Reutilization process for painting and coating pigment pf paper mill

A technology of paper mills and pigments, applied in the field of industrial solid waste recycling process, to achieve the effect of protecting the ecological environment, simple process steps, and realizing resource regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

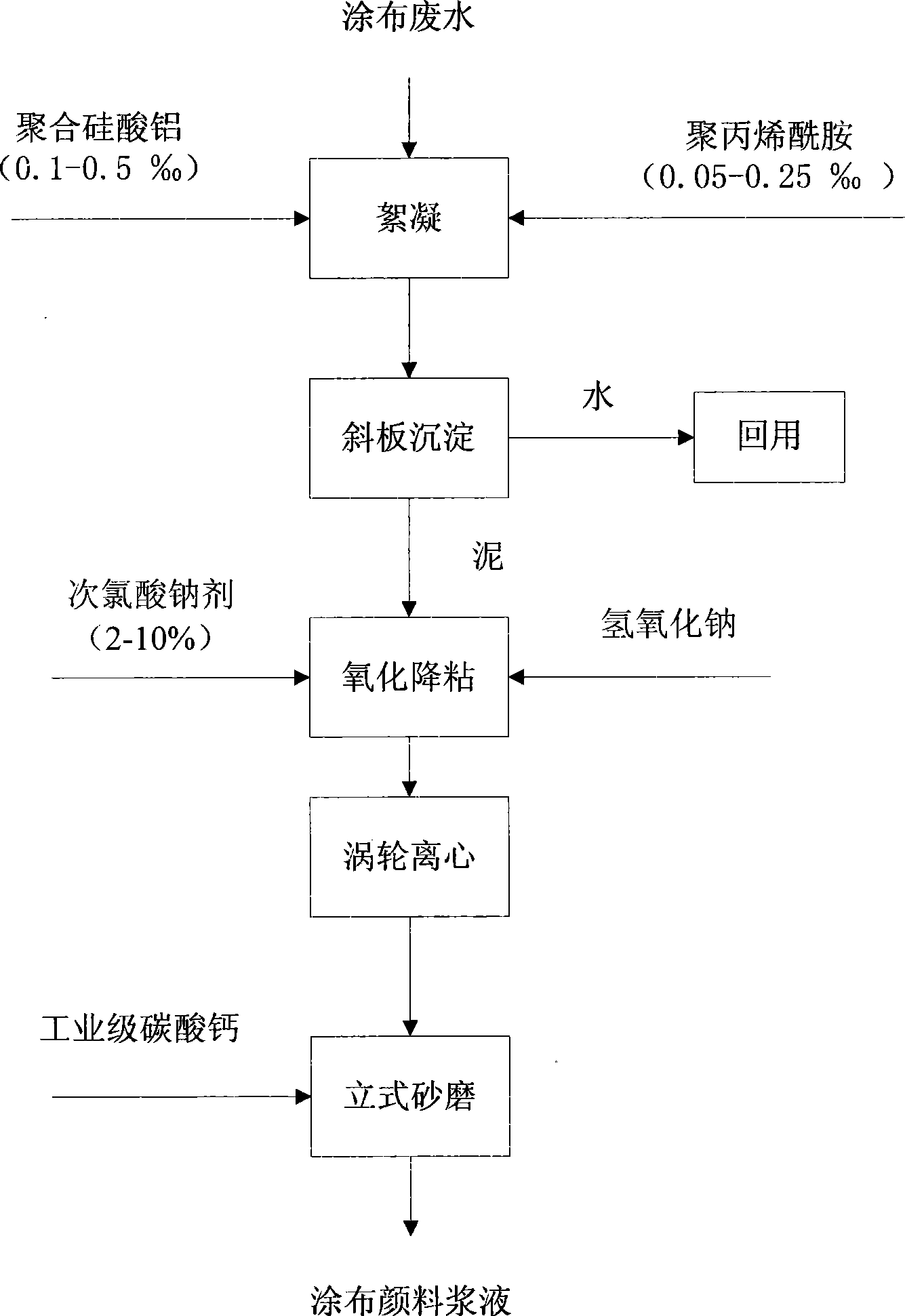

Method used

Image

Examples

Embodiment 1

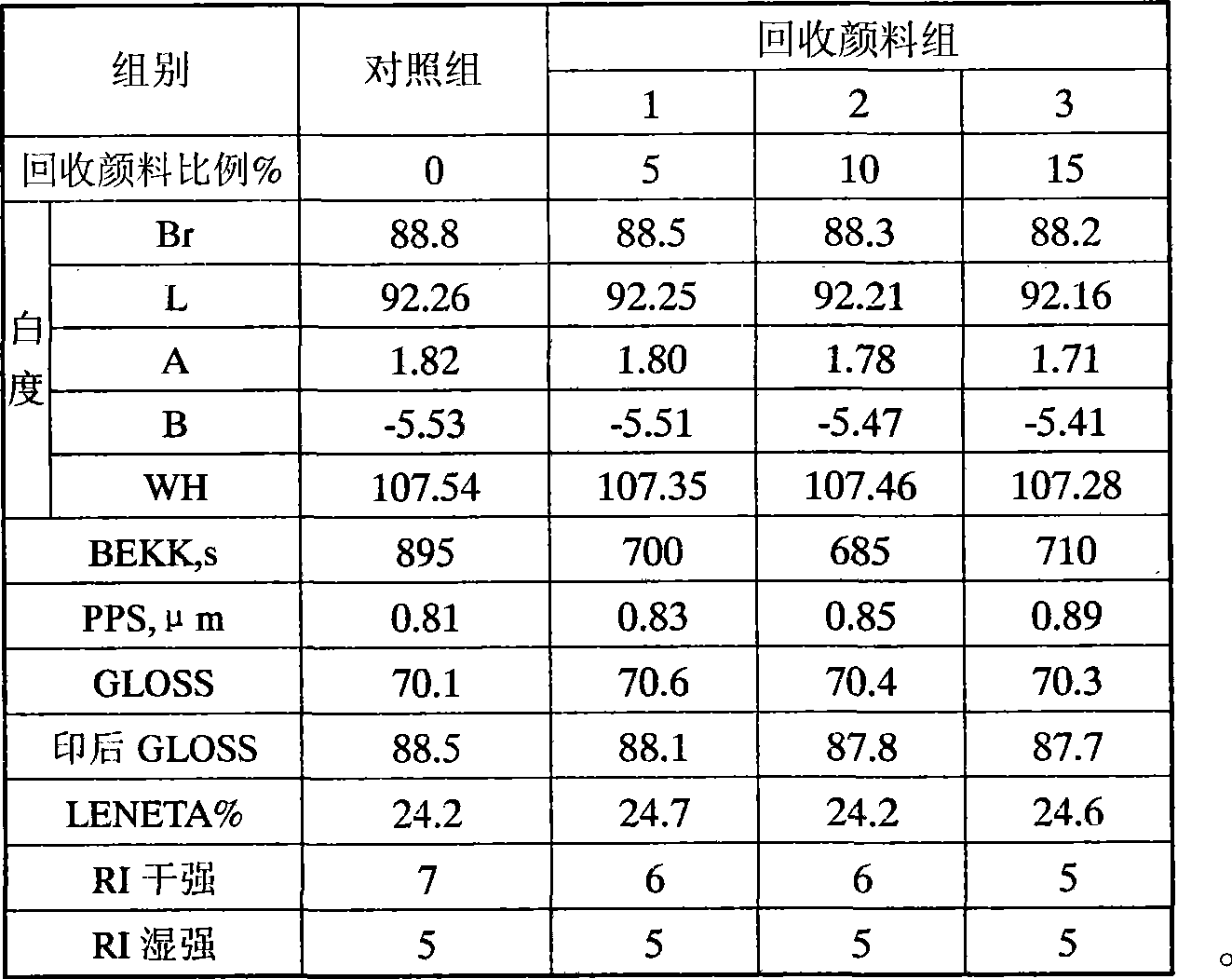

[0020] Coating wastewater from a large paper mill enters the flocculation tank. First, add polyaluminum silicate (self-made) at a dosage of 0.35‰ and stir rapidly for 10 minutes, then add nonionic polyacrylamide at a dosage of 0.2‰, and then stir at a slow speed for 30 minutes; plate sedimentation tank for sedimentation, reuse the supernatant, and oxidize the precipitated sludge; first add sodium hydroxide to adjust the pH value to 11, then add 5% sodium hypochlorite, stir at room temperature for 2 hours to fully oxidize; after oxidation, enter the turbine centrifuge machine for dehydration; the pigment recovered after oxidation and industrial grade calcium carbonate (400 mesh) are entered into a vertical grinder according to the proportioning ratio of 5%, and ground for 27min, the slurry particle diameter≤2μm% is 65.4%, the slurry solid content is 73.9%, ISO Whiteness 92.4%. The quality of the obtained product was verified by the coating test, and the physical properties of t...

Embodiment 2

[0022] Coating wastewater from a large paper mill enters the flocculation tank. First, add polyaluminum silicate (self-made) at a dose of 0.5‰ and stir quickly for 10 minutes, then add non-ionic polyacrylamide at a dose of 0.25‰, and stir at a slow speed for 45 