Microwave-assisted supercritical carbon dioxide cyclic fracturing system and microwave-assisted supercritical carbon dioxide cyclic fracturing method

A technology assisted by carbon dioxide and microwave, applied in earthwork drilling, waveguide devices, gas discharge, etc., can solve problems such as strong penetration of fracturing fluid, holes and cracks entering coal, etc., to promote gas desorption and reduce Fracture pressure, improve the effect of gas drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

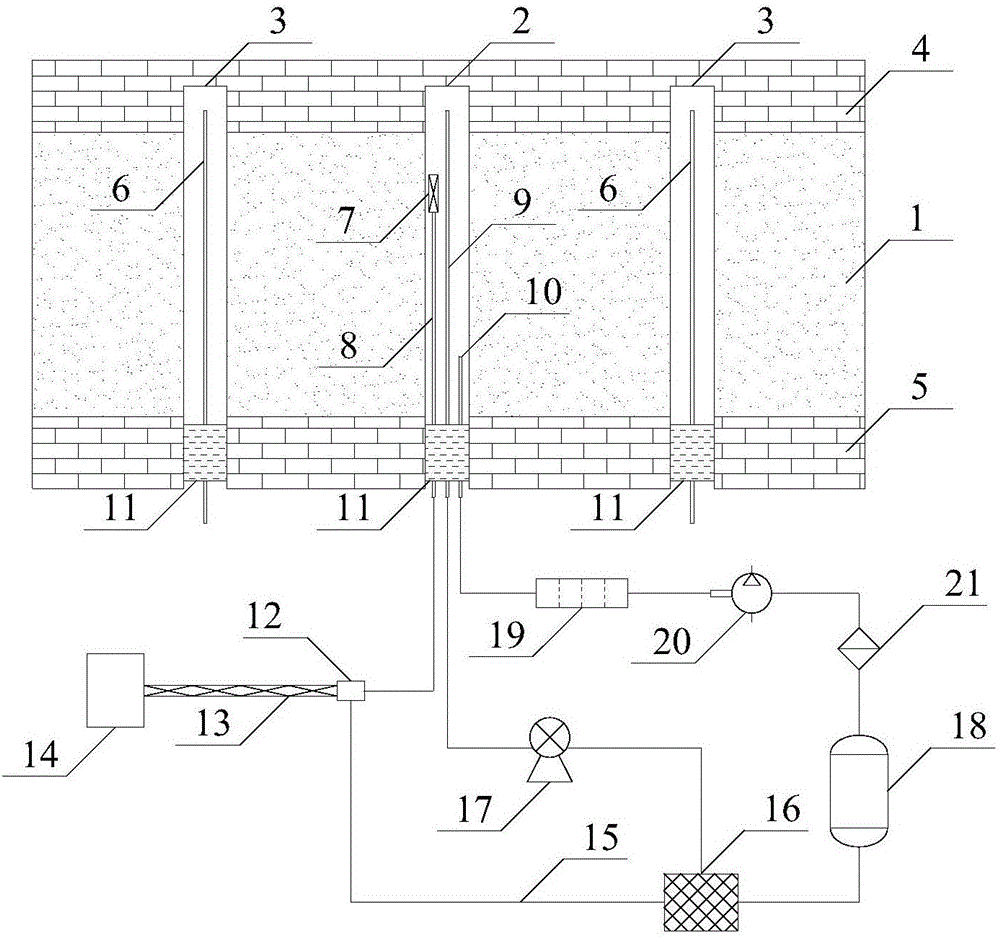

[0025] Such as figure 1 As shown, the microwave-assisted supercritical carbon dioxide circulation fracturing system of the present invention includes a three-phase separator 19 connected to the recovery pipe 10, an air compressor 20 connected to the three-phase separator 19, and a cooling system connected to the air compressor 20. 21 and the liquid carbon dioxide storage tank 18 connected with the cooler 21, the pipeline on the lower side of the liquid carbon dioxide storage tank 18 is connected with a heater 16, and the heater 16 is connected with a booster pump 17 connected with the fracturing pipe 9 through the pipeline. One path is connected with a waveguide converter 12 connected to the coaxial waveguide 8 to form a loop for realizing supercritical carbon dioxide circulation fracturing and forming a fracture network in the coal seam; the coaxial wavegu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com