Method for preparing ceramsite by water supply sludge and sewage sludge

A technology for sewage sludge and water supply sludge, which is applied in the production of clay products, ceramic materials, and other household appliances, etc., can solve the problems of water sludge and sewage sludge affecting the environment and hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

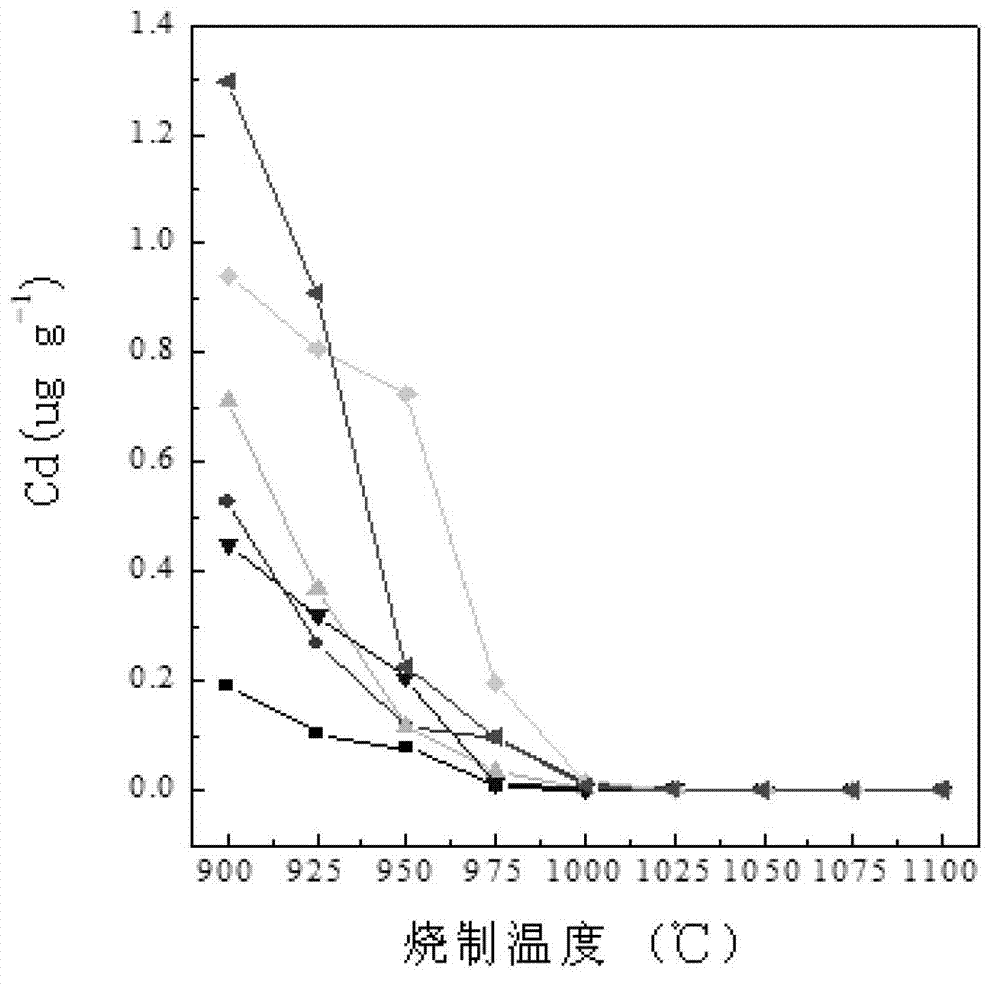

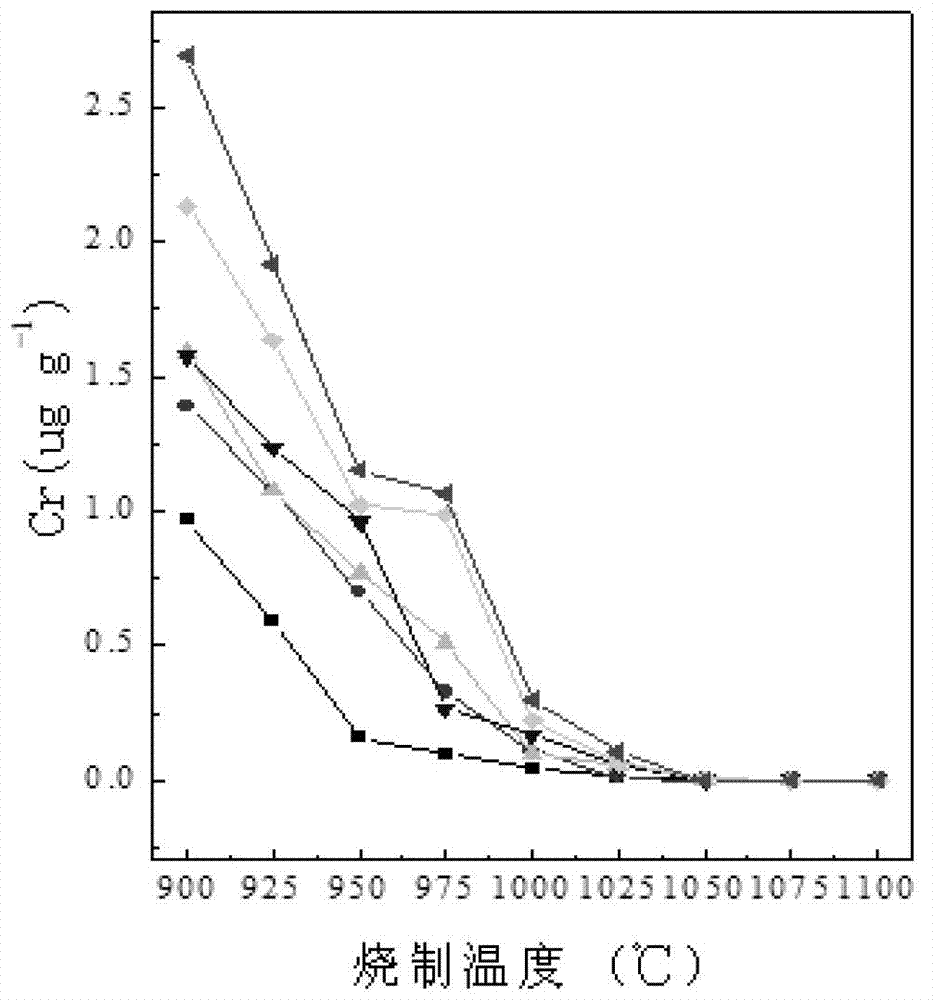

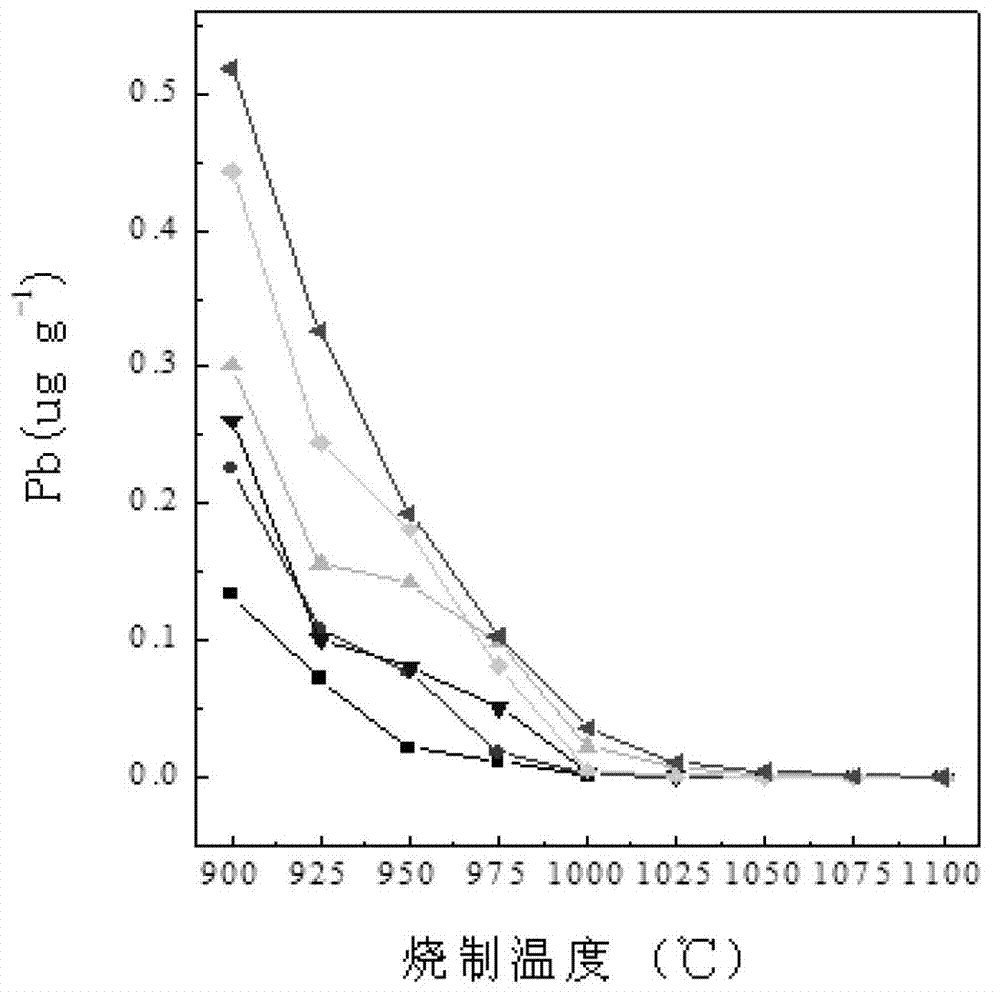

[0015] Specific embodiment 1: In this embodiment, a method for preparing building ceramsite by using water supply sludge and sewage sludge is carried out according to the following steps: press water supply sludge and sewage sludge by (7 / 3~1.5): 1 The mass ratio is mixed to obtain a mixture, and then silicate substances are added, and the amount of the silicate substances is 8% to 15% of the mixture mass, mixed evenly, and then placed in a granulator for extrusion molding, and naturally dried Dry, heat up at a rate of 8-10 ℃ / min, then keep warm at 950-1000 ℃ for 25-35 minutes, and cool with the furnace; the building ceramsite is obtained.

[0016] After testing, the loose bulk density of building ceramsite is 550~750 kg / m 3 , the particle apparent density is 1050~1400 kg / m 3 , the porosity is 41%-53%, the water absorption is within 15%, the cylinder compressive strength is 8-17 MPa, and the mud content is 0.3%-0.5%.

[0017] In order to investigate whether it is possible to ...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that: feedwater sludge and sewage sludge are mixed at a mass ratio of (3~2):2; %~15%. Incubate at 1000°C for 30 minutes. Other steps and parameters are the same as those in the first to third specific embodiments.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the silicate substance is sodium silicate. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com