Compound shellfish modified biological phosphorus removal material and preparation method and application thereof

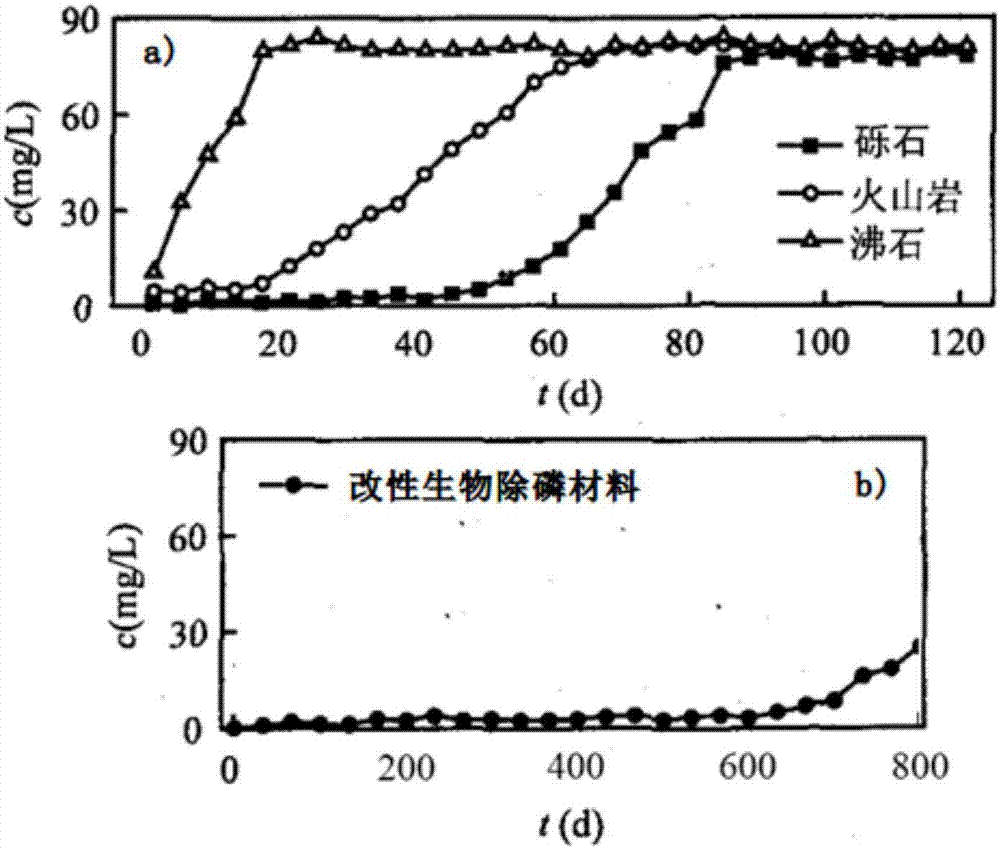

A technology for biological phosphorus removal and shellfish removal, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of difficult recovery, long interval, serious secondary pollution, etc. Phosphorus removal effect and maintenance time, the effect of good phosphorus removal and water purification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

