Cutting-exploding coupled coal anti-reflection method in drilled hole

An in-hole, coupled technology, applied in the fields of fluid extraction, earthwork drilling, gas discharge, etc., can solve the problem of limited effective influence range of a single slotted hole, and achieve the expansion of the effective pressure relief influence range. The method is simple, The effect of reducing the gas adsorption potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

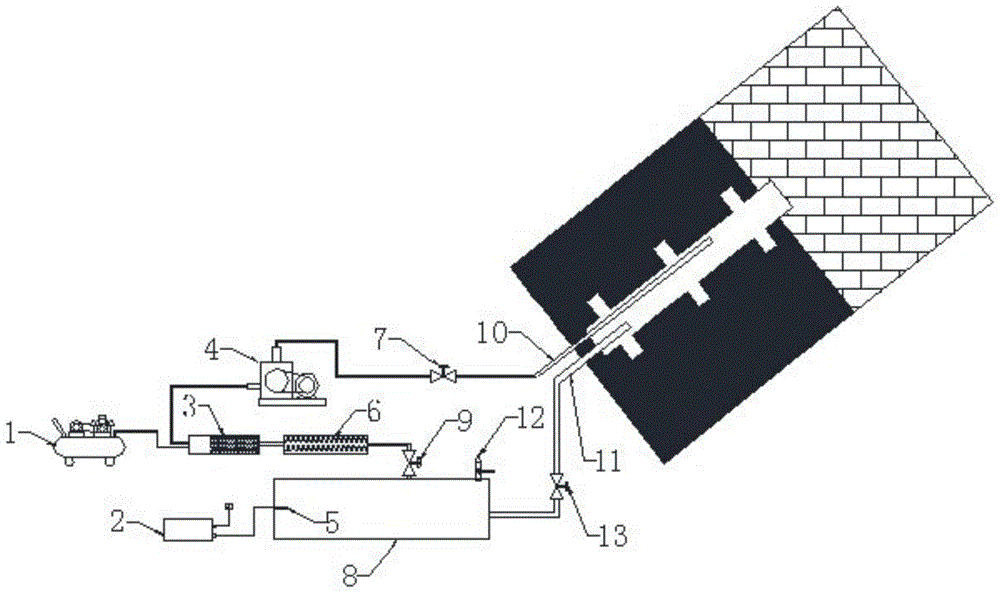

[0019] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0020] The drilling internal cutting-explosion coupling type coal body anti-reflection method of the present invention, the specific steps are as follows:

[0021] a. Alternately arrange the hole positions of drainage boreholes and percussion boreholes in the coal seam to ensure that the drainage boreholes are all within the influence range of percussion boreholes;

[0022] b. Use ordinary drill bits to drill into the hole position of the drainage borehole until it completely penetrates the coal seam, and after sealing the hole, connect it to the gas drainage pipe network for gas drainage;

[0023] c. Use the integrated drilling and cutting drill bit to drill into the hole position of the percussion drilling to 1m past the roof of the coal seam, withdraw the drill, and perform hydraulic cutting on the coal seam in the drill hole;

[0024] d. After withdraw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com