Vacuum adiabatic body and refrigerator

A technology of vacuum heat insulation and refrigerators, which is applied in household refrigerators, heat exchange equipment, lighting and heating equipment, etc. It can solve the problems of heat insulation of conduits, reduction of internal space of conduits, and increase of cold air loss, so as to promote expansion, Effect of reducing irreversible loss and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

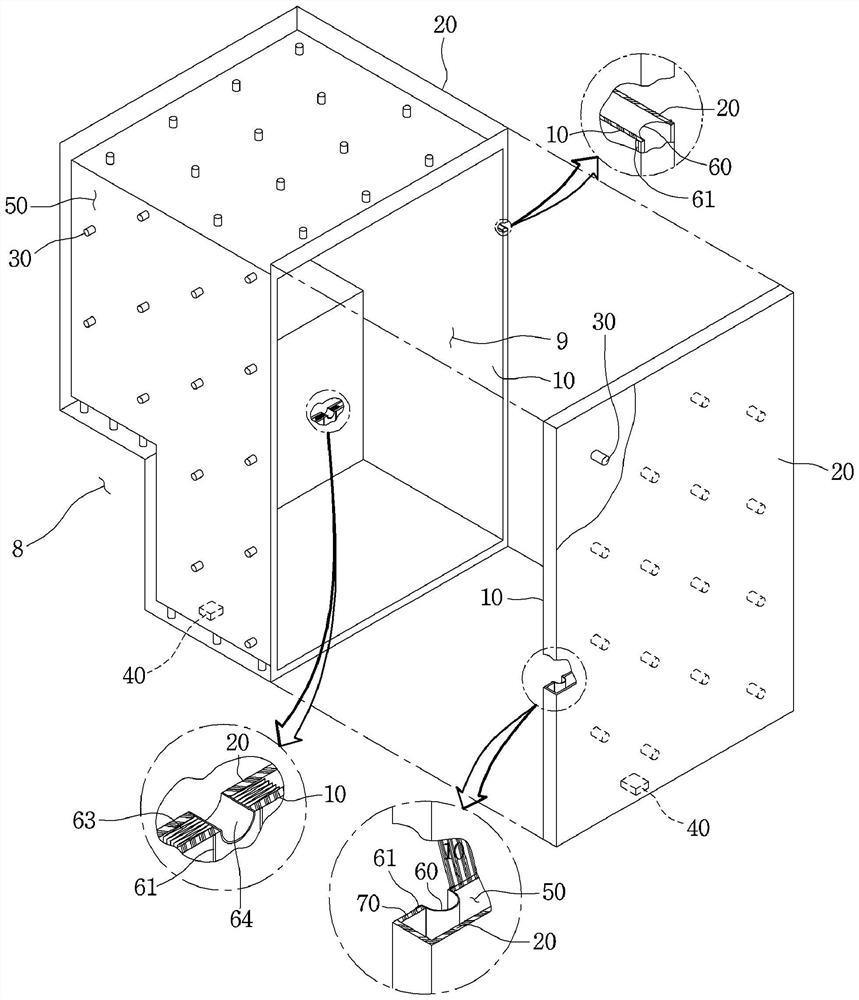

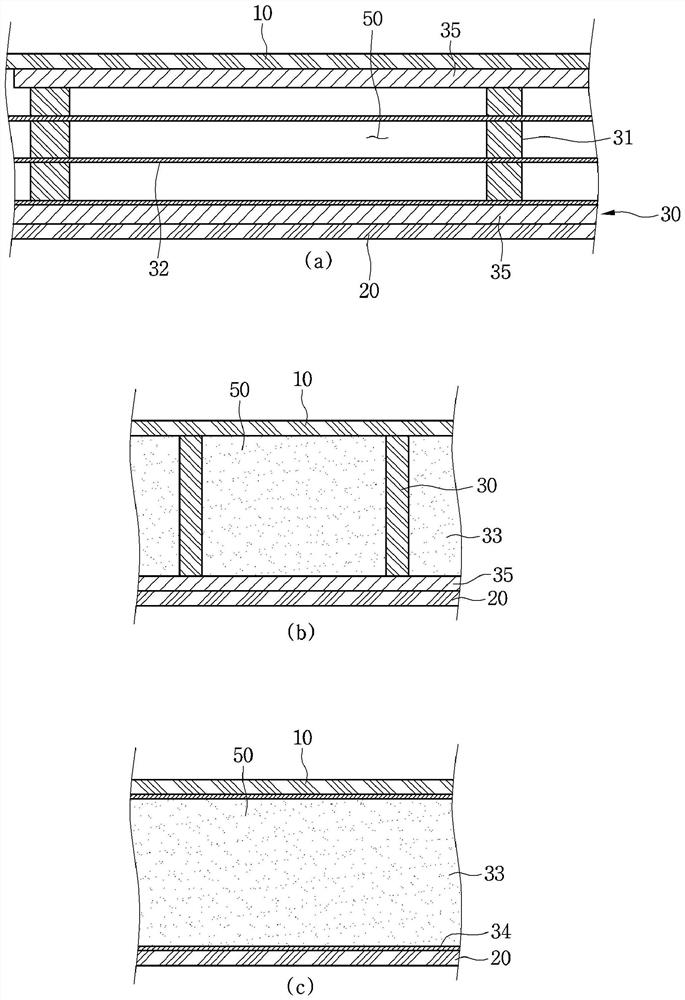

[0078] Hereinafter, exemplary embodiments will be described with reference to the accompanying drawings. However, the present invention can be embodied in many different forms and should not be construed as limited to the embodiments described herein, and those skilled in the art who understand the spirit of the present invention can easily make additions, changes, deletions and additions components to implement other embodiments included within the scope of the same concept; but it should be understood that they are also included within the scope of the present invention.

[0079] Hereinafter, in order to describe the embodiments, the drawings shown below may be shown differently from actual products, or exaggerated or simple or detailed parts may be deleted, but this is intended to facilitate understanding of the technical idea of the present invention. It should not be construed as limiting. However, it will try to display the actual shape as much as possible.

[0080] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com