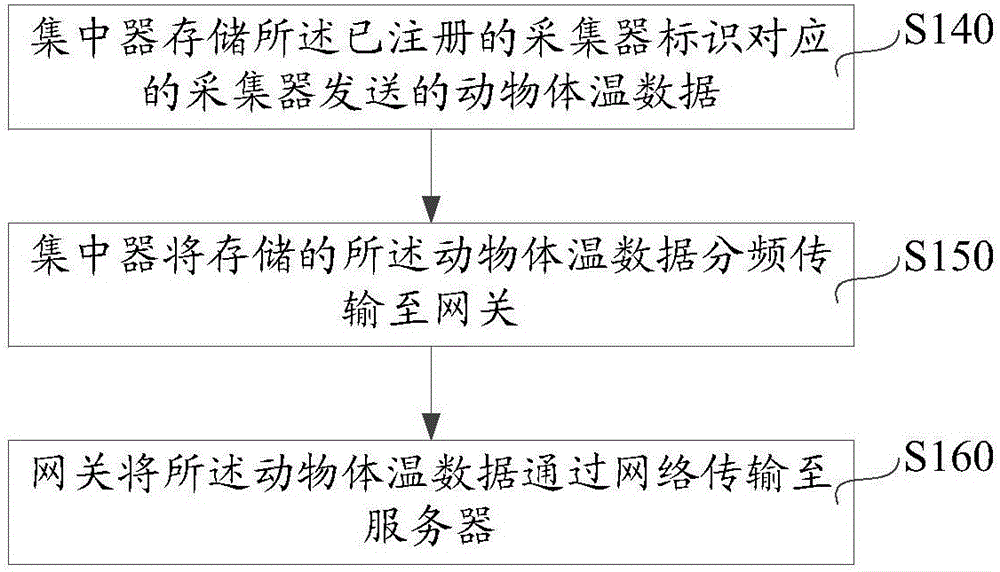

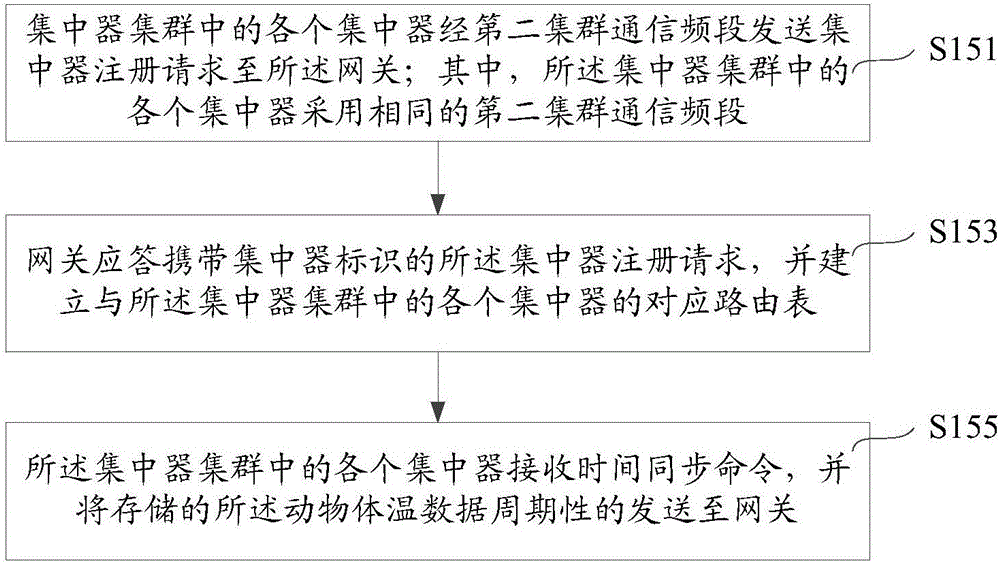

Animal body temperature acquisition method and system

ActiveCN106210107AReal-time acquisitionReliable data transmissionTransmission systemsNetwork topologiesReal time acquisitionData transmission

The invention relates to an animal body temperature acquisition method and system. According to the animal body temperature acquisition method, each collector in a collector cluster sends login requests by using the same first cluster communication band and the same first transmission period concentrator, and animal body temperature data is sent by a collector corresponding to a registered collector identifier according to a first transmission cycle after the collector sends the corresponding login request, that is, animal body temperature data in several collectors are acquired according to different frequencies at different times, and the concentrator can collect the animal body temperature data in a plurality of collectors. Therefore, real-time acquisition of body temperature of livestock and animal is realized; the method and the system are suitable for large-scale body temperature acquisition in the growing processes of animals; and during the data collecting process, data transmission is reliable and low in power consumption, and cost is reduced.

