Hydraulic control system for viscosity speed regulation clutch

A hydraulic control system and clutch technology, applied in clutches, fluid clutches, mechanical equipment, etc., can solve problems such as unfavorable operation and maintenance, large resistance loss of coolers, and oil-water mixing of fluid-viscous speed-regulating clutches. The effect of operation operation and maintenance operation, improving operation reliability and improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

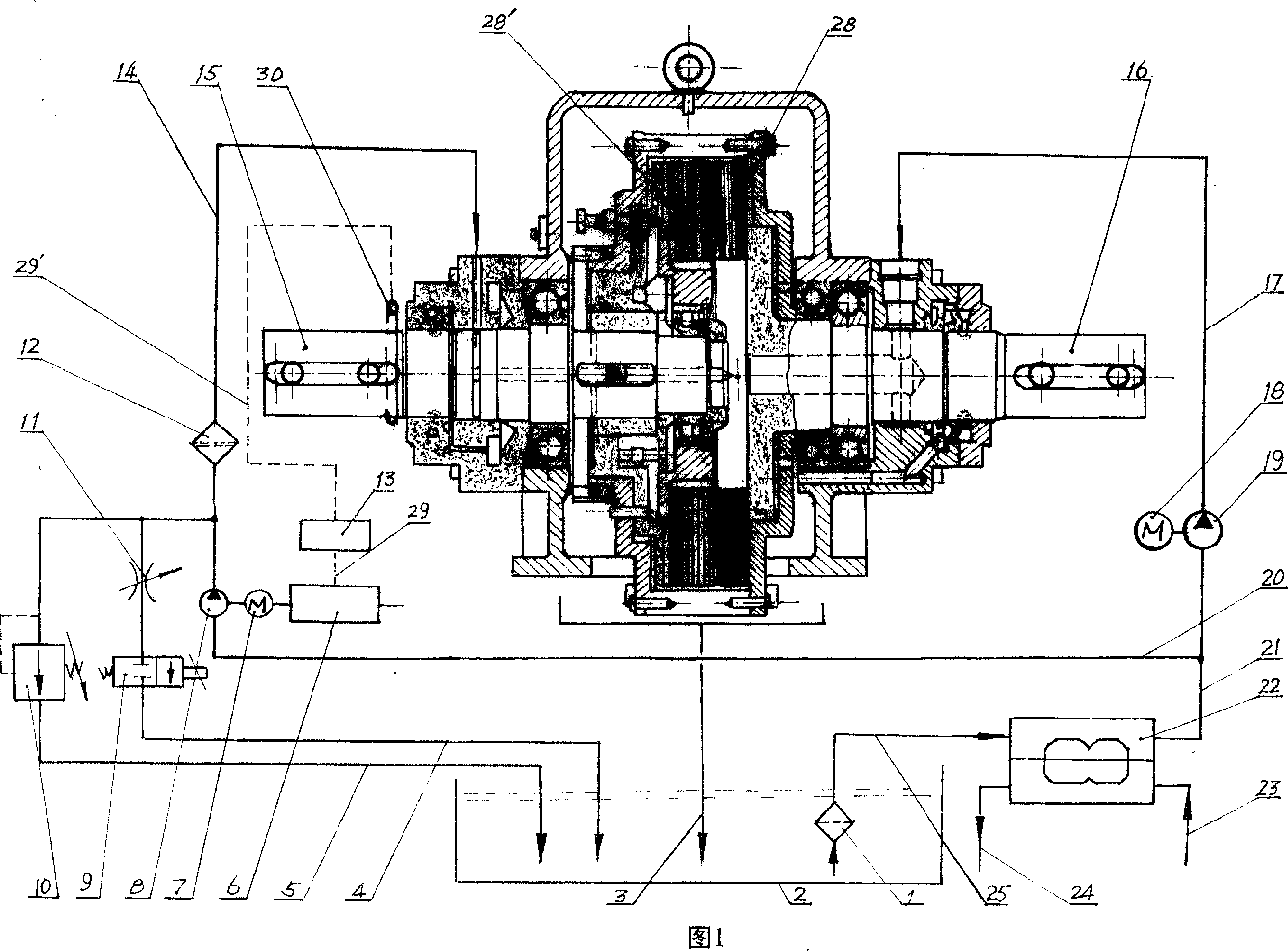

[0017] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0018] For the sake of clarity, the main engine of the clutch related to the new hydraulic control system of the fluid-viscous speed-adjusting clutch is also marked in Fig. 1 . The driving shaft 16 of the clutch main frame is connected with the shaft of the corresponding motor, and the rotating speed of the driving shaft 16 is equal to the rotating speed of the connected motor, which is constant, while the driven shaft 15 of the clutch main machine is connected to the working machine (such as fan, water pump, or other large industrial equipment, etc.), the rotating speed of the driven shaft 15 is determined according to the required rotating speed of the working machine in a certain period of time, so the rotating speed of the driven shaft 15 changes. The driving shaft 16 is connected with the active friction plate 28, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com