Carrying device of three advance geology forecasting instruments on TBM (Tunnel Boring Machine)

A technology of advanced geological forecasting and instruments, which is applied in the field of TBM to achieve the effect of ensuring stability, solving limited modification space and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further explained below through specific examples and drawings.

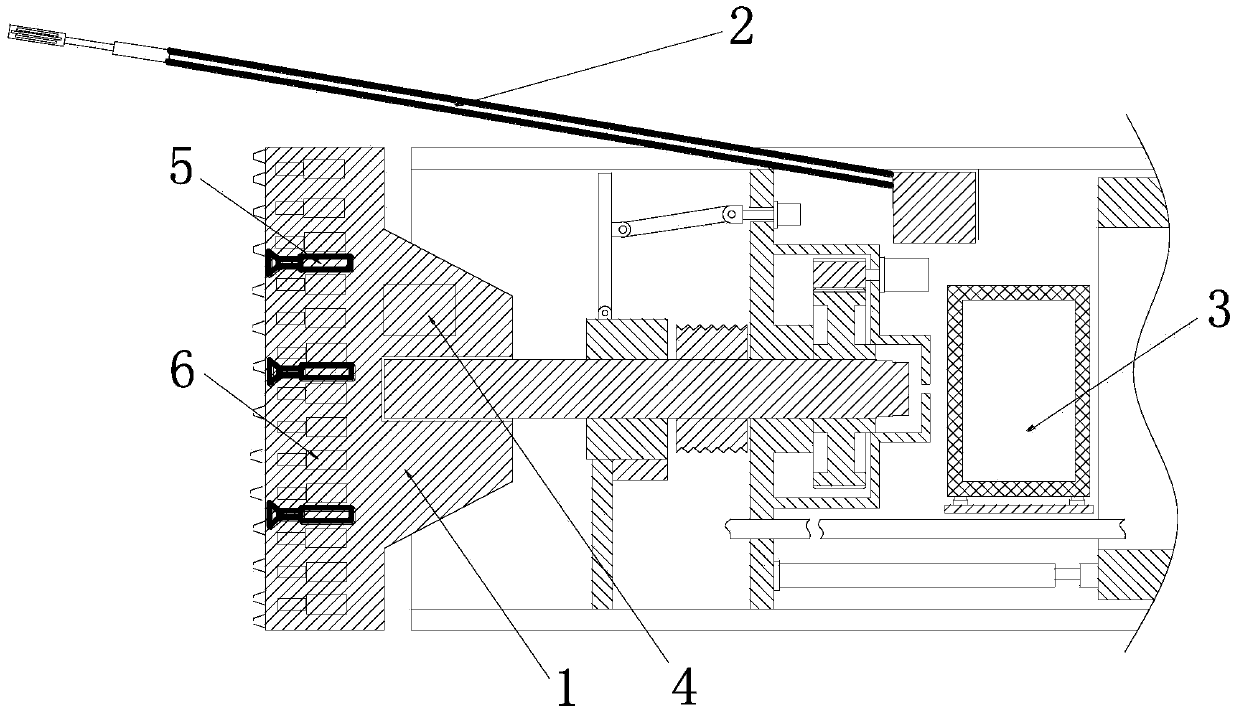

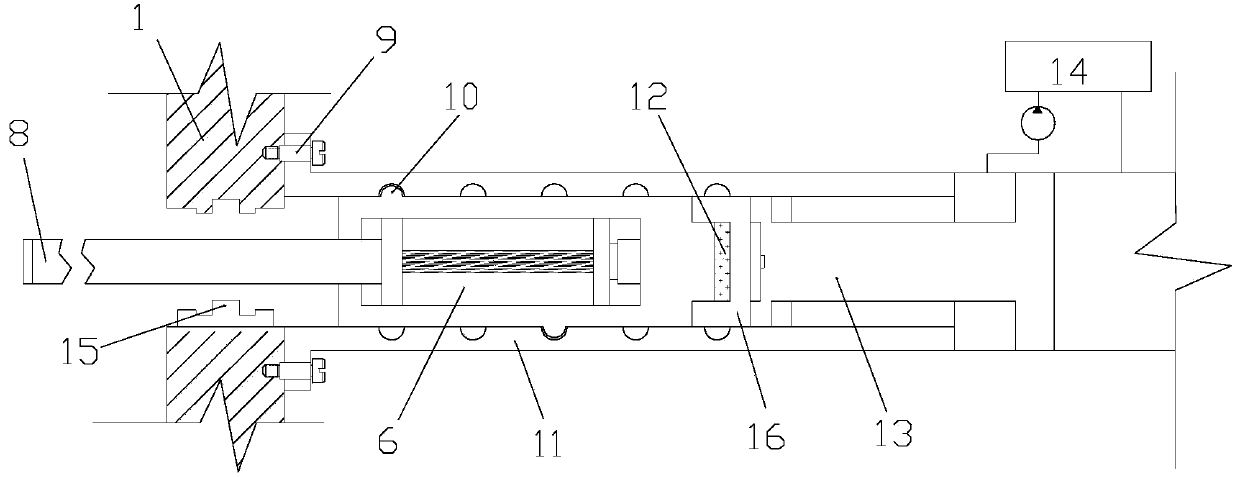

[0042] The mounting device of the three advanced geological forecast instruments on the TBM of the present invention, such as figure 1 The display mainly includes three parts, namely the carrying device of the detection instrument on the cutter head 