Internal-combustion engine assisted sea water desalinization/poor-quality water purification method and device thereof

An internal combustion engine and water purification technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as high raw water quality requirements, unstable equipment operation, and difficulty in meeting water quality standards. Achieve the effect of good effluent water quality, high equipment reliability and loose working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

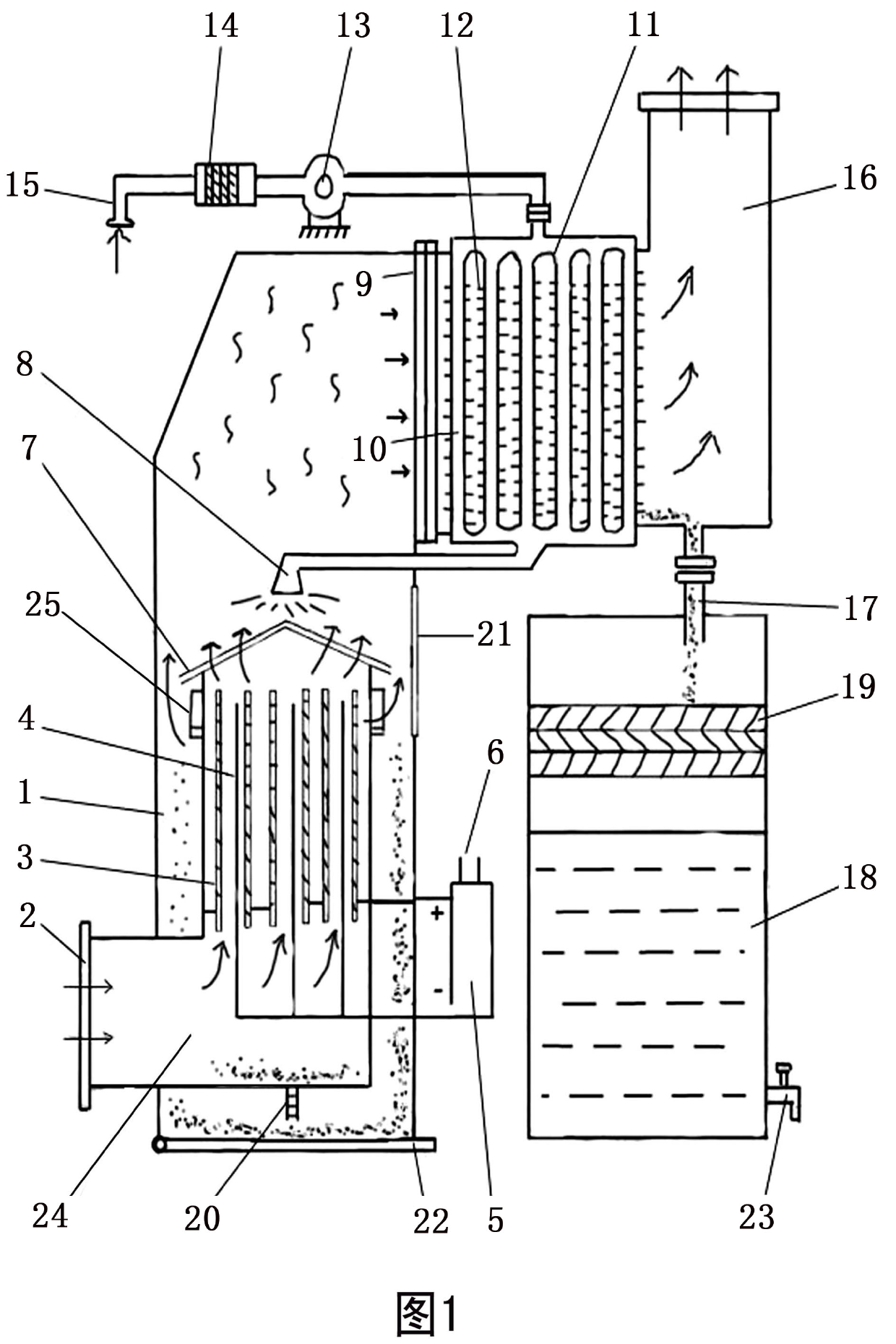

[0126] Embodiment one, see figure 1 As shown, this embodiment is a kind of desalination / purification equipment that can be used for small and medium-sized ships, and it includes raw water pipe 15, evaporation chamber 1, condensation heat exchange chamber 10 and fresh water tank 18, and the bottom of described evaporation chamber has air inlet 2. There is an atomizing nozzle 8 in the middle of the evaporation chamber. The condensation heat exchange chamber 10 is located on the upper part of the evaporation chamber. The top of the evaporation chamber has a smoke exhaust port 16. The purifier 24 is connected, and the exhaust gas inlet of the exhaust gas purifier 24 is communicated with the smoke exhaust pipe 27 of the internal combustion engine. The corona tubes 3 are vertically arranged in the exhaust gas purifier, and each corona tube is connected with the positive pole of the DC high voltage generator 5. Metal wires 4 are arranged between the tubes, and each metal wire is conn...

