Rotary drum washing machine scouring barrel capable of forming compound solid current and scouring method

A pulsator washing machine and washing tub technology, applied in the field of washing tubs, can solve the problems of poor effect, high cost, insufficient washing, etc., achieve good washing effect and prevent partial washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

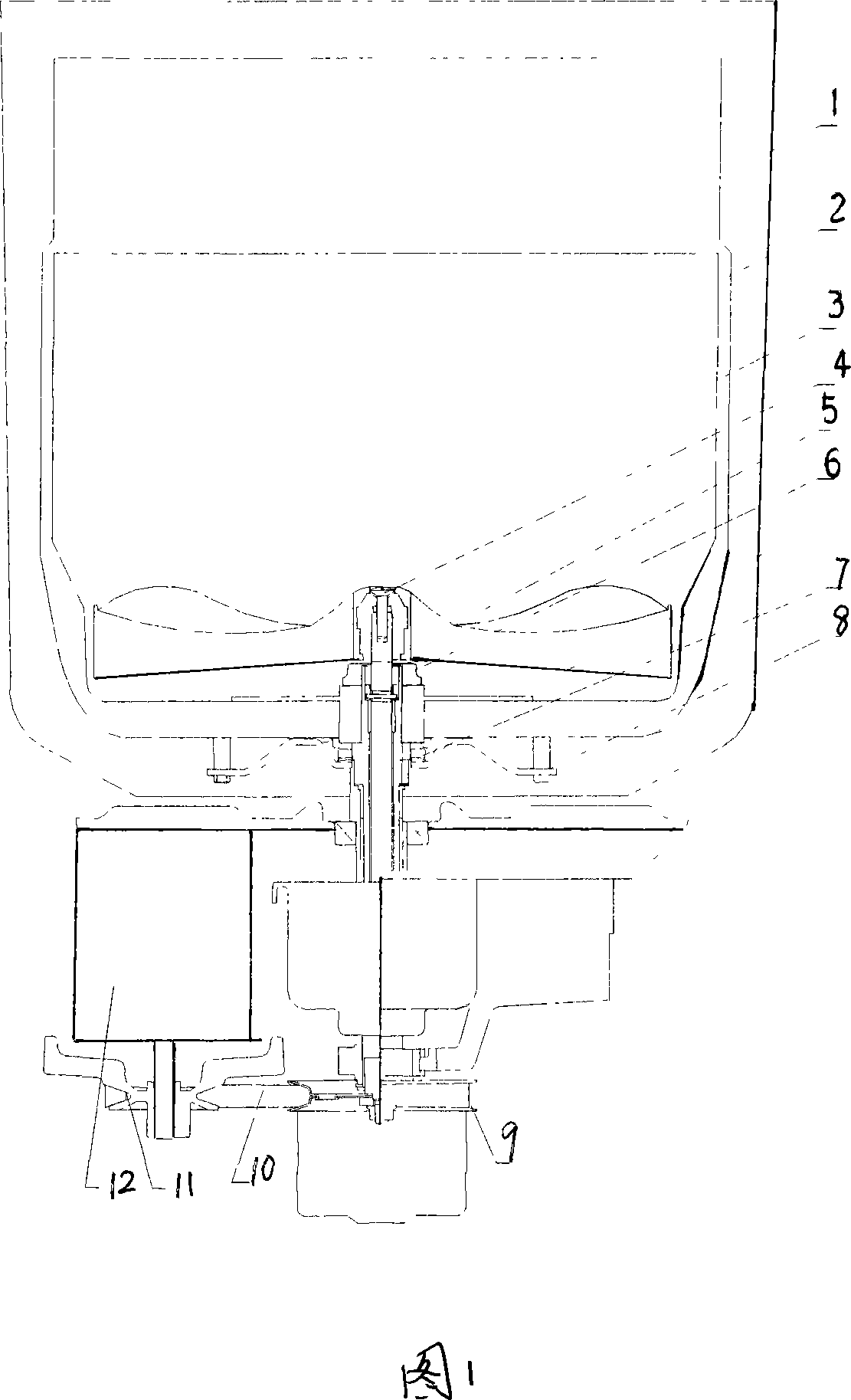

[0018] The structure of the washing bucket is shown in the accompanying drawings, 1. Water bucket; 2. Upper half washing bucket; 3. Lower half washing bucket; 4. Wave wheel screw; Fastening screw of the half washing bucket; 8. Flange of the upper half washing bucket; 9. Clutch of three output shafts; 10. Belt; 11. Pulley; 12. Motor.

[0019] In this invention, the clutch used in the upper half washing tub and the lower half washing tub is a three-output shaft clutch 9, which has three coaxial center shafts and axle sleeves, which are connected to the upper half washing tub by fastening screws 7 and the upper half washing tub respectively. The barrel 2 is connected; the lower half washing barrel is connected with the lower half washing barrel 3 through the fastening nut of the lower half washing barrel; Motor 12 is through belt pulley 11 and belt 10, and the input end of input three output shaft clutch 9, three output shaft clutches 9 output three powers, drive pulsator 5, uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com