Owner:SHENZHEN FLAMINGO TECH CO LTD

Apparatus and method for transmitting and receiving

InactiveUS8774306B2Simple signal processingLow Power TransmissionMultiple modulation transmitter/receiver arrangementsData rate detection arrangementsFrequency shiftFrequency-shift keying

A transmitting apparatus groups a data bit sequence to groups each formed of a predetermined number of bits, modulates predetermined bits of one of groups through a frequency shift keying (FSK) modulation method, non-continuously aligns the FSK modulation signals, and transmits the non-continuous FSK modulation signals.

Owner:ELECTRONICS & TELECOMM RES INST

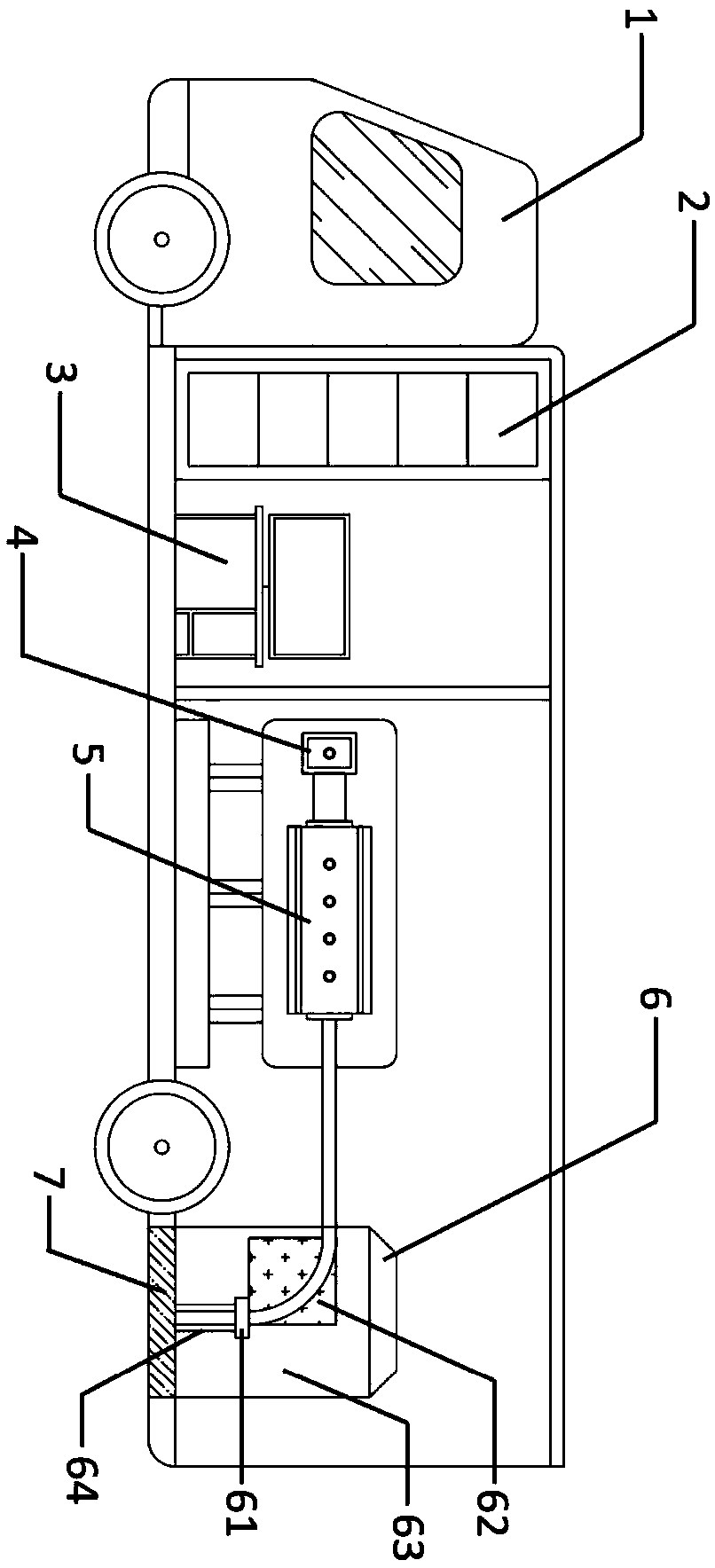

A neutron source photography system for a vehicle-mounted proton linear accelerator

