Composite heat insulation wallboard and manufacturing method thereof

A technology for thermal insulation wall panels and manufacturing methods, which is applied in the direction of manufacturing tools, ceramic molding machines, building components, etc., and can solve the problems of overall wall panel strength influence, no decorative performance, and weight reduction of wall panels, and achieve transportation and on-site Easy installation and operation, flexible and convenient construction, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

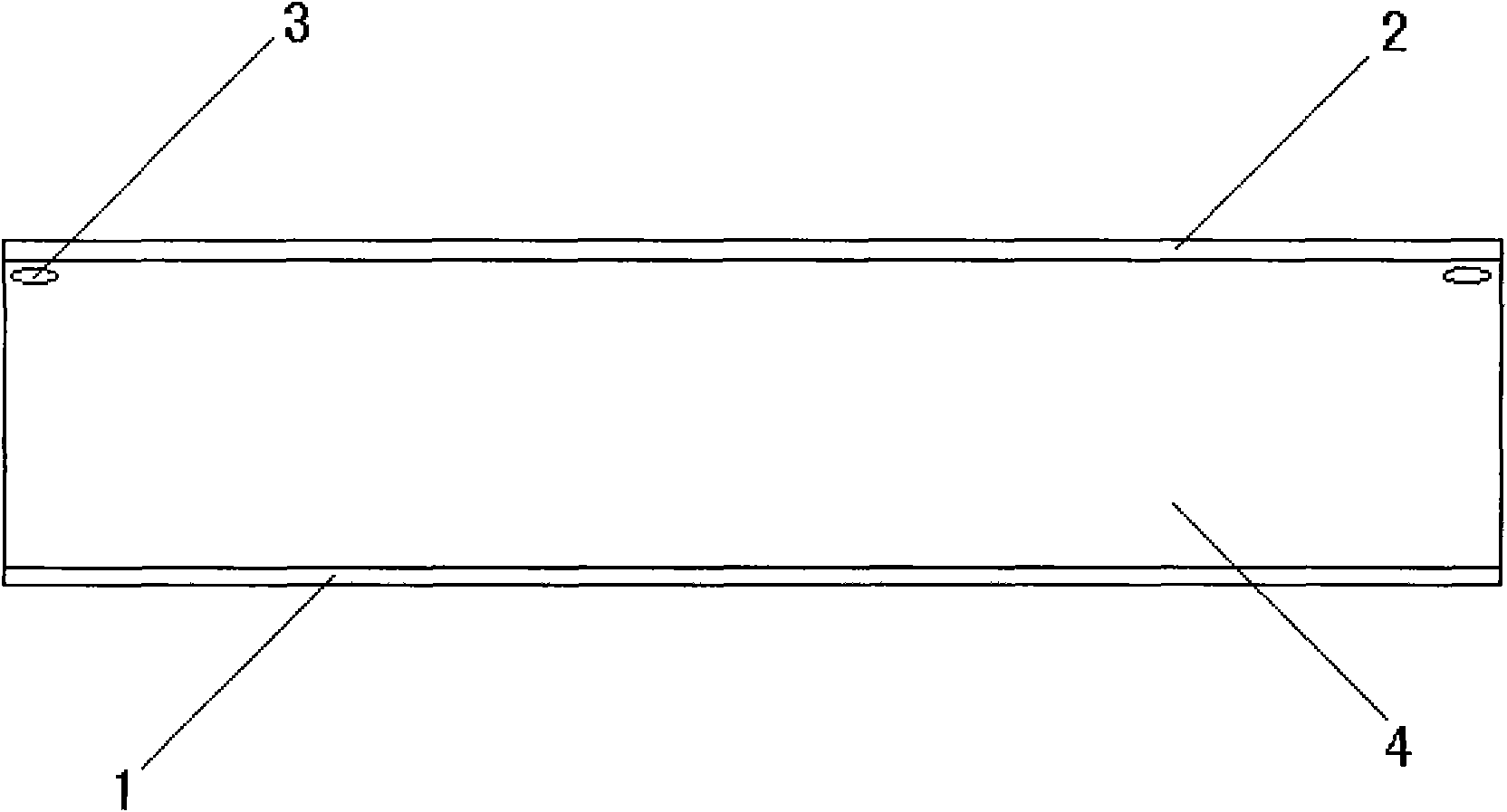

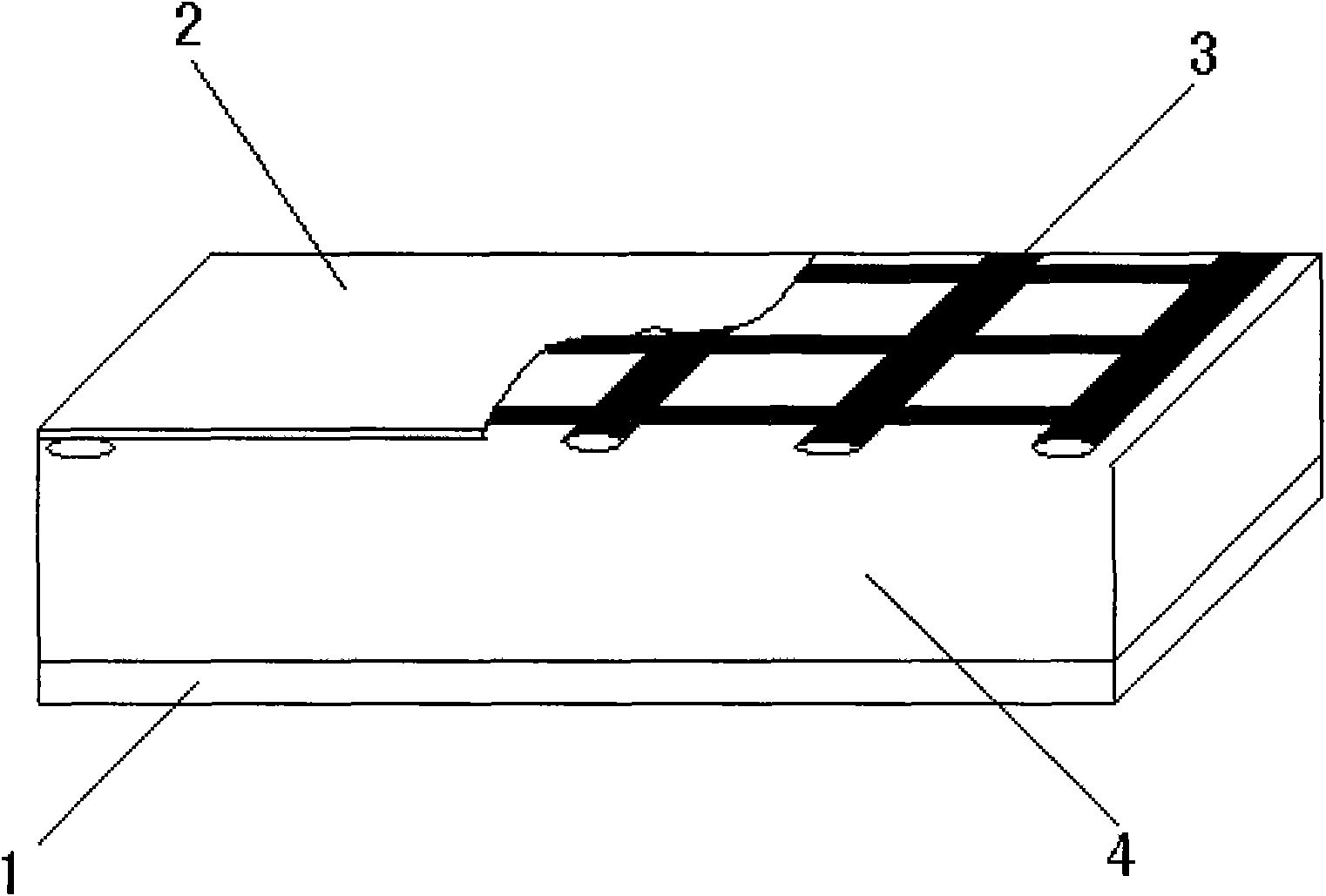

[0018] Example 1: The structure of composite thermal insulation wallboard

[0019] Such as figure 1 , figure 2 As shown, the composite thermal insulation wallboard of the present invention includes a bottom surface layer 1, a thermal insulation layer 2 made of cement foam material is arranged on the top of the bottom surface layer 1, and a layer of grid-shaped insulation layer is embedded in the thermal insulation layer 2 near the top. The metal frame 3 is provided with a decorative layer 4 on the top of the thermal insulation layer 2 .

[0020] In the above embodiment, the bottom surface layer 1 can be a cement layer directly built by masonry, or a purchased cement pressure board or cement board, etc., which can protect the insulation layer 2 . The thickness of the bottom layer 2 may generally be 0.4-1 cm.

[0021] In the above embodiments, the insulation layer 2 can use conventional cement foam material, or other insulation materials. The thickness of the insulation laye...

Embodiment 2

[0025] Example 2: The first manufacturing method of composite thermal insulation wallboard

[0026] The preparation method of the composite thermal insulation wallboard in the above-mentioned embodiment 1 comprises the following steps:

[0027] 1) Build a cement layer in the mold for making the thermal insulation wall;

[0028] 2) Suspending the welded metal frame 3 in the mold at the designed position above the bottom layer 1;

[0029] 3) Pouring cement foam material into the mold to the designed position;

[0030] 4) After the cement foam material is solidified and molded together with the metal frame 3 and the bottom surface layer 1 to form an insulation layer, a decorative layer 4 is bonded on the top of the insulation layer with a resin cement adhesive.

Embodiment 3

[0031] Example 3: The second manufacturing method of composite thermal insulation wallboard

[0032] The difference between this embodiment and embodiment 2 is that the bottom surface layer 1 in step 1) can replace the cement layer of the masonry with the cement pressure board or cement board purchased directly, and before pouring the cement foam material, the After smearing the resin cement bonding agent on the bottom surface layer 1 top of shape, pouring cement foaming material again.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com