Glass-steel reinforced plastic pipe and manufacturing method thereof

A technology of glass fiber reinforced plastics and plastic pipes, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., which can solve problems such as deformation, insufficient internal and external fastening of products, and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

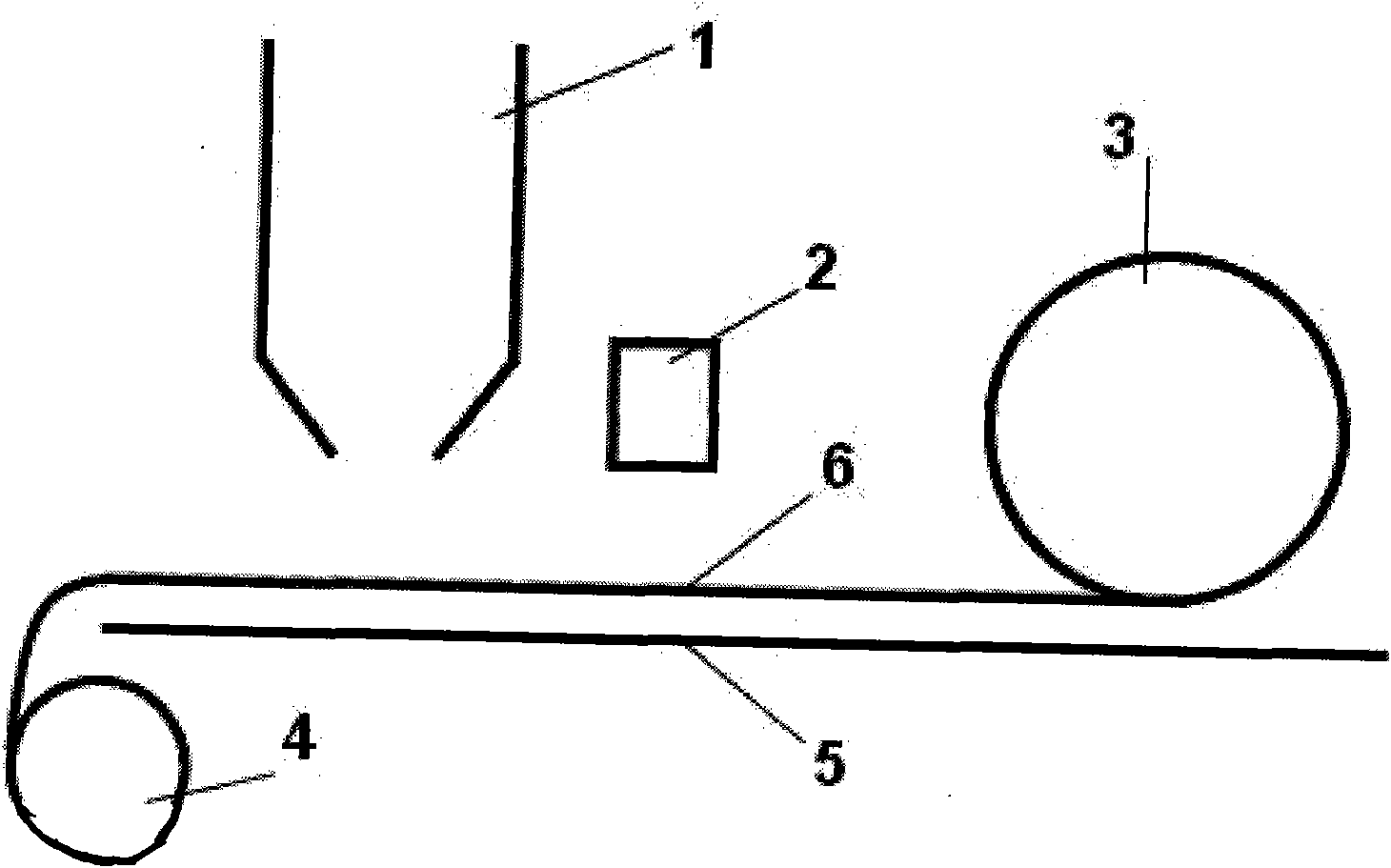

[0022] The following is a detailed example of the production (inner diameter of 110mm FRP communication pipe) to illustrate the production process of FRP reinforced plastic pipes:

