Manual green tea processing technology

A processing technology, green tea technology, applied in the field of manual green tea processing technology, can solve the problems of not reaching the level of high-quality tea, weak bones, poor color, etc., to achieve strong bones, green color, and string tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

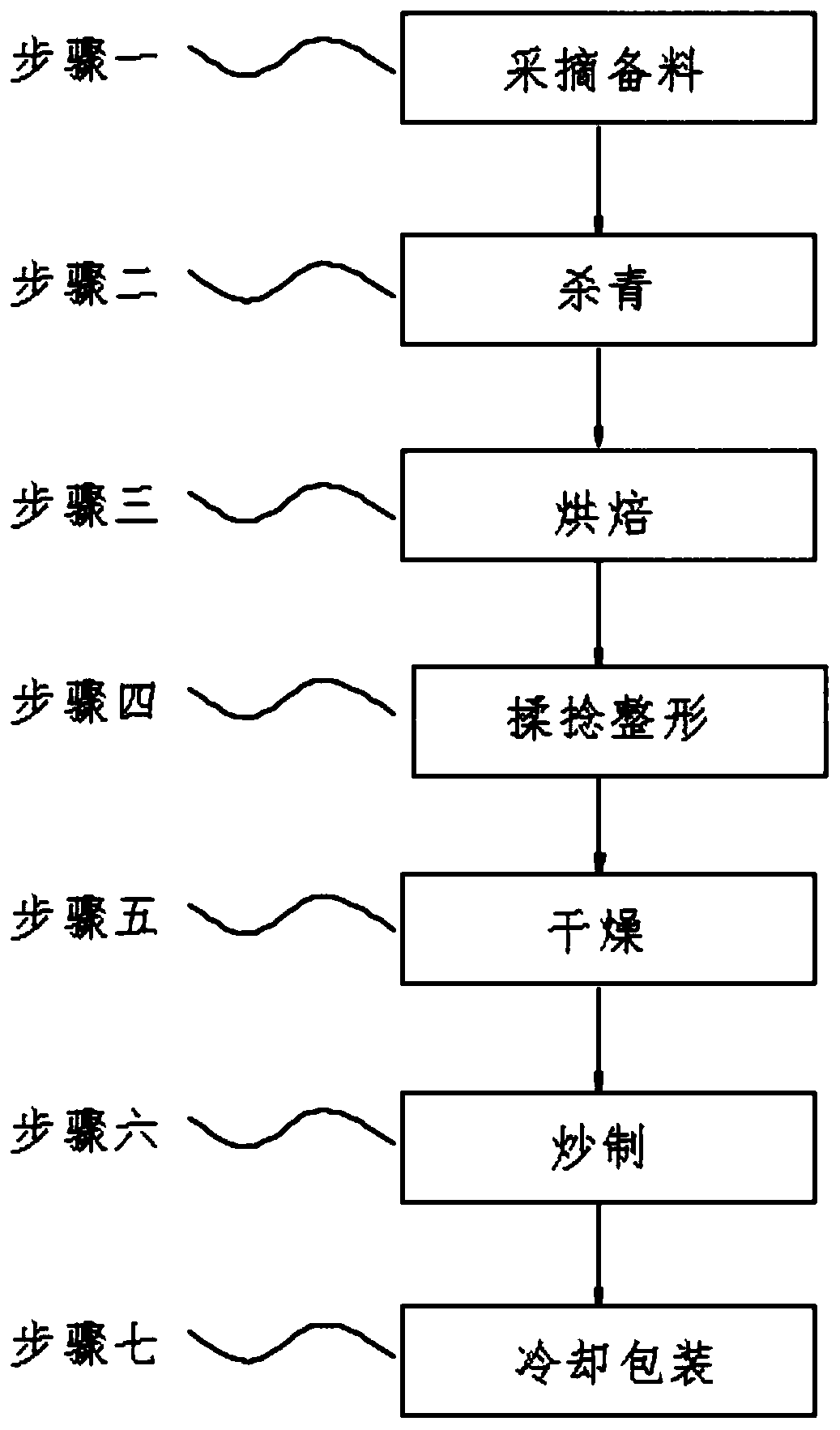

[0022] A handmade green tea processing technology, comprising the following steps: Step 1, picking and preparing materials; Step 2, curing; Step 3, baking; Step 4, kneading and shaping; Step 5, drying; Step 6, frying; Step 7, cooling and packaging:

[0023] Wherein in the above-mentioned step 1, the fresh leaves from after the vernal equinox to before the grain rain are picked, and the standard of fresh leaves is one bud and one leaf for the first time, and the buds and leaves of the fresh leaves have the same length and uniform size;

[0024] Wherein in the above-mentioned step 2, the fresh leaves are put into an electric frying pan with a temperature of 400° C. for the first greening to obtain fresh leaves with a water content of 40%. The time for greening is 3 minutes. The method of post-shaking;

[0025] In the above step three, after the tea leaves regain moisture, quickly increase the temperature of the roasting machine to 120°C, and after the tea leaves become soft, qui...

Embodiment 2

[0031] A handmade green tea processing technology, comprising the following steps: Step 1, picking and preparing materials; Step 2, curing; Step 3, baking; Step 4, kneading and shaping; Step 5, drying; Step 6, frying; Step 7, cooling and packaging:

[0032] Wherein in the above-mentioned step 1, the fresh leaves from after the vernal equinox to before the grain rain are picked, and the standard of fresh leaves is one bud and one leaf for the first time, and the buds and leaves of the fresh leaves have the same length and uniform size;

[0033] Wherein in the above-mentioned step 2, the fresh leaves are put into an electric frying pan with a temperature of 400° C. for the first greening to obtain fresh leaves with a water content of 40%. The time for greening is 3 minutes. The method of post-shaking;

[0034] In the above step three, after the tea leaves regain moisture, quickly raise the temperature of the roasting machine to 120°C, and after the tea leaves become soft, quickl...

Embodiment 3

[0040] A handmade green tea processing technology, comprising the following steps: Step 1, picking and preparing materials; Step 2, curing; Step 3, baking; Step 4, kneading and shaping; Step 5, drying; Step 6, frying; Step 7, cooling and packaging:

[0041] Wherein in the above-mentioned step 1, the fresh leaves from after the vernal equinox to before the grain rain are picked, and the standard of fresh leaves is one bud and one leaf for the first time, and the buds and leaves of the fresh leaves have the same length and uniform size;

[0042] Wherein in the above-mentioned step 2, the fresh leaves are put into an electric frying pan with a temperature of 400° C. for the first greening to obtain fresh leaves with a water content of 40%. The time for greening is 3 minutes. The method of post-shaking;

[0043] In the above step 3, after the tea leaves regain moisture, quickly increase the temperature of the roasting machine to 120°C, and after the tea leaves become soft, quickly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com