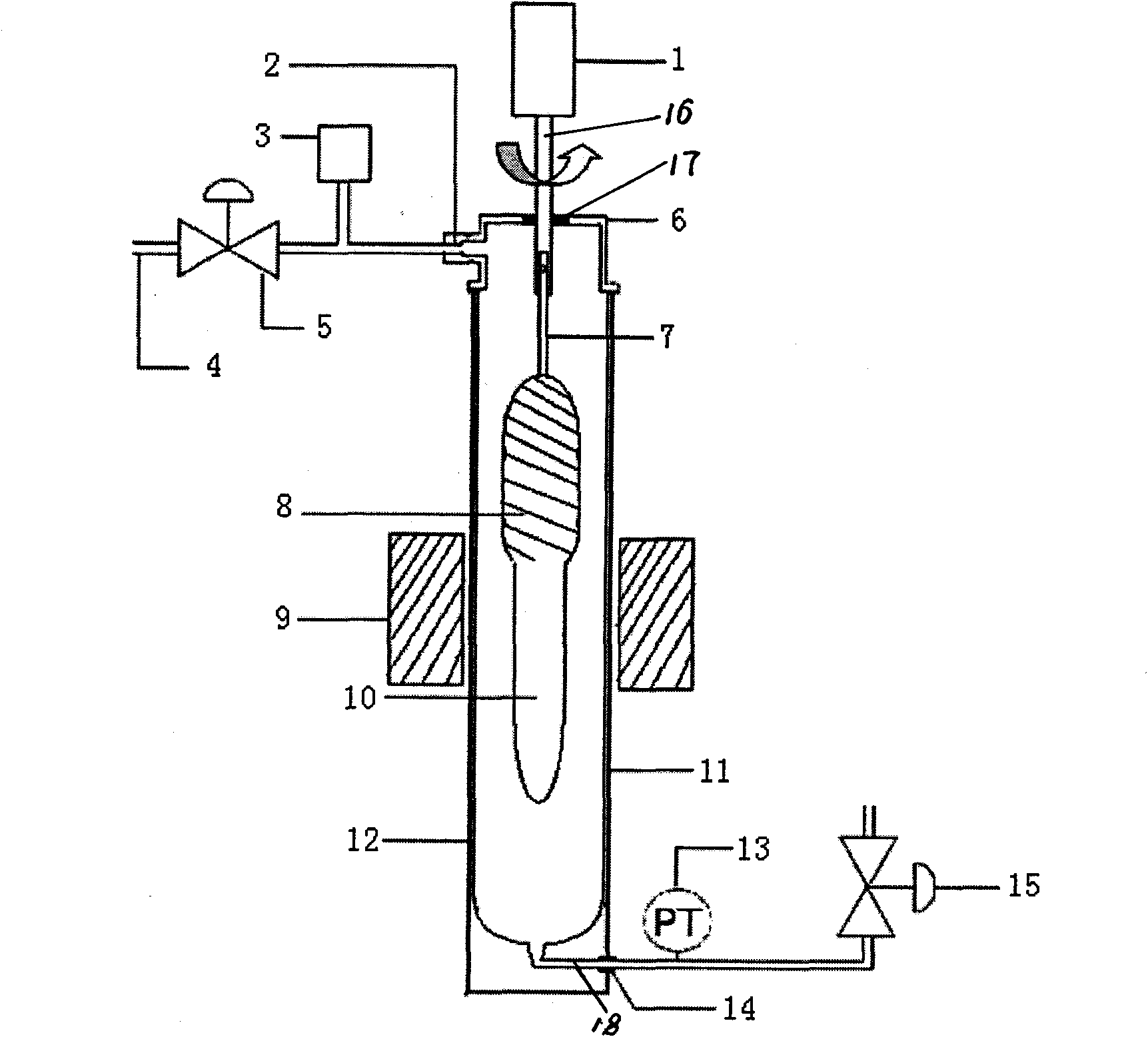

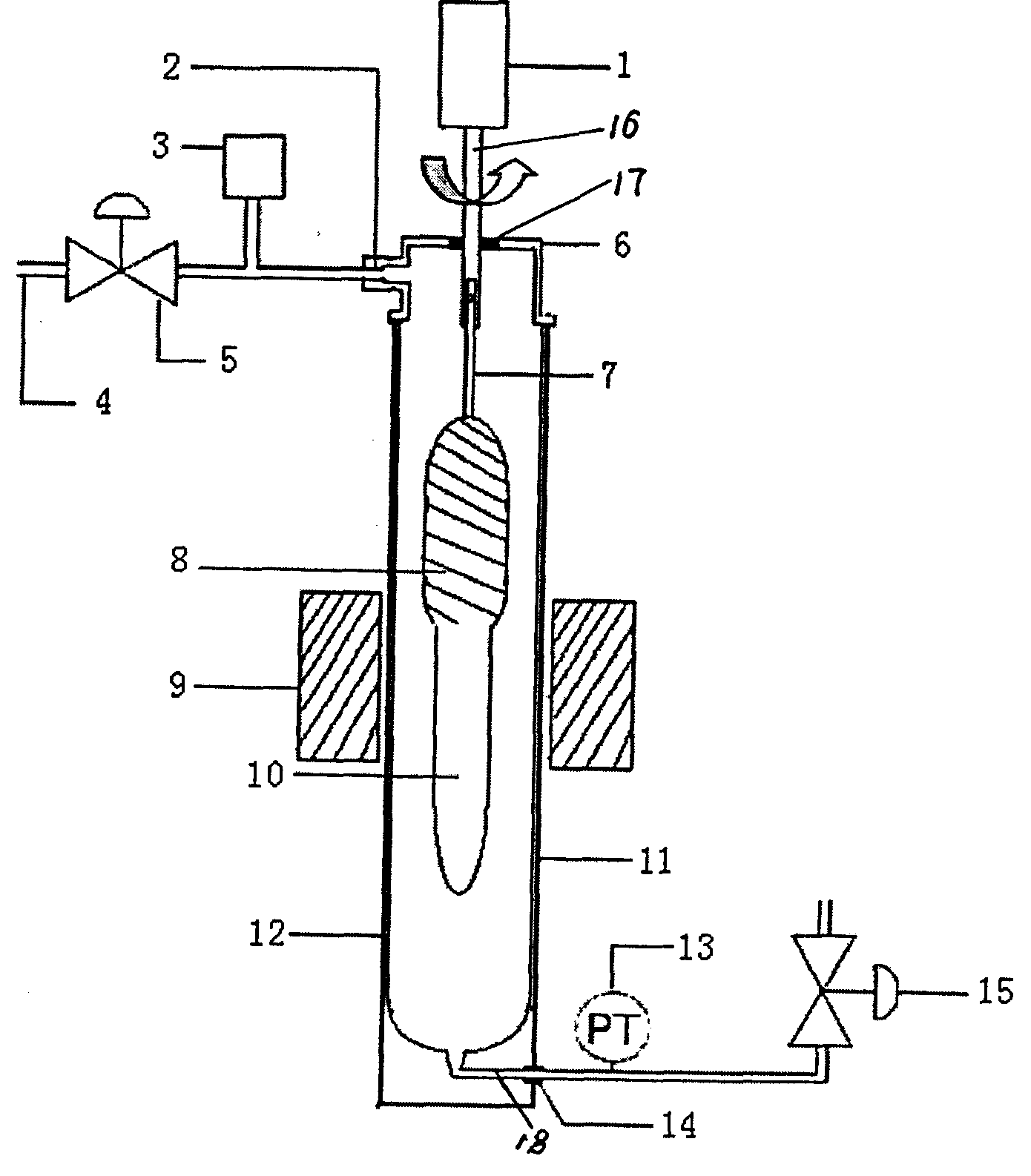

Equipment for loose body optical fiber prefabricated rod integral sintering desaeration and method thereof

A technology of optical fiber preform and loose body, which is applied in the field of equipment where vitrification and degassing are carried out simultaneously. It can solve the problems of residual bubbles in optical fiber preform, achieve the effects of shortening the production cycle, high pass rate, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

