Carbide-containing austempered ductile iron plowshare and production method thereof

A technology of isothermal quenching and production method, which is applied in the directions of plough, application, agricultural machinery and implements, etc., can solve the problems of high production cost, poor wear resistance, poor toughness, etc., so as to reduce agricultural production cost and solve the problem of poor toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

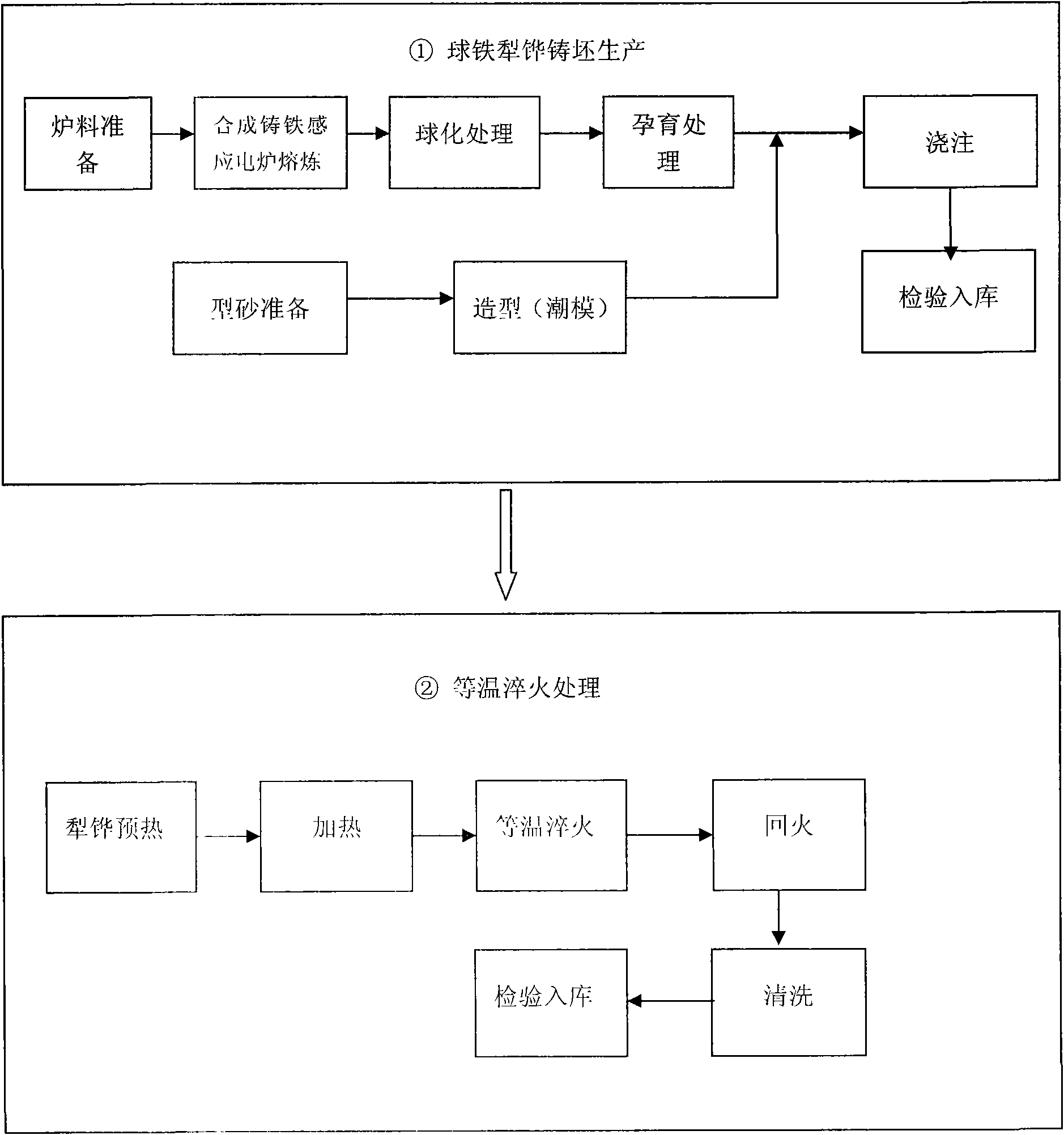

Method used

Image

Examples

Embodiment 1

[0036] A plowshare of austempering ductile iron with carbides, the plowshare is made of austempering nodular cast iron, and the nodular cast iron includes the following chemical components in weight percentage:

[0037] C 3.40, Si 2.20, Mn 0.20, P≤0.03, S≤0.02,

[0038] Mg 0.03, Re 0.01, Cr 0.25, the rest is iron;

[0039] The metallographic structure of graphite in the ductile iron is as follows: nodularization rate is above grade 2, graphite size is above grade 6, and the number of graphite is more than 100 pieces / mm 2 ;

[0040] The matrix of the austempering ductile iron is: martensite+lower bainite+retained austenite+carbide; the carbide is 5wt%.

[0041] A method for producing an austempering ductile iron plowshare with carbides, comprising the steps of:

[0042] 1) Production of nodular cast iron: melting nodular cast iron molten iron in an induction furnace, the chemical composition requirement of the former molten iron of nodular graphite cast iron is (wt%):

[00...

Embodiment 2

[0058] A plowshare of austempering ductile iron with carbides, the plowshare is made of austempering nodular cast iron, and the nodular cast iron includes the following chemical components in weight percentage:

[0059] C 3.80, Si 2.80, Mn 0.50, P≤0.03, S≤0.02, Mg 0.04, Re 0.02,

[0060]Cr 0.50, the rest is iron;

[0061] The metallographic structure of graphite in the ductile iron is as follows: nodularization rate is above grade 2, graphite size is above grade 6, and the number of graphite is more than 100 pieces / mm 2 ;

[0062] The matrix of the austempering ductile iron is: martensite+lower bainite+retained austenite+carbide; the carbide is 5wt%.

[0063] Aforesaid production method of austempering nodular cast iron plowshare with carbide, comprises the steps:

[0064] 1) Production of nodular cast iron: melting nodular cast iron molten iron in an induction furnace, the chemical composition requirement of the former molten iron of nodular graphite cast iron is (wt%):

...

Embodiment 3

[0080] A plowshare of austempering ductile iron with carbides, the plowshare is made of austempering nodular cast iron, and the nodular cast iron includes the following chemical components in weight percentage:

[0081] C 3.56, Si 2.62, Mn 0.22, P 0.024, S 0.015,

[0082] Mg 0.038, Re 0.014, Cr 0.30, the rest is iron;

[0083] The metallographic structure of graphite in the ductile iron is as follows: nodularity rate 2, graphite size 7, graphite number 200 / mm 2 ;

[0084] The matrix of the austempering ductile iron is: martensite+lower bainite+retained austenite+carbide; the carbide is 10wt%.

[0085] Aforesaid production method of austempering nodular cast iron plowshare with carbide, comprises the steps:

[0086] 1) Production of nodular cast iron: melting nodular cast iron molten iron in an induction furnace, the chemical composition requirement of the former molten iron of nodular graphite cast iron is (wt%):

[0087] C 3.80, Si 1.80, Mn 0.50, P≤0.03,

[0088] S≤0.02,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact toughness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com