Cutting tool

A cutting tool and tool technology, applied in the manufacture of tools, drilling accessories, turning equipment, etc., can solve the problems of difficult to ensure wall thickness and tool rigidity, and achieve good workability, improved loading and unloading operability and eccentric adjustment Accuracy and improved workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

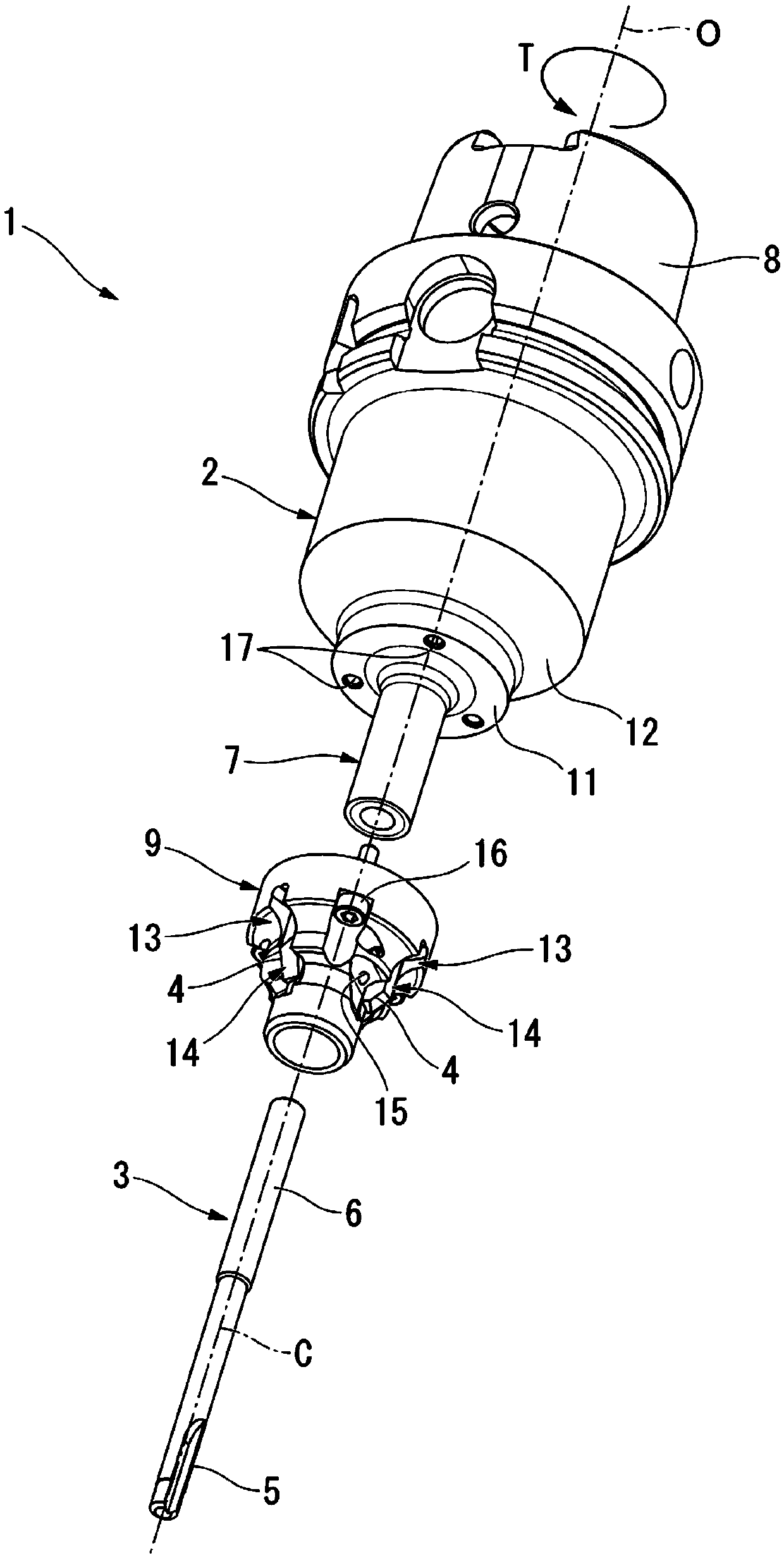

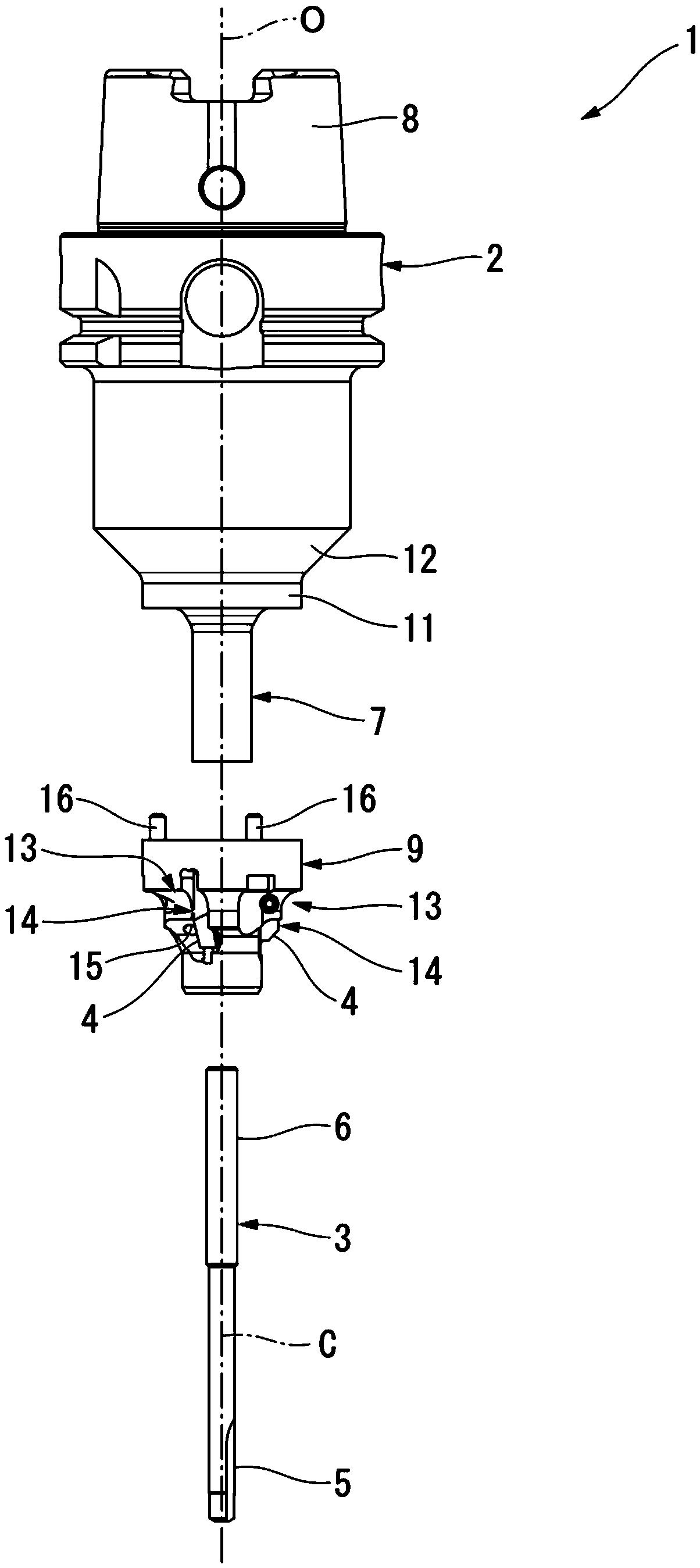

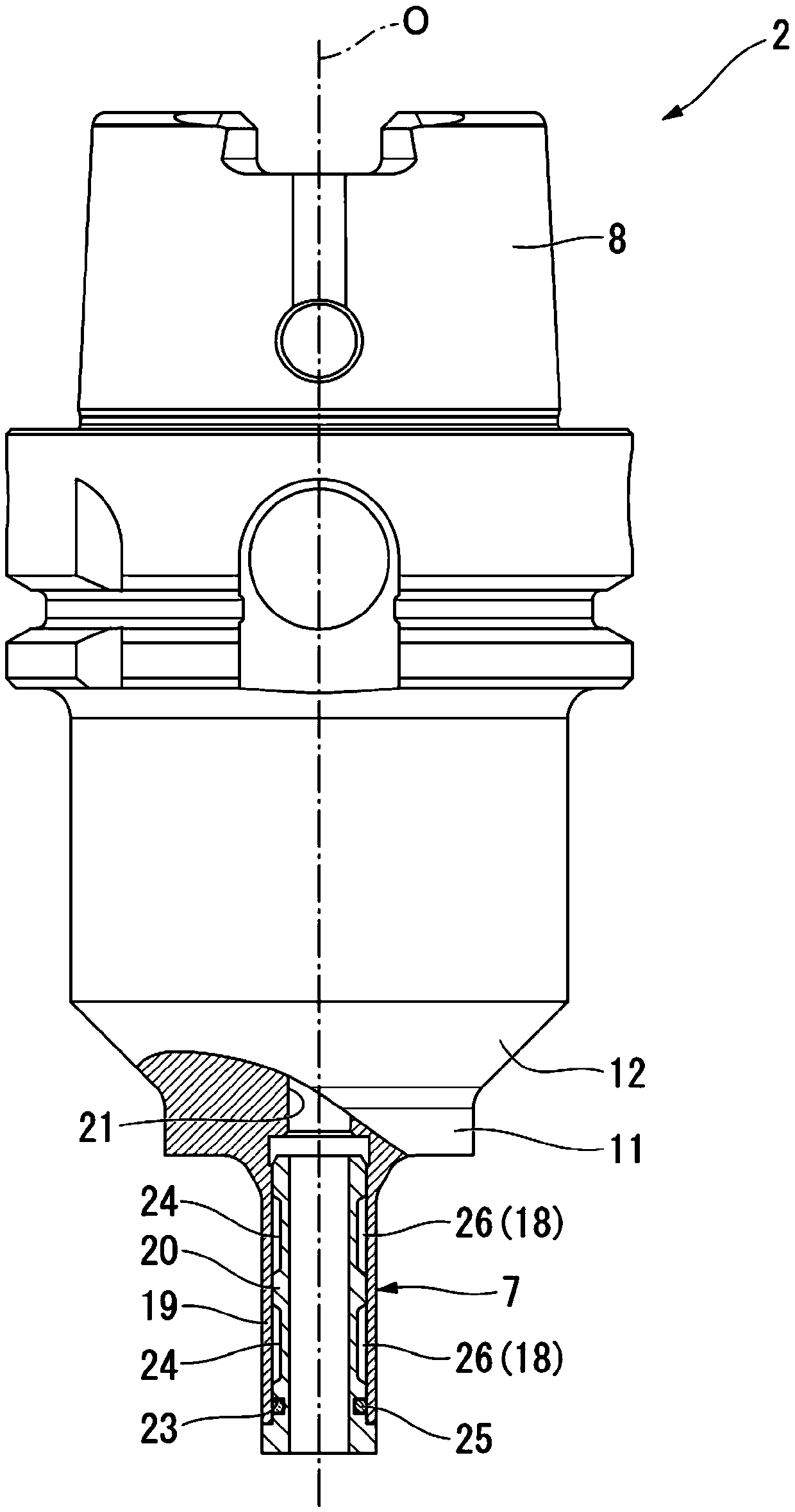

[0042] Hereinafter, a cutting tool 1 according to an embodiment of the present invention will be described with reference to the drawings.

[0043] The cutting tool 1 according to the present embodiment performs hole machining on a workpiece material with a reamer (hole machining tool) 3 extending along the axis O of the tool body 2, and a pair of cutting edges 4 provided on the outer periphery of the front end portion of the head 9. The opening of the machining hole of the workpiece material to be machined is cut. A so-called valve dresser, which is an example of such a cutting tool, performs finishing machining of a valve stem guide hole and machining of a valve seat in a cylinder head of a four-stroke engine coaxially in the same cutting process.

[0044] Such as Figure 1 to Figure 4 As shown, this cutting tool 1 has: a reamer 3 as a shaft-shaped hole machining tool extending along a central axis C; a tool body 2 that rotates around an axis O; and a cylindrical head 9 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com