Method for determining gas production rate of organic matrix in biochemical gas production stage

A technology of biochemistry and gas production rate, applied in the direction of material inspection products, fuel oil testing, etc., can solve the problems that affect the obtained results, cannot objectively represent the gas production rate, and have great differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

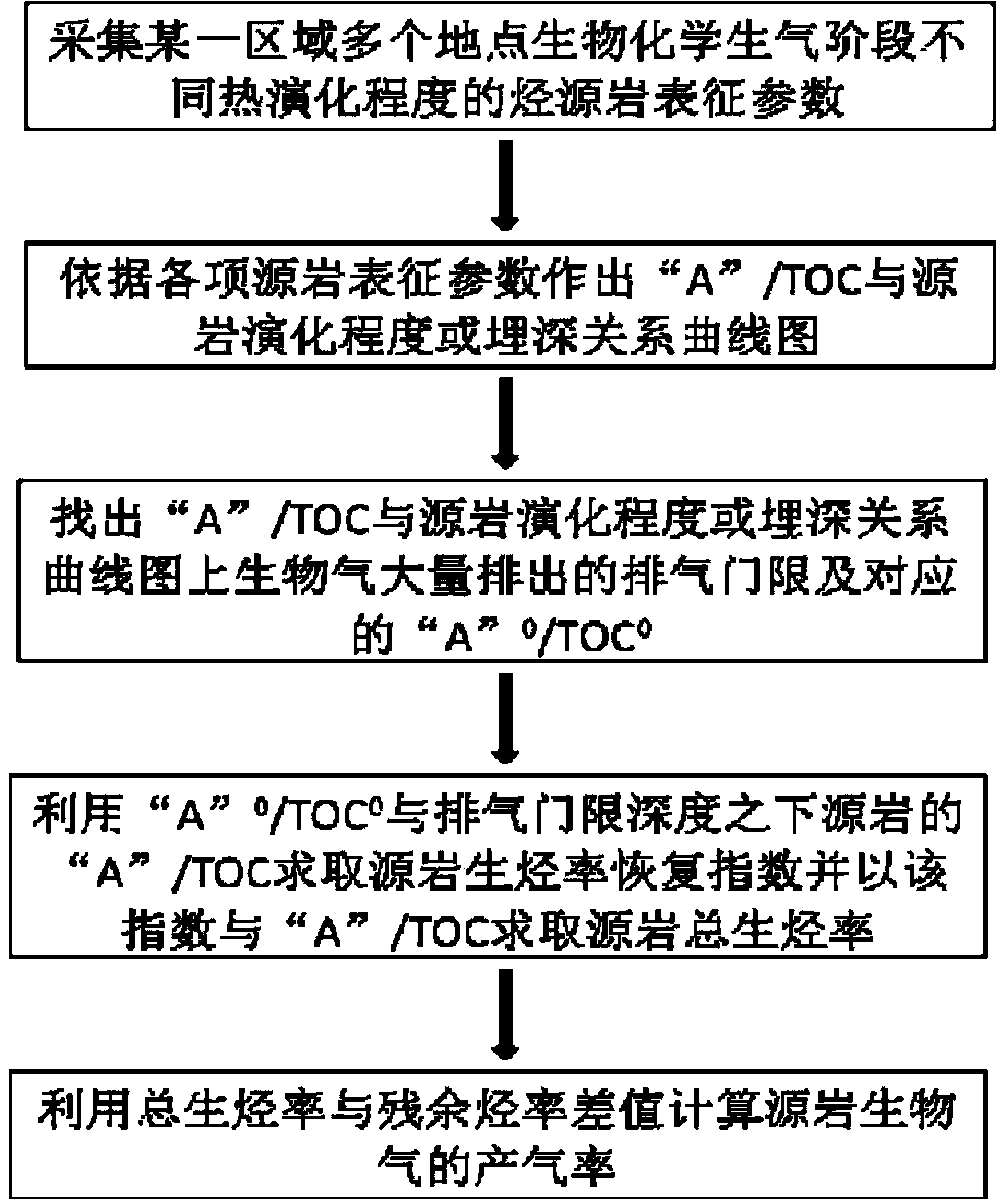

[0062] In order to understand the present invention in depth, the present invention will be described in detail below with reference to the drawings and specific embodiments.

