A laser drilling and cutting integrated enhanced gas drainage system and method

A gas extraction and laser technology, which is applied in drilling equipment and methods, gas discharge, and earth-moving drilling, etc., can solve the problems of large gas gushing, multi-gas, and gas exceeding the limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

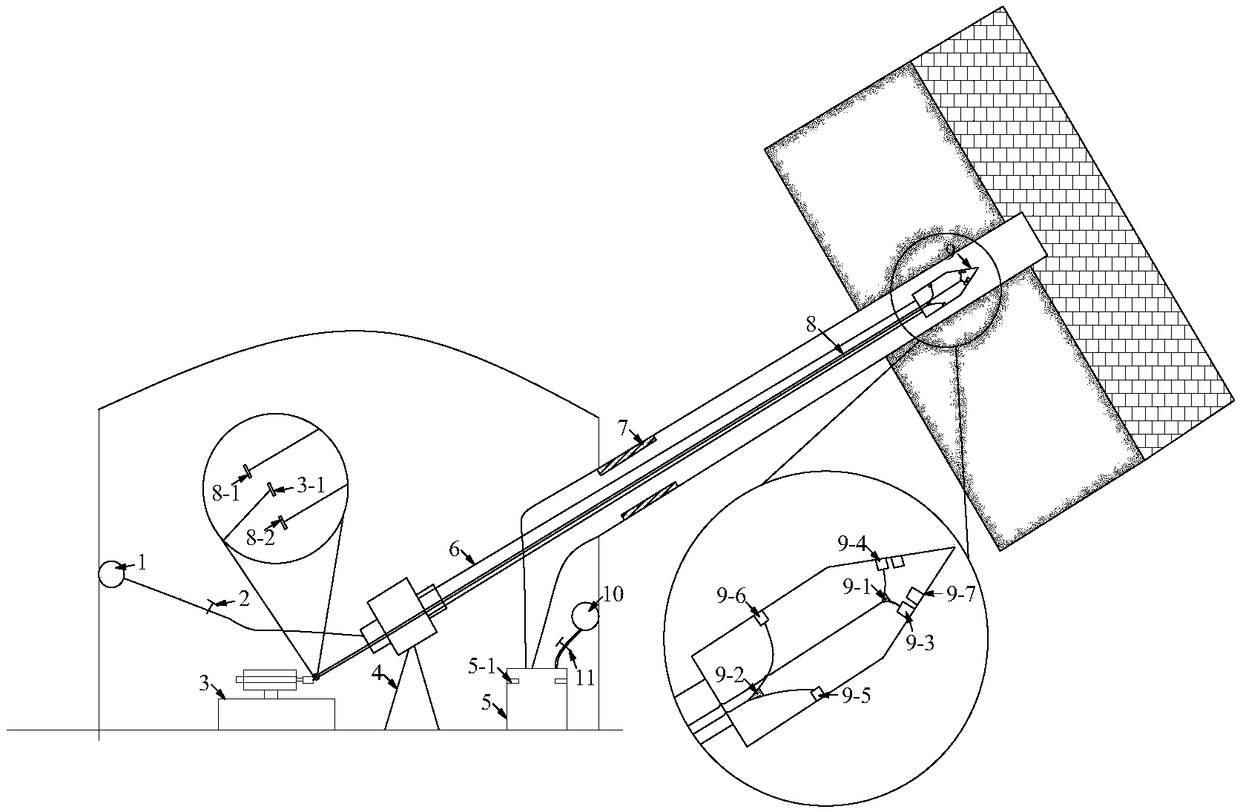

[0027] A laser drilling and cutting integrated enhanced gas drainage system is characterized in that it mainly includes a compressed air pipeline 1, a compressed air pipeline valve 2, a laser generator 3, a drilling rig 4, an air slag separator 5, a drill pipe 6, and an orifice Sealer 7, optical fiber 8, drill bit 9, gas extraction pipeline 10 and gas extraction pipeline valve 11.

[0028] The compressed air pipeline 1 is connected with a drilling rig 4 . The compressed air pipeline 1 is equipped with a compressed air pipeline valve 2 . The drilling machine 4 drives the drilling rod 6 to drill in. The drill rod 6 is hollow, ie has an axial channel for receiving the optical fiber 8 . One end of the drill rod 6 is connected to a drill bit 9 . The laser generator 3 is respectively connected to the optical fiber connector II8-1 and the optical fiber connector III8-2 through the optical fiber connector I3-1. Optical fiber connector II8-1 and optical fiber connector III8-2 are r...

Embodiment 2

[0034] This embodiment discloses a laser drilling and cutting integrated enhanced gas drainage method based on the system described in Embodiment 1, which is characterized in that it includes the following steps:

[0035] 1) Connect the optical fiber connector 3-1 and the optical fiber connector 8-1, open the air pressure pipe valve 2, start the drilling rig 4 and the laser generator 3, and the drilling rig 4 drives the drill bit 9 to drill 2m to form a hole on the coal seam or rock wall. During the drilling process, the high-energy laser is emitted from the laser head 9-3 and the laser head 9-4, forming an advanced free surface in the rock mass ahead of the drill bit 9, so as to reduce the drilling resistance of the drill bit 9. The air flow ejected from the injection hole 9-7 carries the cuttings into the gas slag separator 5. At this time, the water mist ejected from the atomizing nozzle 5-1 catches the cuttings, and the air flow enters the gas extraction pipeline 10.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com