Microwave-assisted extraction and hydrofracture cooperative coal seam anti-reflection method

A hydraulic fracturing and microwave-assisted technology, which is applied in the fields of earthwork drilling, gas discharge, and mining fluids, can solve the problems that organic solvents are difficult to penetrate into the popularization and application, so as to improve the gas drainage effect, promote gas desorption, and increase the porosity. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

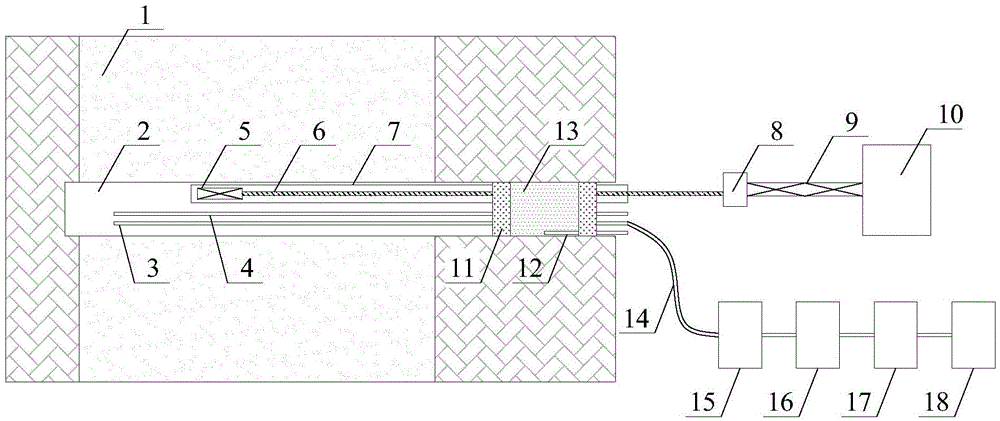

[0032] Embodiment 1, as figure 1 As shown, the method of coal seam permeability enhancement combined with microwave-assisted extraction and hydraulic fracturing: firstly, a hydraulic fracturing borehole 2 is constructed in the coal seam 1, and the hydraulic fracturing borehole 2 is sent into the fracturing borehole 2 after the construction is completed. Pipe 3, microwave protection pipe 7 and gas drainage pipe 4 until the innermost ends of fracturing pipe 3 and gas drainage pipe 4 reach the roof of coal seam 1, and the innermost end of microwave protection pipe 7 reaches the middle of coal seam 1. At the position 0.1m away from the orifice, the microwave protective tube 7 is made of polytetrafluoroethylene. Then, connect the outer end of the microwave antenna 5 to the coaxial waveguide 6 and send the microwave antenna 5 and the coaxial waveguide 6 into the microwave protection tube 7 until the microwave antenna 5 reaches the innermost end of the microwave protection tube 7; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com