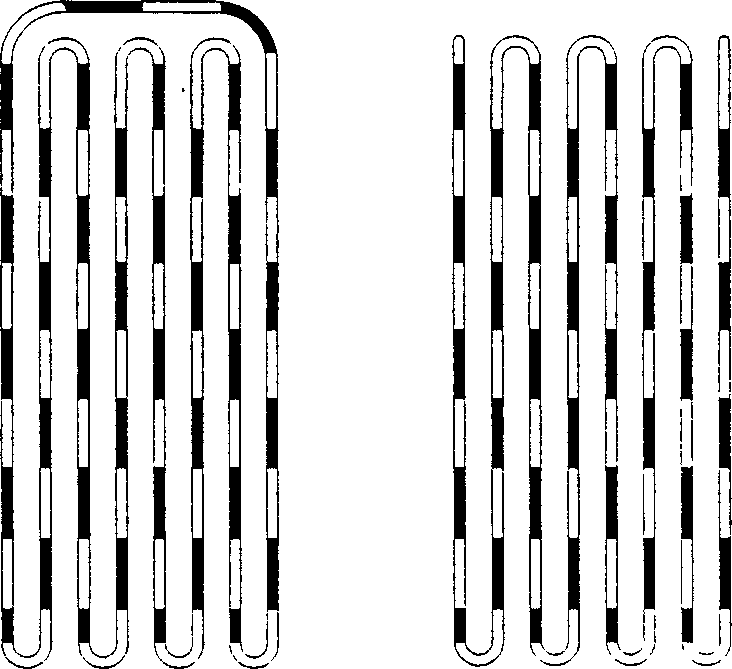

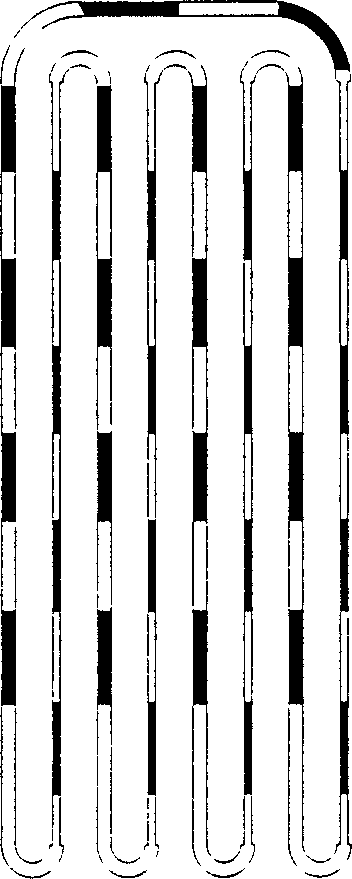

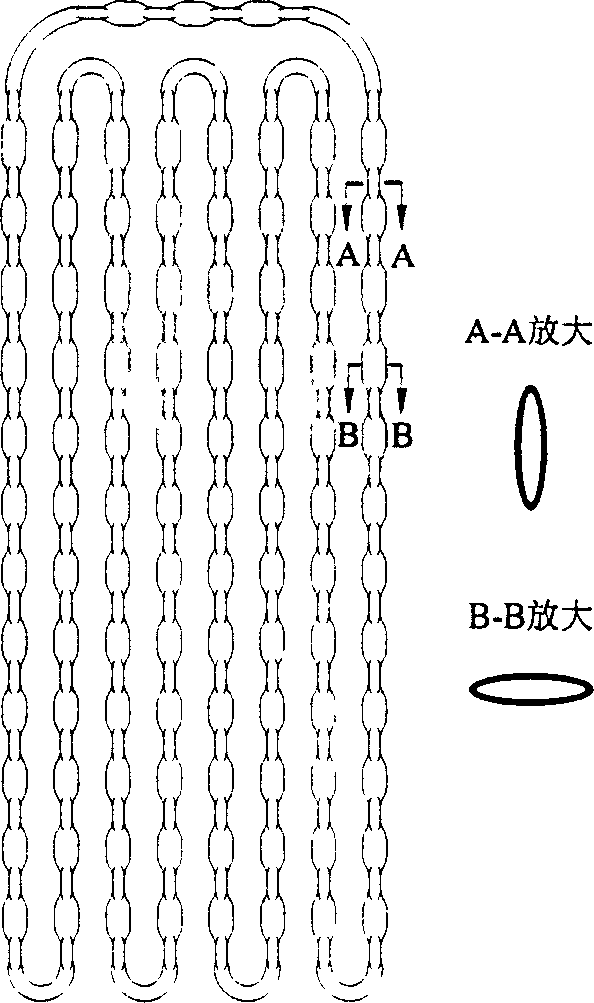

Heat transfer process for variable cross section intensive selfoscillatory flow heat pipe

A self-excited oscillation and variable section technology, which is applied in the field of heat exchange to achieve the effects of high heat transfer efficiency, easy processing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The two end regions of the variable cross-section self-excited oscillating flow heat pipe are in contact with the cold source and the heat source respectively. If the cold and heat sources are solid, the ends should be closely attached to the solid surface or embedded in the solid interior; if the cold and heat sources are gas or liquid, the end should be immersed in the fluid, and the contact area between the cold and heat source and the heat pipe is determined according to the amount of heat exchange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com