Treatment method for reducing toxicity of tanning sludge

A technology of tannery sludge and treatment method, which is applied in the directions of sewage/sludge fertilizer, biological organic part treatment, preparation of organic fertilizer, etc. Environmental risks and other issues, to achieve the effect of simple operation, easy control of process parameters, and conducive to large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

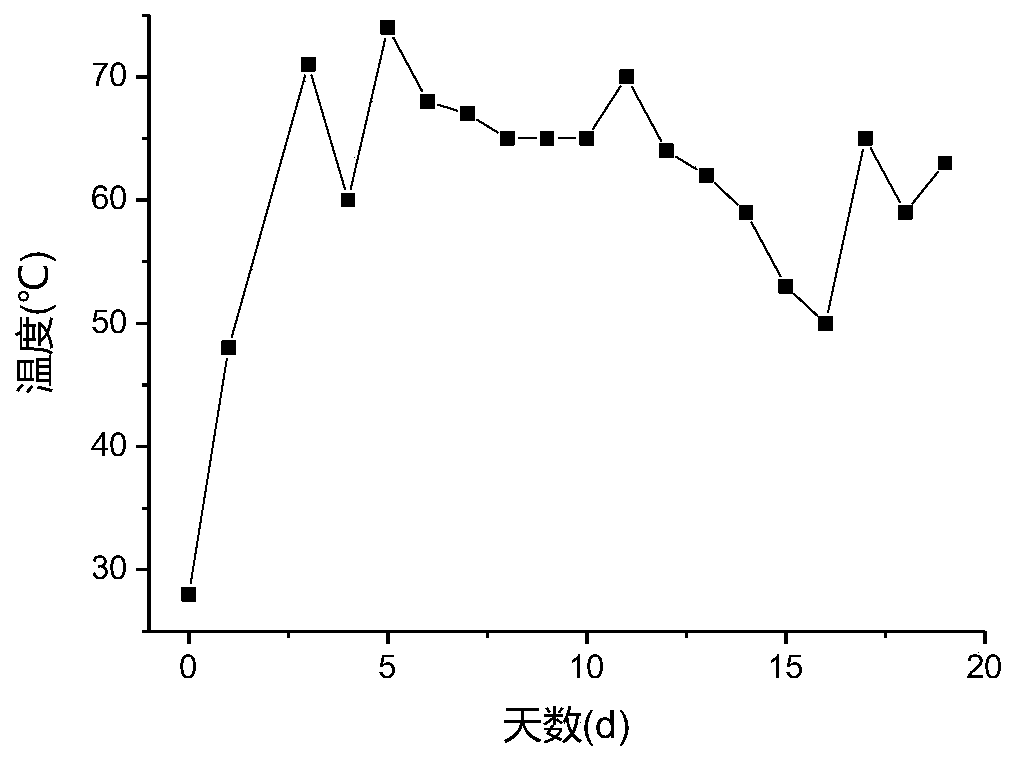

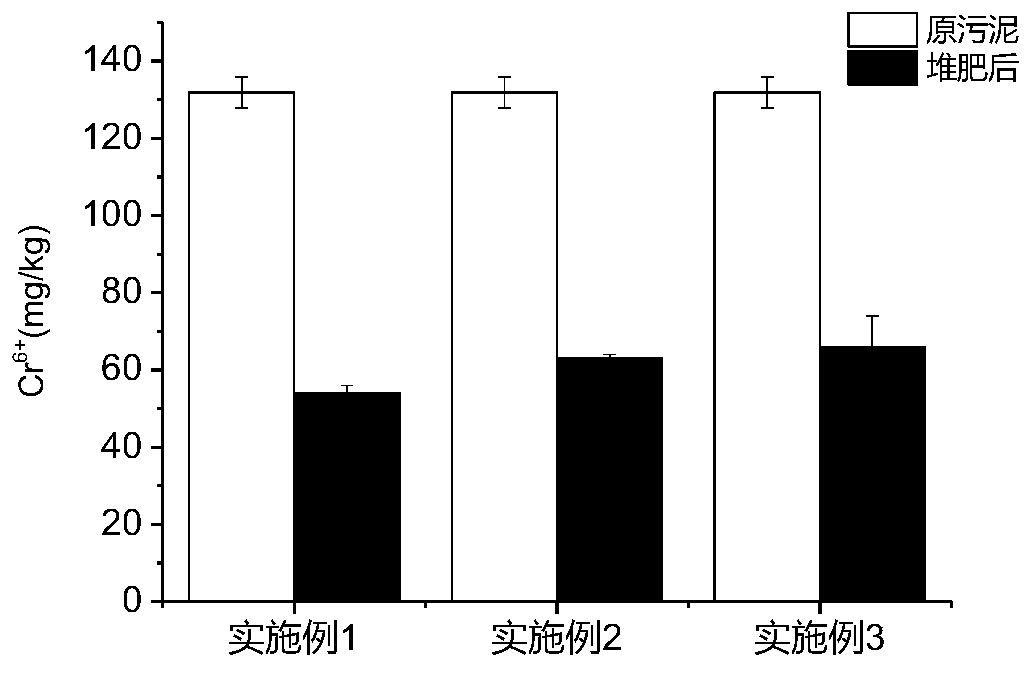

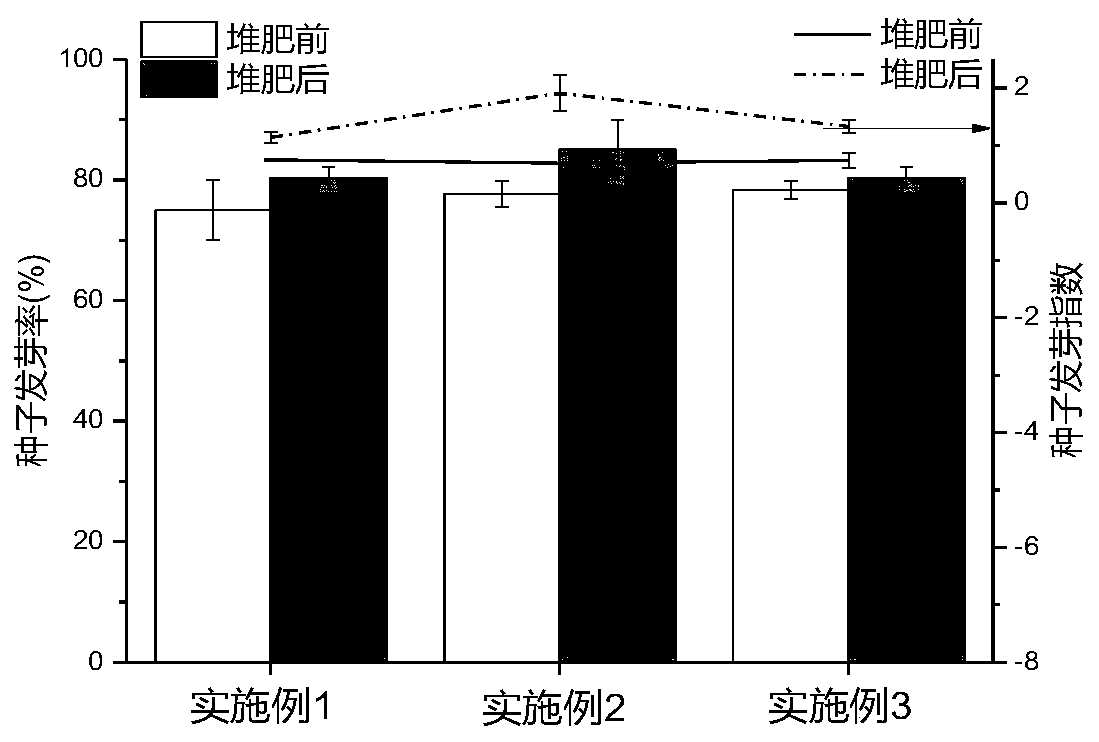

[0028] The tannery sludge and chicken manure were mixed at a volume ratio of 3:1, and the initial moisture content was 65%, covered with plastic film for strip-stack pre-composting. In the initial stage, the temperature of the compost rapidly rises to above 50°C and is maintained for 15 days. The compost is artificially turned and ventilated every day. After 20 days of high-temperature composting, pre-composted sludge with a diameter of about 3-4 cm after crushing is obtained. Using pre-composted sludge accounting for 30% of the total composting material as raw material, supplemented with additives such as straw, chicken manure, fly ash and bentonite, the materials are mixed evenly according to the volume ratio of 6:6:5:2:1, and the initial moisture content is adjusted After fully mixing, place it in a composting tank for aerobic composting, use a blower to mechanically ventilate, blow air for 30 minutes every day, and maintain the oxygen content of the heap above 18%. The tem...

Embodiment 2

