Process technique for threshing and redrying tobacco

A technology for tobacco leaf processing, threshing and redrying, which is applied in the fields of tobacco, tobacco preparation, and application. It can solve the problems of fluctuation in process quality, no means of material flow control, and large sorting area, so as to ensure consistency and uniformity. performance, solve the problem of water loss, uniform and stable material flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described by embodiment now.

[0022] 1. Basic data (taking 600,000 tons / year, or 30,000 tons / year as an example)

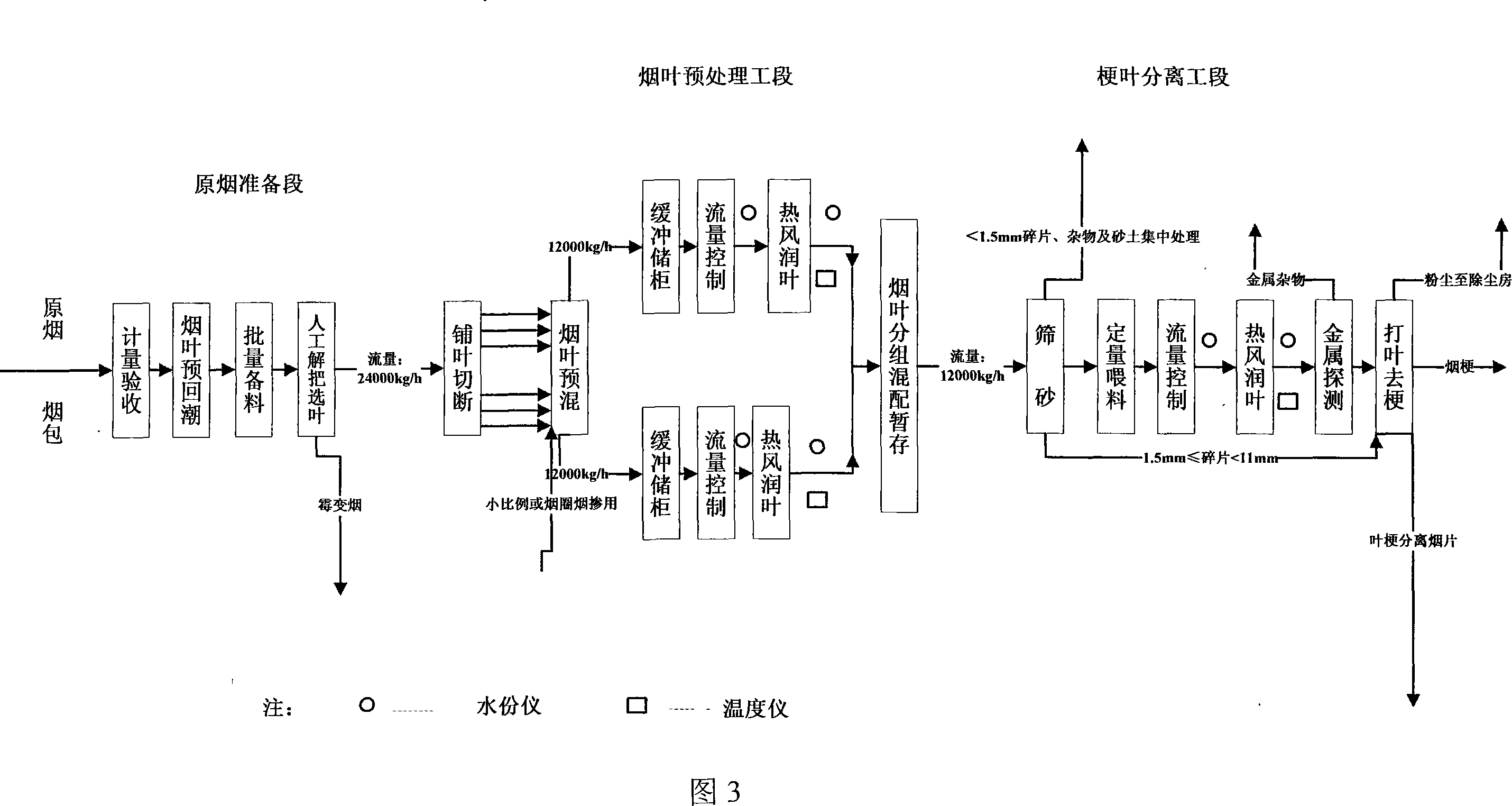

[0023] (1) Production shifts: leaf selection room and material preparation process, two shifts per day, 12 hours; leaf threshing and re-roasting production line, three shifts per day, 21 hours.