minutes; plate sedimentation tank for sedimentation, reuse the supernatant, and oxidize the precipitated sludge; first add sodium hydroxide to adjust the pH value to 11, then add 10% sodium hypochlorite, stir at room temperature for 2 hours to fully oxidize; after oxidation, enter the turbine centrifuge Machine dehydration; the pigment reclaimed after oxidation and industrial grade calcium carbonate (400 mesh) enter vertical grinder by proportioning 10%, grind 26min, slurry particle diameter≤2μm% is 64.8%, slurry solid content 73.3%, ISO Whiteness 92.3%. The quality of the obtained product was verified by the coating test, and the physical properties of the paper are shown in Table 1.

Embodiment 3

[0024] Coating wastewater from a large paper mill enters the flocculation tank. First, add polyaluminum silicate (self-made) at a dose of 0.5‰ and stir quickly for 10 minutes, then add non-ionic polyacrylamide at a dose of 0.25‰, and stir at a slow speed for 45 minutes; plate sedimentation tank for sedimentation, reuse the supernatant, and oxidize the precipitated sludge; first add sodium hydroxide to adjust the pH value to 11, then add 10% sodium hypochlorite, stir at room temperature for 2 hours to fully oxidize; after oxidation, enter the turbine centrifuge Machine dehydration; the pigment reclaimed after oxidation and industrial grade calcium carbonate (400 mesh) enter vertical grinder by proportioning 15%, grind 26min, slurry particle diameter≤2μm% is 65.3%, slurry solid content 73.5%, ISO Whiteness 92.1%. The quality of the obtained product was verified by the coating test, and the physical properties of the paper are shown in Table 1.

[0025] Table 1 Paper physical pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com