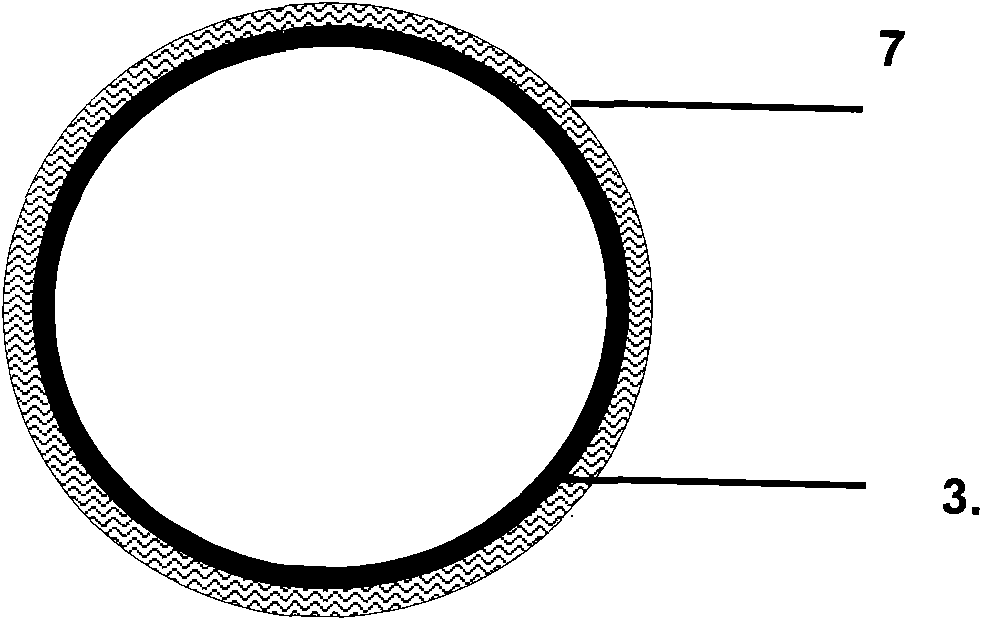

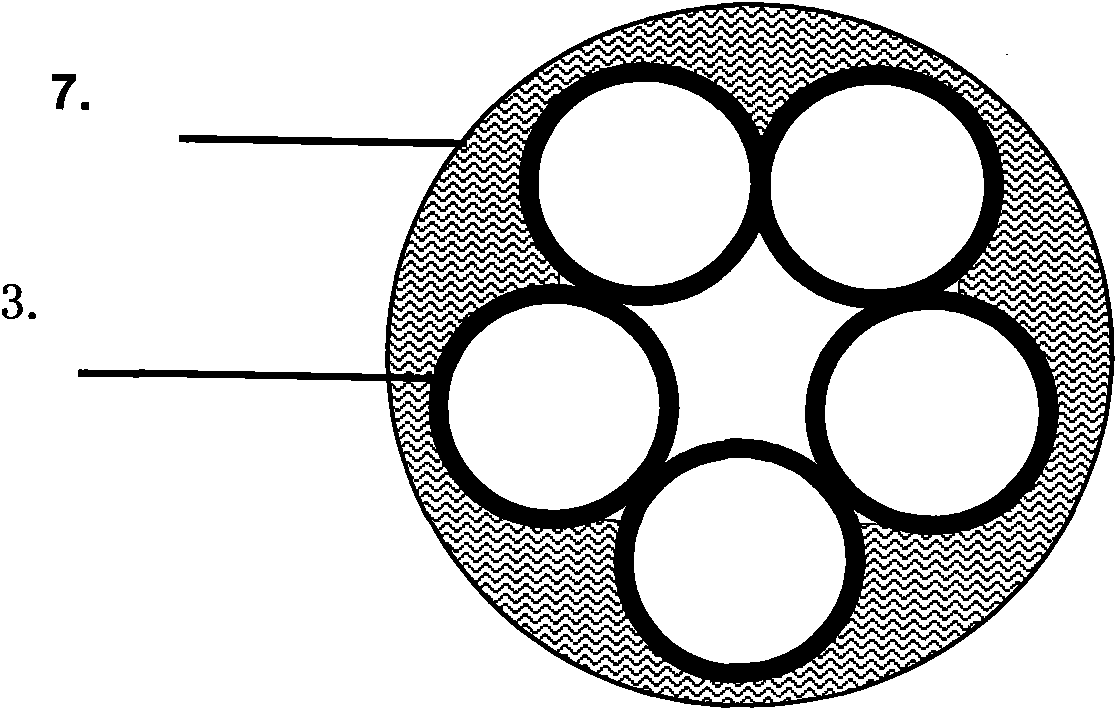

[0023] First select the existing PVC pipe with a diameter of 110mm and a thickness of 2mm. Put this PVC pipe on a steel mold with a diameter of 100mm, and fill the gaps tightly with fillers. Brush a layer of resin on the outer surface of PVC as a glue, and then use PVC pipe as the inner mold pipe (ie mold core), and wind it repeatedly through the glass fiber reinforced plastic winding equipment according to the set thickness of 5mm, during which 1-3 sand layers can be made, and All can be wet-wound with glass fiber filaments evenly mixed with resin. After the specified thickness is reached, the surface coating is leveled and revised, and then the curing time at room temperature is about 48 hours, or about 5 minutes with infrared ray curing, and the temperature is controlled below 350°C, so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com