Control of gas composition of a gas separation system having membranes

A gas separation and membrane separation technology, applied in the field of biogas or natural gas treatment, can solve the problems of expensive, inconvenient, and unfavorable energy control technology, and achieve the effect of a simple, accurate and simple control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

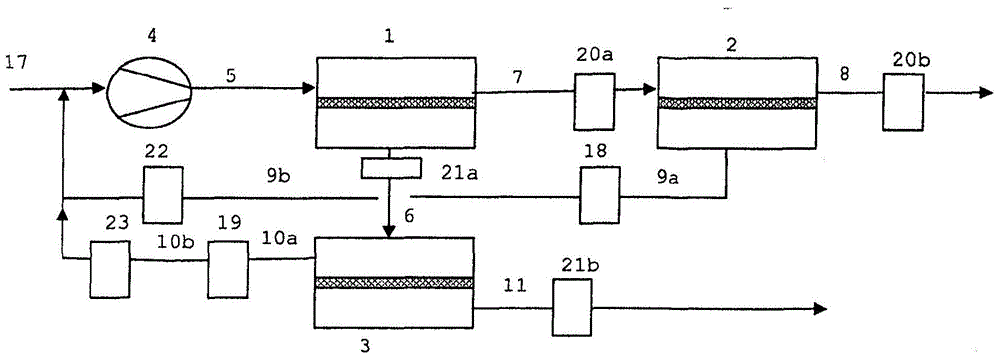

Method used

Image

Examples

Embodiment 1

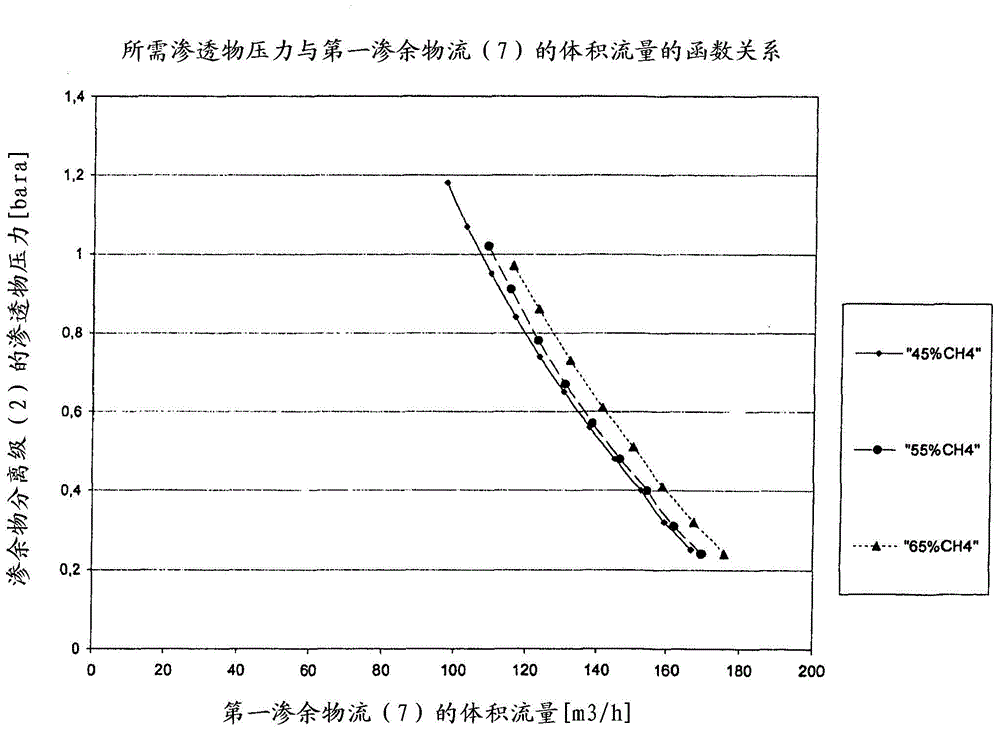

[0116] The purpose of this experiment was to find the calibration straight line that allows maintaining the product in retentate stream 8 by changing the permeate pressure of retentate separation stage 2 when the feed flow rate or compressor speed in feed stream 5 is changed The gas quality is constant, and the exhaust gas quality in the permeate stream 11 is kept constant by varying the retentate pressure of the permeate separation stage 3 .

