Cobalt-based high-temperature alloy and preparation method thereof

A high-temperature alloy, cobalt-based technology, applied in the field of high-temperature alloys, can solve the problems of unfavorable high-temperature oxidation resistance of alloys, not optimal overall performance of alloys, low-density structure stability, etc., to achieve good application prospects, good oxidation resistance, The effect of high tissue stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

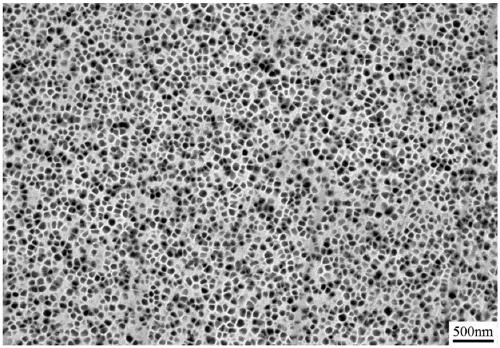

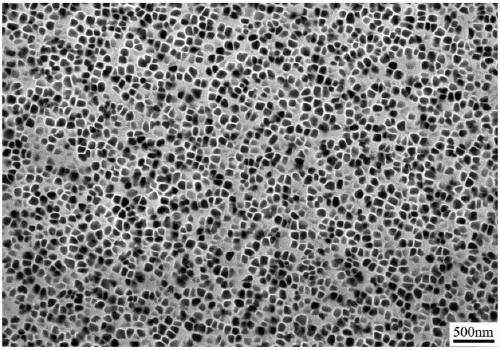

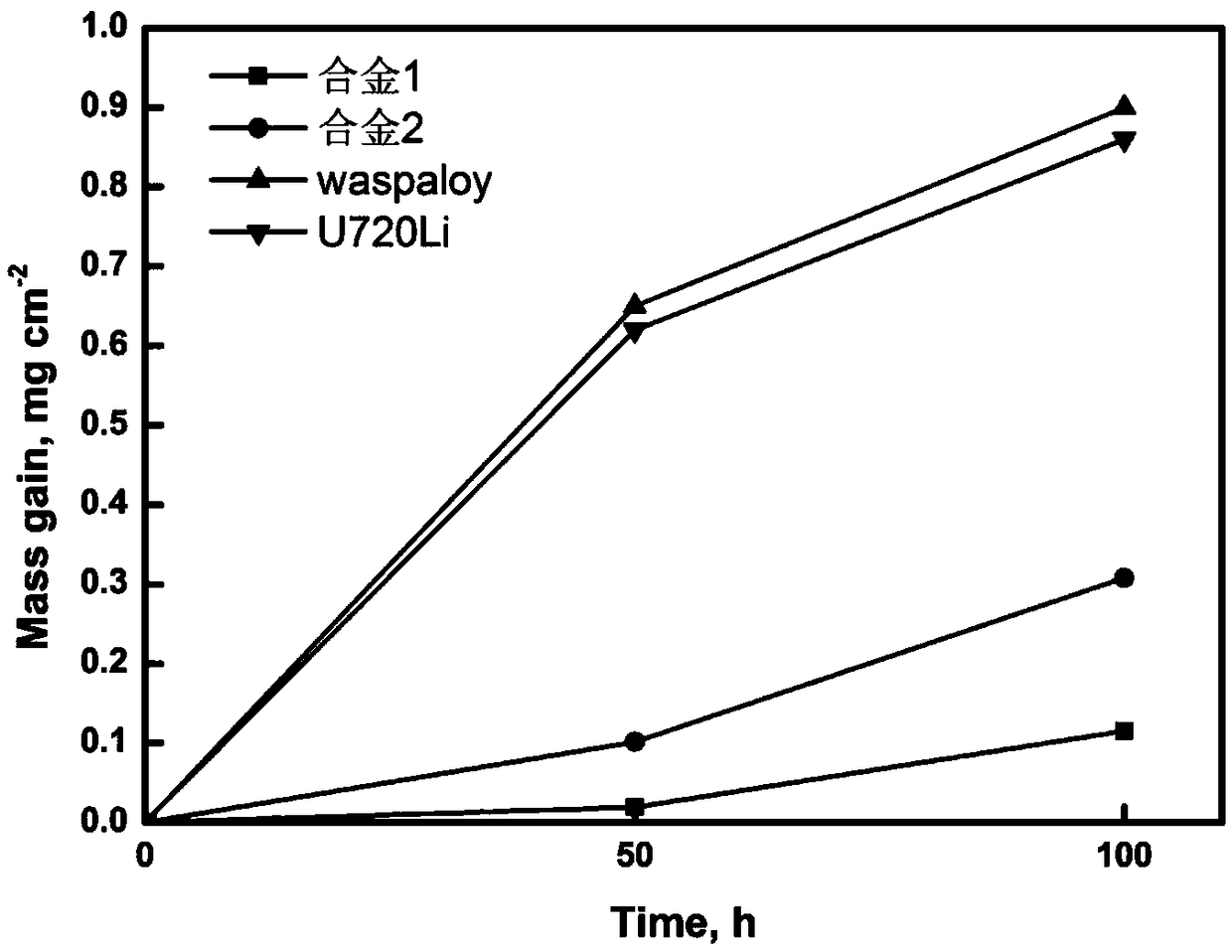

[0041] Weigh the elemental materials such as Co, Al, W, Ti, Ta, Ni, Cr according to the composition ratio shown in alloy 1-2 in Table 1; place the above-mentioned elemental raw materials weighed in the crucible of the vacuum arc melting furnace, the first Vacuum down to 3×10 times -3 Pa, filled with high-purity Ar protective gas to 7 × 10 4 Pa, then evacuated to 3×10 for the second time -3 Pa, then filled with high-purity Ar protective gas to 7×10 4 Pa; the alloy is smelted in a high-purity Ar protective atmosphere, and the current of the smelting arc is controlled at 250A. After the alloy is completely melted, it is kept for 60 seconds, and then the power is turned off and cooled until the alloy is completely solidified. Repeat the smelting step 8 times to finally obtain cobalt base superalloy ingot; in a high-purity Ar protective atmosphere, the above-prepared cobalt-based superalloy ingot was kept at a solution temperature of 1250°C for 24 hours, and air-cooled; then kept...

Embodiment 2

