Radiating device for LED lamp and radiator component

A technology of LED lamps and heat sinks, which is applied to cooling/heating devices, lighting devices, electric solid-state devices and other directions of lighting devices, can solve problems such as poor light concentration, weakened luminous efficiency, and unsolvable heat dissipation problems, and achieves heat transfer. High efficiency, saving development costs, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

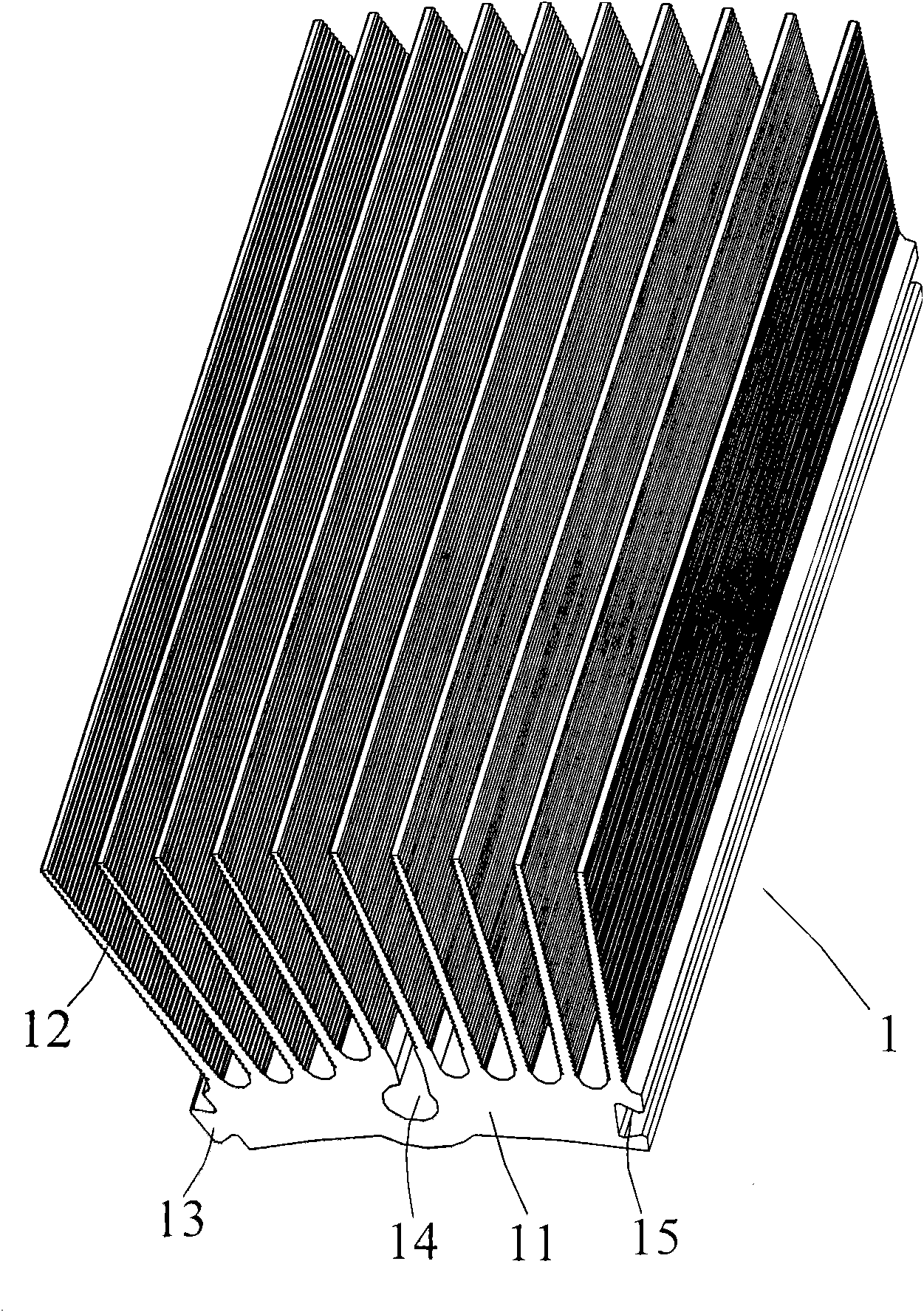

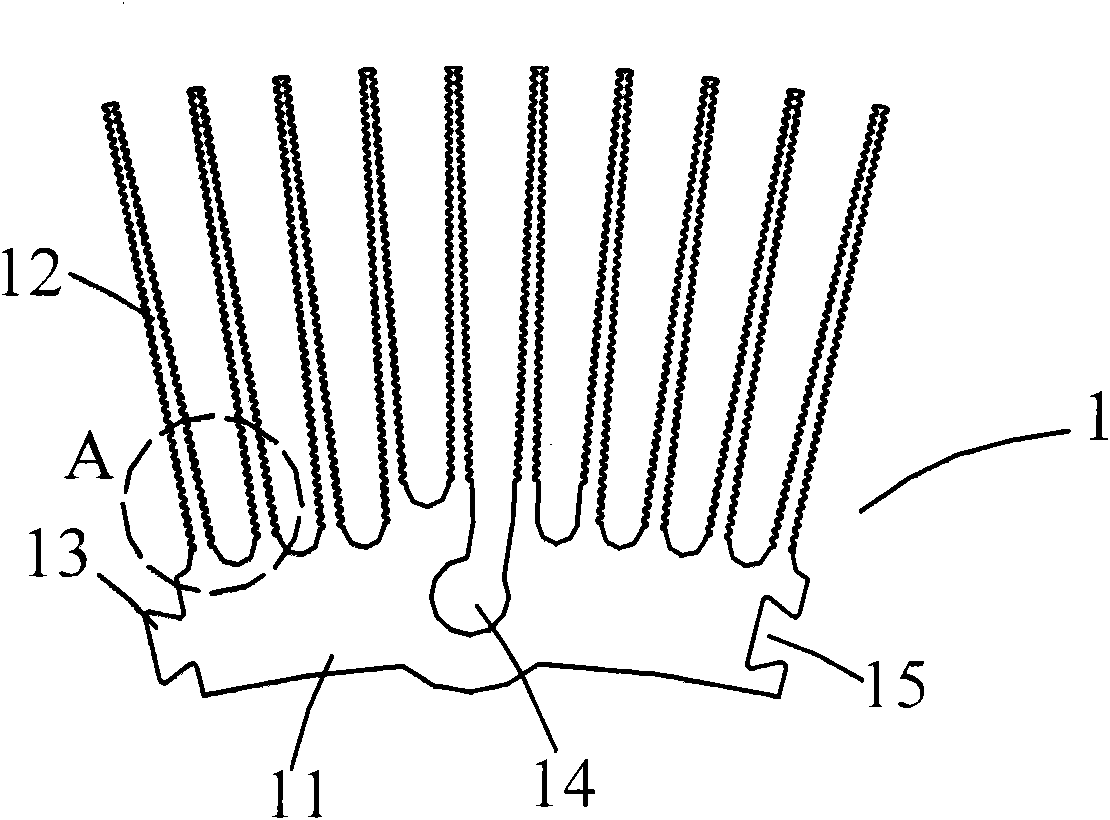

