Optimization design method of anaerobic continuous flow agitator bath type biological hydrogen production reactor

A hydrogen production reactor and biological hydrogen production technology, applied in the field of environmental engineering, can solve the problems of limited parameter data, unrealizable economy and time, difficult to reflect the influence of the actual flow field reaction, etc., and achieve the effect of optimal design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] Example 1 : The following is the process that the inventor carried out the optimal design of the hydraulic flow field by taking the anaerobic continuous flow stirred tank type biological hydrogen production reactor with an effective volume of six liters as an example.

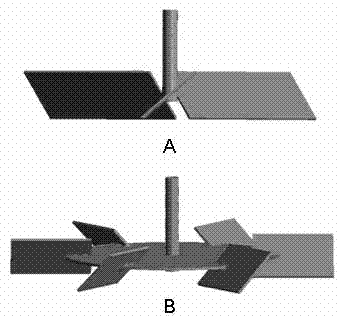

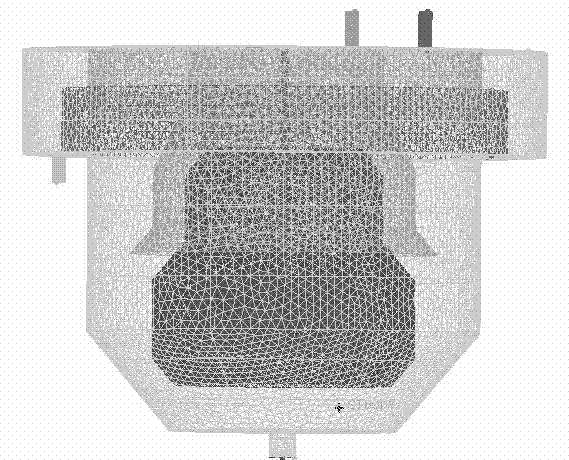

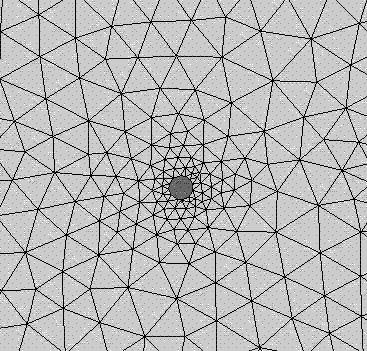

[0091] 1. Pre-processing - geometric modeling, mesh generation

[0092] According to the actual geometric size of the anaerobic biological hydrogen production reactor, choose such as figure 2 The PBT stirring impeller and the RT stirring impeller are shown as two types of stirring impellers, among which the three types of propeller groove diameter ratios are 0.4, 0.5 and 0.6 respectively. Aansys ICEM CFD 12.0 is used to analyze the PBT stirring impellers with three kinds of propeller groove diameter ratios. Three-dimensional geometric modeling and grid generation of the anaerobic biohydrogen reactor with RT stirring paddles with three paddle diameter ratios, and the reactor inner cylinder, three-phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com