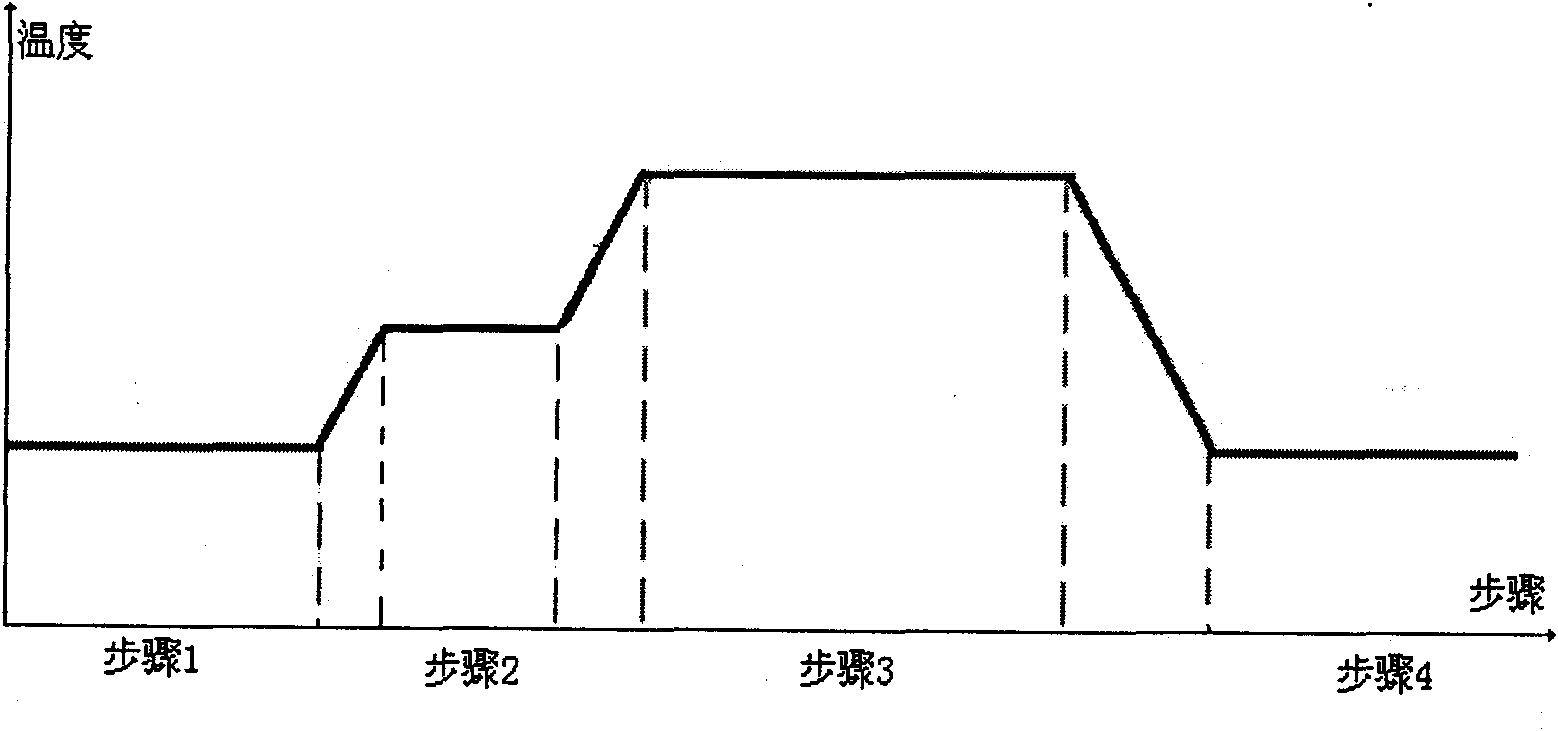

[0053] Embodiment 1. The temperature of the sintering furnace 9 was raised to 1150° C., and the chlorine gas pneumatic valve was opened to feed chlorine gas into the sintering furnace, and the flow rate of the chlorine gas was controlled at 0.8 L / min. Turn on the lowering rod system, control the descending speed of the powder preform at 5 mm / min, and control the rotation speed at 6 rpm. After the rod of the powder preform arrives at the hot zone 9 of the sintering furnace, the dehydration is completed, the falling of the powder preform is stopped, and the chlorine gas is turned off. The temperature of the sintering furnace 6 was raised to 1400°C, and helium gas was introduced into the sintering furnace 9, and the flow rate was set at 6 L / min. After 15 minutes, deuterium gas is introduced into the furnace core tube 12, and the flow rate is controlled at 0.1L / min. After the deuterium and helium are fully mixed, they enter the quartz furnace core tube 12 and react with the powder...

Embodiment 2

[0055] Embodiment 2, the difference from Embodiment 1 is that the flow rate of chlorine gas is controlled at 1.2L / min during the dehydration process. During the feeding process of the mixed gas of helium and deuterium, the flow rate of deuterium is controlled at 0.15L / min. The deuterium and helium are fully mixed in the gas buffer box and then enter the quartz furnace core tube to react with the optical fiber preform at a rate of 12mm / min. Raise the preform to the initial position at a speed of . The number of bubbles inside the obtained optical fiber preform and the relevant parameters after being drawn into an optical fiber are as follows:

[0056] The number of bubbles with a diameter greater than 2mm

Embodiment 3

[0057] Embodiment 3 is different from Embodiment 1 in that the vacuum pump is turned on during the sintering process to control the ambient pressure of the optical fiber preform to between 450-500 mbar. Start the lowering rod system, and control the lowering speed of the preform rod at 4.5mm / min. The number of bubbles inside the obtained optical fiber preform and the relevant parameters after being drawn into an optical fiber are as follows:

[0058] The number of bubbles with a diameter greater than 2mm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com