[0044] Weigh the elemental materials such as Co, Al, W, Ti, Ta, Ni, Cr according to the composition ratio shown in alloy 1-2 in Table 1; place the above-mentioned elemental raw materials weighed in the crucible of the vacuum arc melting furnace, the first Vacuum down to 3×10 times -3 Pa, filled with high-purity Ar protective gas to 7 × 10 4 Pa, then evacuated to 3×10 for the second time -3 Pa, then filled with high-purity Ar protective gas to 7×10 4 Pa; the alloy is smelted in a high-purity Ar protective atmosphere, and the current of the smelting arc is controlled at 250A. After the alloy is completely melted, it is kept for 60 seconds, and then the power is turned off and cooled until the alloy is completely solidified. Repeat the smelting step 8 times to finally obtain cobalt base superalloy ingot; in a high-purity Ar protective atmosphere, the above-prepared cobalt-based superalloy ingot was kept at a solution temperature of 1250°C for 24 hours, and air-cooled; then kept...

Embodiment 3

[0047] Weigh the elemental materials such as Co, Al, W, Ti, Ta, Ni, Cr according to the composition ratio shown in alloy 1-2 in Table 1; place the above-mentioned elemental raw materials weighed in the crucible of the vacuum arc melting furnace, the first Vacuum down to 3×10 times -3 Pa, filled with high-purity Ar protective gas to 7 × 10 4 Pa, then evacuated to 3×10 for the second time -3 Pa, then filled with high-purity Ar protective gas to 7×10 4 Pa; the alloy is smelted in a high-purity Ar protective atmosphere, and the current of the smelting arc is controlled at 250A. After the alloy is completely melted, it is kept for 60 seconds, and then the power is turned off and cooled until the alloy is completely solidified. Repeat the smelting step 8 times to finally obtain cobalt base superalloy ingot; in a high-purity Ar protective atmosphere, the above-prepared cobalt-based superalloy ingot was kept at a solution temperature of 1250°C for 24 hours, and air-cooled; then kept...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com