Heat dissipation device and system for blade server chip

A blade server and heat dissipation device technology, applied in the field of computer room heat dissipation, can solve the problems of huge auxiliary supporting systems, limited heat dissipation efficiency, and cumbersome maintenance in the later stage, and achieve improved space utilization, strong heat dissipation and temperature control capabilities, and reduced thickness and volume. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the public implementation manners of the present invention in detail with reference to the accompanying drawings.

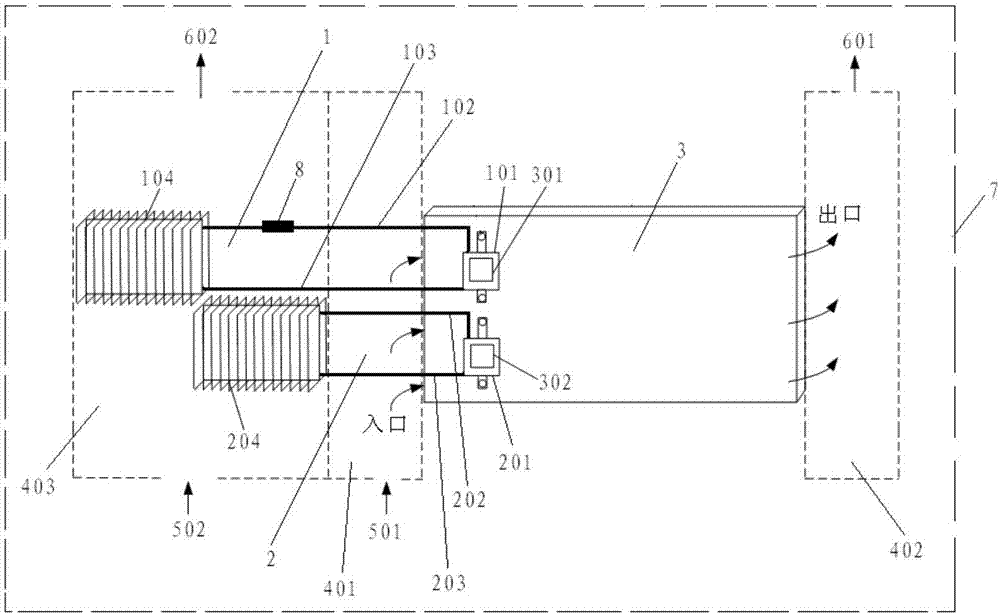

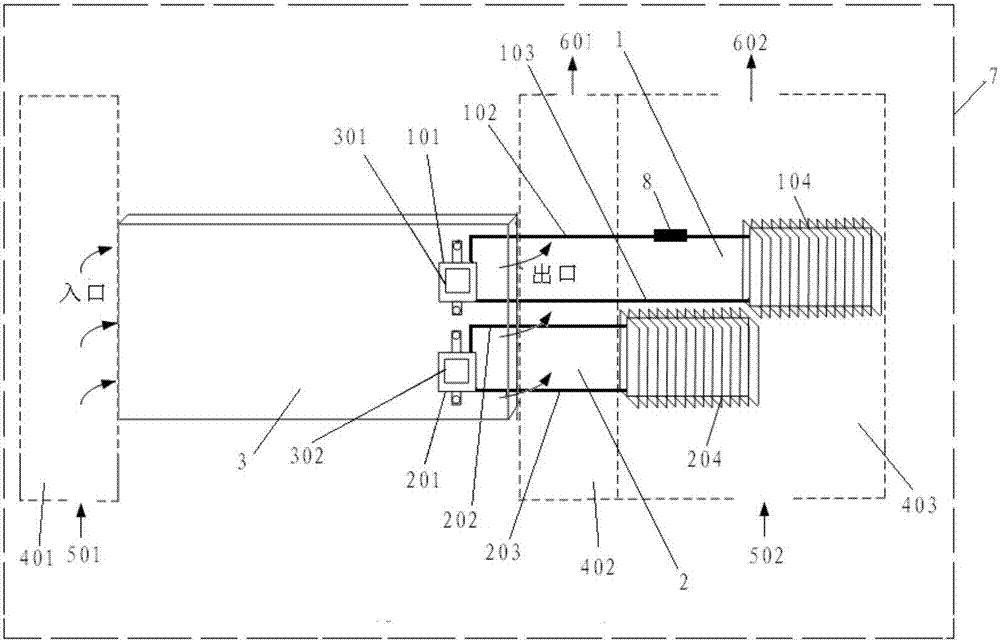

[0059] refer to figure 1 , shows a schematic structural diagram of a heat dissipation device for a blade server chip in an embodiment of the present invention. In this embodiment, the heat dissipation device for blade server chips includes: a first embedded heat pipe 1, and a second embedded heat pipe 2 arranged below the first embedded heat pipe 1, and a blade Server 3.

[0060] like figure 1 , the first embedded heat pipe 1 includes: a first evaporator 101 , a long gas pipeline 102 , a long liquid pipeline 103 and a first finned condenser 104 connected in sequence.

[0061] In this embodiment, the specific connection structure between the components in the first embedded heat pipe 1 is as follows: one end of the long ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com