Method for preparing nano-hydroxyapatite

A technology of nano-hydroxyapatite and phosphate solution, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of easy decomposition, loss, instability of nanoparticles, etc., and achieve good processability , Appropriate mechanical properties, and the effect of being convenient for wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Dissolve 30g of slag 1# in 620mL of 1.0mol / L dilute hydrochloric acid at room temperature of 20°C, stir magnetically, and centrifuge to obtain the filtrate.

[0037] (2) Adjust the pH of the filtrate to 10 with 1.0 mol / L ammonia water, and centrifuge to obtain the filtrate.

[0038] (3) Determination of Ca 2+ The concentration is 0.02mol / L, measure 100mL of 0.12mol / L diammonium hydrogen phosphate, adjust the pH to 10 with 0.0010mol / L ammonia water, drop it into the calcium source at 40°C, stir evenly, after the addition is completed Continue to stir for 1 hour, keep the pH constant during the process, age for 12 hours, wash with deionized water until neutral, and dry to obtain nano-hydroxyapatite.

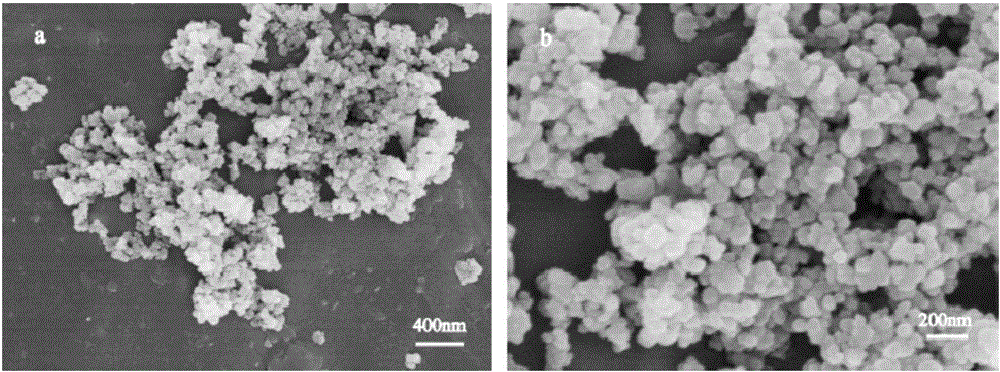

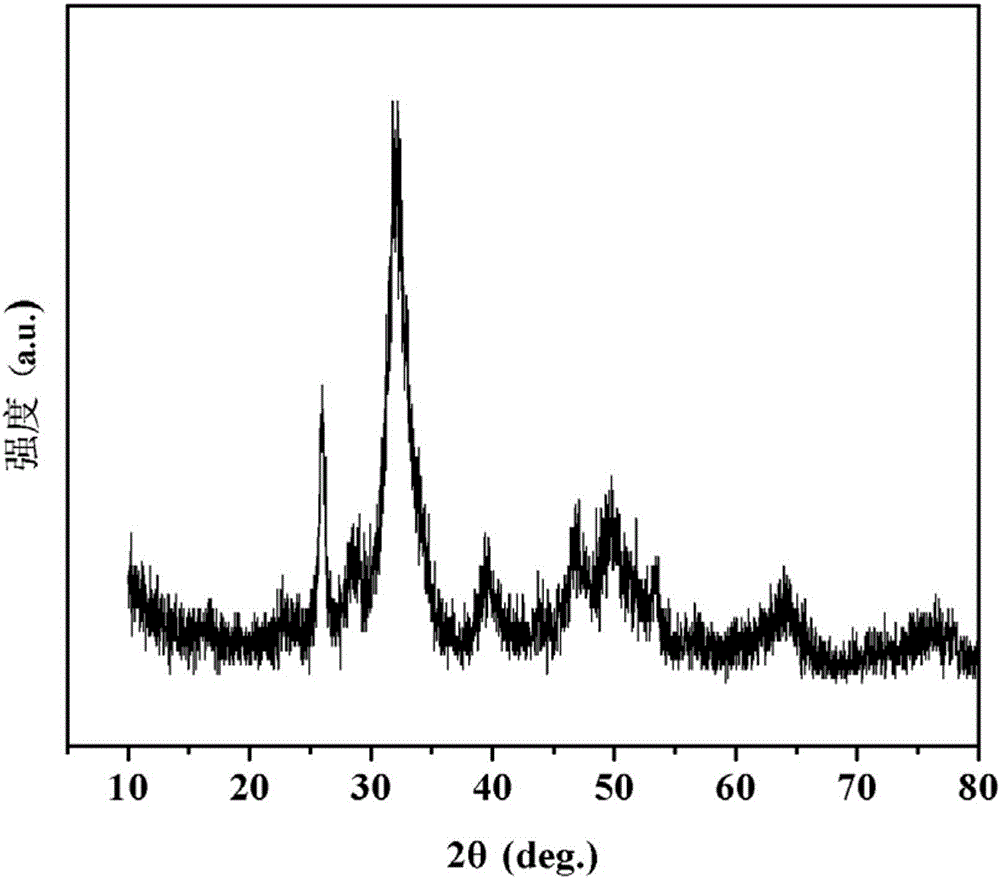

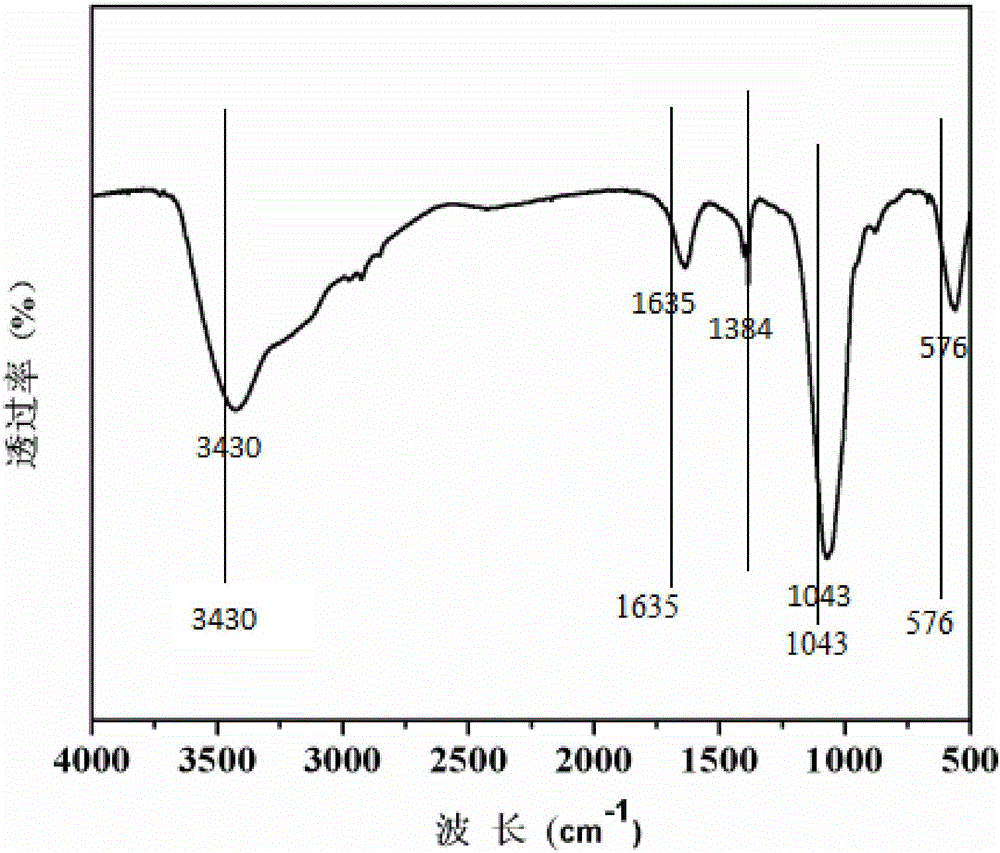

[0039] The morphology and composition of the nano-hydroxyapatite obtained in embodiment 1 are characterized, and the scanning electron microscope image (SEM) obtained, and the X-ray diffraction pattern (XRD) are respectively determined by such as figure 1 with figure...

Embodiment 2

[0042] The nano-hydroxyapatite of embodiment 1 gained is carried out the adsorption experiment of heavy metal ion:

