Method for volatilizing and enriching molybdenum from molybdenum tailings

A molybdenum tailings and enrichment technology, applied in the field of solid waste recycling, can solve the problems of no relevant research reports and limitations of enrichment and recovery, and achieve the effect of solving sand and dust pollution and debris flow hidden dangers and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

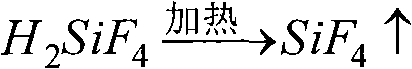

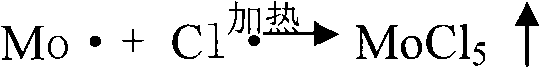

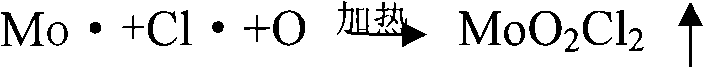

Embodiment 1

[0025] Huludao molybdenum tailings are used, and the main phase of the tailings is SiO 2 , the molybdenum content is 0.19%, the tailings are ball milled to a particle size within the range of 0.08-0.1mm, and water is added to stir, so that the molybdenum tailings form a molybdenum tailings slurry with a certain rheological property with a water content of 30%-40% WT , in order to better contact and react with acid. Then add 0.25mlHF (hydrofluoric acid) metering according to every gram of dry base molybdenum tailings, the concentration of this HF is 40%WT, after the reaction bubble disappears, add HCl (hydrochloric acid), the concentration of HCl is 36%WT, the addition of hydrochloric acid The amount is 0.25ml HCl / g dry molybdenum tailings. After adding acid, cover and heat at 250°C for 40 minutes, remove the cover after heat treatment, and dry at 65°C until the mass change is less than 5%. The pretreated molybdenum tailings are heated by HF-HCl and heat-treated at 900°C to m...

Embodiment 2

[0027] Except that the added amount of hydrochloric acid is 1ml HCl / g dry base molybdenum tailings, the others are the same as in Example 1, and the high-temperature volatilization rate of molybdenum can reach 98.6% at 900°C.

Embodiment 3

[0029] Except that the addition of hydrofluoric acid is 0.625ml / g dry base molybdenum tailings, and the addition of hydrochloric acid is 0.625ml / g dry base molybdenum tailings, the rest are the same as in Example 1, and the high temperature volatility of molybdenum at 900°C can be Reached 85.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com