Method for increasing permeability in drilling holes in cold expansion and heat driving mode

A technology for drilling inside and coal bodies, which is applied in the direction of mining fluid, earthwork drilling, gas discharge, etc. It can solve the threat of underground safety production, laborious charging and other problems, and achieve the expansion of the scope of effective pressure relief, low cost, Enhance the effect of gas extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

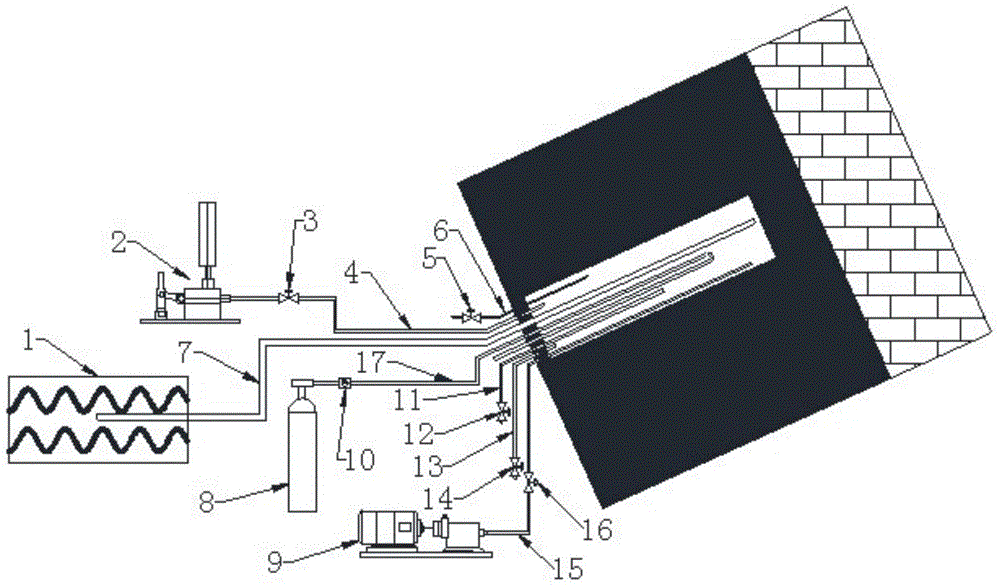

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0019] a. Alternately arrange the hole positions of drainage boreholes and enhanced drainage boreholes in the coal seam to ensure that the drainage boreholes are within the influence range of the enhanced drainage boreholes;

[0020] b. Construction drainage drilling, sealing, connecting to the gas drainage pipeline for gas drainage;

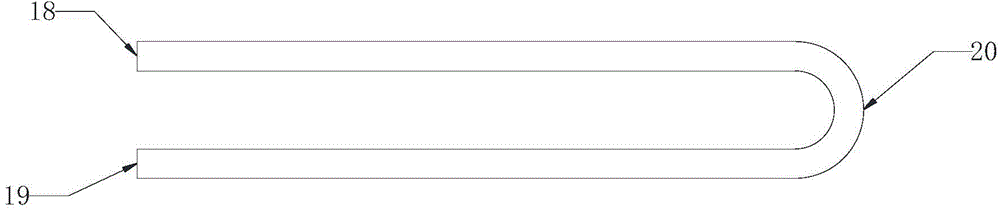

[0021] c. Construction enhanced drainage drilling, after the drill pipe is withdrawn, the grouting pipe 4, the grouting pipe 6, the heat pipe 7, the extraction pipe 11, the water discharge pipe 13, the water injection pipe 15 and the condensation pipe 17 are sent into the borehole, and the injection The exposed end of the slurry pipe 4 is connected to the grouting pump 2, the inlet end of the condensation pipe 17 is connected to the condensation device 8, the exposed end of the water injection pipe 15 is connected to the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com