Hand rubbing bionic mechanism

A two-handed, frame-based technology, applied to mechanical equipment, transmission devices, belts/chains/gears, etc., can solve the problems of high cost, complex structure, high cost, etc., and achieve wide popularization and use, high work reliability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

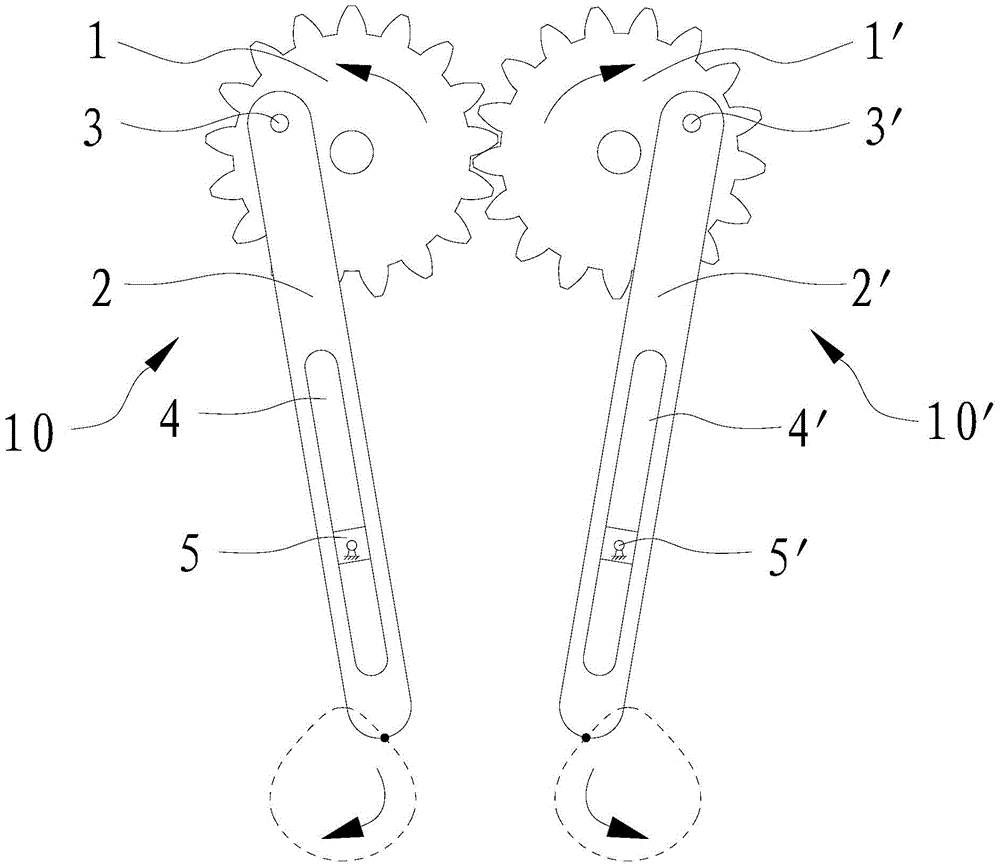

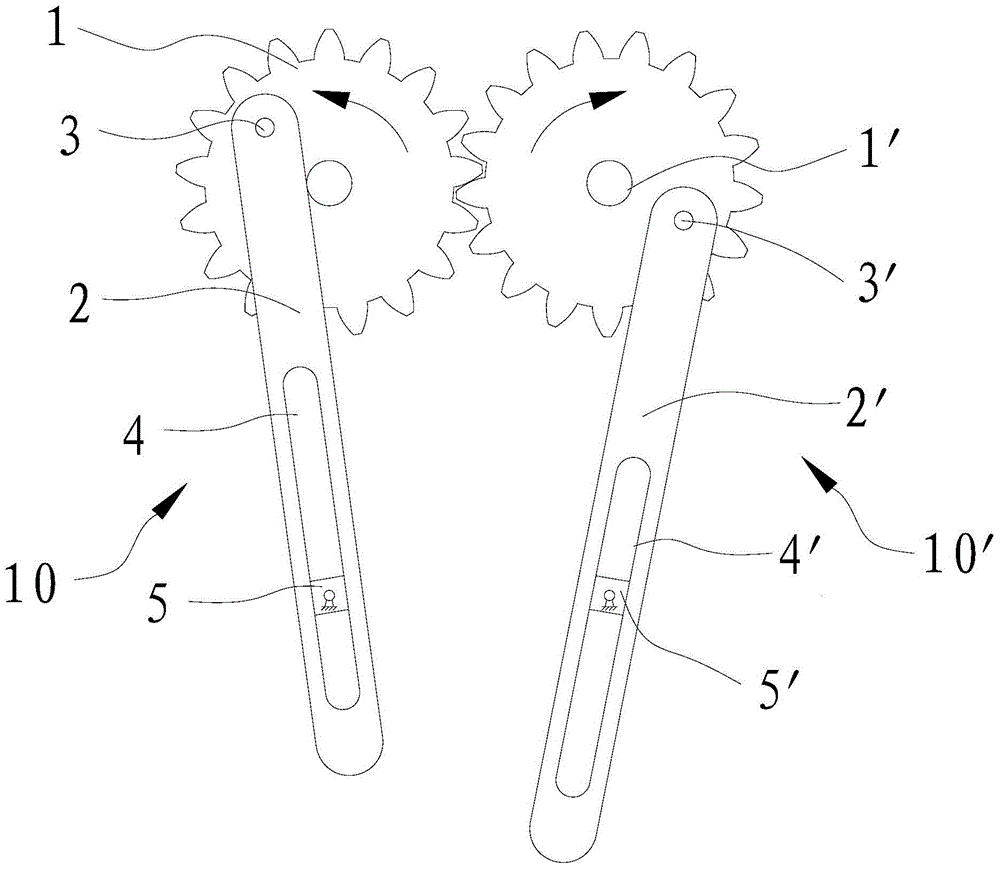

[0021] see picture 1 ,picture 2 The bionic mechanism for hands rubbing shown includes a frame (not shown in the figure), two sets of rubbing components arranged on the frame 10 、 10 ’。