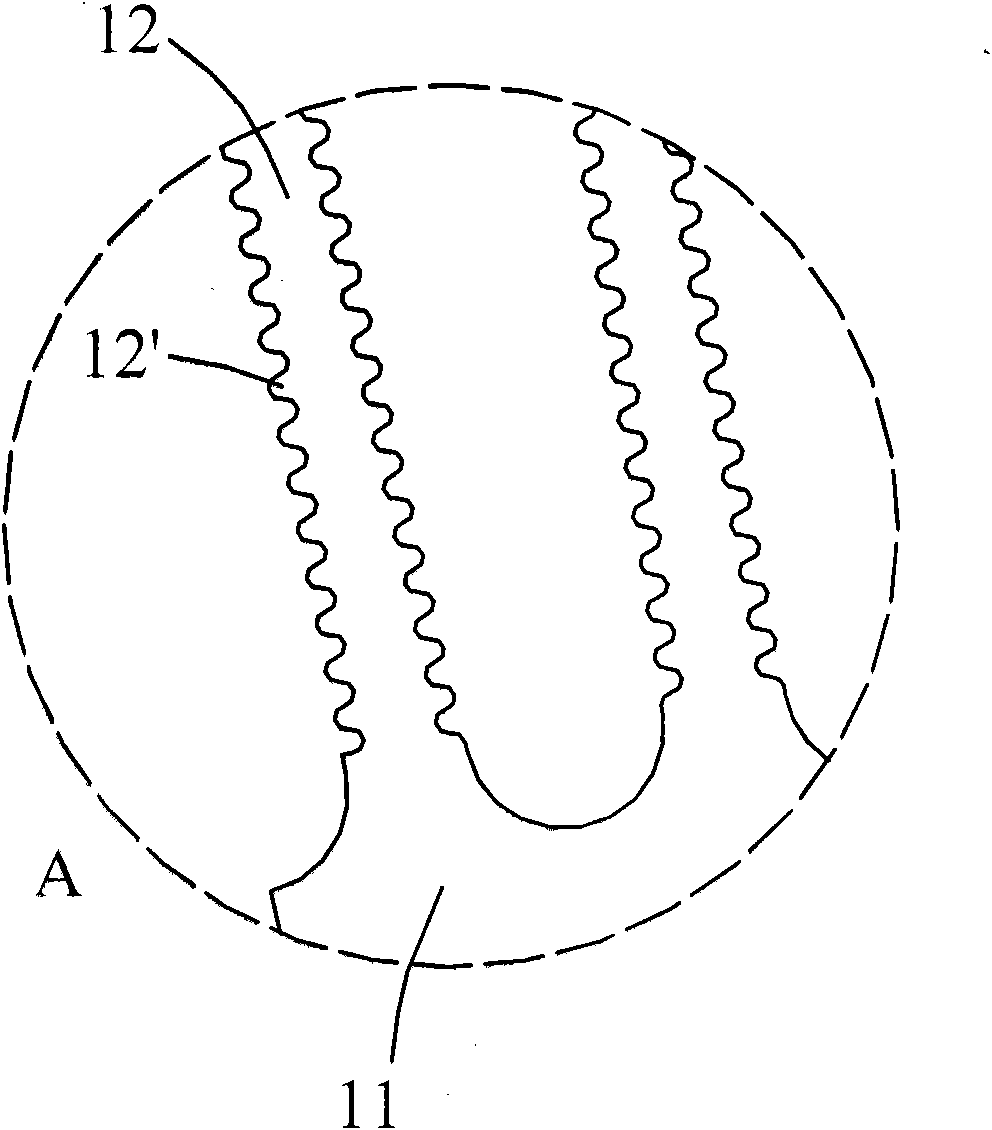

[0029] refer to Figure 1-3 The heat sink component 1 used for LED lamps comprises an arc-shaped plate 11, the outer arc surface of the arc-shaped plate 11 extends outwards a number of spaced cooling fins 12, and a longitudinal end surface of the arc-shaped plate 11 is longitudinally provided with connecting grooves 15, The other longitudinal end face is longitudinally provided with connecting protrusions 13, and at least one heat pipe installation hole 14 is established on the arc-shaped plate 11 along the direction of the connecting groove 15 (ie longitudinally); the bottom of the heat sink 12 is thick, the top is thin, and The surface is covered with protrusions 12'.

[0030] The section of the connecting protrusion 13 of the arc-shaped plate 11 is trapezoidal, and the connecting groove 15 of the arc-shaped plate 11 is a trapezoidal groove, and the size of the trapezoidal groove matches the size of the connecting protrusion 13 . In practical application, the connecting pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com