Manufacturing method for broadband THz wave absorber unrelated to wide-angle polarization

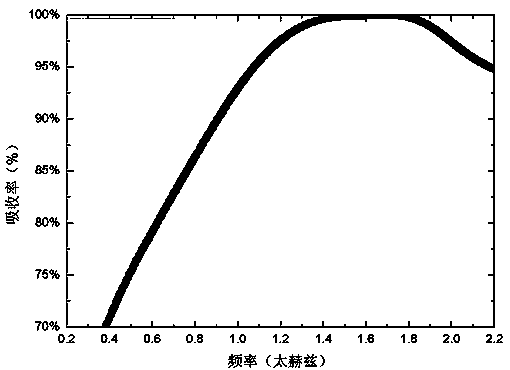

A manufacturing method and terahertz technology, which is applied in the field of terahertz wave absorbers, can solve problems such as the small range of high absorption rate of terahertz absorbers, and achieve the effects of wide incident angle, wide range of materials, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

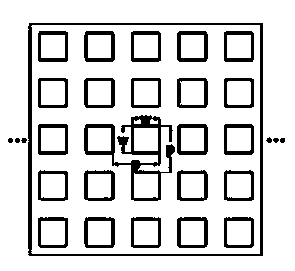

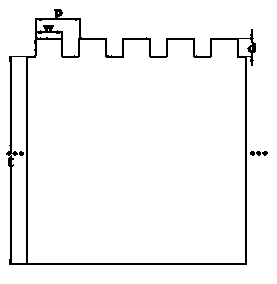

[0011] Such as figure 1 , 2 Top view and left view of the wide-angle polarization-independent broadband terahertz wave absorber shown: a wide-angle polarization-independent broadband terahertz wave absorber, including a substrate layer for reducing transmittance and a grating layer for reducing reflectivity, the grating layer The grating depth d, width w, period p, etc. determine the reflectivity of the absorber for terahertz waves, and the extinction coefficient and thickness t of the substrate material determine the transmittance of the absorber for terahertz waves. The parameters of the absorber grating layer and the substrate layer can be adjusted to realize the change of absorption frequency band and absorption bandwidth. The absorber grating layer and the substrate layer are semiconductor silicon with the same doping concentration, and the grating layer is prepared by using photolithography process, ICP process etching or chemical etching process on the surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com