[0022] kneading components 10 Consists of gears rotatably arranged on the frame around the axis 1 , through the pin 3 rotatably set on the gear 1 connecting rod 2 . gear 1 There is an eccentric pin hole on the top, the center line of the pin hole is parallel to the gear 1 axis, pin 3 one end connected to the connecting rod 2 The upper part, the other end of which is rotatably passed through the above-mentioned pin hole. link 2 There is a chute on the top 4 , the chute 4 along the connecting rod 2 Extending in the length direction, the frame is provided with a central hinge on the frame to provide linkage 2 guide slider 5 , the slider 5 The center position of the two axial ends of the hinge is hinged on the frame, and the slider 5 ...

Embodiment 2

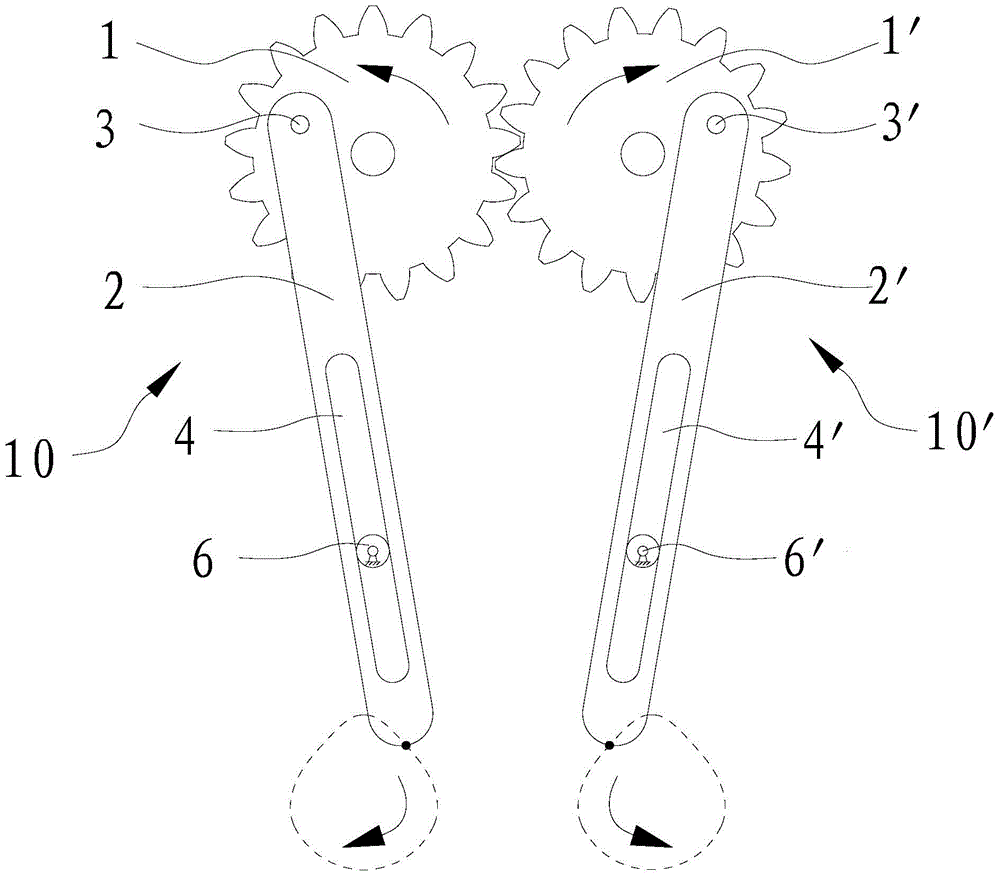

[0031] see picture 3 Shown both hands rubs the bionic mechanism, this bionic mechanism and embodiment 1 The difference is mainly in the provision of connecting rod 2 、 2 ’ Guided component settings. In this embodiment, a connecting rod is provided 2 、 2 ’ Guided parts are centrally fixed guides on the frame 6 、 6 ’, the guide 6 、 6 ’ respectively set in the chute with clearance fit 4 、 4 ’, the guide 6、 6 ’ up and chute 4 、 4 The circumferential outer surface matched with the groove wall in the length direction is a cylindrical surface, and the guide piece 6 、 6 ’ respectively with chute 4 、 4 ’ to form a plane high pair. When the external drive mechanism drives the gear 1 ,gear 1 ’ When one of the gears rotates, the connecting rod 2 、 2 ’ respectively on the pin 3 、 3 ’ under the action of the guide relative to the cylindrical outer surface 6 、 6 ’Does both linear motion and swing, so that the connecting rod 2 、 2 ’...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com