[0024] (2) Effective operating rate of leaf threshing and redrying production line: 0.75;

[0025] (3) Production scale: 600,000 tons / year (30,000t / y);

[0026] (4) Process production capacity:

[0027] a. Leaf selection and material preparation process: 24000kg / h

[0028] b. Threshing and redrying production line: 12000kg / h

[0029] Second, the characteristics of the process

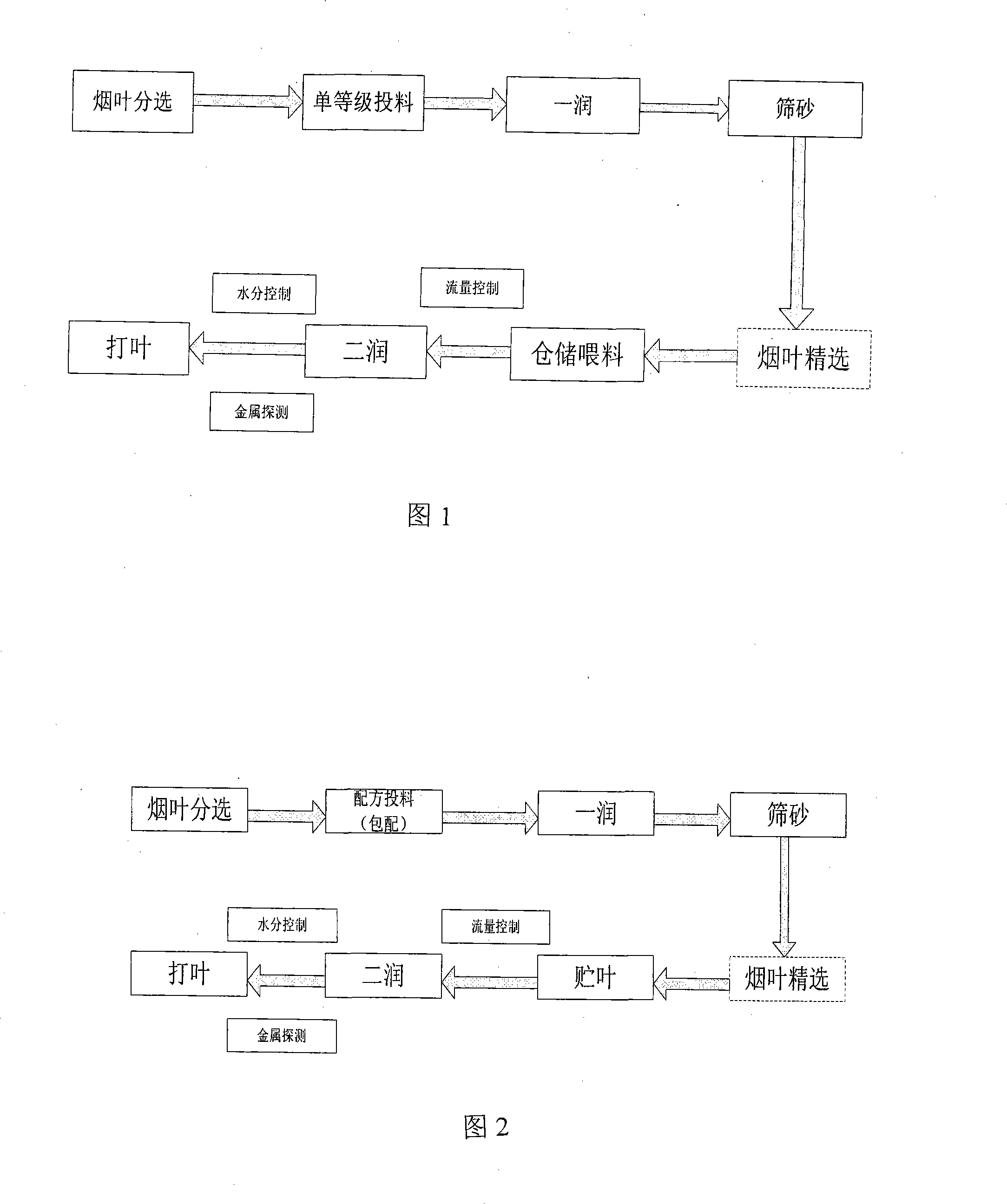

[0030] According to the characteristics of tobacco leaf quality, tobacco leaf thickness, tobacco leaf length, tobacco leaf toughness, etc., combined with the requirements of cigarette factories for the use of leaf quality, the tobacco leaves are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com