Polypyrrole/polyvinylidene fluoride nano fiber composite resistance type film gas-sensitive element and manufacturing method thereof

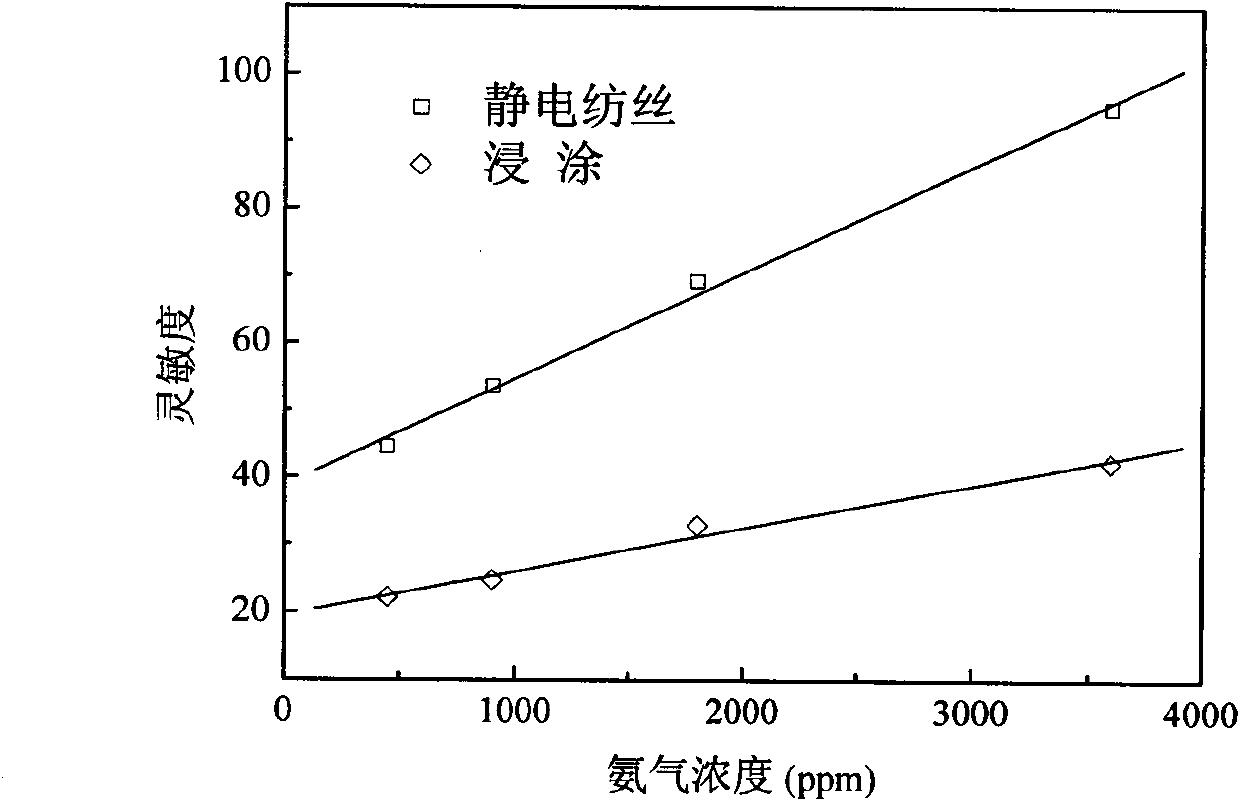

A technology of polyvinylidene fluoride and nanofibers, which is applied in the direction of material analysis, instruments, and analysis materials through electromagnetic means, which can solve problems such as insufficient response sensitivity, poor reversibility, and application obstacles, and achieve high response sensitivity and easy regulation , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

