A method for solidifying chromium-containing solid waste

A solid waste and solid content technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of poor anti-leaching performance, threats to human health, and high cost, so as to increase the amount of leaching and facilitate Capturing detoxifying, cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

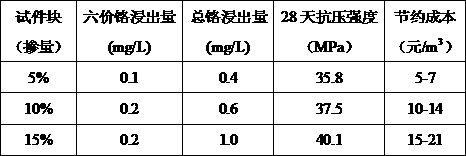

Embodiment 1

[0045] The method for solidifying chromium-containing solid waste in this embodiment comprises the following steps in turn:

[0046] (1) Take the chromium slag and refine it until the median particle size is less than 1mm, then add water to mix and stir to prepare slurry A with a solid content of 15%;

[0047] (2) Take 100 parts by mass of slurry A and pump it into a wet mill for wet grinding until the median particle size reaches 2 μm to obtain slurry B;

[0048] (3) Add 20 parts by mass of steel slag powder with a median particle size of 20 μm and 5 parts by mass of polymaleic acid to slurry B, mix them uniformly, and then wet grind them again until the particle size is 2 μm to obtain slurry C;

[0049] The following wet grinding process parameters are used in steps (2) and (3):

[0050] The grinding medium is zirconium silicate grinding balls with a particle size of 0.5~3.0mm, the filling rate of the grinding medium is 60%~70%, the ball material ratio is 1:2~1:4, and the s...

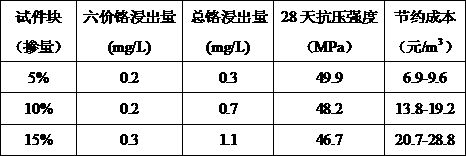

Embodiment 2

[0061] The method for solidifying chromium-containing solid waste in this embodiment comprises the following steps in turn:

[0062] (1) Take the chromium salt mud and refine it until the median particle size is less than 1mm, then add water to mix and stir to prepare slurry A with a solid content of 20%;

[0063] (2) Take 100 parts by mass of slurry A and pump it into a wet mill for wet grinding until the median particle size reaches 1 μm to obtain slurry B;

[0064] (3) Add 20 parts by mass of steel slag powder with a median particle size of 60 μm and 1 part by mass of sodium stearate to slurry B, mix well and then wet grind again until the median particle size is 4 μm to obtain slurry C ;

[0065] The wet grinding process parameters in steps (2) and (3) are the same as those in Example 1, and will not be repeated here.

[0066] (4) Gradually add 8 parts by mass of industrial by-product gypsum powder to slurry C until the pH value of the slurry is 11 to obtain slurry D;

...

Embodiment 3

[0076] The method for solidifying chromium-containing solid waste in this embodiment comprises the following steps in turn:

[0077] (1) Take the chromium slag and refine it until the median particle size is less than 1mm, then add water to mix and stir to prepare slurry A with a solid content of 18%;

[0078] (2) Take 100 parts by mass of slurry A and pump it into a wet mill for wet grinding until the median particle size is 2 μm to obtain slurry B;

[0079] (3) Add 23 parts by mass of steel slag powder with a median particle size of 40 μm and 3 parts by mass of sodium dodecylbenzenesulfonate to slurry B, mix well and then wet mill again until the median particle size is 2 μm, Obtain slurry C;

[0080] The wet grinding process parameters in steps (2) and (3) are the same as those in Example 1, and will not be repeated here.

[0081] (4) Gradually add 10 parts by mass of industrial by-product gypsum powder to slurry C until the pH value of the slurry is 7 to obtain slurry D;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com