Embodiment 2

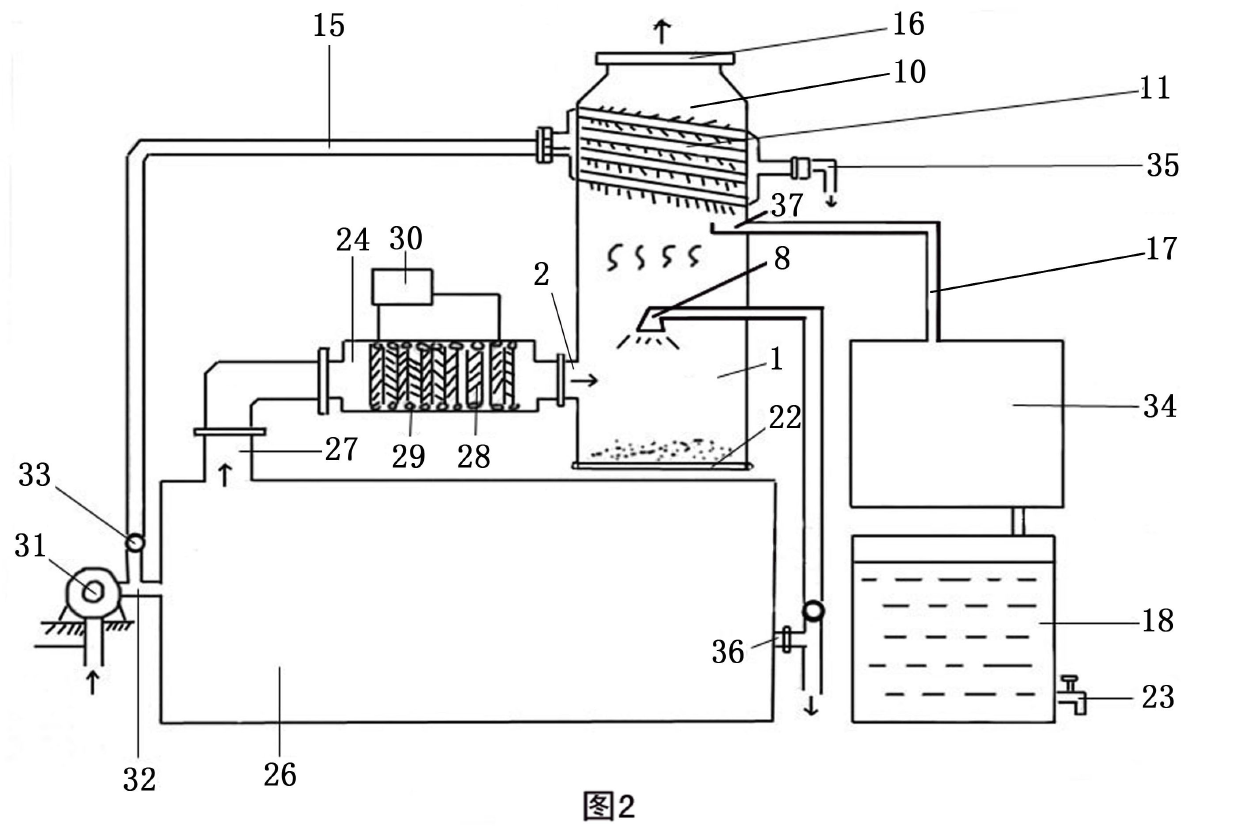

[0127] Embodiment two, see figure 2 As shown, the present embodiment is a seawater / brackish water direct drinking device that can be used for medium-sized ships or units, and it includes a raw water pipe 15, an evaporation chamber 1, a condensation heat exchange chamber 10 and a fresh water tank 18, and the evaporation chamber The lower part of the evaporation chamber has an air inlet 2, the middle part of the evaporation chamber has an atomizing nozzle 8, the condensation heat exchange chamber 10 is located at the top of the evaporation chamber, and the top of the evaporation chamber has a smoke exhaust port 16, and the air inlet at the bottom of the evaporation chamber is connected with the device. It is connected to the exhaust gas purifier 24 on the outside of the evaporating chamber, and the exhaust gas inlet of the exhaust gas purifier 24 communicates with the smoke exhaust pipe 27 of the internal combustion engine. There are filter material layers 28 and heating wires 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com