[0043] (1) Weigh 0.5g of nano-hydroxyapatite, lead ion concentration is 800mg / L, and sewage with pH=5.5 is adsorbed at 20°C with a stirring rate of 400rpm, regularly sampled, and titrated with 1.0000mmol / L of EDTA solution The concentration of lead ions remaining in solution until adsorption equilibrium is reached.

[0044] (2) The nano-hydroxyapatite prepared in Example 2 is drawn and analyzed at different concentrations, different pHs, and different temperatures to adsorb lead ion experimental data, as shown in table 2, the lead ion adsorption curve is as follows image 3 As shown, and the SEM after the adsorption of lead ions as Figure 4 a and Figure 4 As shown in b, compared with the adsorption effect of existing adsorption materials on heavy metals in sewage, the adsorption effect of nano-hydroxyapatite prepared by the present invention on heavy metal i...

Embodiment 3

[0048] (1) Dissolve 10 g of slag 2# in 17.5 mL of 12.0 mol / L dilute hydrochloric acid at room temperature of 20°C, stir magnetically, and centrifuge to obtain the filtrate.

[0049] (2) Adjust the pH of the filtrate to 10 with 12.0 mol / L ammonia water, and centrifuge to obtain the filtrate.

[0050] (3) Determination of Ca 2+ The concentration is 1.5mol / L, measure 100mL 0.27mol / L diamine hydrogen phosphate, adjust the pH to 10 with 12mol / L ammonia water, drop it into the calcium source at 40°C, stir evenly, continue to Stir for 1 hour, keep the pH constant during the process, age for 12 hours, wash with deionized water until neutral, and dry to obtain nano-hydroxyapatite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com