Al-Er alloy conductor material and preparation method thereof

A technology of alloy wires and aluminum alloy wires, applied in the field of metal alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

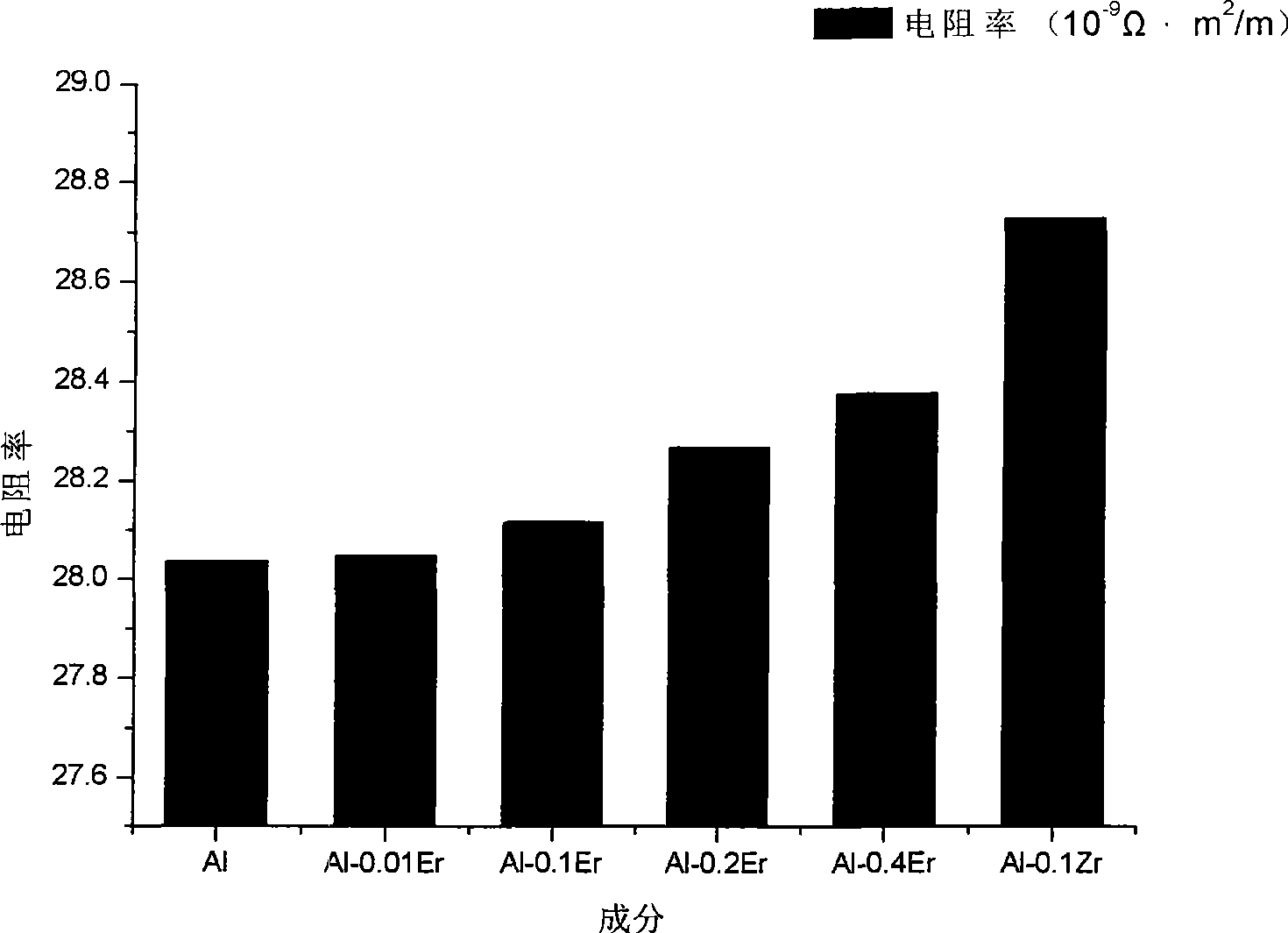

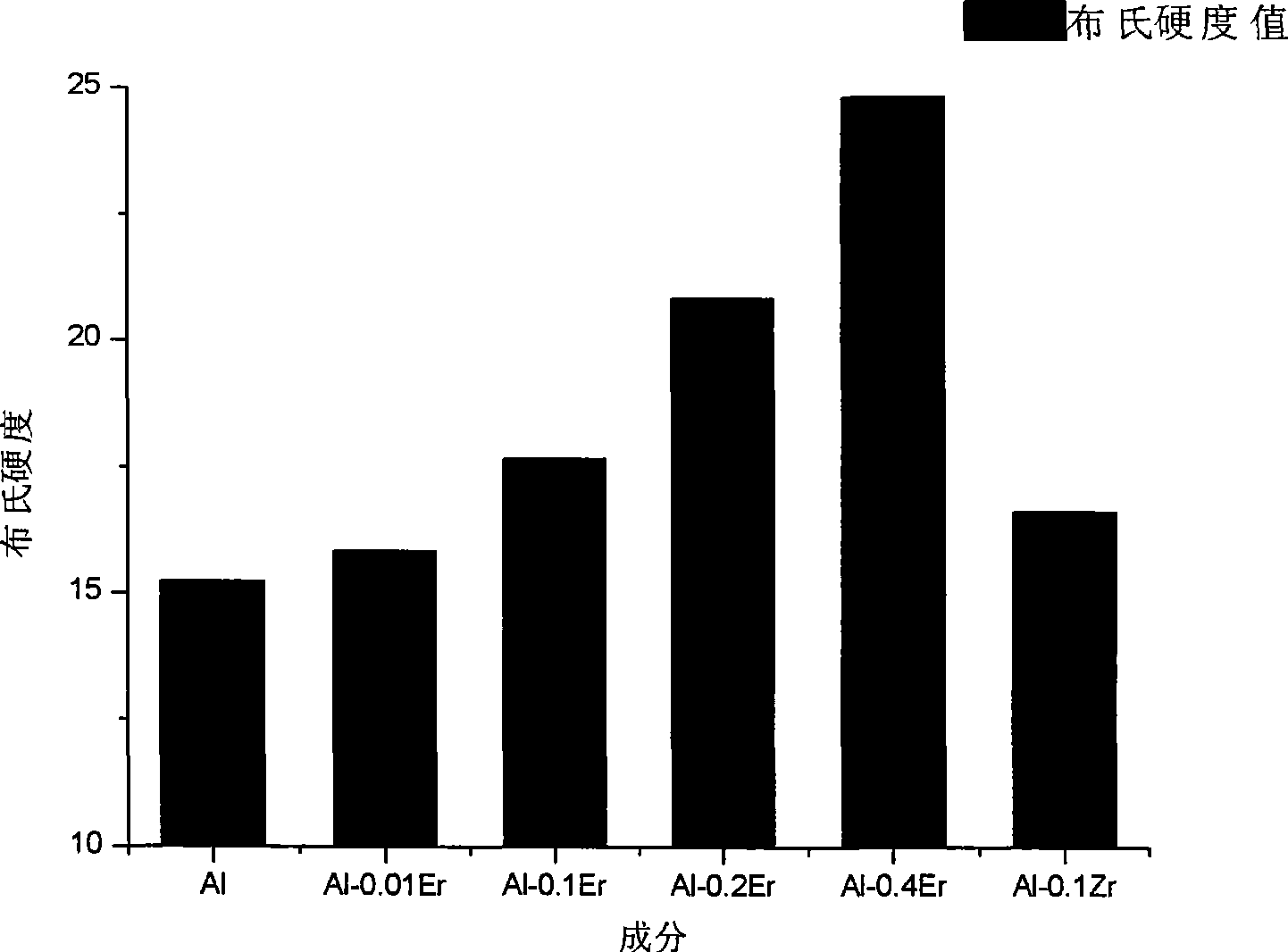

example 1

[0012] Example 1: Using pure aluminum ingot as raw material, the melting temperature is 750°C, after stirring, C 6 Cl 6 Degassing and refining, continuous casting with a continuous casting machine, continuous casting into a Φ100mm aluminum alloy ingot, hot extrusion at 420°C by an extruder to make a Φ10mm aluminum alloy rod, annealing at 420°C for 50 hours, and then On the wire drawing machine, after multiple passes of drawing, a Φ4mm pure aluminum wire was prepared, and its hardness and resistivity were tested. The results are shown in Table 1 for alloy A.

example 2

[0013] Example 2: Using pure aluminum ingots and Al-Er intermediate alloys as raw materials, the melting temperature is 750 ° C, after stirring, C 6 Cl 6 Degassing and refining, continuous casting with a continuous casting machine, continuous casting into a Φ100mm aluminum alloy ingot, hot extrusion at 420°C by an extruder to make a Φ10mm aluminum alloy rod, annealing at 420°C for 50 hours, and then On the wire drawing machine, after multiple passes of drawing, a Φ4mm Al-0.01Er alloy wire was prepared, and its hardness and resistivity were tested. The results are shown in the B alloy in Table 1.

example 3

[0014] Example 3: Using pure aluminum ingots and Al-Er intermediate alloys as raw materials, the melting temperature is 750 ° C, after stirring, C 6 Cl 6 Degassing and refining, continuous casting with a continuous casting machine, continuous casting into a Φ100mm aluminum alloy ingot, hot extrusion at 420°C by an extruder to make a Φ10mm aluminum alloy rod, annealing at 420°C for 50 hours, and then On the wire drawing machine, after multiple passes of drawing, a Φ4mm Al-0.1Er alloy wire was prepared, and its hardness and resistivity were tested. The results are shown in Table 1 for alloy C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com