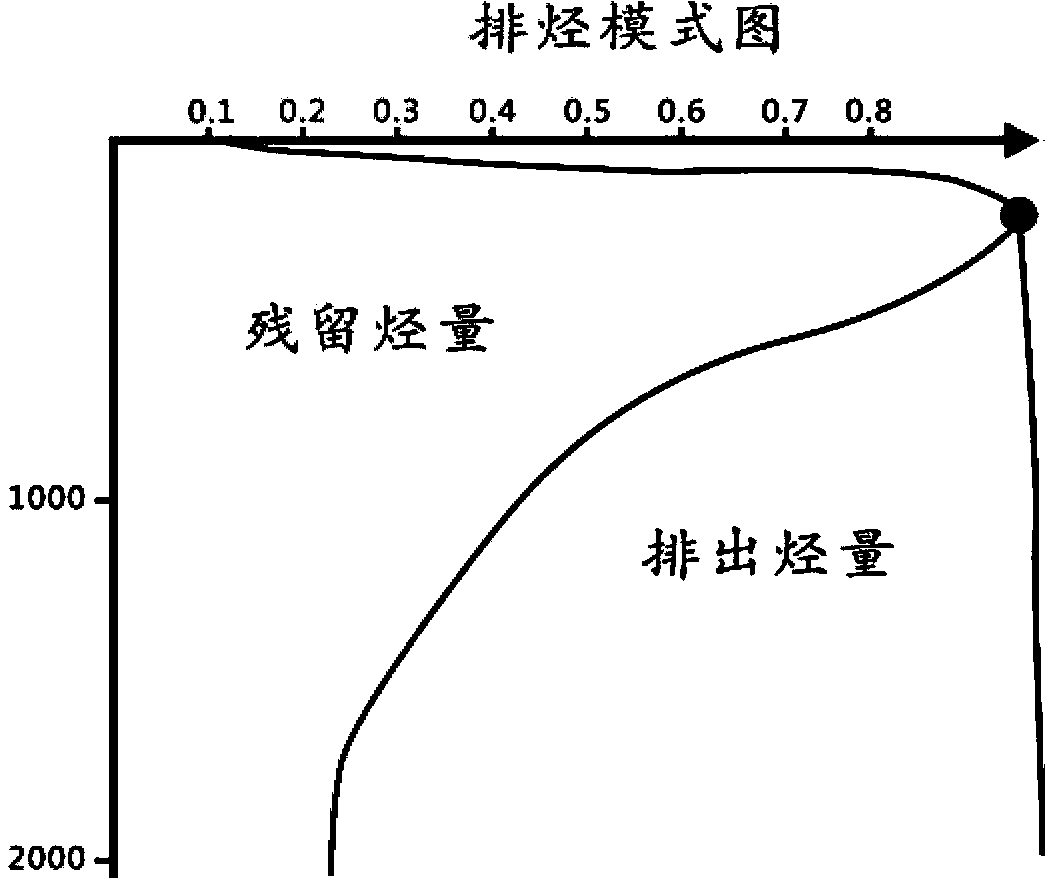

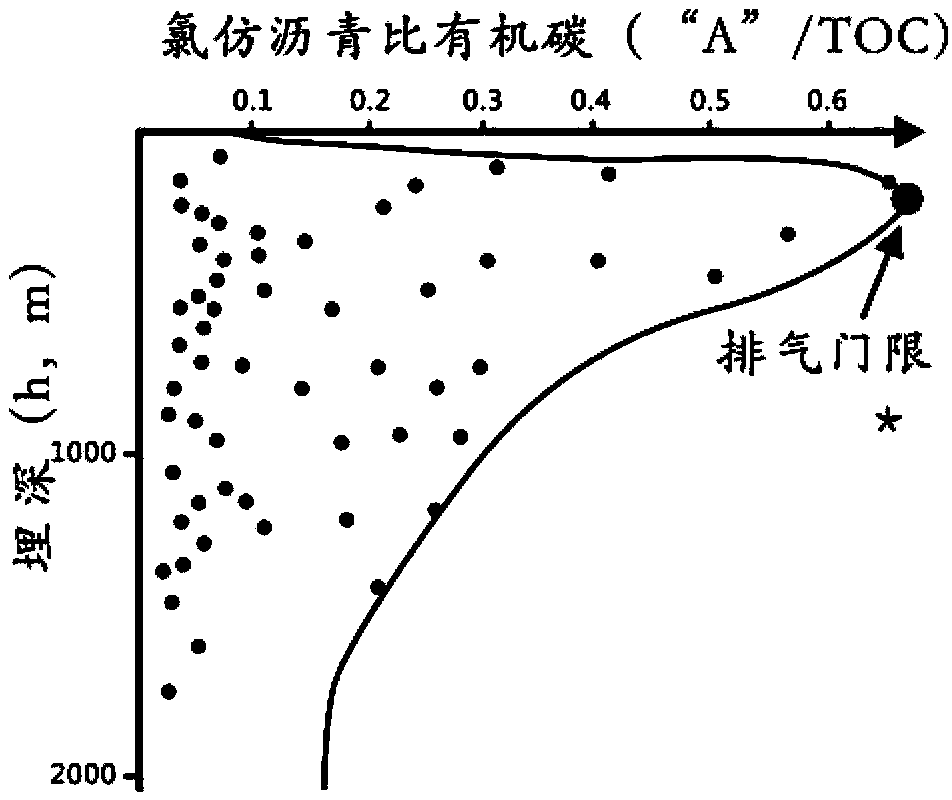

[0063] Such as figure 1 , The present invention provides a method for determining the gas production rate of organic parent material in the biochemical gas generation stage. The specific process includes five steps; at the same time, the theoretical template diagram of the method is proposed, such as figure 2 ; From the perspective of technical implementation, this method is aimed at the shortcomings of low reliability of the gas production rate value obtained by the existing biogas gas production rate calculation method, and the application source rock hydrocarbon generation is equal to the sum of the discharged hydrocarbons and the residual hydrocarbons. The principle of material balance is more objective, convenient and accurate to obtain the biogas production rate of the source rock, which has a wide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com