1, the carrying mechanism of the diagonal single-hole geological radar transmitting and receiving antenna 2 above the TBM backing, the carrying mechanism of the seismic wave sensor 4, the instrument cabin 3 and the rear of the host Wiring panel at the front and rear shield connection. Through the synergy of several parts of the mounted equipment, the operation of the three instruments on the TBM is jointly completed to form the entire mounted device. First, the method and device for mounting the power supply / measurement electrode 5 and the seismic wave exciter 6 on the TBM cutter head are introduced.

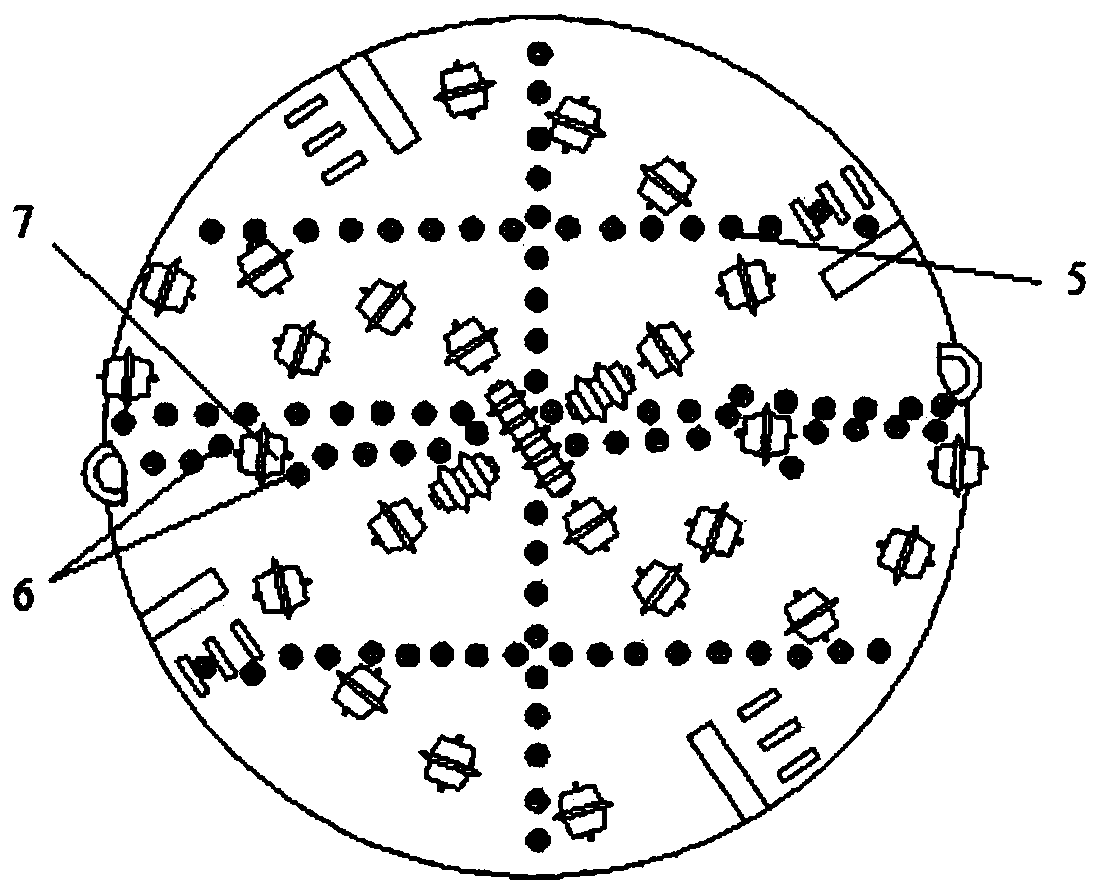

[0043] Such as figure 2 Shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com