Method for accurately measuring absorbed phase density of methane on shale

An accurate measurement and adsorption phase technology, applied in the field of geological exploration, can solve problems such as the great difference in the research results of different scholars, the influence of rock adsorption capacity, and the complex pore structure of shale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0062] The invention provides a method for accurately testing the density of methane adsorption phase on shale, which comprises the following steps:

[0063] 1) Pulverize a shale sample to 60-80 mesh and divide it into two parts.

[0064] 2) Carry out a volumetric adsorption isotherm experiment on the first shale sample, and obtain the content of adsorbed methane (the amount of methane substance n) 吸附CH4 ) calculation model, the specific process is as follows:

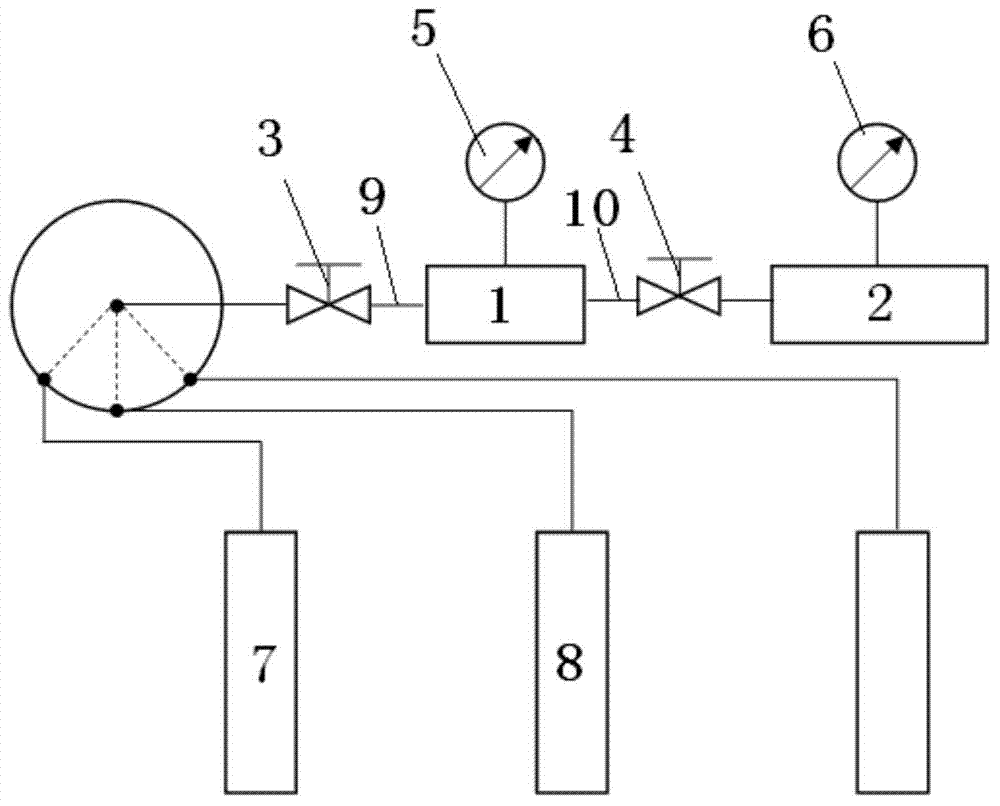

[0065] ①If figure 1 As shown, set up a reference cell 1, sample cell 2, first valve 3, second valve 4, first temperature and pressure gauge 5, second temperature and pressure gauge 6, helium gas source 7 and methane gas source 8 Volumetric isothermal adsorption instrument, wherein, the reference cell 1 is connected to an inlet pipeline 9 and an outlet pipeline 10 respectively, the first valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com