Multi-layer composite T-shaped pipe separator and separation method for separating two-phase flow or multiphase flow

A multi-layer composite and separation method technology, applied in separation methods, chemical instruments and methods, immiscible liquid separation, etc., can solve the problem that the complete separation point of the separator is not easy to control, etc., and achieve simple structure, low cost, and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

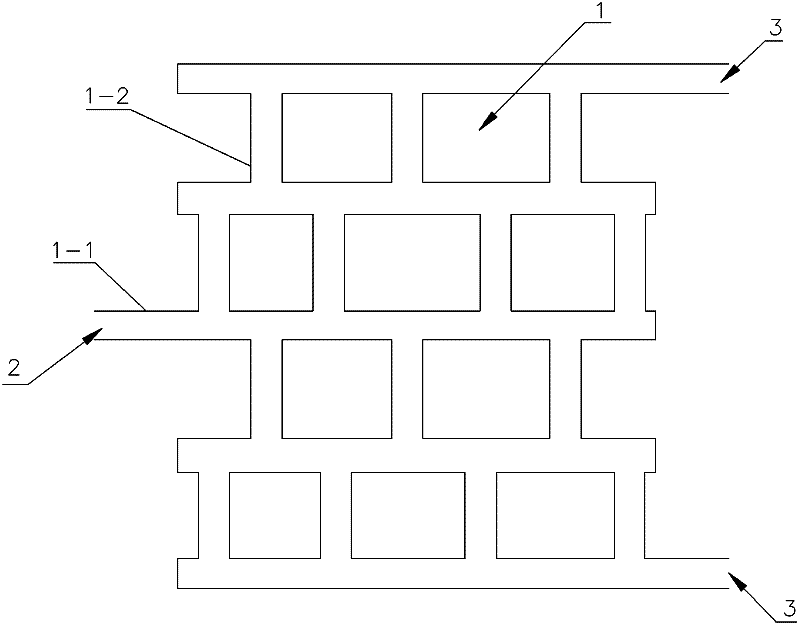

[0030] Embodiment 1 adopts figure 1 The shown multi-layer composite T-tube separator for gas-liquid two-phase flow separation

[0031] The gas-liquid two-phase flow system is composed of air and water. figure 1 The multi-layer composite T-shaped tube separator with a 4-layer structure as shown includes four composite T-shaped tube layers 1, and two adjacent composite T-shaped tube layers 1 are placed vertically or obliquely or horizontally, and the composite T-shaped tube Layer 1 includes two main pipes 1-1 and at least two intermediate connecting pipes 1-2 vertically connected between the two main pipes 1-1, and a common main pipe 1-1 is shared between adjacent composite T-shaped pipe layers 1, The multi-layer composite T-shaped pipe separator for the separation of two-phase flow or multi-phase flow also has an inflow port 2 for the inflow of the mixture and two outflow ports 3 for the outflow of the separated fluid, on each main pipe 1-1 The inflow port 2 for mixture inflo...

Embodiment 2

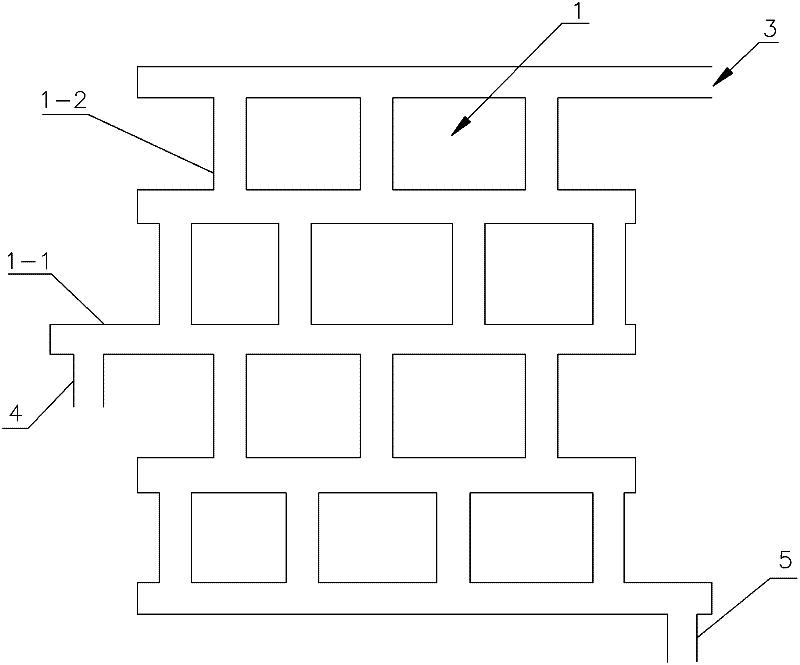

[0033] Embodiment 2 adopts figure 2 The shown multi-layer composite T-tube separator for liquid-liquid two-phase flow separation

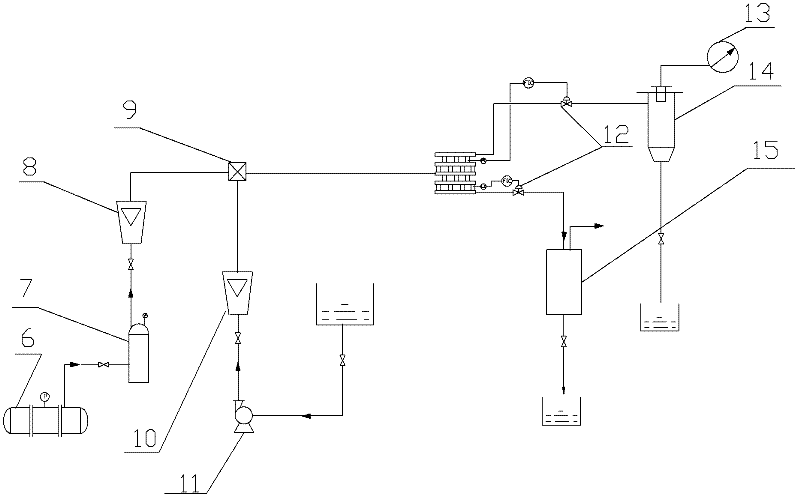

[0034] Will image 3 The air supply system of the medium-use compressor is transformed into a system of kerosene delivery by an oil pump, and the separation and metering system of the two outlets after the separation of the multi-layer composite T-tube separator is correspondingly transformed. image 3 The device can also be used to test the phase separation characteristics of liquid-liquid two-phase flow at the multi-layer composite T-shaped pipe. The liquid-liquid two-phase flow system is composed of kerosene and water. figure 2 The multi-layer composite T-shaped tube separator with a 4-layer structure as shown includes four composite T-shaped tube layers 1, and two adjacent composite T-shaped tube layers 1 are placed vertically or obliquely or horizontally, and the composite T-shaped tube Layer 1 includes two main pipes 1-1 and at least two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com