Hand rubbing type washing machine

A washing machine and hand-rubbing technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of clothes entanglement, achieve the effects of reducing washing time, improving transmission effect, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

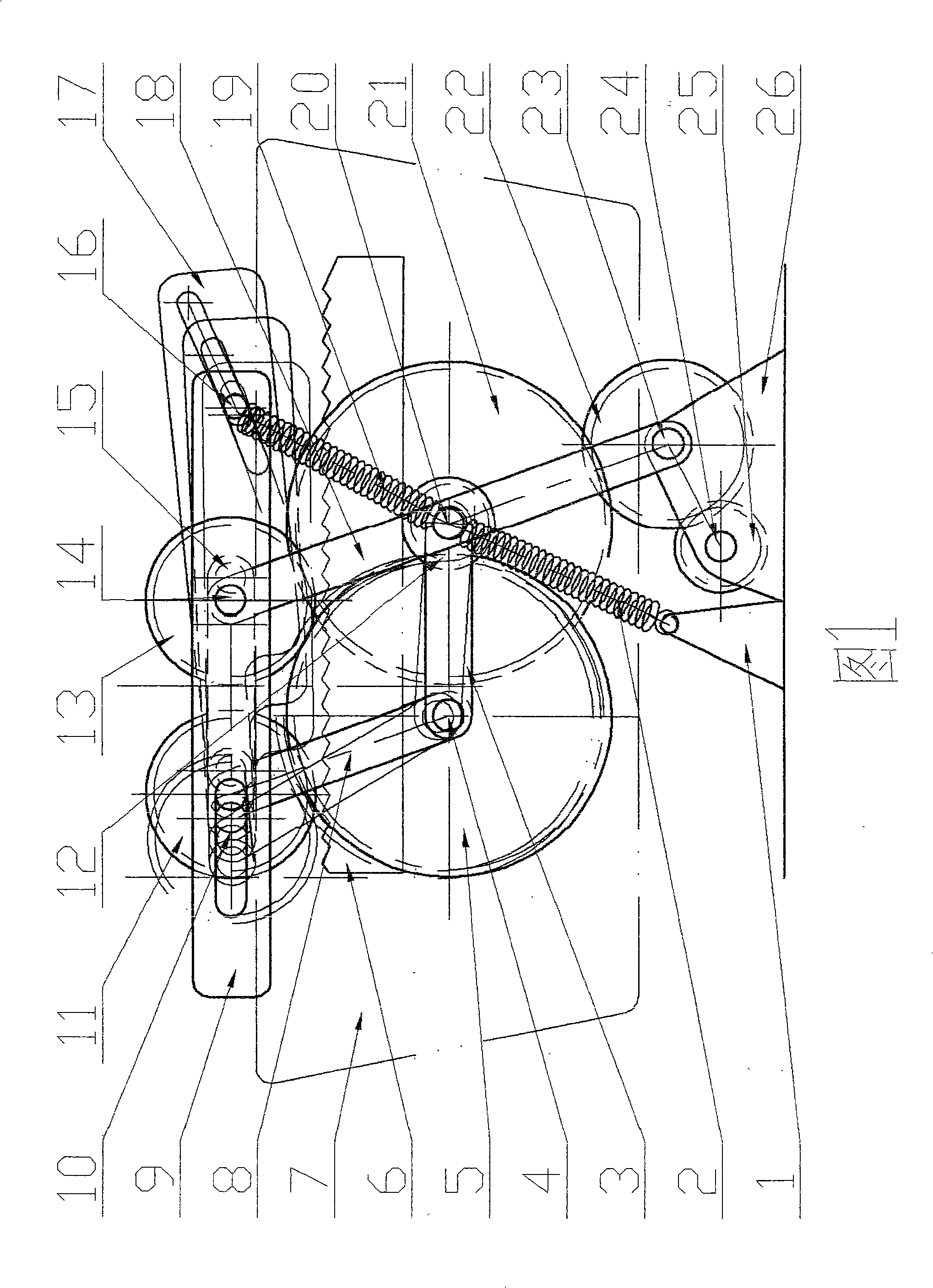

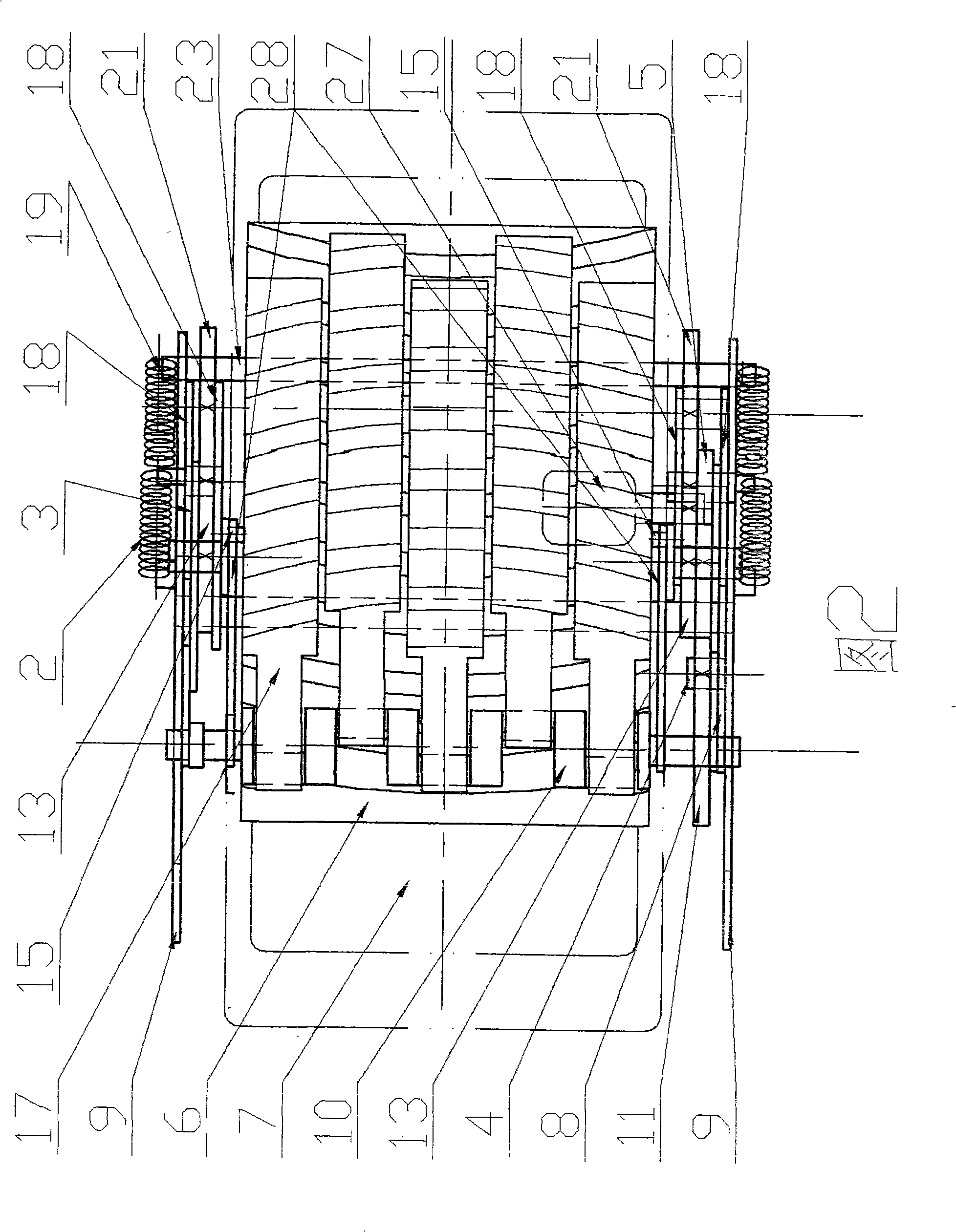

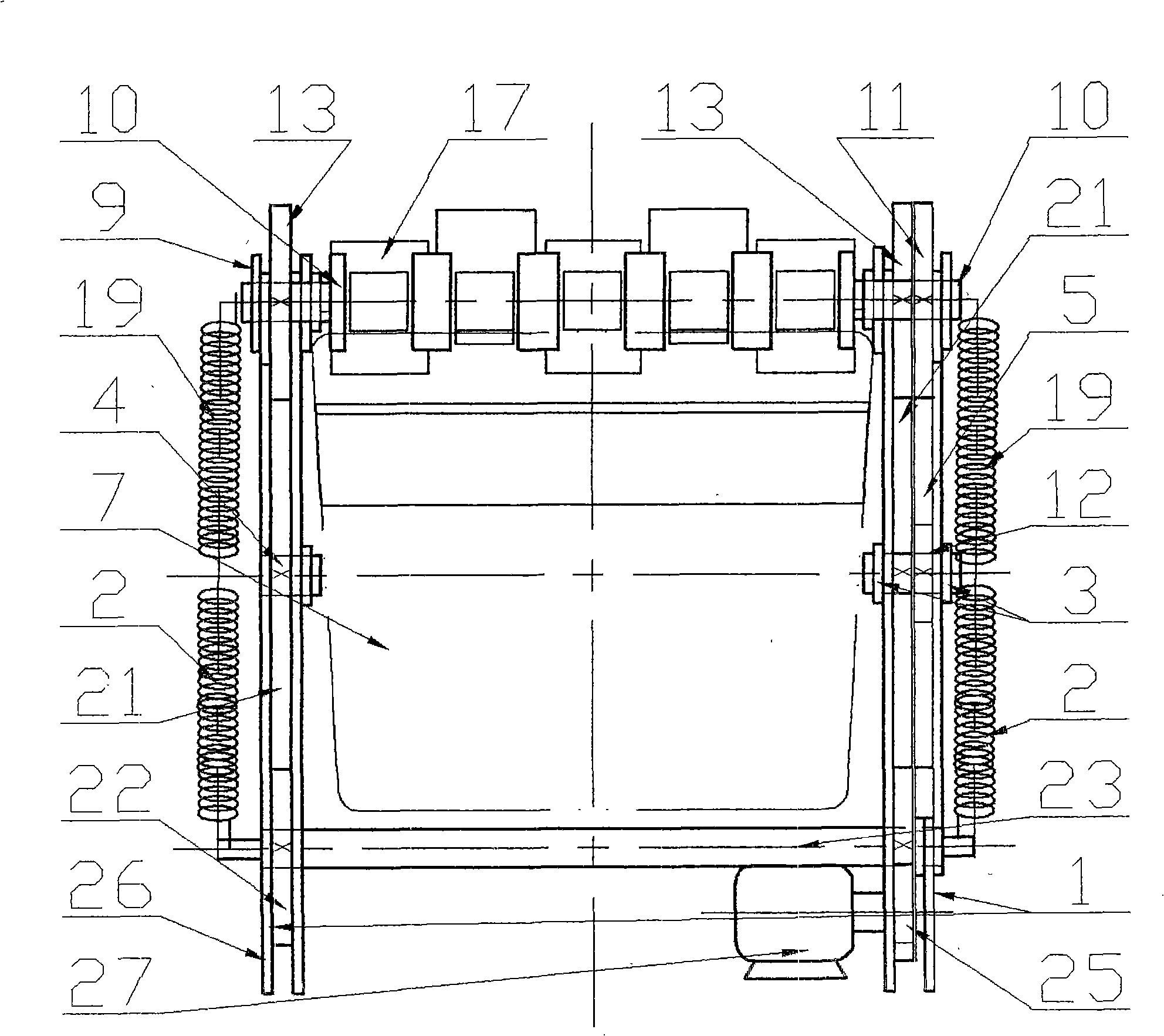

[0018] Firstly, the transmission system of the molding machine is described in Fig. 1. When the motor rotates, the motor gear 25 is driven to rotate to drive two coaxial transmission gears 22, and the two transmission gears 22 rotate to drive two variable speed gears 21; Gear 21 as an intermediate gear drives two synchronous gears 13, two synchronous gears 13 drive two eccentric wheels 15 through two synchronous gear shafts 14, and two eccentric wheels 15 pull two eccentric pull rods 28 to pull both ends of the crankshaft 10 for synchronization Horizontal translation, gear shift gear 21 and gear shift pinion 12 rotate synchronously, gear shift pinion drives transition gear 5 to do deceleration rotation, transition gear 5 transmits power to crankshaft gear 11, crankshaft gear 11 drives crankshaft 10 to rotate, because the rotation of crankshaft 10 makes The two sets of upper washboards 17 move up and down slowly alternately; all transmission pairs are connected by hinges to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com