[0117] To this end, in a 3-stage interconnection arrangement operated according to the general experimental arrangement, the compressor efficiency was increased stepwise. An attempt was then made to keep the exhaust gas concentration 11 and the product gas concentration 8 constant within narrow ranges by varying the permeate pressure of retentate separation stage 2 and the retentate pressure of permeate separation stage 3 . As the compressor efficiency increased from an initial 60% to a final 75%, the feed volume flow5 increased from 3....

Embodiment 2

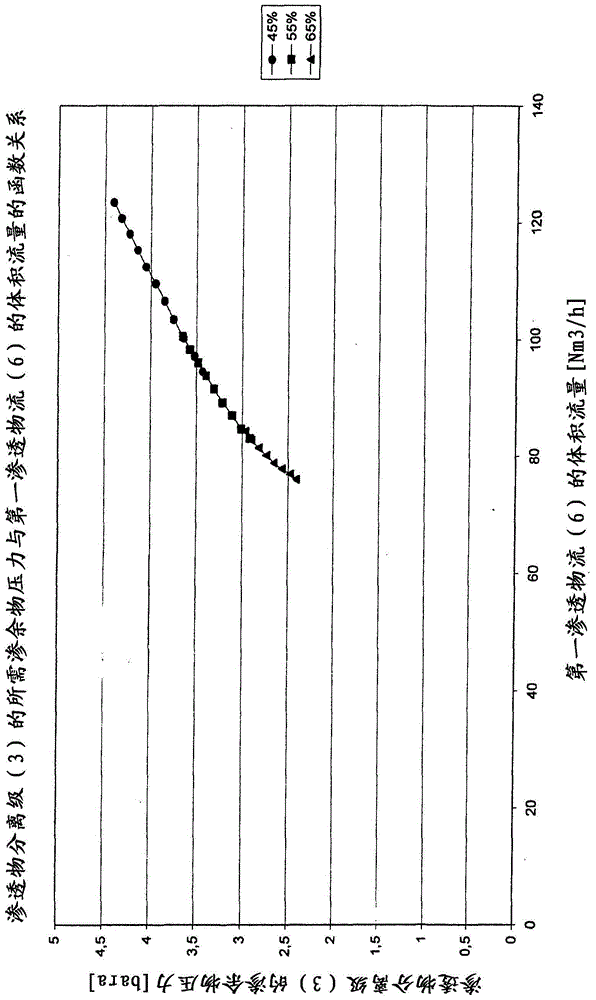

[0126] It was checked whether by changing the retentate pressure of the permeate separation stage 3 using the control unit 19 in the third retentate stream 10 a change in the methane concentration in the exhaust gas from this unit (third permeate stream 11 ) could be achieved and obtain a calibration curve. This calibration relationship can then be used to adapt the methane content in the exhaust if there is a change in the measurement of the exhaust concentration.

[0127] To this end, while keeping the compressor speed constant, the retentate pressure of the permeate separation stage 3 is varied with the control device 19 in the third retentate stream 10 and the correspondingly varied third permeate stream 11 (exhaust gas ) methane concentration. The volumetric flow rate of the device is also recorded. Values are shown in Table 2.

[0128] Table 2:

[0129]

[0130] As shown in Table 2, as the retentate pressure in permeate separation stage 3 increases, the methane ...

Embodiment 3

[0133] Variation of the methane concentration in the product gas (=second retentate stream 8 ) of this unit can be achieved by varying the permeate pressure of the retentate separation stage 2 with the control unit 18 in the second permeate stream 9a. This calibration relationship can be used to adapt the methane content in the product gas if there is a change in the measurement of the product gas concentration.

[0134] For this purpose, the permeate pressure of retentate separation stage 2 was varied while the compressor speed was kept constant and the methane concentration in the product gas was measured as a result of the variation. Values are shown in Table 3.

[0135] table 3:

[0136] Stage 2 Permeate Pressure [bara]

c(CH in retentate stream 8 4 )[%]

1.005

96.44

0.95

96.77

0.9

97.03

0.85

97.23

0.8

97.48

0.75

97.68

0.7

97.93

0.65

98.14

0.6

98.34

0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com