Multilayer aquagel, and preparation method and application thereof

A hydrogel and gel technology, applied in the field of multilayer hydrogel and its preparation, can solve the problem of poor mechanical properties of gel, immature gel size, shape and structure, and unstable structure of multilayer hydrogel High-level problems, to achieve good application prospects, the effect of a wide range of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

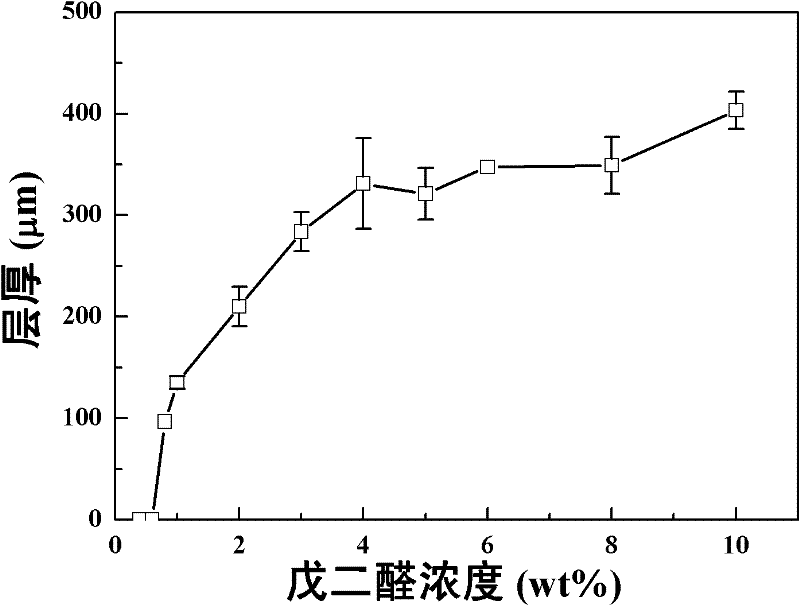

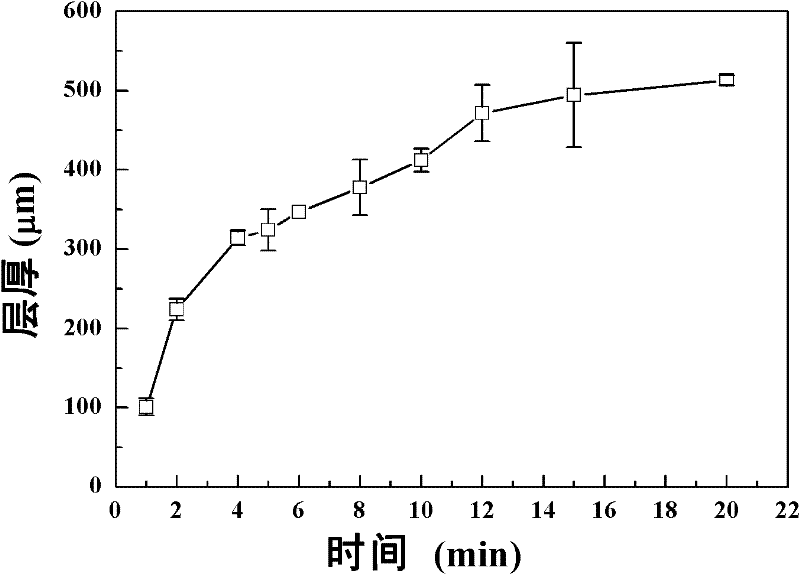

[0025] 3wt% chitosan acetic acid solution was added dropwise into 1mol / L NaOH solution with a 1ml syringe, and gelled for 10min to obtain a spherical gel core with a diameter of 3-4mm. After the NaOH remaining on the surface of the spherical gel core was washed with distilled water, it was immersed in a 70°C, 1wt% glutaraldehyde solution for 5min. After it was taken out, the glutaraldehyde on the surface was washed with distilled water, and then immersed in 0.5 wt% chitosan acetic acid aqueous solution at 70° C. and pH=6 for 3 min. According to the above-mentioned steps, it is alternately and repeatedly dipped in glutaraldehyde and chitosan aqueous solution for 3 times to obtain a chitosan multilayer hydrogel with 4 layers of membranes. Its morphology was photographed and observed with a digital camera in the eyepiece of an optical microscope.

Embodiment 2

[0027] Use a 1ml syringe to add the heated and dissolved chitosan / agarose / 2wt%HAc (3:1:96) mixed solution dropwise into cyclohexane, stir continuously, and gel for 10 minutes to obtain chitosan with a diameter of 2-3mm. Sugar / agarose spheroid core. The chitosan / agarose spherical gel core was immersed in 1wt% glutaraldehyde solution at 80°C for 5min. After it is taken out, clean the glutaraldehyde on the surface with distilled water and then immerse it in the 1wt% chitosan acetic acid aqueous solution of pH=2 at room temperature for 2min, then take it out and clean the chitosan on the surface with distilled water Then immerse in 1wt% glutaraldehyde aqueous solution at 70° C. for 5 min to further cross-link to obtain a chitosan hydrogel with a monolayer film, and its morphology is observed by a digital camera in an optical microscope eyepiece.

Embodiment 3

[0029] Use a 1ml syringe to add heated and dissolved 3wt% agarose aqueous solution dropwise into cyclohexane, stir continuously, and gel for 1min to obtain agarose gel spherical gel core with a diameter of 1-2mm. The agarose gel spherical gel core was immersed in 2wt% epichlorohydrin solution at 80°C for 2min. After taking it out, wash the epichlorohydrin on the surface with distilled water and then immerse it in 0.5wt% sodium alginate aqueous solution with pH=12 for 3min at room temperature. Alternately and repeatedly immersing in sodium alginate aqueous solution for 4 times, a multi-layer sodium alginate hydrogel with 4-layer membrane structure similar to "onion" was obtained, and its morphology was photographed and observed in the eyepiece of an optical microscope with a digital camera.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com