The invention discloses a neutron source photography system of a vehicle-mounted proton linear accelerator, comprising an ion source, a proton linear accelerator, a neutron photography device, a central control and data acquisition and processing system, a target station and a power source for supplying energy. The target station comprises a shielding cover, a lithium target, a magnetic deflectiondevice and a neutron collimator. The proton beam produced by ion source is accelerated by proton linear accelerator and deflected by magnetic deflector, causing the lithium target to produce a neutron beam, the neutron beam generated by lithium target passes through the neutron collimator and bombards the object to be measured, The neutron radiography device receives the neutron reflected by theobject to be measured. The output end of the neutron radiography device is connected with the central control and data acquisition and processing system. The radiography system has low requirements for shielding, high neutron generation efficiency, and can realize vehicle-mounted operation.

Owner:XI AN JIAOTONG UNIV +1

Gated range scanning LFMCW radar structure

ActiveUS10338207B2High sensitivityLarge coverage rangeRadio wave reradiation/reflectionFrequency mixerRadar

Owner:INTELLIGENT FUSION TECH

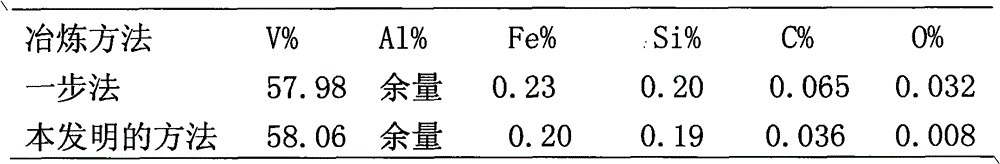

Method for preparing vanadium-aluminum alloy

InactiveCN101906546BSolving the melting puzzleImprove appearance qualityIntermediate frequencyInduction furnace

The invention discloses a method for preparing a vanadium-aluminum alloy and relates to a method for preparing a vanadium-aluminum intermediate alloy for producing a titanium alloy. The method is characterized by comprising the following steps of: firstly, with aluminum as a reducing agent, reducing vanadium pentoxide to prepare a vanadium-aluminum alloy in one step by adopting a metallothermic reduction method; secondly, crushing and drying the vanadium-aluminum alloy prepared in one step; and adding aluminum in the dried vanadium-aluminum alloy prepared in one step and refining in a second step in a vacuum intermediate-frequency induction furnace to obtain a final product of the vanadium-aluminum alloy. In the method, by taking the aluminum as the reducing agent in the metallothermic reduction method (one-step method) and reserving a small part of aluminum during smelting of the vanadium-aluminum alloy and adding the aluminum in the refining of the vacuum intermediate-frequency induction furnace, the problem that the vanadium-aluminum alloy is molten in the vacuum intermediate-frequency induction furnace can be effectively solved. In addition, compared with the one-step method for preparing the alloy, the appearance quality, the consistency, impurity components, the uniformity and other aspects of the alloy are superior and the aim of refining can be achieved. Meanwhile, when being used for refining the vanadium-aluminum alloy, the process can be used for completely molting the alloy at the lower feeding power and has remarkable the energy-saving effect.