[0032] The tannery sludge and chicken manure were mixed at a volume ratio of 3:1, and the initial moisture content was 65%, covered with plastic film for strip-stack pre-composting. In the initial stage, the temperature of the compost rapidly rises to above 50°C and is maintained for 15 days. The compost is manually turned every day for ventilation. After 20 days of high-temperature composting, pre-composted sludge with a diameter of about 3-4 cm after crushing is obtained. Using pre-composted sludge accounting for 50% of the total composting material as raw material, supplemented with additives such as straw, chicken manure, fly ash and bentonite, the materials are mixed evenly according to the volume ratio of 10:5:1:3:1, and the initial moisture content is adjusted After fully mixing, place it in a composting tank for aerobic composting, adopt mechanical forced ventilation, blow air for 30 minutes every day, and maintain the oxygen content of the heap above 18%. The temperat...

Embodiment 3

[0036] The tannery sludge and chicken manure were mixed at a volume ratio of 3:1, and the initial moisture content was 65%, covered with plastic film for strip-stack pre-composting. In the initial stage, the temperature of the compost rapidly rises to above 50°C and is maintained for 15 days. The compost is manually turned every day for ventilation. After 20 days of high-temperature composting, a crushed pre-composted sludge with a diameter of about 3-4 cm is obtained. Using pre-composted sludge accounting for 70% of the total composting material as raw material, supplemented with additives such as straw, chicken manure, fly ash and bentonite, the materials are mixed evenly according to the volume ratio of 14:3:1:0:2, and the initial moisture content is adjusted After fully mixing, place it in the composting tank for aerobic composting, adopt mechanical forced ventilation, blow air for 30 minutes every day, and maintain the oxygen content of the heap above 18%. The temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com