Novel spouted circulating fluid bed timber rapid pyrolysis apparatus and technological process

A circulating fluidized bed and spouted fluidized bed technology, which is used in the petroleum industry, special forms of dry distillation, biofuels, etc., can solve the problems of low heat and mass transfer efficiency, high operating costs, and non-compact structure. The effect of low operating cost, wide application range of materials, and easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

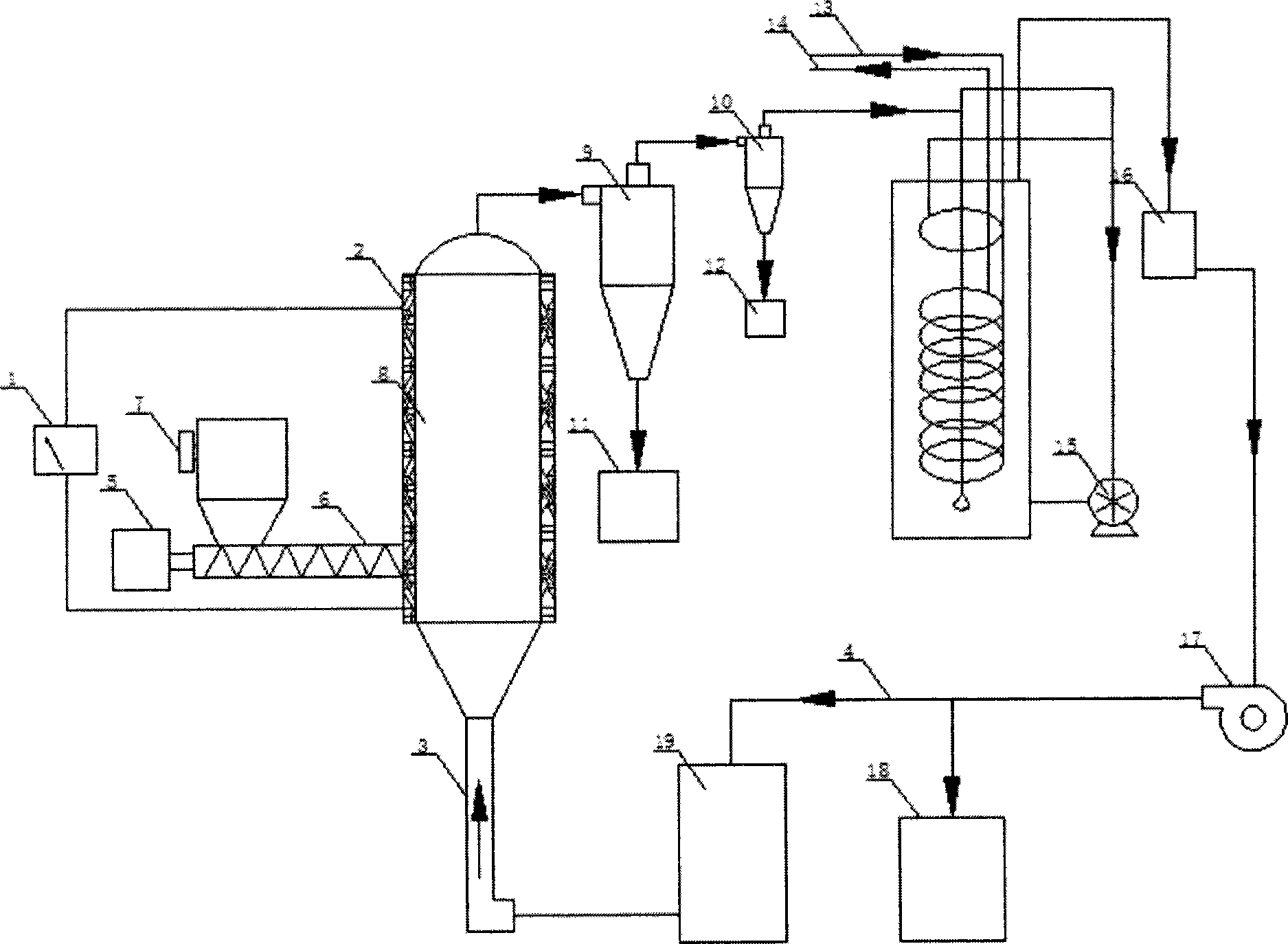

[0049] As shown in the accompanying drawings, the specific embodiment for realizing the present invention is as follows: a novel spouted circulating fluidized bed with a feed rate of 5Kg / h is used to process larch. The device consists of: 1. Monitoring system, 2. Main heating system, 3. Preheating system, 4. Circulation pipeline, 5. Stepless frequency modulation motor, 6. Screw feeder, 7. Vibrator, 8. Sprayer Fluidized bed reactor, 9. primary cyclone separator, 10. secondary cyclone separator, 11. primary biochar collection box, 12. secondary biochar collection box, 13. condensed water inlet pipe, 14. Condensed water return pipe, 15. Circulating pump, 16. Fluidized medium dehumidification system, 17. Roots blower, 18. Voltage stabilization system, 19. Non-condensable gas collection system.

[0050] The process method is as follows: firstly, the computer, the monitoring instrument, the thyristor voltage regulator and the voltage frequency regulator are turned on, and the monito...

Embodiment 2

[0053] As shown in the accompanying drawings, the specific embodiment for realizing the present invention is: the novel spouted circulating fluidized bed with feed rate of 15Kg / h is used to process poplar. The device consists of: 1. Monitoring system, 2. Main heating system, 3. Preheating system, 4. Circulation pipeline, 5. Stepless frequency modulation motor, 6. Screw feeder, 7. Vibrator, 8. Sprayer Fluidized bed reactor, 9. primary cyclone separator, 10. secondary cyclone separator, 11. primary biochar collection box, 12. secondary biochar collection box, 13. condensed water inlet pipe, 14. Condensed water return pipe, 15. Circulating pump, 16. Fluidized medium dehumidification system, 17. Roots blower, 18. Voltage stabilization system, 19. Non-condensable gas collection system.

[0054] Its processing method is with embodiment one.

[0055] The temperature inside the spouted fluidized bed reactor was set at 650°C. Turn on the Roots blower and adjust the circulating air vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com