Owner:CHENGDE TIANDA VANADIUM IND

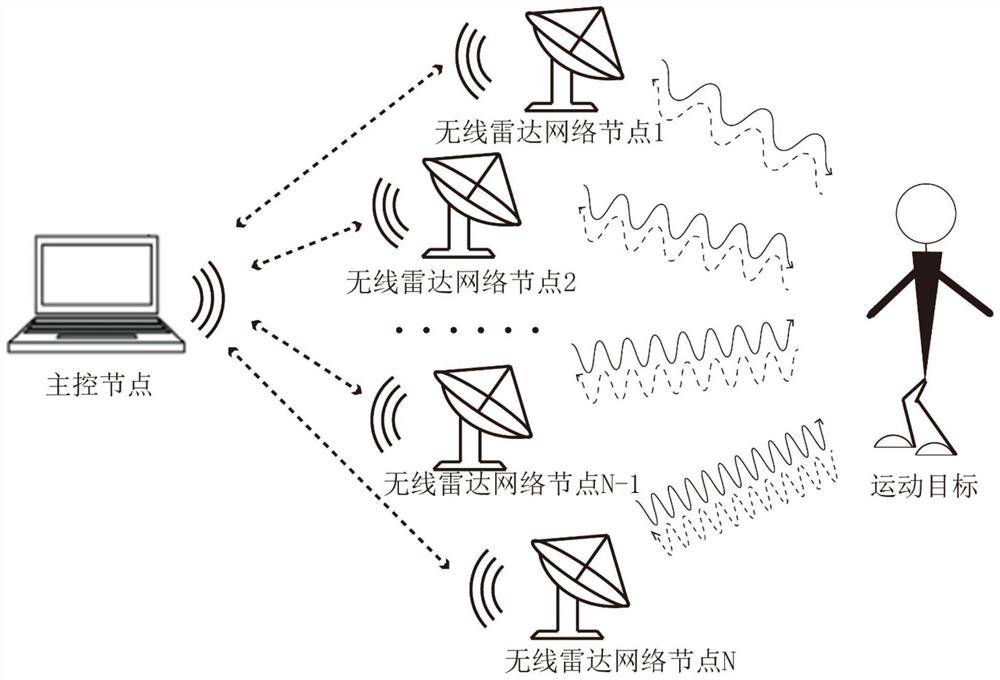

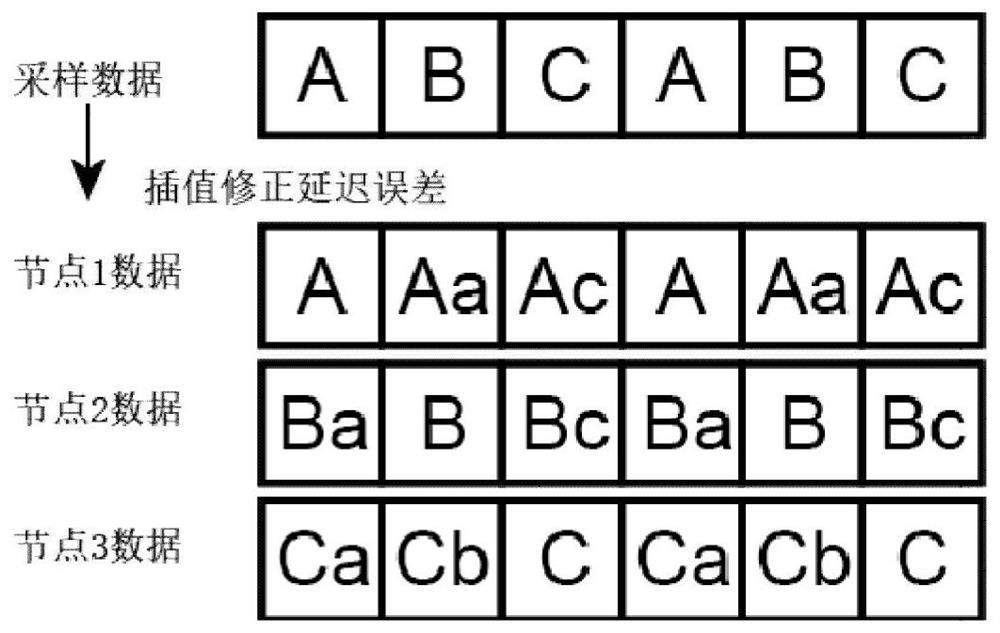

A method of indoor moving target localization based on doppler sensor network

ActiveCN111208507BIncrease or decrease the number of nodesImprove portabilityParticular environment based servicesNetwork topologiesTelecommunicationsRadar network

The invention discloses an indoor moving target positioning method based on a Doppler sensor network. Including multiple wireless radar network nodes and master control nodes, each wireless radar network node includes a reference clock and a Doppler radar sensor, but there is no clock synchronization relationship established between them, the Doppler radar sensor and the master control node of multiple wireless radar network nodes Form a wireless link; the wireless radar network node detects the Doppler information of the moving target, and the master control node reads the Doppler information obtained by each wireless radar network node through the wireless link in a time-division multiplexing polling manner, and fuses The position and displacement information of the moving target in the indoor multipath environment is obtained. The invention has the characteristics of multi-node connection, low-power transmission, working in a multi-path indoor environment, can flexibly configure the position and quantity of sensors, and realize positioning and tracking of different dimensions and different moving targets, and has a good application prospect.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com