Plate-type pulsating heat pipe used in large power LED heat radiation

A pulsating heat pipe, high-power technology, used in indirect heat exchangers, lighting and heating equipment, semiconductor devices of light-emitting elements, etc., can solve the problems of unstable temperature fluctuations in the evaporation section, difficult working cycle stability, and local temperature rises. , to achieve the effect of enhancing startup performance and heat transfer efficiency, improving work reliability, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

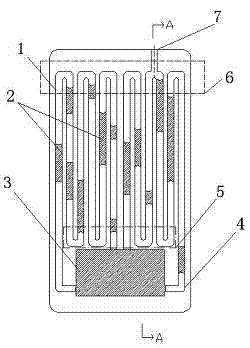

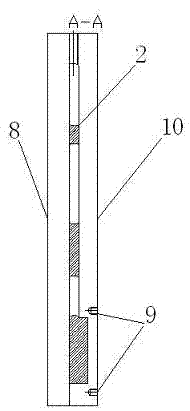

[0027] The structure of the present invention includes: a cover plate, a base plate, a capillary bundle, a liquid plug, a cavity, a lower elbow group of the capillary bundle, an upper elbow group of the capillary bundle, a liquid filling port, and an LED chip mounting screw hole;

[0028] A capillary bundle, a cavity communicating with the lower part of the capillary bundle, and a liquid filling port located at the upper part of the capillary bundle and communicating with the capillary bundle are milled out on the substrate. The cross-section of the capillary is rectangular or triangular. The cavity is connected, and the connection position is asymmetrical. The base plate and the cover plate are connected by vacuum brazing. The liquid filling port is installed with a valve to form a sealed space that can form a vacuum environment. The mounting screw hole is connected to an external LED chip. channel structure;

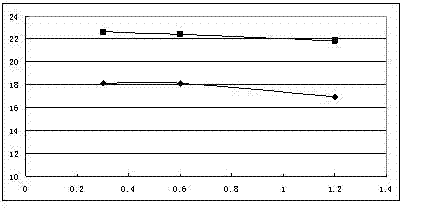

[0029] The equivalent diameter of the capillary adopted by the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com