Method for treating casing processing wastewater and application of treatment product

A technology for processing wastewater and casings, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. The problem of high oxygen content can reduce the difficulty of treatment, save resources and simplify the treatment method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

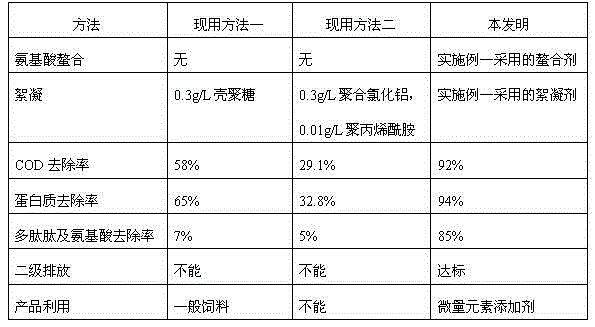

Embodiment 1

[0020] Embodiment 1: Unless otherwise specified below, the operating methods are all carried out at normal temperature and normal pressure.

[0021] A method for treating casing processing wastewater developed by the present invention comprises the following steps: (1) under the condition of temperature of 45-55°C, the pH value of the casing processing wastewater is adjusted to 6.0-7.0 with a mass concentration of 10% hydrochloric acid , to obtain solution I;

[0022] (2) Add chelating agent in the solution I obtained, and stir evenly, the time of stirring is 60~90min, obtains solution II;

[0023] (3) Add a coagulation aid to the obtained solution II, and stir evenly for 3 to 5 minutes to obtain a solution III;

[0024] (4) Add flocculant to the obtained solution III, and stir evenly for 1 to 3 minutes to obtain solution IV;

[0025] (5) The obtained solution IV was left to stand for 1 to 3 hours, and after collecting the supernatant, the precipitate was filtered, and the f...

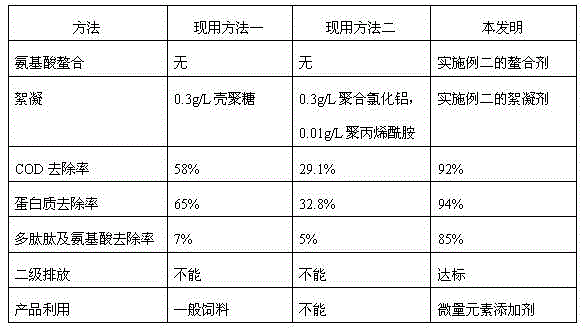

Embodiment 2

[0040] Embodiment 2: Invention and development of a method for treating casing processing wastewater, comprising the following steps, (1) under the condition of a temperature of 45 to 55°C, the pH value of the casing processing wastewater is adjusted to 10% hydrochloric acid with a mass concentration of 6.0~7.0, to obtain solution I;

[0041] (2) Add chelating agent in the solution I obtained, and stir evenly, the time of stirring is 60~90min, obtains solution II;

[0042] (3) Add a coagulation aid to the obtained solution II, and stir evenly for 3 to 5 minutes to obtain a solution III;

[0043] (4) Add flocculant to the obtained solution III, and stir evenly for 1 to 3 minutes to obtain solution IV;

[0044] (5) The obtained solution IV was left to stand for 1 to 3 hours, and after collecting the supernatant, the precipitate was filtered, and the filtered precipitate contained amino acid chelates and protein peptides;

[0045] (6) drying the sediment obtained by filtration;...

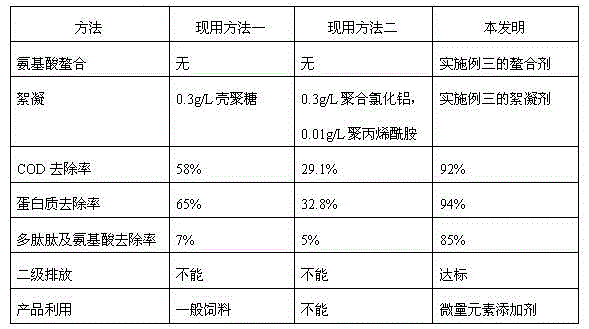

Embodiment 3

[0054] Embodiment 3: Invention and development of a method for treating casing processing wastewater, comprising the following steps, (1) under the condition of a temperature of 45 to 55°C, the pH value of the casing processing wastewater is adjusted to 10% hydrochloric acid with a mass concentration of 6.0~7.0, to obtain solution I;

[0055] (2) Add chelating agent in the solution I obtained, and stir evenly, the time of stirring is 60~90min, obtains solution II;

[0056] (3) Add a coagulation aid to the obtained solution II, and stir evenly for 3 to 5 minutes to obtain a solution III;

[0057] (4) Add flocculant to the obtained solution III, and stir evenly for 1 to 3 minutes to obtain solution IV;

[0058] (5) The obtained solution IV was left to stand for 1 to 3 hours, and after collecting the supernatant, the precipitate was filtered, and the filtered precipitate contained amino acid chelates and protein peptides;

[0059] (6) drying the sediment obtained by filtration;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com