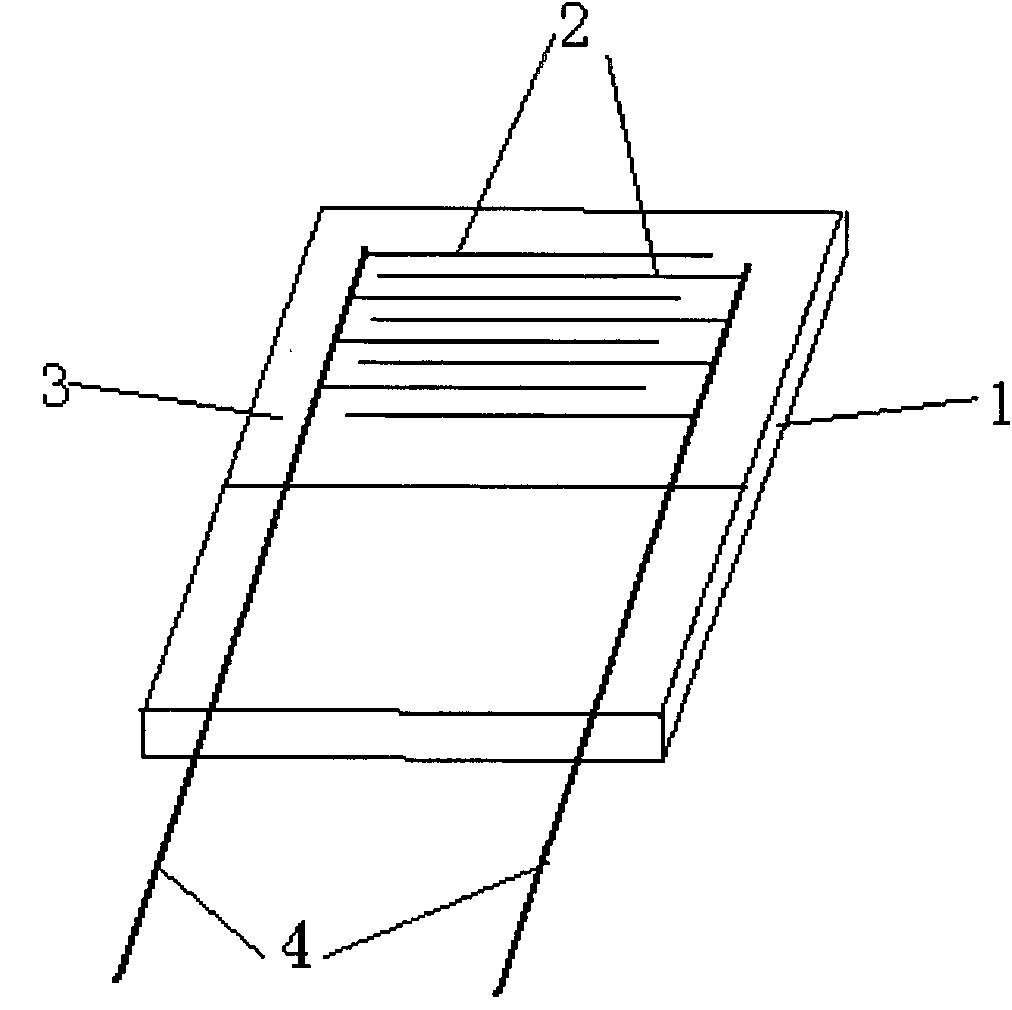

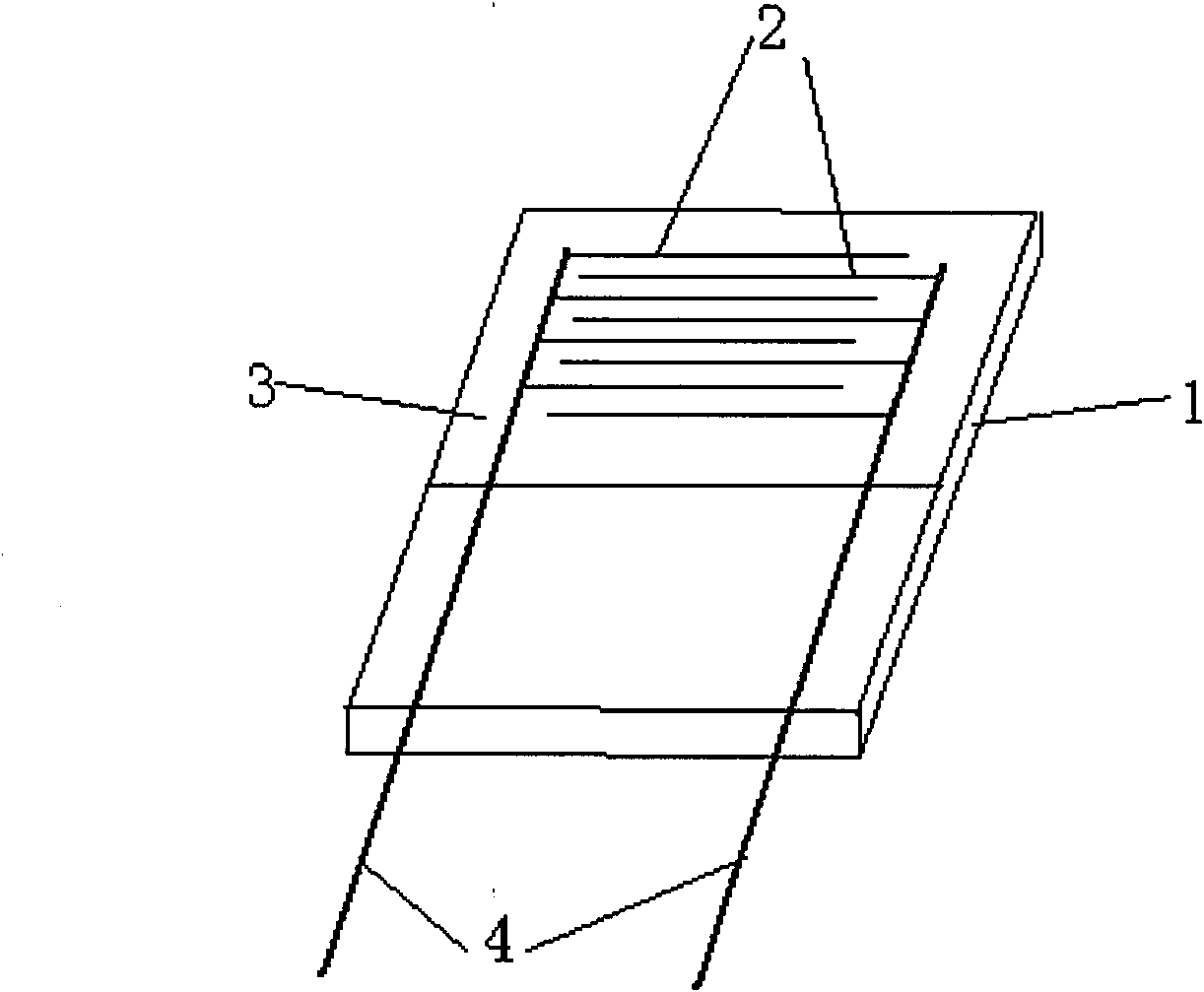

[0027] 1) Cleaning the surface photolithography and evaporating the ceramic substrate with interdigitated gold electrodes, drying for later use;

[0028] 2) Preparation of polyvinylidene fluoride nanofibers by electrospinning: N,N-dimethylacetamide containing polyvinylidene fluoride with a concentration of 0.1g / ml and iron trichloride with a concentration of 0.02g / ml The solution is packed in a syringe with a needle, the injection needle is connected to the positive pole of the high-voltage power supply, the negative pole of the high-voltage power supply is connected to the copper plate, and the interdigitated gold electrode with a ceramic substrate is placed on the copper plate; a 10kV power supply voltage is applied between the syringe needle and the copper plate, The distance between the needle and the copper plate is 10cm, and the solution in the syringe is extruded at a flow rate of 0.2ml / h by a syringe pump, and deposited on the interdigitated gold electrode and the surfa...

Embodiment 2

[0031] 1) Cleaning the surface photolithography and evaporating the ceramic substrate with interdigitated gold electrodes, drying for later use;

[0032]2) Preparation of polyvinylidene fluoride nanofibers by electrospinning: N,N-dimethylacetamide containing polyvinylidene fluoride with a concentration of 0.01g / ml and iron trichloride with a concentration of 0.005g / ml The solution is packed in a syringe with a needle, the injection needle is connected to the positive pole of the high-voltage power supply, the