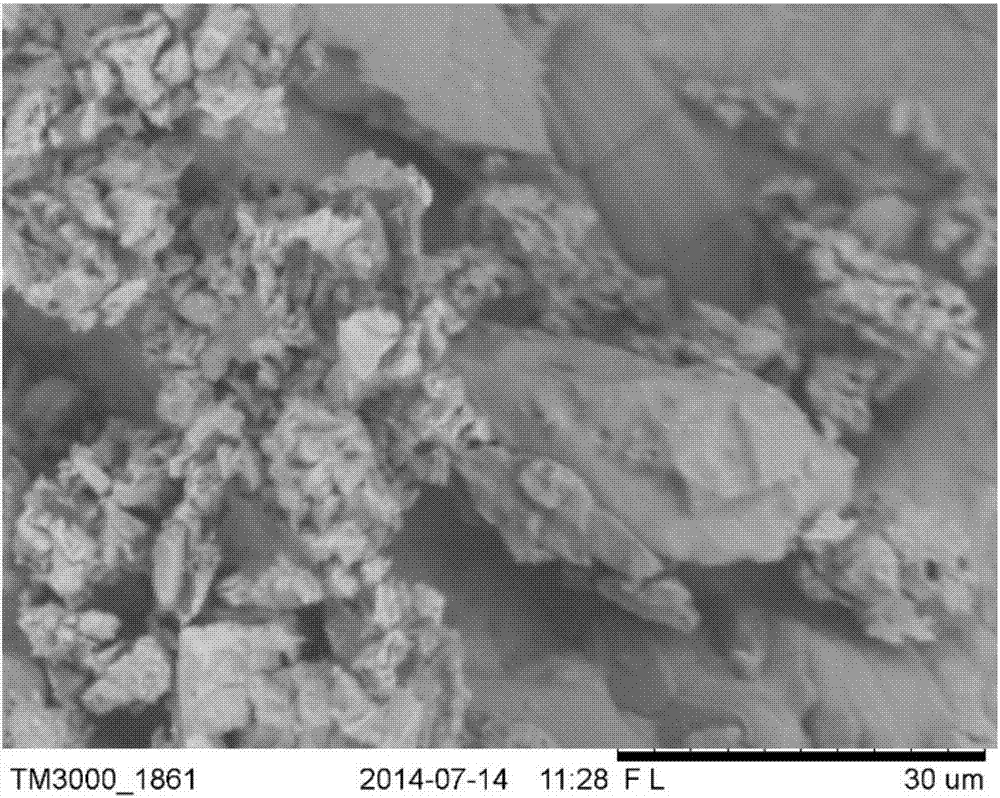

[0035] This embodiment provides a method for preparing a composite shellfish modified biological phosphorus removal material, the method comprising the following steps:

[0036] 1) Remove the fleshy tissues of fresh mussels, oysters, and scallops, wash them with clean water, and dry the shells naturally for 2 to 5 days to remove weeds and other substances attached to the surface for later use.

[0037] 2) According to the mass percentage, the mussel shells are 30%, the oyster shells 45%, and the scallop shells 25%. The air-dried shell shells are respectively weighed and crushed into particles with a diameter of 50-150 mm.

[0038] 2) Take about 250g of the above pulverized particles and put them into the crucible, and raise the temperature of the muffle furnace to 350°C. After the temperature is stable, put the crucible into the muffle furnace to preheat for 1 hour, and then raise the temperature To 700°C, calcined for 0.5 hours.

[0039] 3) When the calcination time is up, l...

Embodiment 2

[0041] This embodiment provides a method for preparing a composite shellfish modified biological phosphorus removal material, the method comprising the following steps:

[0042] 1) Remove the fleshy tissues of fresh mussels, oysters, and scallops, wash them with clean water, and dry the shells naturally for 2 to 5 days to remove weeds and other substances attached to the surface for later use.

[0043] 2) Take about 250g of the above pulverized particles and put them into the crucible, raise the temperature of the muffle furnace to 450°C, after the temperature stabilizes, put the crucible into the muffle furnace to preheat for 2 hours, then raise the temperature of the muffle furnace Calcined at 750°C for 1 hour.

[0044] 3) When the calcination time is up, reduce the temperature of the muffle furnace to 250°C, keep it warm for 2 hours, then turn off the power of the muffle furnace, cool it naturally, take out the material in the crucible after it is powdery, and store it in a...

Embodiment 3

[0047] This embodiment provides a method for preparing a composite shellfish modified biological phosphorus removal material, the method comprising the following steps:

[0048] 1) Remove the fleshy tissues of fresh mussels, oysters, and scallops, wash them with clean water, and dry the shells naturally for 2 to 5 days to remove weeds and other substances attached to the surface for later use.

[0049]2) Take about 250g of the above pulverized particles and put them into the crucible, raise the temperature of the muffle furnace to 500°C, after the temperature stabilizes, put the crucible into the muffle furnace to preheat for 3 hours, and then raise the temperature of the muffle furnace Calcined at 800°C for 2 hours.

[0050] 3) When the calcination time is up, lower the temperature of the muffle furnace to 300°C, keep it warm for 3 hours, then turn off the power of the muffle furnace, cool it naturally, take out the material in the crucible after it is powdery, and store it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com