Multi-material building three-dimensional printing and molding method

A technology of three-dimensional printing and molding method, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of low molding precision, weak strength, slow molding speed, etc., and achieve the effect of wide application prospect and comprehensive performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The specific process of using 3D printing to produce multi-material buildings that contain multiple independent distributions is as follows:

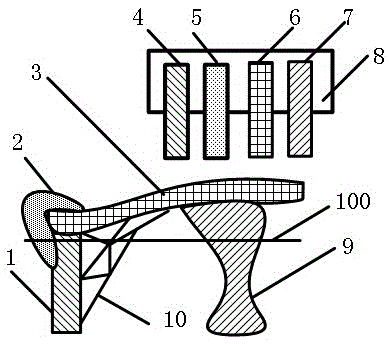

[0044] Establish its 3D CAD solid model based on the pre-printed multi-material building, which includes four molding materials, namely concrete 1, wood-plastic 2, plastic 3 and plaster 9; for the building model 3 is a cantilevered structure, The corresponding supporting structures 9 and 10 are designed and generated in the computer, 9 of which will be retained after printing is completed, and 10 will be dismantled after printing; the materials used in this multi-material building have their obvious material interfaces with each other, and have their own The respective material properties; the computer slices the 3D CAD solid model including the support structure, and obtains the structural information, material information and motion trajectory of the solid part and support part of each layer; during the printing process of each ...

Embodiment 2

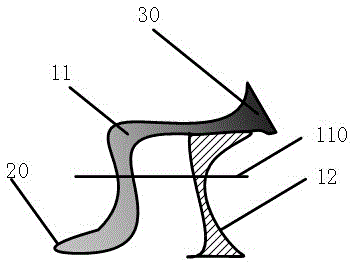

[0046] The present invention can also print buildings containing organic mixtures of various materials, the following examples combine image 3 and Figure 4 Be explained.

[0047] Establish its three-dimensional CAD solid model according to the pre-printed multi-material building, the solid model includes three kinds of molding materials, respectively wood 20, plastic 30 and plaster 12, wood 20 and plastic 30 are the solid parts of the building, and gypsum 12 is The supporting part of the building also plays a decorative role, and will not be dismantled after printing is completed; the solid part of the building is organically composed of two materials: wood 20 and plastic 30, the bottom is nearly 100% wood, and the top is nearly 100% plastic , the middle part is the wood-plastic material mixed in different proportions; when printing a certain layer 110 of the building, this layer includes two parts 111 and 112, of which 111 is wood 20 and plastic 30 in a certain proportion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com