Technology for preparing base geopolymer eco-material

A technology of ecological materials and alkali bases, applied in the field of resource disposal of solid waste, to achieve the effects of good water storage, high utilization rate, and high process waste rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 100 parts of kaolin in a crucible, place it in a muffle furnace at 700°C for calcination for 2 hours, and after cooling to room temperature, grind it through a 100-mesh sieve for use. Take 70 parts of domestic waste incineration fly ash, 30 parts of metakaolin, and 10 parts of sodium hydroxide, put them in a container and mix them evenly, add 30 parts of water, stir at a frequency of 200 rpm for 20 minutes, pour the mixture into the mold to Vibrate at a frequency of 50 times / min for 2 minutes. The mold is placed in a drying oven at 80°C for 12 hours, and then the mold is removed, and the removed block is placed in a drying oven at 30°C for 21 days, and then the alkali-based polymer ecological material is obtained. The detection index of the test piece in embodiment 1 is shown in the subscript.

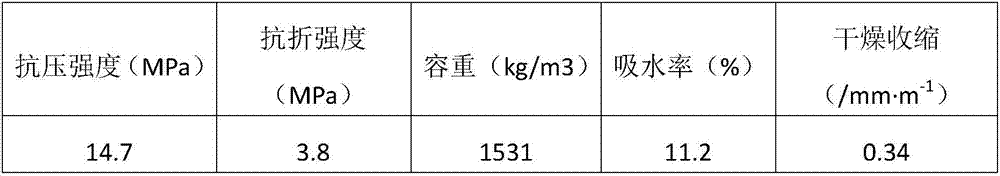

[0022] The test piece detection index in the table 1-1 embodiment 1

[0023]

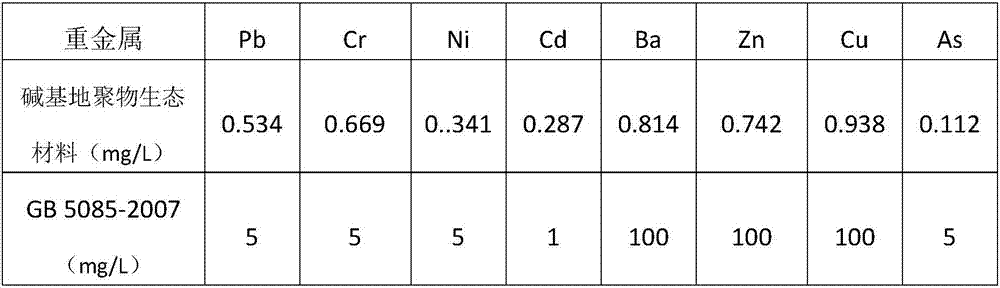

[0024] The test piece heavy metal leaching value in the embodiment 1 of table 1-2

[00...

Embodiment 2

[0027] Take 100 parts of kaolin and place it in a crucible, place it in a muffle furnace at 900°C for calcination for 0.5h, and after cooling to room temperature, grind it through a 100-mesh sieve for use. Take 61 parts of household waste incineration fly ash, 29 parts of metakaolin, and 20 parts of sodium silicate in a container and mix them evenly, add 22 parts of water, stir at 120 rpm for 25 minutes, pour the mixture into the mold for 40 times Vibrate at a frequency of 3 minutes per minute. After the mold is placed in a drying oven at 50°C for 24 hours, the mold is removed, and the molded pieces are placed in a drying oven at 50°C for 16 days to obtain an alkaline-based polymer ecological material. The detection indexes of the test piece in embodiment 2 are shown in the subscript.

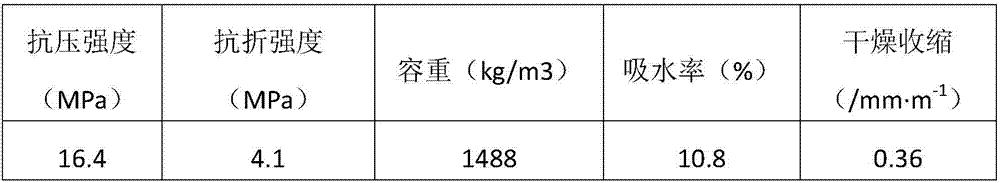

[0028] The test piece detection index in the table 2-1 embodiment 2

[0029]

[0030] The test piece heavy metal leaching value in the embodiment 2 of table 2-2

[0031]

Embodiment 3

[0033] Take 100 parts of kaolin and place it in a crucible, place it in a muffle furnace at 800°C for calcination for 1 hour, and after cooling to room temperature, grind it through a 100-mesh sieve for use. Take 50 parts of domestic waste incineration fly ash, 50 parts of metakaolin, 6 parts of potassium hydroxide and sodium silicate and mix them in a container, add 10 parts of water, stir at 50 rpm for 30 minutes, and inject the mixture after stirring Vibrate in the mold for 6 minutes at a frequency of 20 times / min. The mold was placed in a drying oven at 30°C for 48 hours, and then the mold was removed, and the removed block was placed in a drying oven at 80°C for 12 days to obtain an alkaline-based polymer ecological material. The detection indexes of the test piece in embodiment 3 are shown in the subscript.

[0034] The test piece detection index in the table 3-1 embodiment 3

[0035]

[0036] The test piece heavy metal leaching value in the embodiment 3 in table 3-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com