Advanced treatment method for waste water

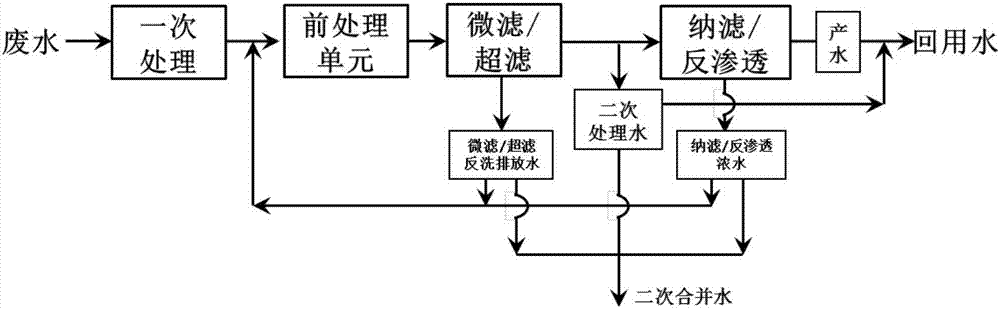

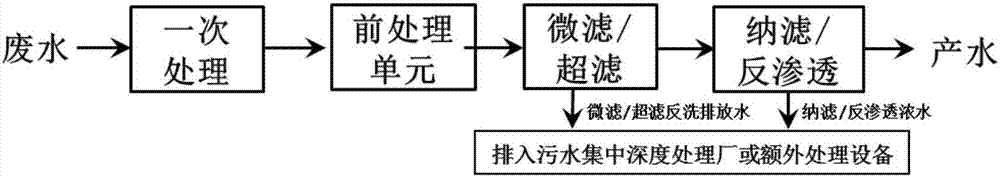

It is a technology for advanced treatment and waste water, which is applied in textile industry waste water treatment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of low utilization rate, ultrafiltration or microfiltration backwash discharge water cannot meet the discharge standard, etc. Achieve the effects of reducing treatment costs, improving water resource utilization, and improving system recovery rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The amount of water treated in this test is 500m 3 / d, a certain wastewater is treated with aerobic biological treatment and coagulation and sedimentation to obtain primary treatment water, the COD of the primary treatment water is 50mg / L, and the content of macromolecules with a molecular weight greater than 100kDa (ie 100,000 Daltons) is 12% , the B / C value is 0.2, the TDS is 250mg / L, the hardness is 60mg / L, and the sulfate radical is 45mg / L. The primary treatment water is treated with ozone, activated carbon and ultrafiltration to obtain ultrafiltration product water, which is recovered by ultrafiltration The rate is 90%. The ultrafiltration product water is treated by reverse osmosis to obtain reverse osmosis product water. The recovery rate of reverse osmosis is 80%, the desalination rate is 98%, and the COD of reverse osmosis concentrated water is 100mg / L, which cannot be discharged directly. 95% of reverse osmosis concentrated water and 100% of ultrafiltration ba...

Embodiment 2

[0034] The amount of water treated in this test is 500m 3 / d, a certain printing and dyeing wastewater is treated with biochemical treatment and precipitation treatment to obtain primary treatment water. The COD of the primary treatment water is 135mg / L, the content of macromolecules with a molecular weight greater than 100kDa is 5%, the B / C value is 0.10, and the TDS is 400mg / L L, the hardness is 100mg / L, and the sulfate radical is 70mg / L. The primary treatment water is treated with ozone, activated carbon and ultrafiltration to obtain ultrafiltration water. The ultrafiltration recovery rate is 90%. The ultrafiltration water is reverse osmosis After treatment, the reverse osmosis product water is obtained, the reverse osmosis recovery rate is 60%, the desalination rate is 99%, and the COD of the reverse osmosis concentrated water is 180mg / L, which cannot be directly or indirectly discharged. 100% reverse osmosis concentrated water and 90% ultrafiltration backwash discharge wa...

Embodiment 3

[0036] The amount of water treated in this test is 500m 3 / d, a certain printing and dyeing wastewater is treated with biochemical treatment and precipitation treatment to obtain primary treatment water. The COD of the primary treatment water is 135mg / L, the content of macromolecules with a molecular weight greater than 100kDa is 18%, the B / C value is 0.15, and the TDS is 400mg / L L, the hardness is 100mg / L, and the sulfate radical is 70mg / L. The primary treatment water is treated with ozone, activated carbon and ultrafiltration to obtain ultrafiltration water. The ultrafiltration recovery rate is 90%. The ultrafiltration water is reverse osmosis After treatment, the reverse osmosis product water is obtained, the reverse osmosis recovery rate is 60%, the desalination rate is 99%, and the COD of the reverse osmosis concentrated water is 130mg / L, which cannot be discharged directly. 65% of the reverse osmosis concentrated water and 90% of the ultrafiltration backwash discharge wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com