negative pole of the high-voltage power supply is connected to the copper plate, and the interdigitated gold electrode with a ceramic substrate is placed on the copper plate; a 20kV power supply voltage is applied between the needle of the syringe and the copper plate, The distance between the needle and the copper plate is 20cm, and the solution in the syringe is extruded at a flow rate of 1.0ml / h by a syringe pump, and deposited on the interdigitated gold electrode and t...

Embodiment 3

[0035] 1) Cleaning the surface photolithography and evaporating the ceramic substrate with interdigitated gold electrodes, drying for later use;

[0036] 2) Preparation of polyvinylidene fluoride nanofibers by electrospinning: N,N-dimethylacetamide containing polyvinylidene fluoride with a concentration of 0.2g / ml and iron trichloride with a concentration of 0.10g / ml The solution is contained in a syringe with a needle, the injection needle is connected to the positive pole of the high-voltage power supply, the negative pole of the high-voltage power supply is connected to the copper plate, and an interdigitated gold electrode with a ceramic substrate is placed on the copper plate; a 30kV power supply voltage is applied between the needle of the syringe and the copper plate, The distance between the needle and the copper plate is 8cm, and the solution in the syringe is extruded at a flow rate of 0.5ml / h by a syringe pump, and deposited on the interdigitated gold electrode and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| interdigital gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com