Method for extracting vanadium from vanadium slag through blank roasting and quaternarization

A technology of blank roasting and vanadium slag, applied in the field of vanadium chemical metallurgy, to achieve the effect of reducing consumption, high heat transfer efficiency, and improving vanadium conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

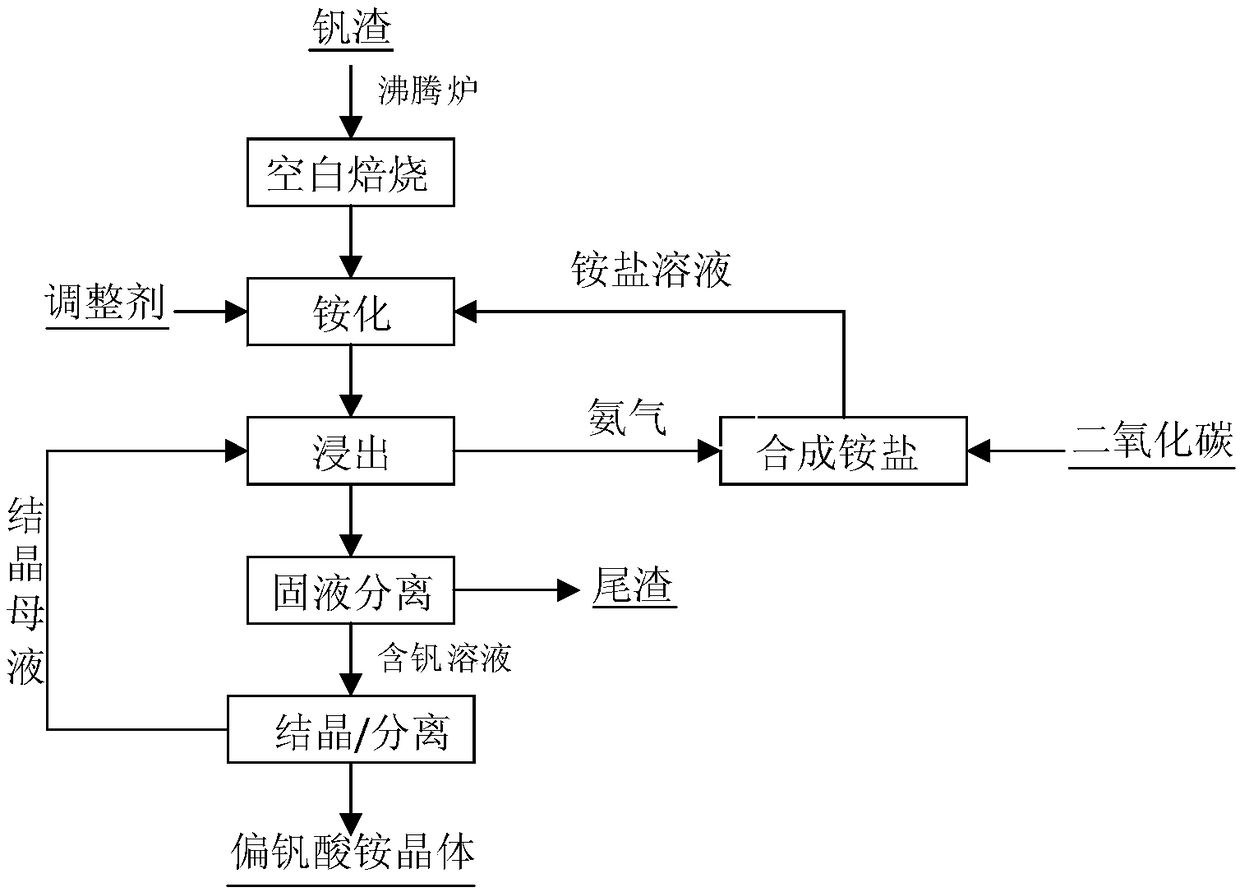

Image

Examples

Embodiment 1

[0052] (1) Add 1 kg of vanadium slag with a particle size of 100-200 mesh into the fluidized fluidized furnace, and control the blast volume of the fluidized fluidized furnace to 4Nm 3 / h (under standard conditions), the air flow rate is 1.0m / s, and the temperature is raised to 900°C for blank roasting for 0.4h, and the roasted clinker is naturally cooled in the air;

[0053] (2) add ammonium bicarbonate solution in the roasting clinker that step (1) obtains and carry out ammonization, add the sodium carbonate regulator of vanadium slag quality 3% simultaneously, the concentration of control ammonium bicarbonate solution is 50wt%, and temperature is 50 ℃, the liquid-solid ratio of solution and roasted clinker is 0.4:1, and the ammonization time is 3h;

[0054] (3) After the ammonization reaction is completed, add hot liquid to the mixed material for leaching, and leaching at 90°C for 3 hours. The ammonia gas and carbon dioxide generated during leaching will synthesize ammonium...

Embodiment 2

[0058] (1) Add 0.1kg of vanadium slag with a particle size of 150-200 mesh into the fluidized fluidized furnace, and control the blast volume of the fluidized fluidized furnace to 1Nm 3 / h (under standard conditions), the air flow rate is 1.8m / s, and the temperature is raised to 800°C for blank roasting for 0.45h, and the roasted clinker is naturally cooled in the air;

[0059] (2) add ammonium bicarbonate solution in the roasting clinker that step (1) obtains and carry out ammonization, add the sodium carbonate regulator of vanadium slag quality 2% simultaneously, the concentration of control ammonium bicarbonate solution is 30wt%, and temperature is 40 ℃, the liquid-solid ratio of solution and roasted clinker is 0.4:1, and the ammonization time is 1h;

[0060] (3) After the ammonization reaction is completed, add hot liquid to the mixed material for leaching, and leaching at 80°C for 2.5 hours. The ammonia gas and carbon dioxide generated during leaching will synthesize ammo...

Embodiment 3

[0064] (1) Add 0.5kg of vanadium slag with a particle size of 100-150 mesh into the fluidized fluidized furnace, and control the blast volume of the fluidized fluidized furnace to 2Nm 3 / h (under standard conditions), the air flow rate is 0.8m / s, and the temperature is raised to 950°C for blank roasting for 0.2h, and the roasted clinker is naturally cooled in the air;

[0065] (2) add ammonium bicarbonate solution in the roasting clinker that step (1) obtains and carry out ammonization, add the sodium carbonate regulator of vanadium slag quality 5% simultaneously, the concentration of control ammonium bicarbonate solution is 45wt%, and temperature is 60 ℃, the liquid-solid ratio of solution and roasted clinker is 0.2:1, and the ammonization time is 1h;

[0066] (3) After the ammonization reaction is completed, add hot liquid to the mixed material for leaching, and leaching at 90°C for 1 hour. The ammonia gas and carbon dioxide generated during leaching will synthesize ammonium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com