Two-stage down-suction biomass gasifier

A gasifier and biomass technology, which is applied in the gasification process, details of gasification devices, chemical industry, etc., can solve the problems of incomplete activation of coke reactivity, low conversion rate of carbon elements, unfavorable removal of tar, etc. The effect of fast reaction, sufficient tar conversion and low tar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

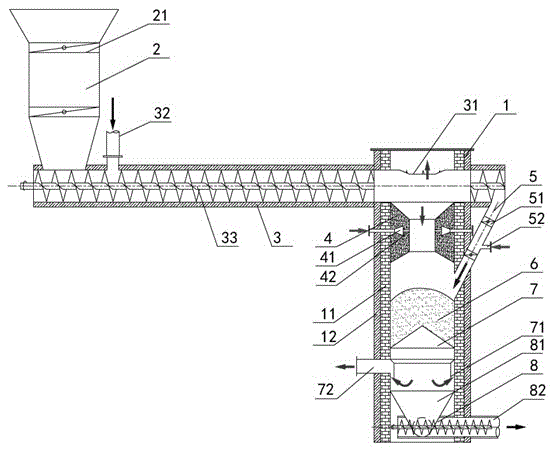

[0020] The following is attached figure 1 The present invention will be further described with examples.

[0021] like figure 1 As shown, the double-stage downdraft biomass gasifier of the present invention mainly consists of a gasification furnace body 1, a furnace wall 11, an insulation layer 12, a feed hopper 2, a gate valve 21, a pyrolysis cylinder 3, and a pyrolysis gas Outlet 31, ash return inlet 32, feed auger 33, concrete throat 4, gas buffer chamber 41, nozzle 42, ash fall pipe 5, ash fall pipe cut-off gate valve 51, ash fall pipe air inlet 52, accumulated ash carbon layer 6. Ash removal grate 7, ash retaining ring 71, gasification gas outlet 72, ash removal device 8, ash collection hopper 81, ash discharge auger 82 and other structures and units.

[0022] The upper part of the gasification furnace body 1 is connected with a pyrolysis cylinder 3, and the pyrolysis cylinder 3 is equipped with a feed auger 33, and the pyrolysis cylinder 3 located in the gasification f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com