Coal seam weakening anti-reflection device and method based on microwave-assisted pre-cracking and high-voltage pulse

A coal seam weakening and microwave technology, which is used in safety devices, earth-moving drilling, measurement, etc., can solve the problems of unstable effect of high-voltage pulse technology, excessive energy loss, and high pulse voltage, so as to achieve good weakening and anti-reflection effect and reduce field Strong and promoting effect of gas desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be briefly described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other implementations obtained by those skilled in the art without creative work Examples, all belong to the protection scope of the present invention.

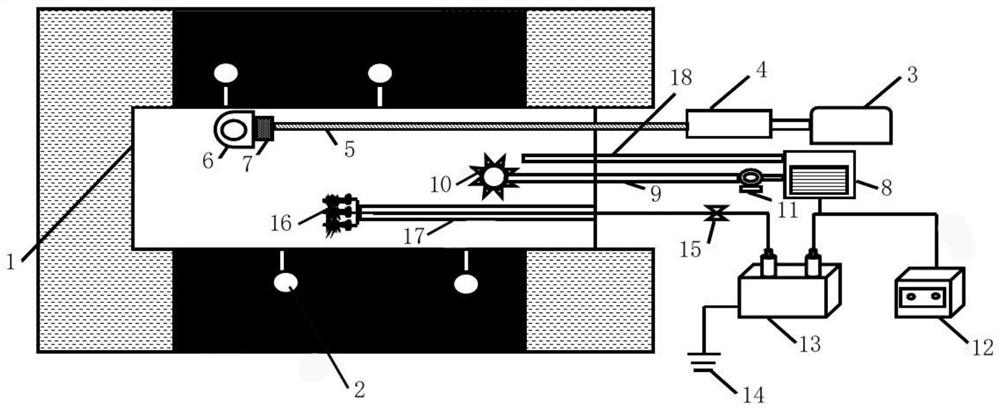

[0033] figure 1 A preferred embodiment of the present invention is shown and analyzed in detail.

[0034] Such as figure 1 The coal seam weakening and anti-reflection device shown in the microwave-assisted pre-splitting and high-voltage pulse coordination includes a microwave generator 3, a microwave converter 4, a coaxial waveguide 5, a microwave antenna 6, an integrated liquid storage and pumping device 8, and a high-voltage power supply 12. An energy storage capacitor 13 and an electrode 16 .

[0035] Wherein, the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com